Most people don't think about the size of testing equipment — until they run out of room.

But in real labs, space disappears fast. One extra table. One unexpected machine. One new team member. Before long, the layout stops working, technicians start bumping into corners, and safety margins shrink. Many labs, especially those handling material testing, find themselves stuck between outdated floor plans and growing demands.

It's tempting to treat this as a secondary problem. After all, performance, accuracy, and reliability come first. But equipment size isn't a side issue. It affects everything from daily workflow to long-term planning. And compact designs don't mean weaker tools — they often mean smarter ones.

This article breaks down how compact equipment changes the game in testing labs. You'll see how it impacts layout, installation, workflow, maintenance, and even cost. If you're building, expanding, or simply trying to make the most of your lab, these insights are worth your time.

Why Lab Space Is Getting Tighter

Laboratory space is becoming harder to secure — and more expensive to maintain. In North America, renting a lab can cost up to ten times more than regular office space. In Europe and the UK, demand for facilities has pushed smaller labs into shared work areas, with some teams operating in less space than they need.

This puts pressure on equipment planning. Larger machines occupy too much room and limit flexibility. A bulky system might block pathways, complicate maintenance access, or take up space that could be used more effectively. For growing labs, that creates a long-term constraint.

Compact machines address this directly. A smaller footprint makes it easier to rearrange layouts, open up movement zones, or add new tools without expanding the floor plan. Some labs use the extra space for walkways or safety margins, while others use it to install additional systems. The benefit is the same: more control over the environment.

Workflow also improves. When machines don't obstruct the space, technicians move faster between sample prep, testing, and analysis. The risk of collision drops. The time lost navigating around oversized setups disappears.

What Compact Testing Equipment Really Means

Compact doesn't mean “just smaller.” In testing equipment, it means better use of space without giving up function. It's about machines designed to fit tighter layouts while still meeting all technical requirements.

There's no universal size that defines compactness. A device that feels compact in one lab may be oversized in another. For one team, it might mean switching from a floor-standing tensile machine to a benchtop model. For another, it might mean replacing two separate stations with a combined milling and polishing unit.

Recent design improvements have made this easier. Instruments that once filled an entire room can now fit on a bench. Universal testing systems that used to rely on heavy frames and external consoles are now available as slim, single-column machines for low-force testing. Some sample prep systems integrate multiple stages into one enclosed body, reducing clutter without changing workflow.

Still, size reduction alone doesn't define compactness. A compact unit must deliver the same test accuracy, force range, or sample preparation quality as its larger alternative. It should meet the same standards — ASTM, ISO, or any others relevant to the lab. Shrinking the footprint only works if performance stays intact.

Lab space is getting tighter and more expensive, and large machines limit flexibility, block pathways, and slow down daily workflow. Compact equipment helps labs reorganize layouts, add new tools, and improve movement without expanding the footprint. When designed properly, compact systems deliver full performance and standards compliance while making the workspace faster, safer, and more adaptable.

Key Benefits of Compact Testing Equipment

Compact machines aren't just about saving floor space. Their design affects how labs are built, how teams work, and how equipment fits into real-world routines. From faster installation to easier maintenance, smaller systems can bring efficiency to places where every meter and every minute matter.

Easier Installation and Mobility

Installing large equipment can be a logistical problem. Some machines don't fit through narrow doorways or elevators, especially in older buildings. Compact systems avoid this issue. A benchtop tester or small prep machine can be delivered and positioned without structural changes.

Mobility is another advantage. Lightweight machines are easier to move when the lab layout changes. Many compact units come on wheels or are small enough to lift without a team. In production settings, this flexibility helps reconfigure zones quickly. Some tools are even portable between sites — not possible with heavy-floor equipment.

Compact machines also tend to have simpler power and utility needs. They often run on standard voltage and don't require dedicated cooling or high-load circuits. That cuts infrastructure costs and speeds up installation.

Workflow Integration and Efficiency

When machines take less space, workflows tighten in a good way. Prep, testing, and analysis zones can sit closer together. That means less walking, fewer delays, and faster overall throughput.

Compact layouts also support parallel work. Instead of queueing for one large system, different teams can use smaller units side by side. This is useful in labs where multiple departments share the same testing resources.

Automation works better too. Smaller devices are easier to position inside robotic work cells or under vision systems. As labs move toward smarter, semi-automated setups, compact gear fits the format. A slim UTM, paired with an automated sample feeder, can operate inside a compact safety enclosure — something harder to do with traditional machines.

Maintenance and Accessibility

Large machines can be difficult to maintain. Tight spacing, heavy frames, and complex subsystems slow down service work. Compact equipment often avoids these issues. Many are designed with front-facing access or removable panels on top. That makes routine tasks faster and less disruptive.

Service flexibility is another point. A smaller tester can be shipped to a service center. A larger one may require an on-site visit. For labs without internal maintenance teams, this difference matters.

Compact machines also have fewer components that require attention. Electromechanical systems often replace hydraulic ones, reducing oil handling and pressure system checks. Simpler architecture means fewer failures and easier troubleshooting. In the long run, this can lower the total cost of ownership.

Safety and Ergonomics

Safety starts with space. When equipment takes up too much room, walkways narrow and hazards increase. Compact machines reduce physical and visual clutter. This helps keep escape paths clear and tools stored properly.

Good ergonomics follow. Compact systems are often built with tabletop use in mind. Controls sit at hand height. Loading zones don't require awkward lifting or bending. Technicians work seated or standing in neutral positions, which reduces fatigue during long shifts.

Some compact tools include built-in safety shields or full enclosures. These are easier to implement at smaller scale and can often be placed under hoods if the test process involves fumes or risk of fragment release. All of this adds up to a safer environment — for both people and equipment.

Compact testing machines save space, install quickly, and require minimal utilities, making them easy to integrate into any lab. They also improve workflow efficiency, support automation, and are simpler to maintain thanks to accessible designs and fewer components. This combination reduces costs while creating a safer, more ergonomic workspace.

What Labs Often Miss When Calculating Cost

Price tags don't tell the whole story. Many labs still focus on purchase cost alone, without fully considering what comes after. That can lead to decisions that seem efficient but add pressure over time.

One example is facility fit. A machine that needs special power, ventilation, or reinforced flooring may double its real cost after installation. A smaller model that avoids these upgrades often turns out cheaper — even if the initial quote was higher.

Service downtime is another factor. Larger systems can take longer to access, maintain, or move, which adds days of delay when things go wrong. Compact machines are usually simpler to open, easier to ship, and faster to return to service.

There's also the cost of rigidity. A bulky system locks your layout in place. If your lab evolves, it becomes a constraint. Compact setups give you options — to add tools, change flow, or scale in phases. That flexibility has real operational value, even if it doesn't show up in a spreadsheet.

Even experienced teams sometimes misjudge what compact lab equipment really offers. Here are the most common misconceptions — and why they don't hold up.

- Smaller means weaker. A compact machine is not a simplified version of a “real” system. In many cases, it uses the same sensors, software, and control modules as its full-size counterpart. Single-column tensile testers, for example, can handle precise loading up to 50 kN or more without compromising accuracy. Performance depends on engineering, not on outer dimensions.

- If space isn't a problem, size doesn't matter. Having enough room doesn't mean large machines are the better choice. Bigger systems may block access, waste electricity, or limit flexibility in the future. Choosing oversized equipment just because you can leads to underused capacity and layout inefficiencies that are hard to fix later.

- Compact means portable. A small footprint doesn't guarantee easy relocation. Some compact units weigh hundreds of kilograms and require recalibration after being moved. Others may be sensitive to vibrations or leveling. Always check the mobility requirements before assuming a unit can be moved like a piece of furniture.

- Small machines can be placed anywhere. Ventilation, stability, and operator access still matter. Pushing a compact unit into a corner, onto a weak table, or under a low shelf can cause overheating, vibration issues, or unsafe working positions. Good placement isn't just about footprint — it's about function and safety.

- Compact machines don't need safety controls. Force, heat, or rotation don't disappear when equipment gets smaller. A benchtop grinder or tensile tester can still cause serious injury. Protective shields, enclosures, and proper PPE remain essential, even with compact designs. Size doesn't replace safety protocols.

- One compact device can replace three others. Multi-function units exist, but they come with trade-offs. For example, a combined cutter and polisher may save space but reduce control over individual steps. It's better to evaluate needs carefully than to expect one device to do everything with the same precision.

- Compact equipment is fragile. This view often comes from older lab devices that weren't built for tough use. Today, many compact machines are made with industrial-grade components, strong frames, and sealed housings. They're designed for busy labs and production floors, not just clean benches.

How to Make a Smarter Equipment Choice

Compact machines can offer real long-term value — but only if selected thoughtfully. A well-matched system saves more than just space. It improves workflow, avoids hidden costs, and adapts as your lab evolves. If you're considering a compact solution, here's how to evaluate it wisely.

Check Your Space, Not Just the Machine

Before comparing specs, measure everything: doorways, ceiling height, cable clearance, and operator access. Some labs have the footprint but not the layout. Don't forget to include space for lid clearance, airflow, and safe technician movement. A machine that “fits” on paper can block pathways or limit maintenance access once installed.

Also, assess the surfaces where equipment will sit. Benchtop units need stable, level support. Overlooking weight load or vibration control often leads to usability issues later.

Focus on Workflow, Not Just Features

A compact machine should simplify the process — not just compress it. Look at how samples are loaded. Are the controls easy to reach? Can the screen be read while standing? Are tasks intuitive for the technician?

Ask for a video or hands-on demo. What seems efficient in a brochure can turn awkward during daily use. For example, a tester with excellent specs may still be rejected by operators if it has an awkward loading height or hard-to-clean parts.

When possible, get input from those who'll actually use the machine. Their feedback on layout, screen size, glove use, or access panels often reveals issues early.

Review Power, Utilities, and Setup

Compact machines often require less infrastructure — but not always. Confirm power supply needs. Will it run on a standard outlet? Does it need external air, special cooling, or reinforced surfaces?

Some machines advertise portability but still require calibration after relocation. Ask whether installation can be handled in-house or needs a technician visit. Knowing this in advance avoids costly surprises.

Also, check how quickly the system can be operational. A “plug-and-play” label means nothing if it takes two weeks to complete setup.

Understand Maintenance and Service Logistics

Compact doesn't always mean low-maintenance. Review the full upkeep schedule. What needs replacing? How often? Are consumables readily available?

Ask whether calibration is on-site or remote. A small tester might ship easily for service — a larger one may need in-lab visits with long wait times. Also confirm whether documentation and support are available locally, especially in North America or Europe.

Simpler machines with fewer subsystems tend to be easier to maintain. But it's worth asking about turnaround times, parts availability, and long-term service commitments.

Think Beyond Today's Needs

If your testing volume or workflow might grow, the machine should grow with it. Some compact systems are modular — offering add-ons like automation ports, software upgrades, or extended capacity.

Also consider redundancy. In some cases, two smaller units provide better uptime and parallel processing than one large centralized machine.

Check if the model is locked into one configuration or if future upgrades are realistic. A small increase in upfront investment often pays off if the system stays relevant longer.

Look at Standards and the True Cost of Ownership

Even a compact machine must meet industry standards. Ask for documentation — calibration certificates, quality test results, ISO or ASTM compliance. Don't assume compact means compromise.

And last — review total cost, not just purchase price. A slightly more expensive unit might save money over time by avoiding extra rent, reducing utility use, or requiring less operator training.

Factor in delivery, setup, service, and real-world operating cost. A smart choice now reduces risk, prevents overspending, and helps the lab stay flexible in the years ahead.

Start by checking whether the machine fits your actual space and daily workflow, not just its listed dimensions. Confirm power, setup, and maintenance requirements to avoid hidden costs later. A model that aligns with your workload, operators' needs, and future growth will deliver the best long-term value.

Compact — When It's Done Right

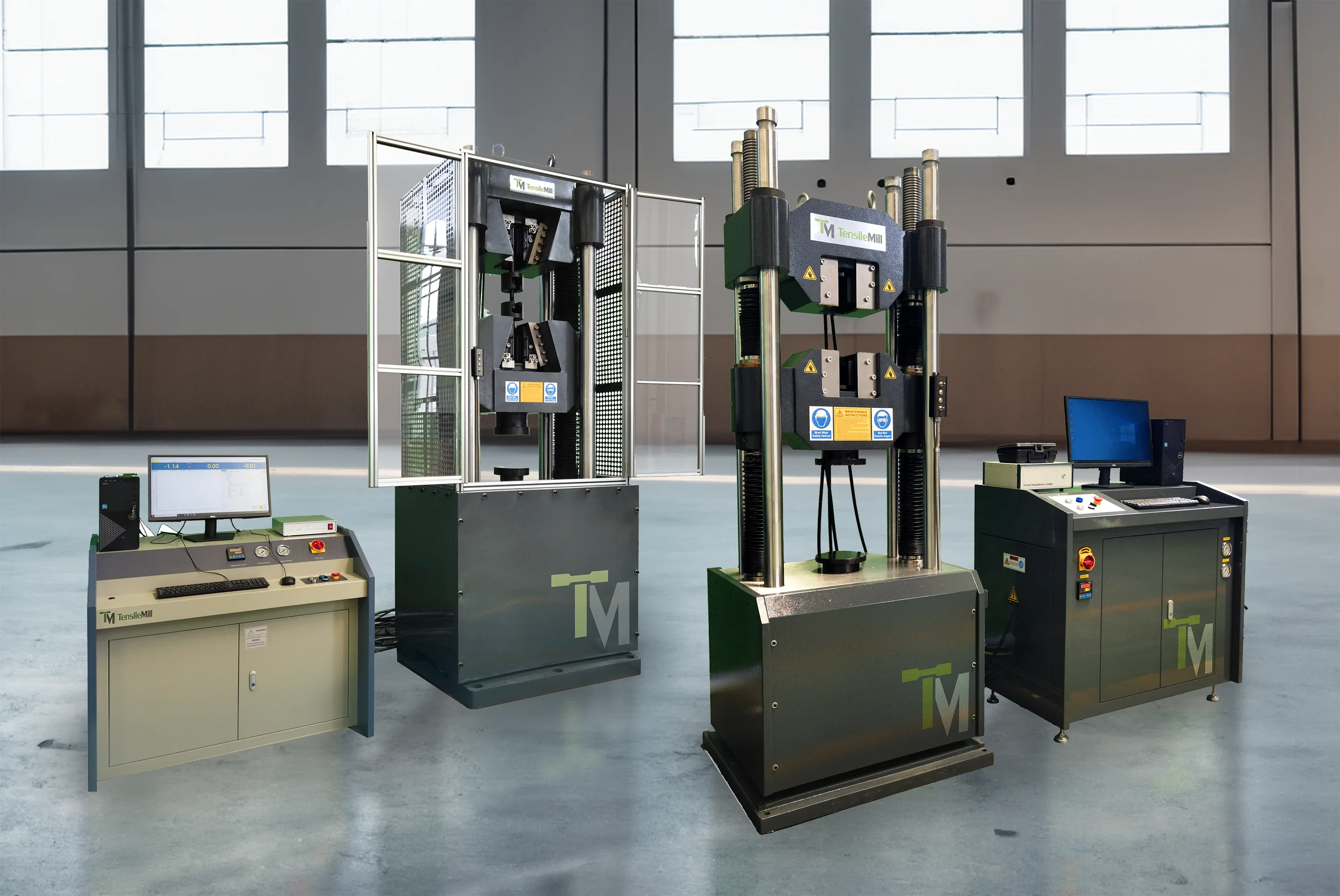

If you've made it this far, chances are you're already thinking about how to optimize your lab space, your workflow, or your equipment investments. Whether you're building a new facility or just trying to get more from the one you have, compact equipment isn't just a convenience: it can be a smart strategic shift. As a company specializing in tensile testing and sample preparation solutions, we've spent years refining tools specifically for these challenges.

Below are two of our most compact and capable systems, each engineered to bring serious performance into smaller footprints without compromising quality, compliance, or reliability.

TensileMill CNC MICRO: Sample Prep Precision in Half the Space

If you're working with flat tensile or impact specimens, and you're tired of outsourcing, improvising, or overpaying for oversized routers, the TensileMill CNC MICRO offers a compelling alternative.

This 2-axis benchtop CNC machine is purpose-built for low-to-medium volume labs that need accuracy, not industrial overkill. It fits where other machines don't (under 24″ wide), and its guided touchscreen workflow means even non-CNC specialists can get clean, symmetric, test-ready specimens in minutes. No G-code. No alignment headaches. Just repeatable results.

What makes it truly stand out in compact environments:

- Flip-jig fixture that machines both sides without realignment — key for precision in gauge section symmetry.

- Full safety enclosure and recirculating coolant system, packed into a mobile frame that feels more like a lab station than a workshop.

- Handles ASTM and ISO geometries, or custom shapes — just select the profile and go.

It's not just small — it's specifically designed to reduce operator dependence, variability, and turnaround time. For labs that need control, speed, and certainty in tensile prep, this machine hits the mark.

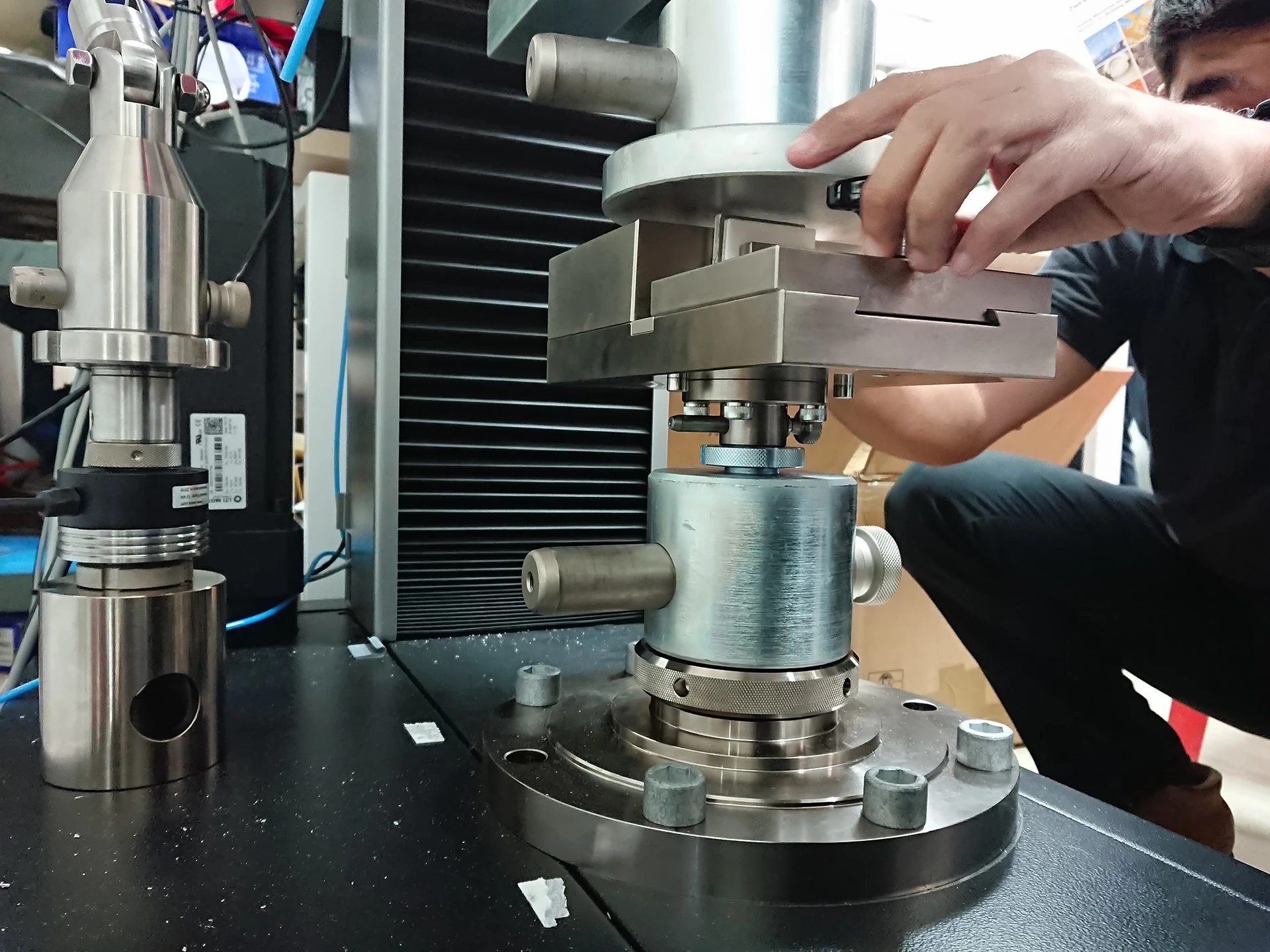

TM-EML Series A: Full-Featured Tensile Testing — Now Benchtop

Don't let the size fool you — the TM-EML Series A is a fully capable universal testing machine for tensile, compression, flexural, and cyclic testing, designed for applications up to 5 kN. Its single-column architecture is rigid, responsive, and stable even under dynamic load.

Highlights that make it ideal for modern, space-conscious labs:

- 1200 Hz closed-loop control with ±0.2% accuracy across a broad range of materials — from flexible packaging films to metal wires and composites.

- Plug-and-play GenTest™ software with method templates, real-time graphing, and automatic result reporting.

- A powerful servo-driven direct-drive system gives high speed and high precision in one unit — whether you're doing high-throughput batch testing or delicate micro-displacement work.

Most importantly, it doesn't cut corners. You still get:

- Certified load cells with full TEDS support

- Optional alignment systems for NADCAP compliance

- Expandable test space and full accessory integration (extensometers, climate chambers, pneumatic grips)

Why Compactness Is No Longer Optional

Space is no longer just a logistical issue. It's become a core performance factor. As labs adapt to tighter environments, expanding testing needs, and evolving safety standards, the role of equipment design becomes even more critical. Compactness is no longer about just shrinking machines: it's about smart, practical design that matches the realities of how modern labs operate.

Well-designed compact equipment doesn't feel like a limitation. On the contrary, it becomes a tool that enables better planning, flexibility, and responsiveness. A good benchtop tester or sample prep machine won't just take up less room, it will give your team room to think, move, and work more efficiently, cutting down on clutter and unnecessary steps.

Thoughtful compact equipment adds value in very real ways. It supports precision. It improves repeatability. It helps labs do more with less, without sacrificing quality or control. As testing demands grow and space becomes tighter, those who treat footprint as a strategic variable, not just a technical spec, will be in a better position to scale and adapt.

If you're planning a new tensile testing lab, upgrading equipment, or simply trying to make the most of limited space, we're here to help. Whether it's selecting a compact tester or a specimen preparation machine, we work closely with teams to match the right tools to the right workflows. Reach out to us or request a quote — we'll help you find a setup that truly fits.