Will burrs remain on tensile specimens after the cutting cycle on a TensileMill CNC sample preparation system?

Edge condition after machining depends on material type, cutter or insert condition, feed and speed, coolant, and toolpath strategy. With the supplied starter tooling and tuned parameters, burr can typically be minimized to a negligible edge or eliminated. Good practices include matching the cutter or insert grade to the alloy, keeping cutting edges sharp, using adequate coolant, and programming climb milling with a light finishing pass of about 0.005 to 0.010 in (0.13 to 0.25 mm) stock. Adding a small edge break of roughly 0.005 in (0.13 mm) with a chamfer or deburr pass helps reduce handling nicks before testing.

If some burr remains, quick secondary methods are common in tensile labs: hand files, deburring blades, small countersinks, tube deburring tools for round gage sections, fine flap wheels, and nonwoven abrasive pads. Remove only the raised edge so gage width or diameter is not altered, then verify dimensions and surface quality prior to testing. Our team can recommend tooling and parameters for both flat and round workflows to help you hit your required finish with minimal rework.

If you would like to source deburring media, end mills, inserts, and related supplies, you can review options on the

Consumables and Spare Parts page.

Which Spare Parts Does the TensileMill CNC MINI Use, Where Can I Buy Them, and How Quickly Do They Ship?

For routine upkeep on the MINI flat-specimen machine, the most common consumables are carbide end mills and related tooling. End mills typically range from $30.00 to $85.00 each and can be purchased directly from TensileMill CNC. Over a longer horizon, the main wear component is the spindle. Depending on duty cycle, some production labs replace the spindle at about 6 years, many units operate 10 to 14 years, and in very rigorous, continuous use a replacement may be required after a couple of years. A replacement spindle is about $1,400.00.

Ordering is handled directly through TensileMill CNC. Most consumables and standard spare parts are stocked in-house or ship within a few weeks. Spindles generally carry a short lead time, and expedited options can be discussed for downtime-sensitive situations. If you need help matching tooling to your specimen materials or fixtures, our team can confirm compatibility when you place your request.

If you would like to review compatible tooling and replacement items for this system, you can read more on the

TensileMill CNC MINI product page.

What Consumables Does the TensileMill CNC MINI Use and Where Can I Purchase Them?

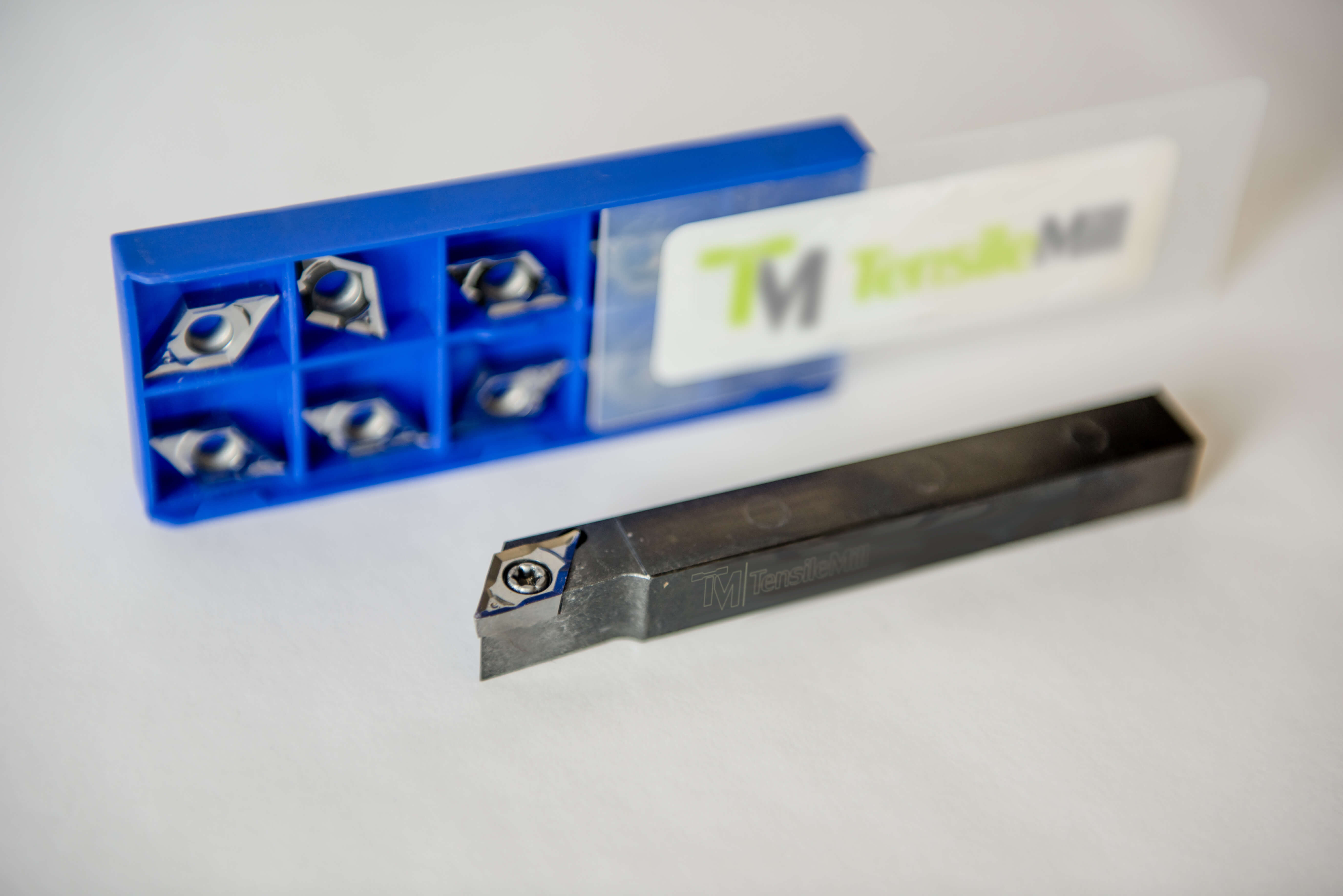

Common consumables for the MINI are specialty carbide end mills engineered for flat tensile specimen geometry. We supply application-specific cutters for aluminum and soft alloys, carbon and stainless steels, and nickel-based materials. Share your alloy, hardness, and expected monthly throughput, and our team will recommend the diameter, flute design, and coating to deliver stable edge quality and consistent dimensions.

Typical pricing runs $35.00 to $80.00 per bit, with bundle pricing available for higher usage. You may purchase end mills directly from TensileMill CNC by requesting a quote. Unlike cutters, base and clamping fixtures operate as long-life tooling when maintained, often serving for many years. During installation, your operators receive one day of hands-on training that covers preventative maintenance steps to extend tool life and reduce per-specimen cost.

If you would like model-specific tooling recommendations or to review compatible fixtures, you may read additional details on the

TensileMill CNC MINI product page.

Where Can I Buy Spare Parts and Consumables for My Tensile Specimen Preparation Machine?

Genuine consumables, clamping fixtures, and replacement parts are available directly from TensileMill CNC. Every new tensile specimen preparation system includes an initial set of specialty end mills and core fixturing suited for long term operation. With routine maintenance, base and clamping fixtures typically serve for many years; if your program changes, additional fixtures can be purchased at any time.

To order, request a quote with your machine model, specimen profile or standard, material type, and typical blank thickness. Our team will recommend the matching tooling geometry, coatings, and any application specific inserts. Common items include carbide end mills, inserts and holders for round specimens, clamping fixtures, ER collets, coolants, and controller components. Most standard parts are stocked, while custom items are produced to order with short lead times.

If you would like to review options or request pricing, you can explore the

Consumables and Spare Parts page for available tooling, fixtures, and replacement components on the product page.

What Are the Unique Advantages of the TensileMill CNC XL for Flat Tensile Specimen Preparation Compared With the Classic and MINI Models?

Compared with the Classic and MINI flat-specimen systems, the XL adds higher workpiece capacity, a more rigid frame, and a standard automatic tool changer that streamlines tensile sample preparation with fewer manual steps.

If you machine larger blanks or harder alloys, the XL’s heavier construction supports bulkier fixturing and reduces vibration, so roughing and finish passes hold neck and gauge tolerances with fewer setups. The integrated ATC swaps between roughing mills, finish end mills, drills, and chamfer tools without manual changes, which compresses cycle time and supports repeatable batch runs. The control software provides template-driven programming for flat specimens to common geometries used in standards such as ASTM E8 or ISO 527, and it also handles general CNC milling for jigs and ancillary lab parts. For ongoing operation, cutters, toolholders, fixtures, polishing media, and replacement components are available directly from TensileMill CNC through our consumables and spare parts program or by requesting a quick quote.

If you would like to compare specifications and software options, you can review details on the

TensileMill CNC XL product page.

What Are the Ongoing Costs for Maintenance, Consumables, and Spare Parts on Tensile Sample Preparation Machines?

Routine ownership costs are modest and typically center on basic maintenance, common consumables, and occasional wear items. Software updates carry no cost for the life of the machine, so there are no recurring software fees.

Maintenance is straightforward: follow the operations manual for periodic checks, chip evacuation, lubrication points, and coolant care. To keep components moving and electronics stable, we recommend cycling the machine every couple of days. Most systems run a recirculating water based coolant; plan for top-offs, concentration checks, and occasional sump cleaning in line with your usage and coolant supplier guidance.

Consumables usually include cutting inserts, workholding fixtures specific to your specimen geometry, and coolant. A starter set is supplied with the machine, and promotional extras are often included. These items are non-proprietary and can be purchased locally; many labs prefer buying from TensileMill CNC to match documented performance and tool life. Spare parts are rarely needed and, when required, are standard industrial components that are easy to source, which helps keep downtime and cost low. Actual spend depends on material hardness, specimen throughput, and surface finish targets, since tougher alloys and heavier stock removal increase insert and coolant consumption.

If you would like to review commonly used inserts, fixtures, coolants, and spares, you can read more on the

Consumables and Spare Parts page.

When Should I Upgrade the Clamping Fixture on My Base Fixture?

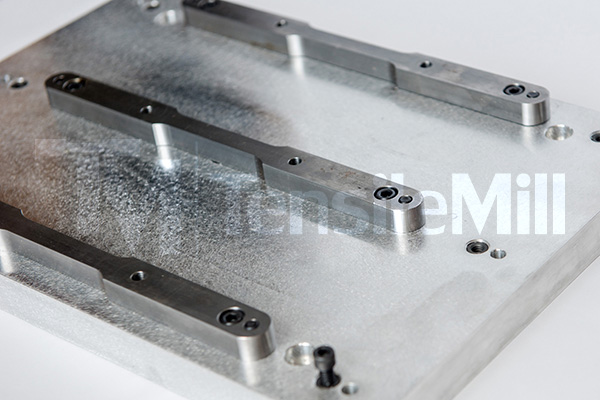

A clamping fixture upgrade is recommended when your starting blank length falls outside the grip window of the base fixture, either shorter or longer than the current jaws support. An application-matched clamp holds the blank rigidly so the milling path remains consistent and the edge finish stays uniform.

Common triggers include changing from short to long blanks, for example moving from 4 in to 15 in (102 mm to 381 mm) stock, switching to stacked blanks, or working with very thin coupons where standard clamps leave too little bite length. Specialty options such as extended-reach jaws, low-profile clamps for cutter clearance, and soft jaws to protect surface finish keep the sample stable and repeatable across runs. Upgraded clamping also helps with throughput by reducing re-clamping and scrap during batch milling. Additional clamp sets are available as add-ons and can be supplied pre-configured for your specimen sizes.

If you would like sizing guidance or part numbers, you can review available options on the

Tensile Sample Preparation Consumables, Fixtures, and Spare Parts page.

What Types of Base Fixtures Are Available for Tensile Sample Preparation Machines?

Flat tensile preparation systems from TensileMill CNC are supplied with a stainless steel base fixture tailored to the specimen geometry in your method library. Optional clamping fixtures expand the holding envelope for different blank lengths, covering approximately 15 in down to 4 in (381 mm to 102 mm). Each package also includes an ER collet and carbide end mills, with only the cutters considered routine consumables.

The base fixture is built for long service life and resists wear in high-throughput labs. It is configured to support common flat specimen profiles used in standards such as ASTM E8 for metals, ISO 6892-1, and ASTM D638 for plastics when applicable to your workflow. When your starting blank length changes, selecting the matching clamping fixture maintains full contact and stable clamping, which helps hold gauge-width tolerance and finish quality during milling. End mill life ranges from weeks to months based on part volume, material hardness, and blank thickness, so keeping a small stock of our coated carbide tools helps prevent unplanned downtime.

If you would like to compare fixture options or check current availability, you can review details on the

Tensile Sample Preparation Consumables, Fixtures, and Spare Parts page.

How Do I Order Consumables and Spare Parts for TensileMill CNC Equipment?

You can order consumables and spare parts directly from TensileMill CNC by phone, email, or through the online quote form; have your machine model and serial number ready for the fastest turnaround.

Please specify the platform you use, such as flat-specimen mills like MICRO, MINI, Classic Upgrade, or XL; round-specimen systems like TensileTurn CNC Classic Upgrade, Industrial Upgrade, or XL; longitudinal polishers; or UTM equipment. List the items you need and any relevant details. Typical requests include cutters, end mills, slitting saws, inserts, collets, arbors, grips, specimen fixtures, coolant and filtration media, belts, and other replacement wear parts. If you are preparing specimens to ASTM E8, ISO 527, or ASTM D638, share the material and geometry so our team can recommend tooling and polishing media that align with your throughput and surface finish targets. Quotes will include availability and lead time; stocked items ship quickly from North America, while special-order components may require additional time.

You may also send a purchase order or attach photos of the parts you are replacing. Our team can cross-reference legacy part numbers or provide current equivalents for earlier-generation machines.

If you prefer to browse available items, you may explore categories and request quotes on the

Consumables and Spare Parts page.

What Consumables Are Available for TensileTurn CNC Round Specimen Preparation Machines?

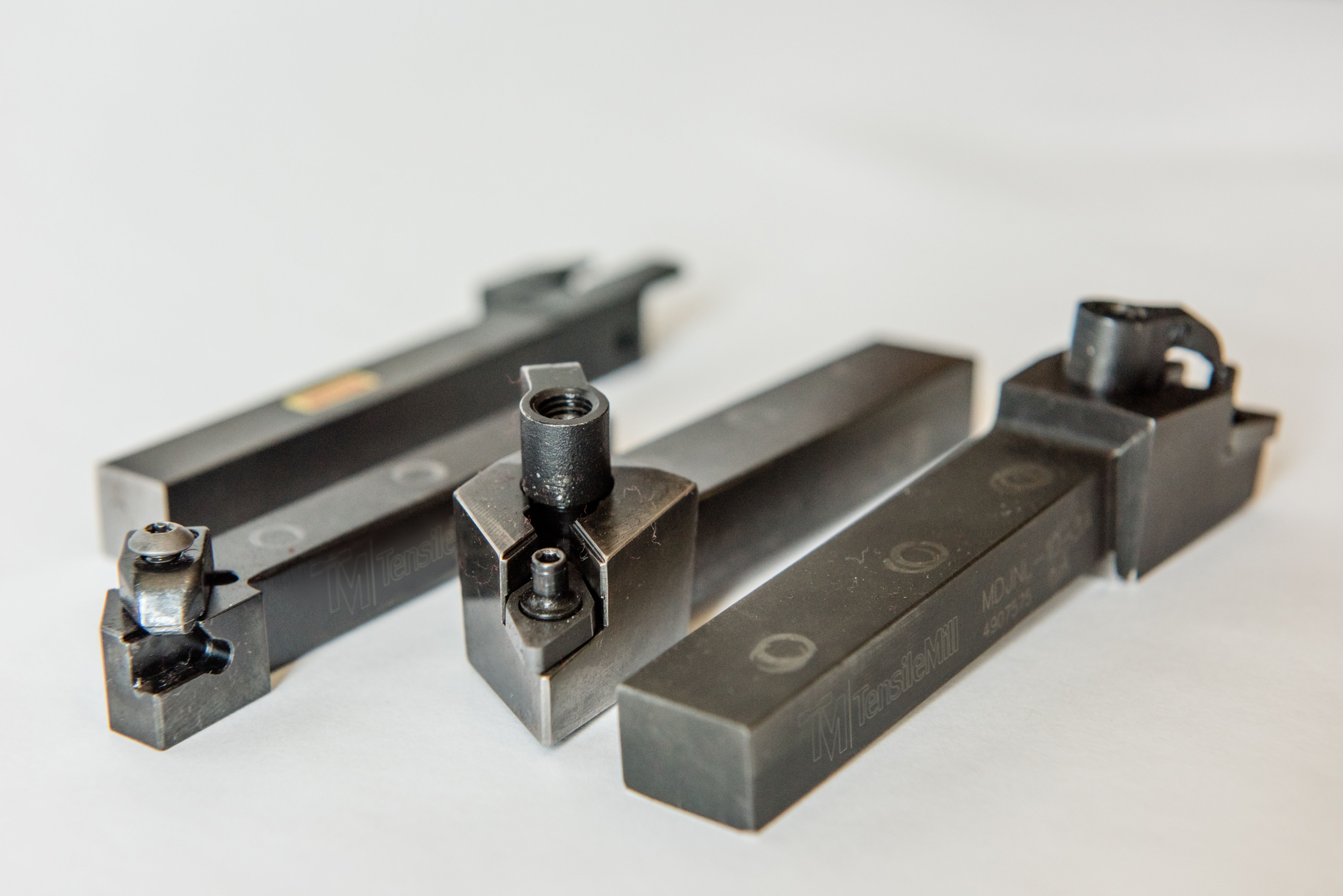

TensileTurn CNC machines rely on a concise set of consumables for round specimen preparation. Each system ships with material-specific holders and matched cutting inserts, which serve as the primary wear items for ongoing operation.

Holders are durable tooling that typically provide multi-year service when kept clean, aligned, and free of crash loads. Inserts are designed for regular replacement. Their life varies with material hardness, feed and speed selection, coolant application, and total run time. Many labs keep insert styles dedicated to aluminum, steels, and nickel-based alloys to maintain predictable finish and geometry.

Routine shop fluids are also part of normal use. A water-soluble coolant supports chip evacuation and heat control, and machine lubrication is consumed through periodic maintenance. While these fluids are not replaced as frequently as inserts, planning them as consumables helps sustain throughput without interruptions.

For uninterrupted production, consider stocking spare insert packs for your most common materials and maintaining backup holders if you change materials often or run multiple shifts.

If you would like to compare insert options or plan a spare tooling kit, you can review available items on the

Consumables and Spare Parts page.

What Are the Lead Times for Tensile Sample Preparation Consumables?

Most commonly used consumables for tensile sample preparation, including specialty end mills, basic fixturing, and common spare parts, are typically in stock. When an item is temporarily unavailable, the standard lead time is 1 to 2 weeks from order confirmation. Lead time quotes reflect current availability and your requested quantities.

For labs running steady throughput, ordering by lot size or setting planned releases helps maintain consistent specimen preparation between batches. If you need a nonstandard cutter geometry or a custom fixture, production timing will be confirmed at the time of request. Partial shipments may be available so you can keep preparing specimens while the balance completes. To receive a live timeframe, share your machine model, material, and expected specimen volume so our team can match the correct tooling and fixturing to your workflow.

If you would like current availability or to request a quote, you can review categories and submit details on the

Consumables and Spare Parts page.

What Is the Typical Lifespan of End Mills for TensileMill CNC Milling Machines?

Tool life varies because it depends on material hardness, blank thickness, toolpath strategy, coolant use, and spindle setup. Our systems ship with specialty carbide end mills in bright finish or Alcrona Pro coating that are engineered for tensile specimen machining. In production labs, these cutters commonly deliver extended service across multiple batches, including high-throughput programs, but there is no single hours-or-parts figure that applies to every application.

For the longest life, match the geometry and coating to the workpiece: bright finish for aluminum and other nonferrous materials, AlCrN-type coatings such as Alcrona Pro for steels, stainless, and nickel alloys. Use conservative radial engagement, climb milling on profiles, ample coolant, and rigid fixturing. Keep spindle runout at or below 0.001 in (0.025 mm). Replace a cutter when surface finish begins to dull, burrs increase, spindle load trends upward, or edge wear and micro-chipping become visible under magnification. Keeping a spare set of identical tools on hand helps maintain consistent specimen quality and uptime.

If you would like application-specific tooling guidance or to review stocked options, you may explore the

Consumables and Spare Parts page for end mills matched to our sample preparation machines.

Will Future TensileMill CNC Accessories Work With Existing or Older Machines?

Yes. New accessories are developed with backward compatibility in mind, so they integrate with current systems and many legacy TensileMill CNC machines and universal testing frames. Our design approach favors common mounting patterns, controller interfaces, and standard UTM connections, and we support legacy fleets with adapter kits when a direct fit is not available.

For testing labs, this means new grips, fixtures, jaw faces, and polishing or cutting tools can often drop into existing workflows without changing procedures tied to ASTM E8 or ISO 527 when those standards apply to your program. For machining-based specimen preparation, holders, collets, and base fixtures are matched to prior spindle and fixturing setups, and software updates keep the operator interface familiar. If your equipment is older or customized, our team can validate fitment before shipment. Sending the model and serial number, photos of the mounting or spindle interface, and your current software revision lets us confirm compatibility and recommend any adapters or simple field updates. This strategy helps extend the service life of installed equipment while maintaining specimen quality and throughput.

If you would like to review compatible tooling, fixtures, and replacement parts by category, you can explore details on the

Consumables and Spare Parts page.

Are Consumables and Spare Parts In Stock for TM-EML Series Universal Testing Machines?

Yes. TensileMill CNC keeps a stocked inventory of consumables and replacement components for TM-EML electromechanical frames to keep labs running and minimize downtime.

Frequently supplied items include grips and jaw sets in manual, pneumatic, and specialty formats, extensometer accessories and cable assemblies, calibrated load cells across multiple capacity ranges, and common wear parts such as bearings, seals, and belts. Control boards and electronic modules are available in versions compatible with GenTest, and assemblies are shipped preconfigured for the intended TM-EML model.

Most parts are plug-and-play, so typical replacements can be completed in-house without a technician visit. For consumables with predictable wear, such as jaw inserts, grip pads, and seals, you may select multi-pack reorder options to support internal stocking programs for QC labs or 24/7 production lines. If a non-standard or legacy item is required, our team can coordinate sourcing and shipment to keep lead times tight.

If you would like to review stocked items and ordering options, you can explore the

Tensile Sample Preparation Consumables, Fixtures, and Spare Parts page for availability and compatible components.

What Spare Parts and Consumables Should Labs Stock to Prevent Downtime in Tensile Specimen Preparation and UTM Testing?

Maintain a core kit that matches your throughput and materials. For flat-specimen machining, keep coated carbide end mills in common sizes such as 0.125 in, 0.250 in, and 0.500 in (3.18 mm, 6.35 mm, and 12.70 mm), matching ER collets and nuts, and at least 1 gal (3.8 L) of approved coolant or cutting fluid. For round-specimen turning, stock inserts with a small nose radius around 0.016 in (0.40 mm), extra holders, and light machine oil for slideways. For polishing, keep belts or papers across 120 to 1200 grit, with typical belt sizes like 2 × 72 in (51 × 1830 mm). These items help maintain edge quality and geometry that support ASTM E8 or ISO 527 compliance when applicable.

Plan for fixture wear and test accessories. Maintain spare clamping jaws or liners sized for your blanks, common fasteners, alignment pins at 0.250 in and 0.500 in (6.35 mm and 12.70 mm), and replacement jaw faces for wedge or pneumatic grips, often 1.0 in (25 mm) wide. For UTMs, keep limit switches, drive belts or couplings where applicable, and hydraulic grip seals if used. Stock a multi-purpose grease tube, 14 oz (400 g), and keep resin-bonded abrasives stored at 60 to 80 F (16 to 27 C) under 60 percent RH.

Use behavior-based reorder points. Replace cutters when flank wear approaches 0.008 in (0.20 mm), change inserts at the first sign of chatter or burr formation, and reorder when inventories fall below two weeks of average use. This approach keeps the machine, fixtures, and test system ready without overstocking.

For stocked options, compatibility notes, and typical lead times, you can review the

Consumables and Spare Parts page for a quick overview aligned with your lab’s needs.

Which Consumables Impact Tensile Specimen Accuracy And When Should They Be Replaced?

Cutting tools, grip jaw faces, polishing media, and coolant systems have the greatest influence on specimen geometry and surface finish. For flat samples, end mills and slotting saws control gauge width and fillet radii; for round samples, lathe inserts define final diameter and shoulder blends. Worn grip faces or liners increase slippage risk during testing, which can compromise results for methods such as ASTM E8 or ISO 527 when precise alignment and consistent clamping pressure are required.

Replace milling cutters when flank wear approaches about 0.008 in (0.20 mm) or measured diameter loss exceeds 0.002 in (0.05 mm). Change turning inserts when nose-radius wear is near 0.004 in (0.10 mm) or built-up edge appears. Renew grip jaw faces when serration height loss is roughly 0.005 in (0.13 mm) or if you observe early slip. Refresh polishing media once cut rate drops or swarf loads the surface; a typical metal sequence is 120, 240, 400, 600, 1200 grit. Maintain water-miscible coolant at 6 to 8 percent concentration, verify daily with a refractometer, and service filters every 40 to 80 operating hours.

For continuity, keep two complete tool sets per machine, at least four spare inserts per operation, one spare pair of jaw faces per grip size, and a week’s worth of abrasives. Verify gauge width or diameter at three locations using a 0.0001 in (0.0025 mm) resolution micrometer, and target ±0.001 in (±0.025 mm) unless a drawing or standard specifies tighter limits. For composites to ISO 527, stock fresh tabs and adhesives and cure per manufacturer guidance, for example 24 h at 72°F (22°C).

If you would like a compatibility checklist and stocking guidance by model, you can review

Consumables and Spare Parts on the equipment page.

What Consumables Should We Stock To Prevent Downtime During Tensile Specimen Preparation?

Keep a focused kit of cutting tools and workholding items on hand. For flat specimens, maintain at least two spare carbide end mills for each commonly used diameter, for example 0.125 in, 0.250 in, 0.375 in, and 0.500 in (3.18 mm, 6.35 mm, 9.53 mm, and 12.70 mm). For round specimens, stock one roughing and one finishing set of inserts per material family, plus a backup holder. Keep one spare ER collet for every shank size you run most, and a small set of replacement vise pads or clamping screws that match your fixtures.

Maintain fluids and maintenance items that directly affect cut quality. Use a water-soluble coolant at 7–10 percent, verify with a refractometer, and keep a spare filter element at 0.0004 in (10 µm). Have light machine oil for slideways, a spare coolant pump seal kit, and one extra drive belt where applicable. For polishing requirements, keep a progression of abrasives that can remove burrs without altering geometry prior to ASTM E8 metals or ISO 527 plastics testing when those finishes are specified.

Apply simple replacement triggers to stay within tolerance. Replace end mills when wear or measured diameter loss exceeds 0.002 in (0.05 mm), or when burr formation increases. Replace collets if measured runout at the tool shank exceeds 0.001 in (0.025 mm). These behaviors help preserve gauge-section accuracy so specimens remain compliant and repeatable.

If you would like a tailored stocking list based on your materials and throughput, you can review options on the

Consumables and Spare Parts page.

What Consumables And Spare Parts Should A Tensile Lab Keep In Stock To Avoid Downtime?

For flat-specimen machining, keep a buffer of carbide end mills in common sizes such as 0.125 in, 0.250 in, and 0.375 in (3.18 mm, 6.35 mm, and 9.53 mm). Maintain spare ER collets that match your spindle, extra collet nuts, and clamping pads or liners that contact the specimen. A sacrificial backing plate, for example 12 in × 12 in (305 mm × 305 mm), helps preserve fixture flatness and surface finish over repeated cycles.

For round-specimen systems, stock OD turning inserts, parting inserts, and center drills, plus spare live center tips and drive centers. Keep common insert nose radii such as 0.016 in and 0.032 in (0.4 mm and 0.8 mm) to control gauge fillet transitions. Having an extra chuck key, jaw set, and a tailstock quill wiper on hand prevents small wear items from halting throughput.

For universal testing machines, maintain grip faces or liners, wedge or screw-grip hardware, alignment pins, and extensometer knife edges. Replace worn grip faces early to preserve specimen alignment and geometry required by ASTM E8 for metals or ISO 527 and ASTM D638 for plastics. A practical inventory rule is to hold 3 to 5 pieces per wear item and reorder when only 2 remain. As an example, if your lab produces 50 specimens per day, a set of 5 cutters per diameter typically covers several weeks on mild steel and longer on aluminum, then you can replenish without interrupting schedules.

If you would like to review available items and typical lead times, you can explore the

Consumables and Spare Parts page for current options on the equipment page.

Which Consumables And Spare Parts Ensure Consistent, Standard-Compliant Tensile Specimens?

Key items include cutting tools, turning inserts, abrasive belts or papers, coolants, jaw faces for grips, collets, alignment pins, and extensometer knife edges. For flat specimens, choose carbide end mills in 0.125 in to 0.500 in (3.18 mm to 12.70 mm) with 3 or 4 flutes and a small corner radius around 0.010 in (0.25 mm) to limit burrs before polishing. For round specimens, select inserts with a 0.015 in to 0.031 in (0.38 mm to 0.79 mm) nose radius to maintain gauge diameter straightness. Match jaw-face texture to the material, for example fine serrations near 0.04 in (1.0 mm) pitch for most metals, and smooth or rubberized faces for polymers per ASTM D638 and ISO 527 practices. When reporting per ASTM E8, plan a grit sequence that can achieve 32 µin Ra (0.8 µm) when required.

Replace cutters when surface roughness trends above 63 µin Ra (1.6 µm) or when gauge width or diameter starts drifting by more than ±0.002 in (±0.05 mm). Change abrasive belts when they no longer reach the target finish within the normal cycle. Maintain water-miscible coolant at 6 to 10 percent concentration, refresh when pH or bacteria checks fail, or every 3 to 6 months. Inspect jaw faces for rounding or glazing and replace if slippage appears at expected clamping loads.

Store resin-bonded abrasives at 60 to 77 F (16 to 25 C) and 35 to 50 percent relative humidity. Keep two complete jaw-face sets per grip size, duplicate collets, a full belt assortment, and common cutter diameters such as 0.250 in and 0.375 in (6.35 mm and 9.53 mm). Verify alignment pins and extensometer knife edges every 500 specimens or quarterly, whichever comes first.

For additional guidance, you can review available items on the

Consumables and Spare Parts page to match your equipment and standards.

Which Hidden Costs Should I Plan For After Buying a Universal Testing Machine?

Accessories add up quickly. Plan for multiple grip sets and jaw faces for different materials and sizes, for example serrated faces for 0.125–0.500 in (3–13 mm) round bars and smooth faces for thin flats. Mismatched adapters can introduce off-axis loading, so budget for proper thread adapters and alignment tools. Extensometers vary from clip-on units with 2 in (50 mm) travel to optical systems that need lighting and calibration targets. Environmental chambers, if you test outside ambient, bring added cabling, fixturing, and insulation costs.

Compliance has recurring expenses. Force verification per ASTM E4 or ISO 7500-1 is typically annual, and high-capacity frames, for example 50,000 lbf (222 kN), require higher-rated proving devices. Alignment checks per ASTM E1012, extensometer verification, and software version validation should be scheduled with downtime in mind, not just the service fee.

Facility and workflow items round out the budget. Hydraulic systems may need three-phase power, while floor models often require a stable footprint around 30 × 36 in (762 × 914 mm) plus working clearance. Specimen preparation drives consumables, such as cutters, inserts, and polishing media, and these scale with throughput and surface finish targets defined by ASTM E8 or ISO 6892 gauge geometry.

If you would like to review load frame options, grips, and accessories, you can explore details on the

All Tensile Testing Equipment equipment page.

How Do Labs Plan An In-House Tensile Specimen Preparation Setup That Meets ASTM And ISO Requirements?

Start with your standards and geometry library. For metals, ASTM E8 subsize and full-size choices often use 2.0 in (50 mm) or 1.0 in (25 mm) gage lengths; plastics commonly follow ISO 527 geometries. A software-driven workflow that lets operators pick a template, then locks critical dimensions and shoulder radii, reduces programming mistakes and shortens onboarding for new staff.

Match equipment to stock. Use a flat-specimen milling system for dog-bone blanks from plate or sheet, and a round-specimen CNC lathe for bars and rods. For consistent finish, leave about 0.020 in (0.50 mm) per side for a final pass near 0.008 in (0.20 mm). Target a surface roughness near 63 µin (1.6 µm) or better; if tool marks remain, a longitudinal polisher helps clean the gauge section without rounding edges.

Plan the workflow details. Keep dedicated fixtures that center the blank on the machine axis and prevent tilt. Stage duplicate cutters and inserts, and track tool life by part count instead of time. Use workholding that clamps outside the shoulder region so the gage section is untouched. Maintain a small kit of consumables, including end mills, lathe inserts, jaw pads, and polishing media, to avoid stoppages.

If you would like to review sample-prep options for your lab, you can connect with our team on the

Contact Us page.

How Does a Single-Vendor Tensile Testing Workflow Improve Compliance and Throughput?

A single-vendor workflow ties specimen preparation, polishing, and tensile testing into one chain. Operators work from standard libraries aligned to ASTM and ISO geometries, which cuts programming steps and reduces mismatches between machined dimensions and test fixtures. Lead time drops because blanks move directly from the mill or lathe to the tester, while one support group handles installation, calibration, and training.

Typical chain: flat milling or round turning to the specified gauge and fillet radii, optional longitudinal polish, then testing on a UTM with matched grips and an extensometer. For metals per ASTM E8, a common gauge length is 2 in (50 mm). For plastics per ASTM D638 or ISO 527, Type I and 1A specimens use 2.0 in (50 mm) gauge length. Size the frame to at least twice the predicted failure load, for example 22 kip (100 kN) for many steels.

On the floor, watch details that affect repeatability. Keep gauge length temperature under 150 F (65 C) during machining to avoid local property changes. Inspect cutters every 25 to 50 parts and adjust feed to prevent chatter that raises surface stress. Use wedge or pneumatic grips with serrations matched to hardness, verify alignment per ASTM E1012, and keep spare jaws and sharp inserts on hand to avoid mid-run delays.

If you would like to discuss your workflow, you can connect with our team on the

Contact Us page.