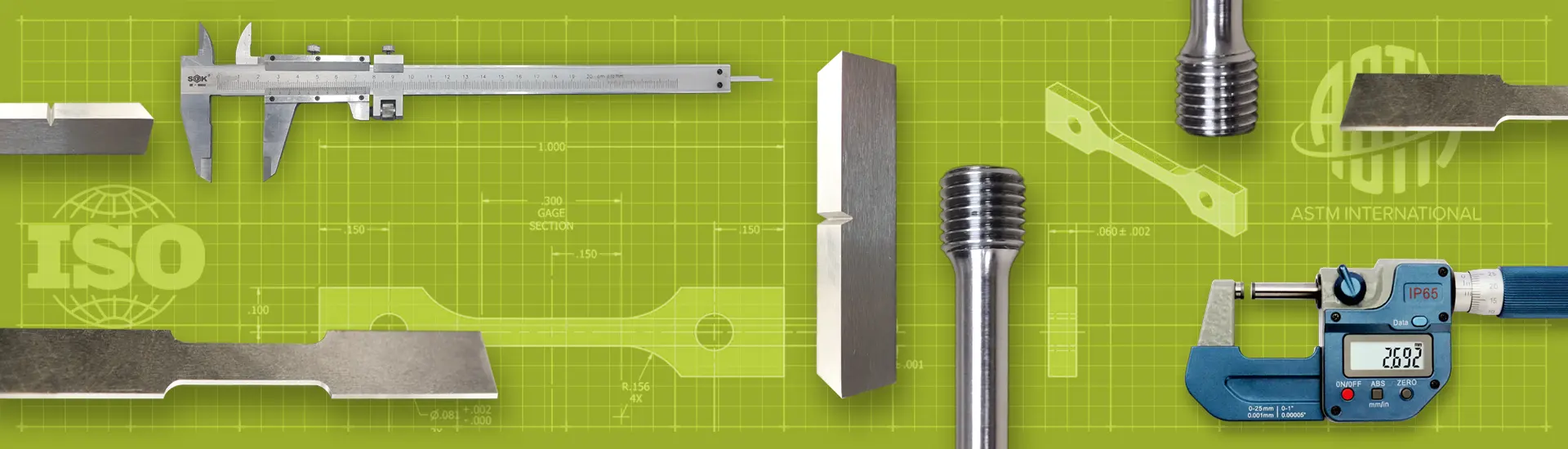

Perfect Solution for Tensile Specimens Sample Preparationand all other CNC Machining Requirements.

What Type of Tensile Samples Do You Need To Prepare?

Empowering operators of all skill levels to attain top-tier quality control results through precise and user-friendly tensile sample preparation solutions

WHO CAN BENEFIT FROM TENSILEMILL CNC?

Testing Facilities

Extrusion Manufacurers

Heat Treating Facilities

Metal Fabricators

Automotive Manufacturers

Tool Manufacturers

Quality Control Laboratories

Aerospace

R&D Facilities

Government Facilities

Educational Facilities

Military

Latest Videos

WHY CHOOSE TENSILEMILL CNC?

Learn what separates TensileMill from our Competition

Unique Value Proposition

Tensile Sample Preparation Machines

Overview

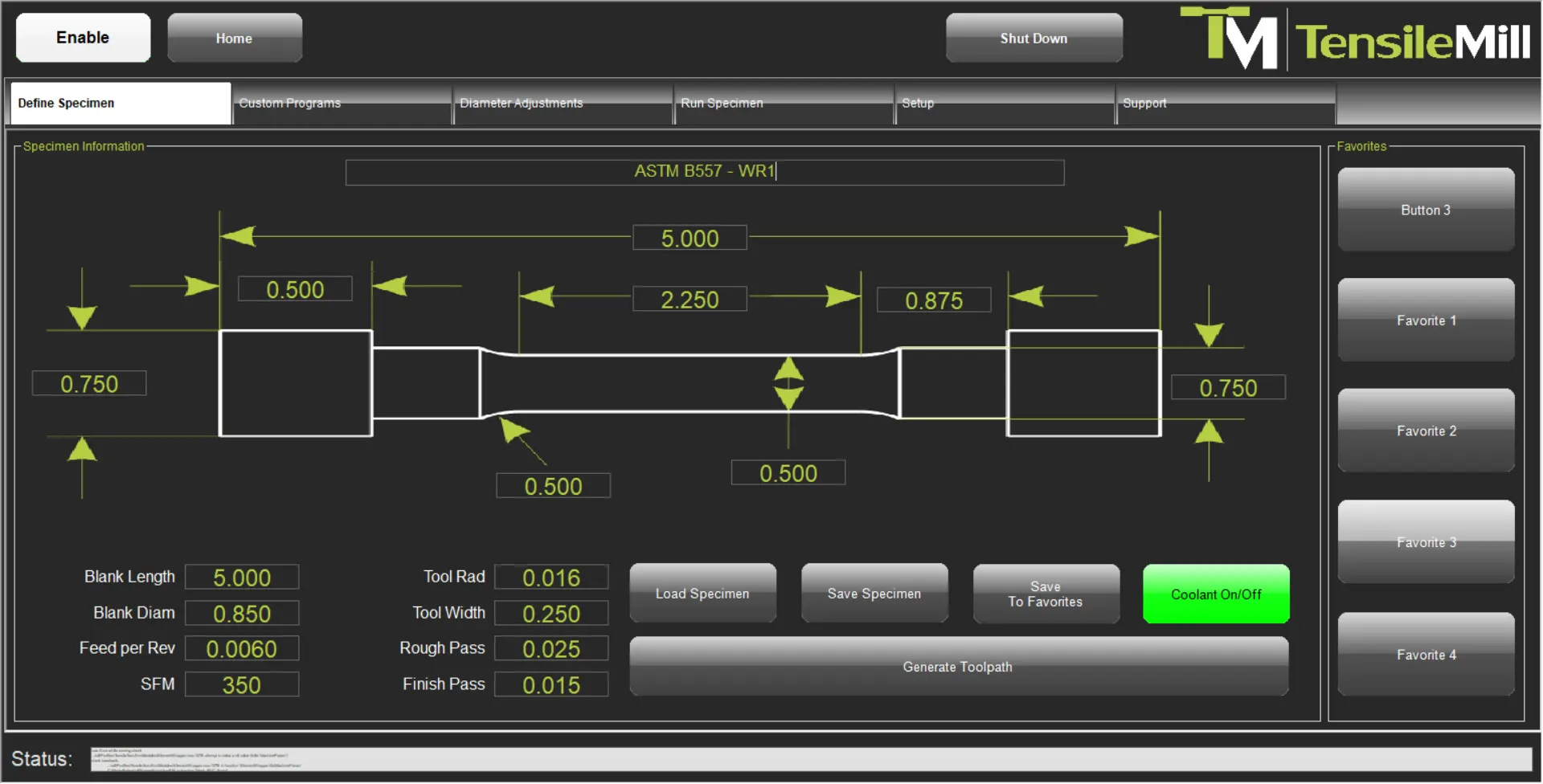

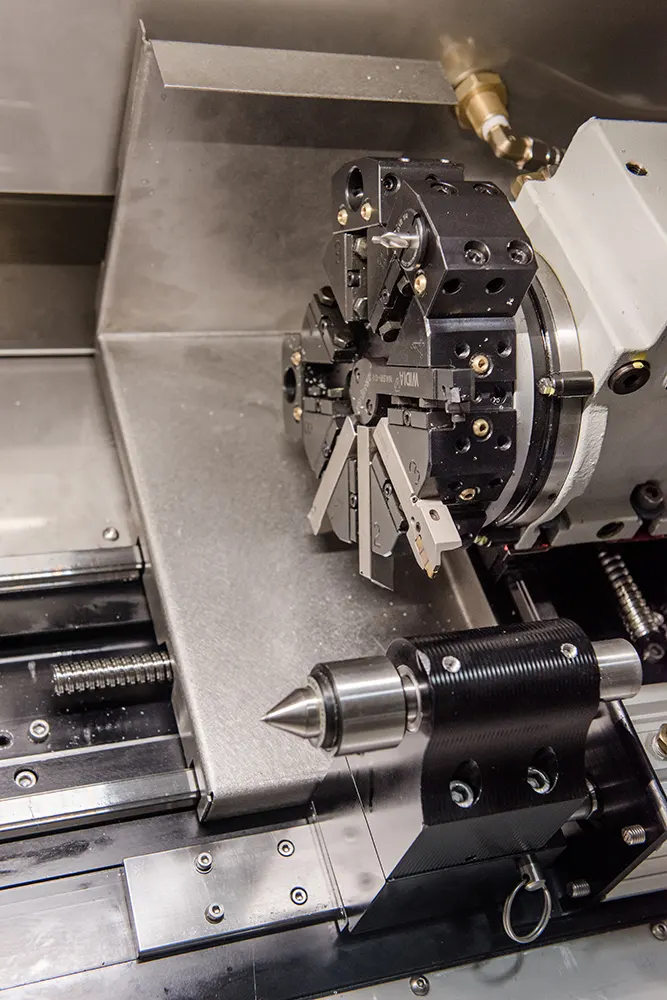

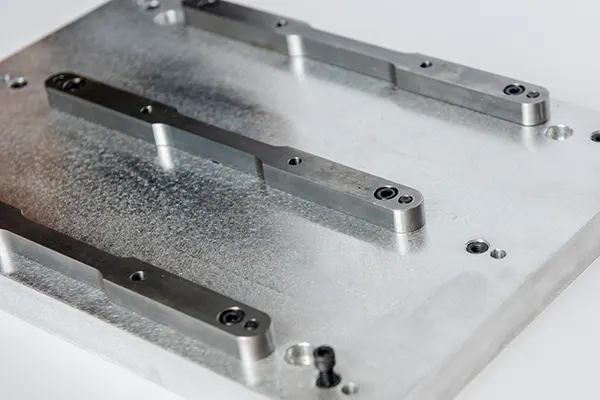

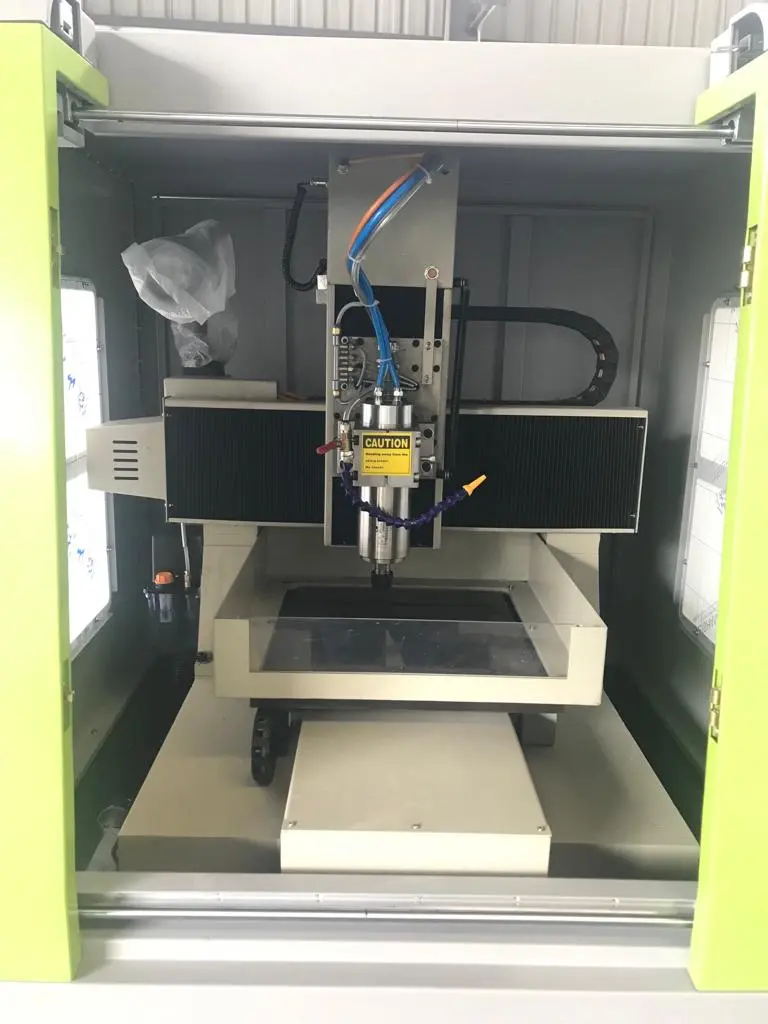

It is TensileMill's mission to empower operators of any skill level to contribute to highest manufacturing testing standards from A to Z. As a result, TensileMill CNC Inc. offers the ultimate flat and round tensile sample preparation systems. Our compact, high speed, machining centers designed to prepare the highest quality flat and round tensile specimens. Equipped with our smart and user friendly tensile software interface, TensileSoft™, we make it easy for virtually any operator to control the machining process from start to finish with only a few buttons. Smart and easy tensile specimen machining is what we do! Our extensive Carbon Mach4 controller is also available for universal CNC machining applications. Let TensileMill CNC help you by providing the highest quality tensile sample preparation for the most accurate tensile material testing results.

Photo Gallery

Our Clients

Perfect Solution for Tensile Specimens Sample Preparation and all other CNC Machining Requirements.

About us

TensileMill's empowers operators of any skill level to contribute to highest manufacturing testing standards from A to Z. This is the reason why thousands of manufacturers, educational facilities, government bodies, NDT facilities, laboratories choose us.

Talk to our specialists

CALL NOW (877) 672-2622

Confused? Contact one of our technical specialists today for a free consultation on how TensileMill CNC can help you!

"Large Enough to Serve and Small Enough to Care"

Recent Blogs

We provide the latest information about building from around the world. Don’t miss it!

-

2026-02-28CNC in a test lab is not a “nice to have.” It becomes a real staffing and risk question. Lab managers need output and repeatability, but they may not have dedicated machinists, and asking a technician to “also run CNC” can feel risky. New operators worry about crashes, scrapping coupons, and producing specimens that look acceptable but generate questionable results. That concern is justified. In tensile te...

-

2026-02-15If test data does not repeat, the first question should not be about the test frame. It should be about the specimen. Small preparation issues can create measurable bias and scatter, especially in tensile testing where stress is calculated from force and cross sectional area. ASTM E8/E8M cautions that improper specimen preparation is often behind incorrect results, while ASTM E23 emphasizes that notch tolerances are...

-

2025-12-30Universal Testing Machines generate data that gets used for QC decisions, supplier approvals, and audit evidence. If the force system or strain measurement drifts, results can look “normal” while quietly moving out of tolerance. When that happens, the problem is rarely caught at the moment of testing. It shows up later, during an audit, a customer challenge, a failed correlation, or a retest that does not match...

Trusted by Thousands of Quality Control Facilities Around the World

Testimonials

In my 15 years of as a QA manager I have never worked with an instrument which is so incredibly simple to operate. When we first got the equipment it took just a few minutes for me to figure it out. Moreover, by the second hour I was comfortably teaching my newer staff how to operate the machine. I love the library of common tensile dimensions and the ability to enter custom data on the touch screen controller. It is rear to see a dummy proof equipment on the market. We than TensileMIll CNC. Inc. for figuring this one out.

Armando F.QA Manager - MST SteelThe Software is astonishing! We particularly enjoy the library of common standards. In our initial discussion of technical specifications, we asked for the machine to be programmed for the ASTM E8 standard based on our customer needs at that time. We were pleasantly surprised to find the software was equipped with many ASTM, ISO, JIS, and DIN standards. This came particularly handy when our recently acquired customers needed us to prepare them with tensile samples according to ISO standards.

Shannon R.Quality Control Engineer - Denso Manufacturing and Denso Automotive GroupHappy with our investment. We received a better value at a more competitive price. Before buying, we sourced 3 quotations, including TensileMill. TensileMill met all technical needs and had the added value of the easy to use software interface. The unit was lower priced relative to the competition and fit well in our budget.

Justin P.Quality Supervisor - Extruded Aluminum CorporationWe specialize in part production with inconel metals. Our meterials are upwards of 50HRC and require a tensile tester with 5000 kN capacity. Daily we prepare roughly 30-40 samples. We were out there looking for a robust and user-friendly machine to be operated by our junior engineers in our new R&D division. We had sent our samples to TensileMill to be tested before making the final purchase. The guys at TensileMIll turned our samples, made a video of the process and sent the sample back to us for inspection. We were very impressed. TensileMIll CNC MINI was the solution for our needs. Over the years, this machine had proven itself over and over to be both powerful and reliable. Since we purchased the MINI, our capacity had increased to roughly 50 samples per day. After months of rigorous work with the unit, the only maintenance expense we have are the endmills. We had looked into purchasing them with other suppliers, however they last about a third of the time that TensileMill?s endmills do, yet the cost is about the same.

John W.Senior Quality Control Officer - Merit Technologies WorldBefore buying the unit, we had never heard of TensileMill CNC Inc. Our trust was earned when TensileMill invited us to visit their facility and see the unit?s operation for ourselves. We brought our specimens along for the trip. I must say, that at first I was very skeptical, because I have never heard of a ?tensile preparation designated machine?. The good news is that skepticism is no longer an issue. We are proud owner of the TensileMIll CNC MINI. What more, we really appreciate the way TensileMill handled themselves prior to the purchase and how they are continuously showing their support after the fact. We get occasional courtesy check ups to make sure that we are all set. It is nice to be cared for.

Randy C.Quality Control Manager - Valmont IndustriesVery easy to use for non-machinist. Terrific technical support.

Eric RaymontQuality Manager - Greenpoint MetalsIn my 15 years as a QA Manager I have never worked with an instrument which is so incredibly simple to operate. When we first got the equipment it took just a few minutes for me to figure it out. Moreover, by the second hour I was comfortably teaching my newer staff how to operate the machine. I love the programmed library of common tensile dimensions and the ability to enter custom data on the touch screen controller. It is rear to see a dummy-proof equipment on the market. We thank TensileMillCNC for figuring this one out.

Mike J.Researcher - NRELProfessional, fast and friendly. Those are the three words that come to mind when speaking to the customer support team. I am a big fan of dealing with professionals. This gives me confidence in the company's ability to solve my situation. The guys at TensileMillCNC are exceptional at identifying the issue and solving it immediately. I really enjoy the remote support which upgraded my machine's software from the convenience of my computer and at no charge. In my eyes, this puts a big A in TensileMillCNC's report card.

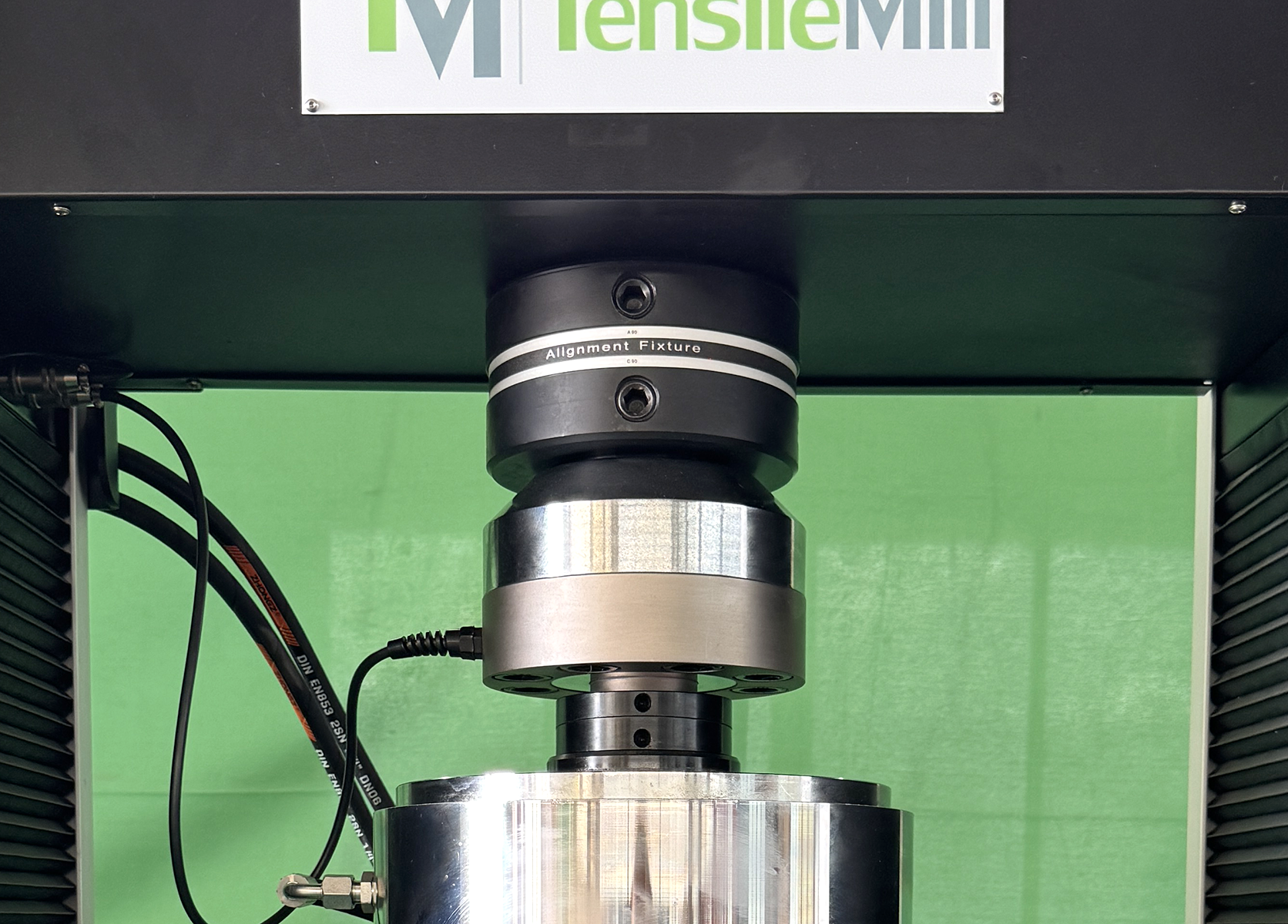

Mike S.QC Supervisor - Metal MaticI give a 5-star review for TensileMill CNC for their exceptional quality, user-friendliness, and technical support for the purchase of a 100kN Universal Testing Machine.

Firstly, the quality of the machine is exceptional. It is evident that TensileMill CNC takes great pride in their work and pays attention to every detail of the manufacturing process. The machine is built to last, and its precision and accuracy are remarkable.

Secondly, the user-friendliness of the machine is second to none. The software is intuitive and easy to use, and the machine is straightforward to set up and operate. TensileMill CNC provides comprehensive documentation and training, ensuring that their customers get the most out of their machine.

Overall, I highly recommend TensileMill CNC for anyone in the market for a Universal Testing Machine. Their exceptional quality, user-friendliness, and technical support make them the clear choice for anyone looking for a reliable and high-performing machine. Five stars all around!Soheil S.University of Arkansas Little RockWe had purchased multiple TensileMill CNC XL for our large volume tensile sample preparation facility. At the end of our 12 hour shift we pull roughly 190 samples of both metal and composite materials accordingly to various ASTM and ISO standards. Fast tensile milling is a must. Our engineering team's production time has been cut by a factor of 2.7 since our upgrade. The easy tensile milling process offered by TensileMill CNC's user-friendly software is unparalleled. Our quality team is able to set the standard and mill the sample in a matter of minutes without having to be physically bound to the unit. As a production supervisor, I could not be happier. Our tensile sample preparation process is inspiring our sister facilities and we have 4 more orders to come. One thing to add is that TensileMill's team is there for us when we need them. We have all of our questions answered immediately which helps us with our commitment to productivity. Thank you TensileMill!

Robert B.NSF InternationalWe purchased the 1000kN Servo Hydraulic Universal Testing machine and the user-friendly tensile sample preparation system from TensileMill. Our team is very happy with the quality of the equipment and the professionalism offered by TensileMIll.

First and foremost, the testing machine and sample preparation system were incredibly user-friendly. Even though I had never used this type of equipment before, I was able to easily navigate the controls and prepare my samples quickly and efficiently. The machine itself is extremely powerful and accurate, and I was able to get precise tensile dog bones with ease.

I also want to give a special shout-out to the team at TensileMill. Though there were some challenges that arose during my use of the equipment, the team was quick to respond and take care of the issues. They were incredibly responsive and helpful throughout the entire process, and their dedication to customer service is truly remarkable.

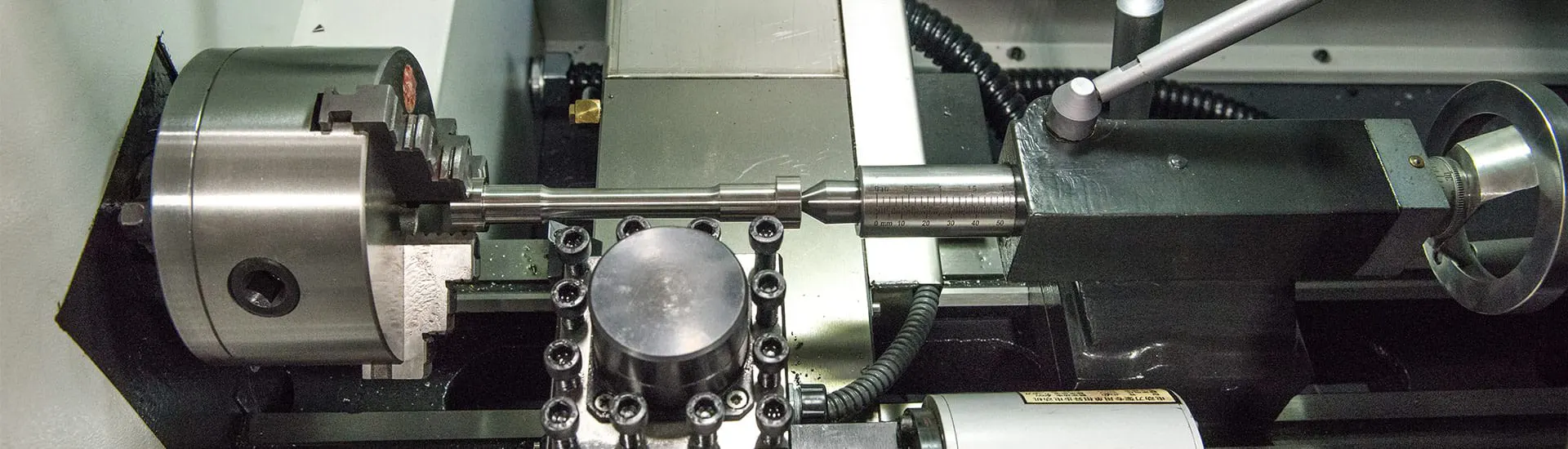

Overall, I cannot recommend TensileMill's products and services enough. The 1000kN Servo Hydraulic Universal Testing machine and tensile sample preparation system are top-notch, and the team behind them is truly outstanding. If you are in need of high-quality testing equipment and exceptional customer service, look no further than TensileMill. They will not disappoint!Wayne S.Var Steel CanadaWe recently purchased the 300kN Electron mechanical Universal Testing System and the Tensile Sample Preparation Lathe, and we are very impressed with both products. The ease of use and precision of these systems are simply outstanding.

The 300kN Electron mechanical Universal Testing System is incredibly powerful and accurate. The machine is incredibly easy to operate, even for someone with limited experience in using such equipment. We got both in-person and remote training and to our pleasant surprise, the software on both units is intuitive and user-friendly, allowing me to easily control the testing process and obtain precise measurements quickly and efficiently.

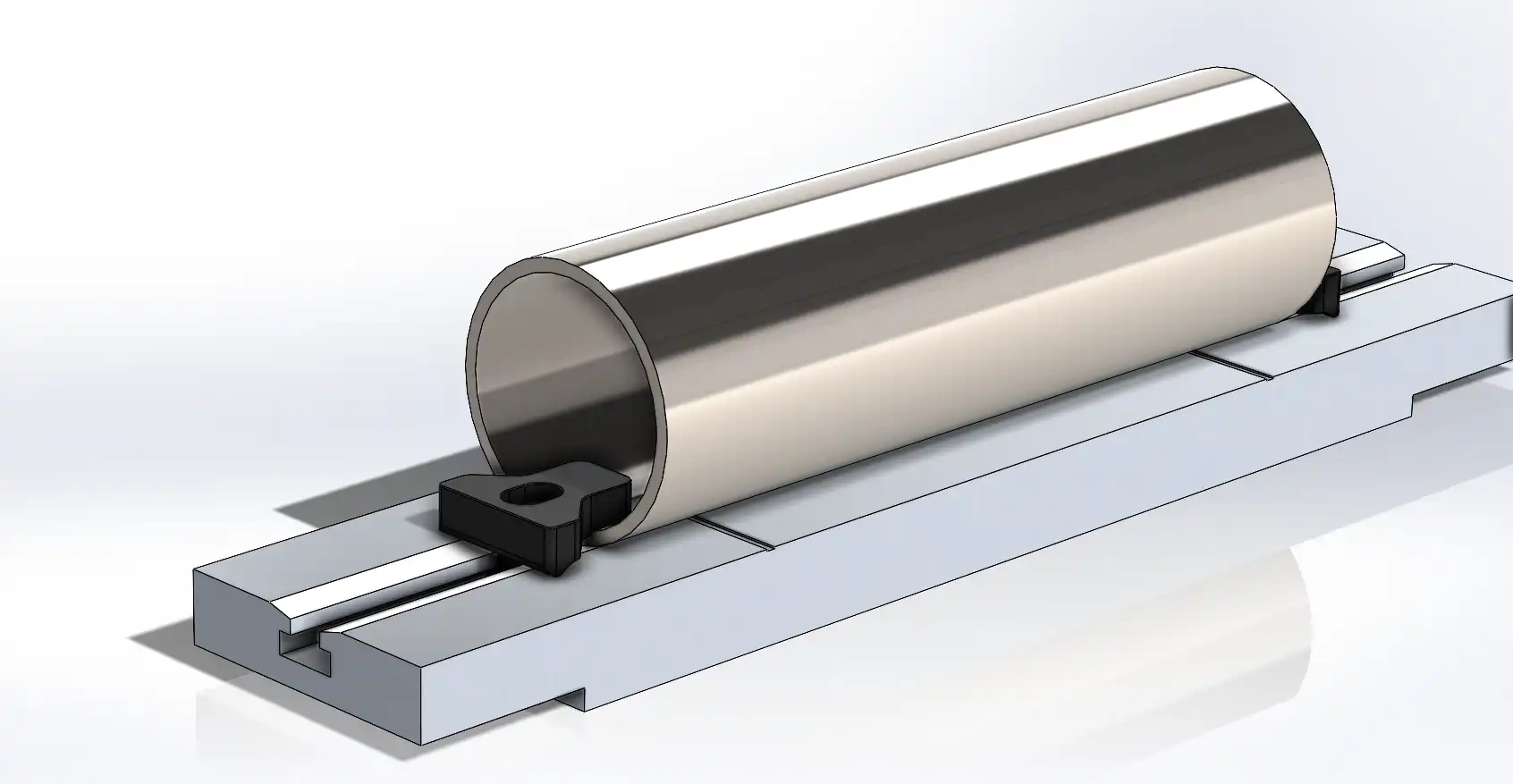

The Tensile Sample Preparation Lathe is another standout product. It is incredibly easy to use and produces consistent, high-quality samples. The lathe is also very easy to maintain, with simple cleaning and maintenance procedures that ensure it continues to perform at a high level for years to come.

Overall, I am incredibly satisfied with my purchase of both the 300kN Electron mechanical Universal Testing System and the Tensile Sample Preparation Lathe. These systems have made my work in the lab much easier and more efficient, and the precision of the results I obtain is truly remarkable. We were able to get additional test results on the software that were above and beyond our expectations. We also were able to increase our system accuracy by increasing each reading from 1 to 3 decimal places.

I would highly recommend these products to anyone in need of high-quality testing equipment. The ease of use and precision of these systems are simply unparalleled, and the customer service provided by the team behind them is truly outstanding. If you are in need of testing equipment, look no further than these two incredible systems from this company.Steve F.Nevada Heat TreatingExceptional technical support. We purchased the unit in June and already received our free software upgrade. The upgrade was done remotely and completed within 15 minutes. The tech rep gave us a mini crash course on the values of the new software. We now have more milling flexibilities and up-to-date industry standards pre-programmed in the machine.

Ron I.Heat Treatment FacilityI had the pleasure of using the MINI Flat Tensile Test Sample Preparation Machine from TensileMill CNC at our facility in Ohio, and I have to say, I was thoroughly impressed with its performance.

The machine was easy to install and set up, thanks to its compact size and user-friendly interface. But what really stood out to me was its precision and accuracy. It consistently produced high-quality tensile test samples that met our exact specifications, with minimal material waste.

What's more, the machine was incredibly efficient, allowing us to prepare multiple samples quickly and easily. This saved us a significant amount of time compared to our previous manual methods, which were slow and labor-intensive.

But perhaps the best thing about the MINI was the exceptional customer service we received from TensileMill CNC. They were always available to answer any questions we had and provide technical support, making the entire process seamless and stress-free.

Overall, I would highly recommend the Compact Flat Tensile Test Sample Preparation Machine to anyone in need of a reliable and efficient sample preparation solution. It's a game-changer for our facility, and we couldn't be happier with the results.Arron P.Greer SteelThe MINI is an exceptional product that truly exceeds expectations. The team behind this product truly understands the needs of their customers, and they go above and beyond to ensure that the TensileMill CNC MINI is not only functional but also easy to use. The level of customer service is top-notch, and any questions or concerns are promptly addressed. With its user-friendly interface and outstanding performance, the TensileMill CNC MINI is a must-have for anyone in need of precision machining.

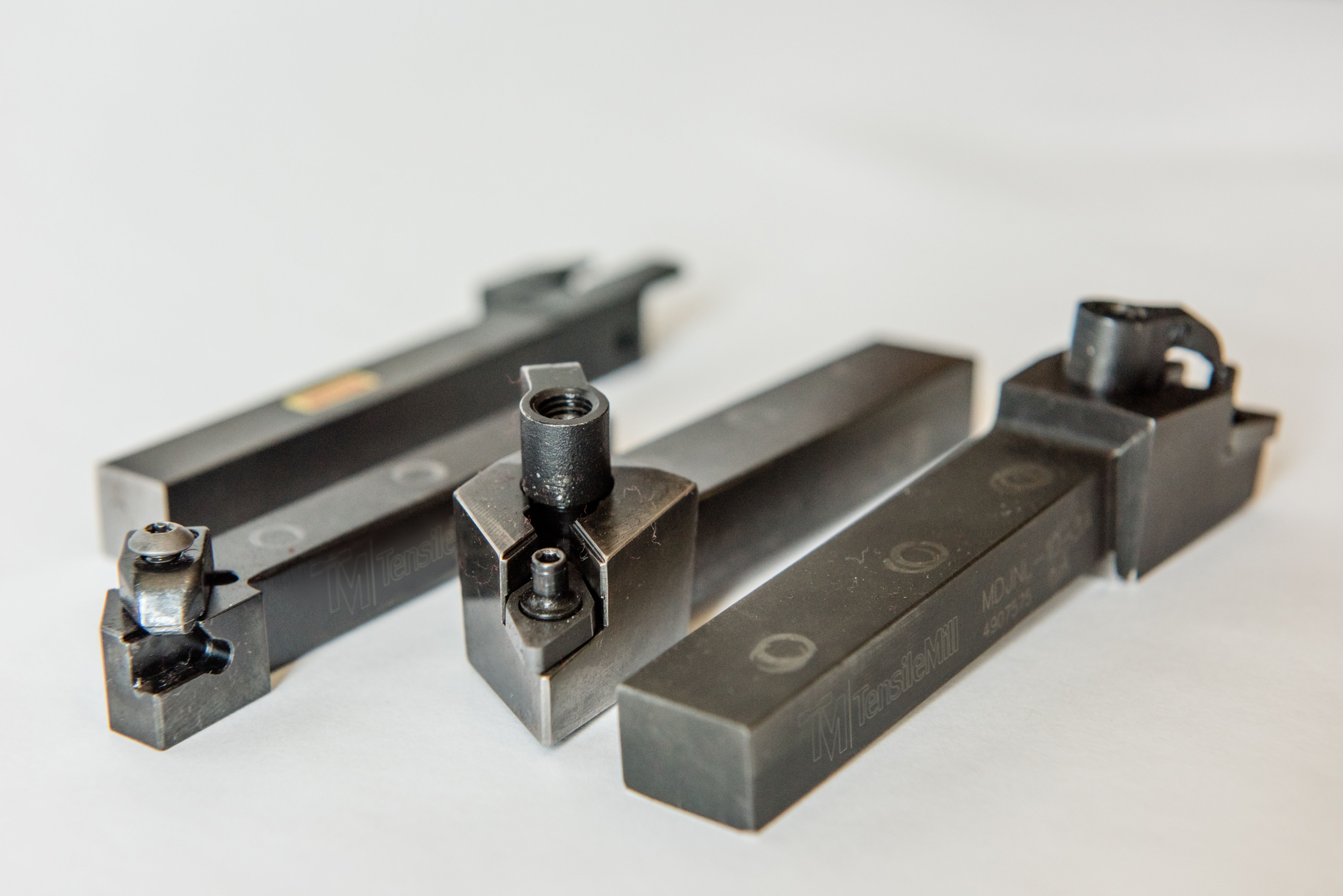

It is also nice that all the necessary tooling are either stocked or have relatively low lead times. I particularly like how TensileMill treats us to free consumables, once in a while.Jeff L.Engineering - Wheeling Nippon SteelWe specialize in Inconel metals. Our dog bones are round tensile specimens which require a tensile tester with 5000 kN capacity. On top of that, we require to test 30-40 samples daily. The round tensile sample preparation machine we needed in our lab was one that is both powerful and reliable. TensileTurn XL was the answer. We had sent our samples to TensileMill to be tested before making the final purchase. The guys at TensileMIll turned our samples, made a video of the process and sent the sample back to us for inspection. We were very impressed. Since we purchased the TensileTurn XL, our capacity had increased to roughly 50 samples per day. After months of rigorous work with the lathe, the only maintenance issue we have is the frequent change of the drill bits. All other components of the tensile lathe such as the custom tooling fixture, the servo motor, the spindle, and the user friendly software are doing a fine job.

Sam V.Senior Quality Engineer - Manufacturing SectorWe needed a tensile sample preparation machine that can mill roughly 50 flat tensile specimens a week with high edge finish quality. We invested in TensileMill CNC flat tensile sample preparation unit. This machine surprised us with its performance. The quality of finish and the ease of use exceeded our expectations. This machine had increased our production 6-fold and reduced as much operator involvement. We are expecting an increased work load in the near future and will require a new facility. The newly developed MINI from the flat tensile products is looing like the perfect fit.

Jeff M.Materials Engineer - Element

How Do I Choose Between Flat And Round Tensile Specimen Preparation Systems?

Start with the form of your incoming material and the standard you must follow. Sheet and plate programs, and plastics dumbbells to ASTM D638, are usually best prepared on a flat-specimen machining system. Bar, rod, and forged stock governed by ASTM E8 or ISO 6892-1 often point to round-specimen lathes, especially when gauge sections must be concentric and free of tool marks.

Match geometry, size range, and required tolerances. Typical flat coupons span about 0.25 to 1.00 in (6 to 25 mm) gauge width and 0.02 to 0.50 in (0.5 to 12.7 mm) thickness. Round specimens commonly run 0.125 to 1.00 in (3 to 25 mm) gauge diameter. Many labs target dimensional tolerances of ±0.002 in (±0.05 mm) and a surface finish near 32 to 63 µin Ra (0.8 to 1.6 µm) to reduce stress risers.

Consider throughput and workflow. Flat systems can fixture multiple blanks for batch cutting, which suits high mix, moderate volume. Round systems with programmable cycles excel for repeated diameters and longer gauge sections such as 2.00 in (50 mm) gauge length or 4D rules. Also verify downstream compatibility, for example wedge or serrated grips for flats, and collets or threaded ends for rounds on your UTM, and whether your polishing step is longitudinal or circumferential.

When in doubt, map your most common part families, smallest and largest sizes, and the governing clause of the standard, then select the machine that meets those boundaries with margin.

If you would like to discuss your testing requirements, you can connect with our team on the Contact Us page for guidance tailored to your workflow.

How Do I Select the Right Tensile Specimen Preparation System for My Lab?

Start with the materials and standards your lab must support. Metals commonly follow ASTM E8/E8M, plastics often follow ASTM D638 or ISO 527. Confirm specimen geometry first, such as flat dog-bone, subsize, or round bar, since that determines whether a CNC milling machine, a CNC lathe, or both are needed. For consistent strain distribution, many labs target width tolerance within ±0.002 in (±0.05 mm) and surface roughness near 32 µin Ra (0.8 µm) after machining and polishing.

Match capacity and accuracy to throughput goals. A practical work envelope for flat workholding is around 12 in × 24 in (305 mm × 610 mm). Typical spindle power for flat machining ranges from 2 to 5 hp (1.5 to 3.7 kW). For round specimens, look for chucking up to about 1.0 in (25 mm) diameter and 12 in (305 mm) length, with machine repeatability near ±0.0005 in (±0.013 mm). If operators run mixed alloys, prioritize recipe control, fixture quick-change, and safe chip or dust extraction.

Plan the finishing and testing steps. Longitudinal polishing equipment helps achieve uniform surface finish that supports valid tensile results, and it reduces the risk of edge artifacts. Verify that shoulder dimensions or threaded ends will seat correctly in your UTM grips, for example wedge or threaded grips rated for the expected load such as 11,200 lbf (50 kN). Aligning machining, polishing, and gripping from the start prevents specimen rework and improves first-pass yield.

If you would like to discuss your testing requirements, you can connect with our team on the Contact Us page.

How Do I Choose Between Flat and Round Tensile Specimen Preparation Machines?

Start with incoming material form and the governing test method. Flat CNC systems best suit sheet, plate, and strip in the 0.02–1.00 in (0.5–25.4 mm) thickness range, delivering dog-bone profiles for methods such as ASTM D638 or ISO 527. Lathe-based round systems excel on bar and rod stock around 0.25–2.00 in (6–50 mm) diameter, supporting metallic coupons for ASTM E8 when a turned gauge section is specified.

Match the specimen geometry to your grips and alignment practices. Wedge or serrated grips favor flat coupons, while collet or threaded-end setups favor round. Many metallic procedures call for a 2.00 in (50 mm) gauge length; plastics often use the same nominal length. Verify required tolerances in the standard, then size the machine to hold typical coupon width and thickness within about ±0.002 in (±0.05 mm) and to blend fillet radii smoothly, for example near 0.50 in (12.7 mm) where applicable.

Consider throughput, surface quality, and operator workflow. For high volume, look for quick-change fixturing, repeatable locating, and tool libraries that maintain profiles across materials from 40–300 HB (≈ 430–3,000 MPa UTS). Aim for a final surface near 63 µin Ra (1.6 µm Ra) or better on metals, remove burrs to roughly a 0.005 in (0.13 mm) edge radius, and use stable coolant delivery so heat does not distort the gauge section. If specimens require longitudinal polishing, plan capacity for repeatable passes and consistent media tracking.

If you would like to discuss your testing requirements, you can reach our team on the Contact Us page for friendly guidance on next steps.

How Do Tensile Sample Preparation Machines Integrate With UTMs For End-To-End Compliance?

Integration starts with producing specimens that meet geometry and finish targets the UTM expects. For metals to ASTM E8, typical dog-bone flats hold gauge width within ±0.001 in (±0.025 mm), gauge length of 2.0 in (50 mm), edge radii of 0.125 to 0.250 in (3.2 to 6.4 mm), and surface finish of 16 to 32 µin Ra (0.4 to 0.8 µm). For plastics to ISO 527 or ASTM D638, consistent gauge thickness and a 2.0 in (50 mm) gauge length improve strain uniformity. Round E8 specimens benefit from concentricity within 0.002 in TIR (0.05 mm) and blends free of toolmarks.

For additional guidance, you can connect with our team on the Contact Us page to review options that fit your testing workflow on the page.

How Do I Choose Between Flat and Round Tensile Specimen Preparation Systems?

Start with your material form and the target geometry required by your test method. Flat preparation is ideal for sheet, plate, or molded panels, commonly used for ASTM E8 metals or ISO 527 plastics. Typical flat dog-bone sizes include 0.25 to 1.00 in (6 to 25 mm) gauge width with 1.00 to 2.00 in (25 to 50 mm) gauge length and 0.125 in (3.2 mm) fillet radii. Round preparation suits bar, rod, wire, or cast buttons, with frequent sizes of 0.250 to 0.500 in (6 to 13 mm) diameter and 2.00 to 4.00 in (50 to 100 mm) gauge length. Target tolerances often hold ±0.001 in (±0.025 mm) in the gauge section and 0.001 in TIR (0.025 mm) concentricity for round specimens.

Consider throughput and handling. For high coupon volumes across multiple alloys, a fixtured flat CNC system supports repeatable nesting and quick changeovers. For rounds, a programmable lathe-style machine with tailstock support and center drilling maintains straightness on longer pieces, for example 6 to 12 in (152 to 305 mm) overall length, while flood or mist coolant protects both metals and polymers.

Confirm UTM and grip compatibility early. Flats pair well with wedge or pneumatic grips using 1 to 2 in (25 to 50 mm) jaw widths. Rounds may require collets, shoulders, or threaded ends such as 0.500-20 UNF, with shoulder perpendicularity within 0.002 in (0.05 mm). Surface finish affects results, so polish the gauge section longitudinally to Ra ≤ 32 µin (0.8 µm), or to 16 µin (0.4 µm) for notch-sensitive materials, and verify dimensions against the selected standard during first-article inspection.

If you are comparing flat and round preparation solutions, you can explore the TensileMill CNC Homepage to review product families on the page.

TensileMill CNC Inc. © 2026