What type of receptacle would be recommended for the system?

A standard single-phase 220 V, 20 A, 3-prong receptacle is recommended for the TensileMill CNC MICRO. In most labs, the machine is simply plugged into this outlet or hardwired to a local disconnect, depending on your electrical safety requirements.

For day-to-day operation, most QC and R&D labs:

Use a dedicated 200–240 V single-phase circuit protected at 20 A

Place a lockable disconnect or breaker within line of sight of the machine

Ensure the circuit is not shared with other high-draw equipment to avoid nuisance trips

In a typical scenario, an in-house electrician will either install a 3-prong 20 A receptacle close to the MICRO or hardwire the machine to a disconnect switch mounted on the wall or the back of the unit. This gives you a clear, compliant way to de-energize the machine during maintenance or relocation.

Because the MICRO is a compact, self-contained tensile and impact coupon milling system, no special multi-phase industrial service is required—just a clean, stable single-phase 220 V supply.

You can explore the full electrical requirements, connection options, and lab-ready setup details on the

TensileMill CNC MICRO page.

Does the MICRO system require a water connection?

No external water or chiller connection is required for the TensileMill CNC MICRO. The machine uses a recirculating flood coolant system with a built-in tank, and the spindle is air-cooled, so you don’t need plumbing or a standalone chiller.

In practice, this means:

You fill and maintain the internal coolant tank in the base of the machine

The coolant is continuously recirculated and filtered during specimen milling

The spindle cooling is handled by integrated air-cooling, not water

A pneumatic connection is optional, typically used for chip blow-off or actuating optional fixtures

For a lab that’s upgrading from manual routers or outsourcing, this is a major simplification: you can park the MICRO almost anywhere you have power and ventilation, without calling facilities to run water lines.

If your process relies heavily on compressed air for fixture actuation or aggressive chip clearing, you can connect a standard shop air supply (following your site’s pressure and filtration practices), but it is not required for basic operation.

More information on the MICRO’s self-contained coolant design, airflow system, and optional pneumatic setup is available on the

TensileMill CNC MICRO product page.

What are the space requirements (footprint) for TensileMill CNC MICRO?

The TensileMill CNC MICRO has a compact footprint designed for laboratory environments. The machine itself is approximately 20.5" × 24" × 59" (52 × 60 × 150 cm) and is supplied on a mobile stand with an integrated coolant tank.

In real-world terms:

Machine envelope: ~0.5 m × 0.6 m footprint, ~1.5 m tall

Suggested floor space: plan for about 2.1 m × 2.0 m (82.7" × 78.5") to allow door opening, operator access, and safe maintenance clearance.

TensileMill CNC

Mobility: the base includes a mobile stand, so the MICRO can be repositioned inside the lab when workflows change.

Typical use cases:

A QC lab places the MICRO against a wall with enough space for the operator to open the enclosure, load blanks, and empty chips/coolant.

An R&D or educational lab may put the MICRO on a shared equipment row, relying on the compact footprint to keep aisles clear while still providing a full tensile and impact coupon milling capability.

Because the coolant tank and enclosure are built into the stand, there is no need for extra external coolant modules or chip bins that extend the footprint beyond the planned area.

If you want to check precise dimensions, layout suggestions, and positioning tips, you can find them on the

TensileMill CNC MICRO page.

What is the suggested cooling fluid to be used with the system?

The TensileMill CNC MICRO uses a recirculating flood coolant system located in the base of the machine. We recommend a water-miscible metalworking coolant suitable for your material mix, refreshed approximately every 6–12 months depending on usage.

In most labs, a semi-synthetic or synthetic coolant formulated for aluminum and steel is ideal. Well-known brands such as Cimcool, Hocut, or Blaser are commonly used in tensile specimen preparation because they:

Provide good lubricity for consistent edge quality

Offer corrosion protection for both machine and specimens

Reduce foaming and odor in recirculating systems

Support long sump life with proper maintenance

Practical guidance:

For a lab running intermittent batches, checking concentration and topping up every few weeks is usually sufficient.

For daily production, implement a simple coolant maintenance routine (concentration checks, chip cleaning, occasional tank cleaning) to maintain surface finish and tool life.

The spindle is air-cooled, so no additional fluid is required for spindle cooling.

If you want tailored guidance on coolants for your specific material mix, you can find it on the

TensileMill CNC MICRO page.

What is the suggested lubrication fluid to be used with TensileMill CNC MICRO?

For linear guides and moving components, the TensileMill CNC MICRO is designed to work with a standard ISO 68 way lubricant (or equivalent) commonly used on CNC mills.

An ISO 68 way lube:

Provides a stable oil film on linear rails and sliding surfaces

Reduces wear and friction during rapid moves

Helps maintain positioning accuracy and repeatability over time

Common ISO 68 way lube brands from suppliers such as Mobil, Shell, or Irving are appropriate, as long as they meet typical machine tool way-lube specifications.

A practical maintenance pattern many labs follow:

Visual check of lube reservoir during routine operator checks (weekly or monthly, depending on usage)

Top-ups when levels drop below the recommended mark

Inclusion of lubrication checks in an annual preventive maintenance visit to confirm lines and metering devices are functioning properly

Correct lubrication directly supports long-term accuracy of tensile and impact coupon milling, especially when your lab is running repetitive ASTM/ISO programs where consistency is critical.

For a maintenance plan aligned with your specimen volumes and usage pattern, review the details on the

TensileMill CNC MICRO product page.

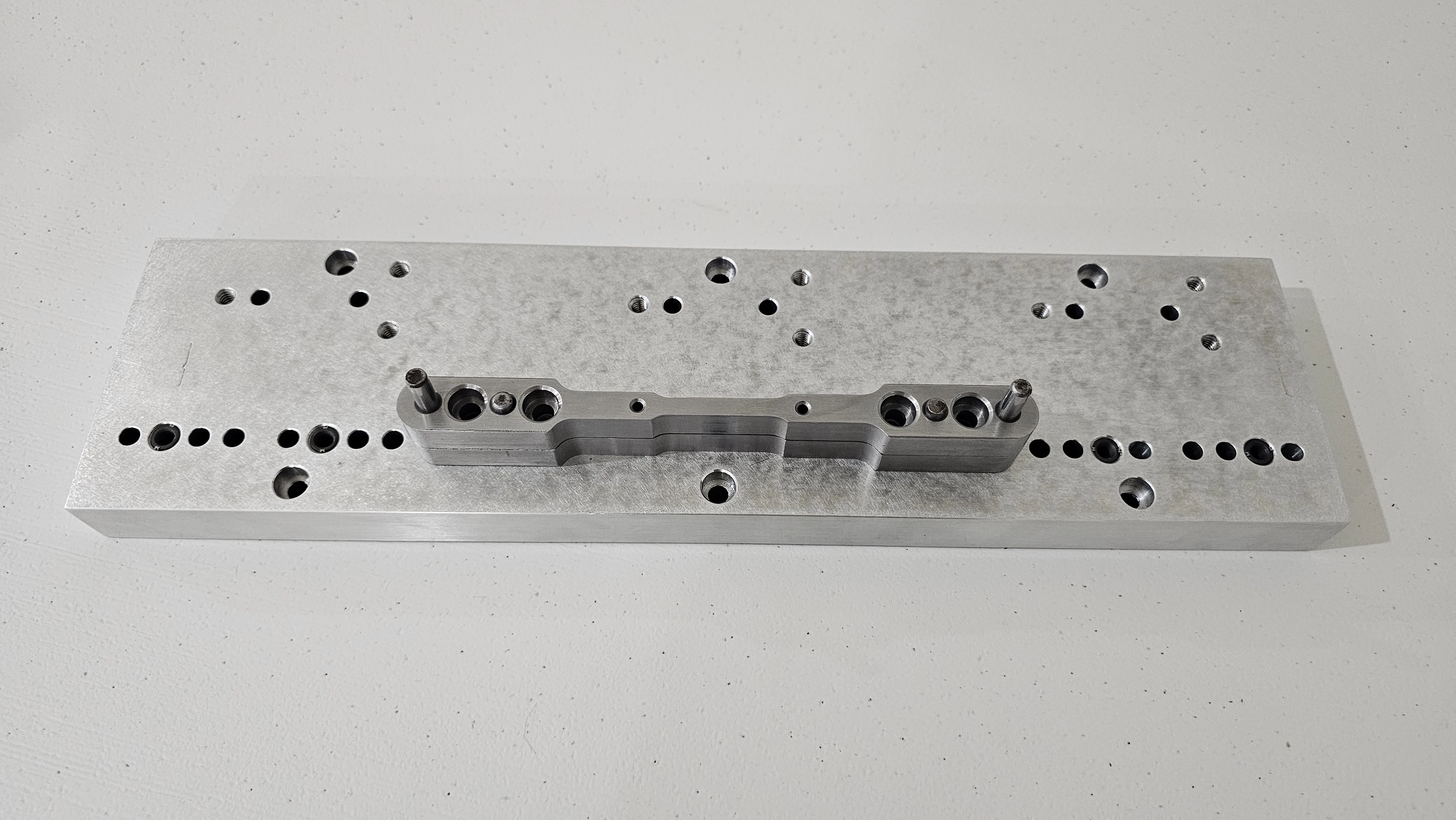

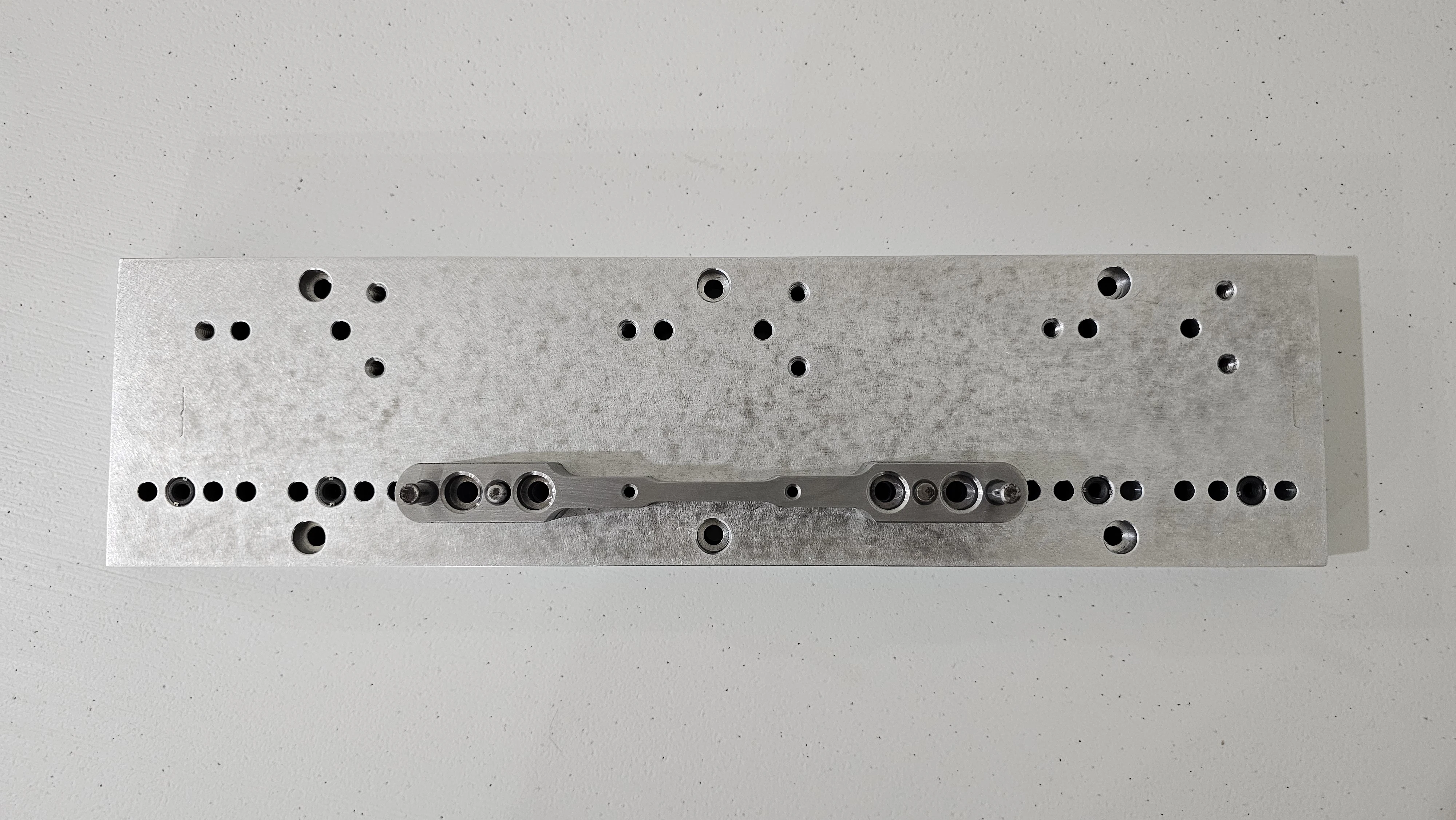

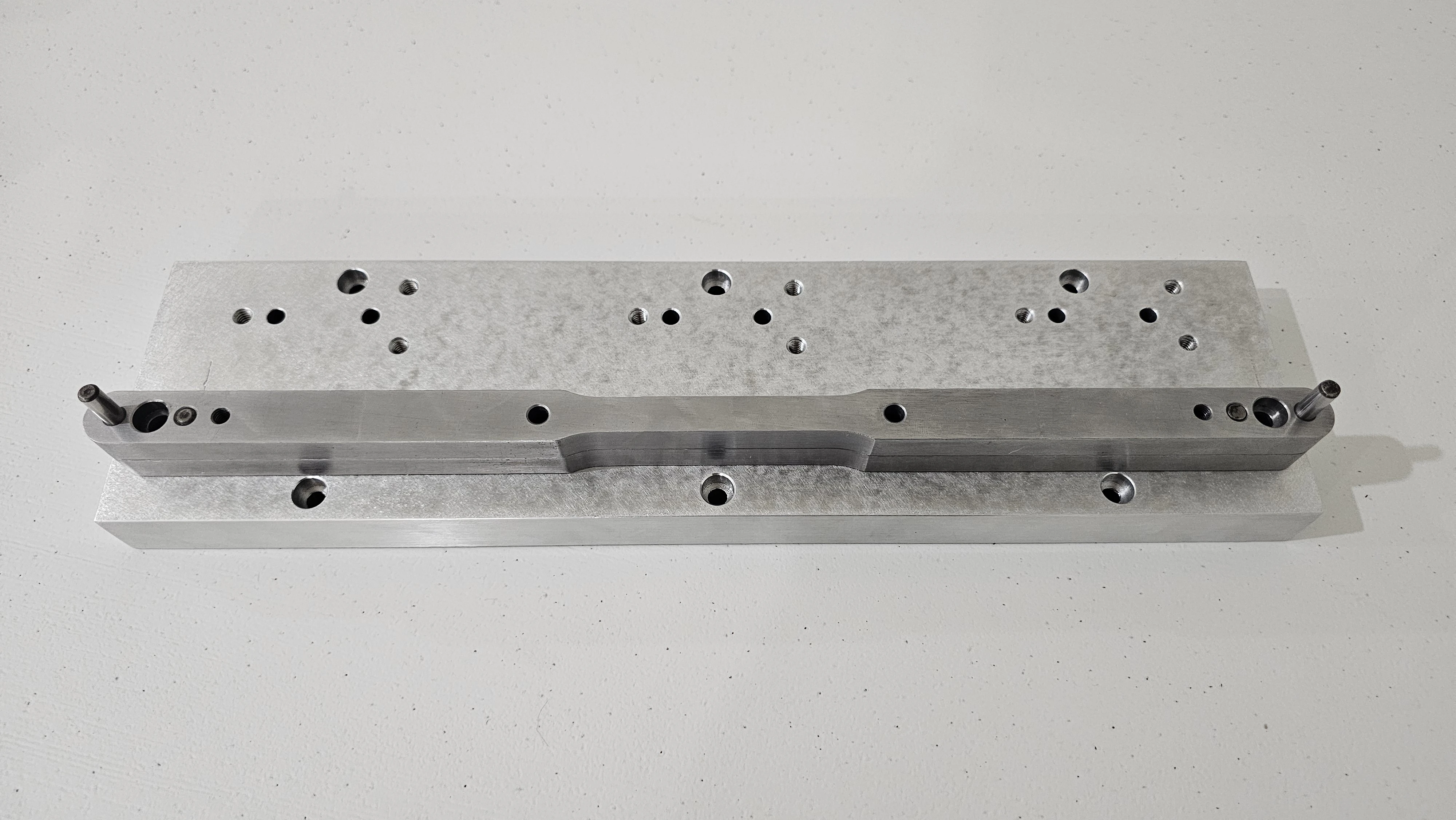

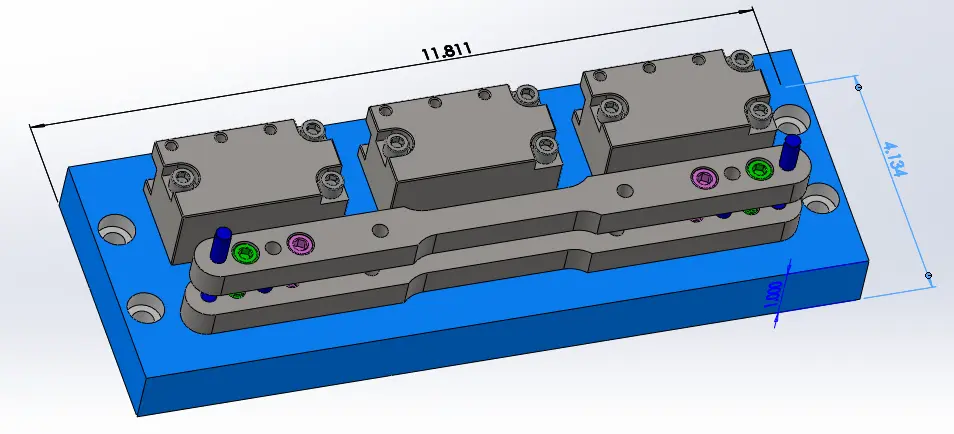

What types of tables and clamping fixtures are included as a turnkey package with the MICRO?

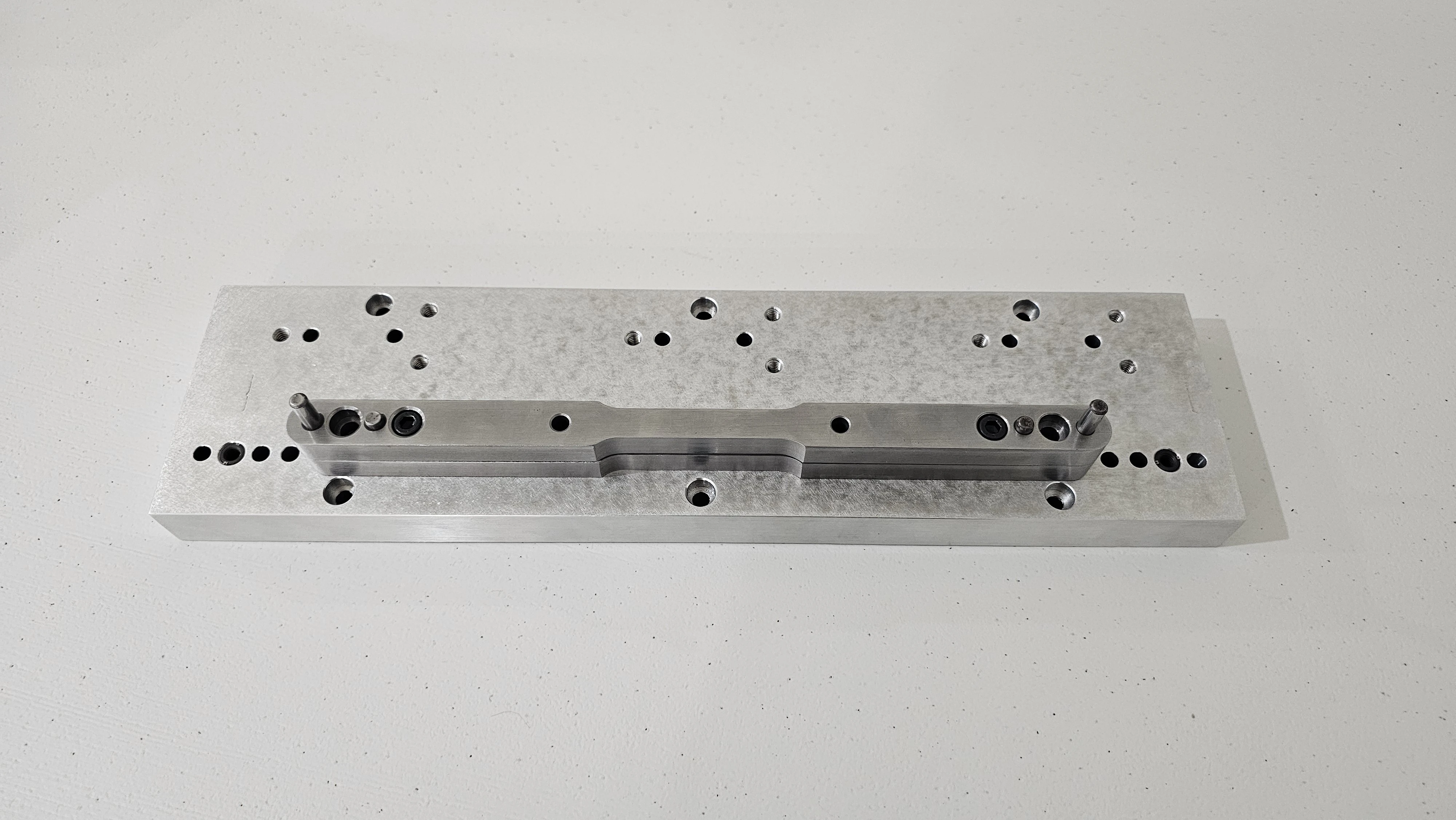

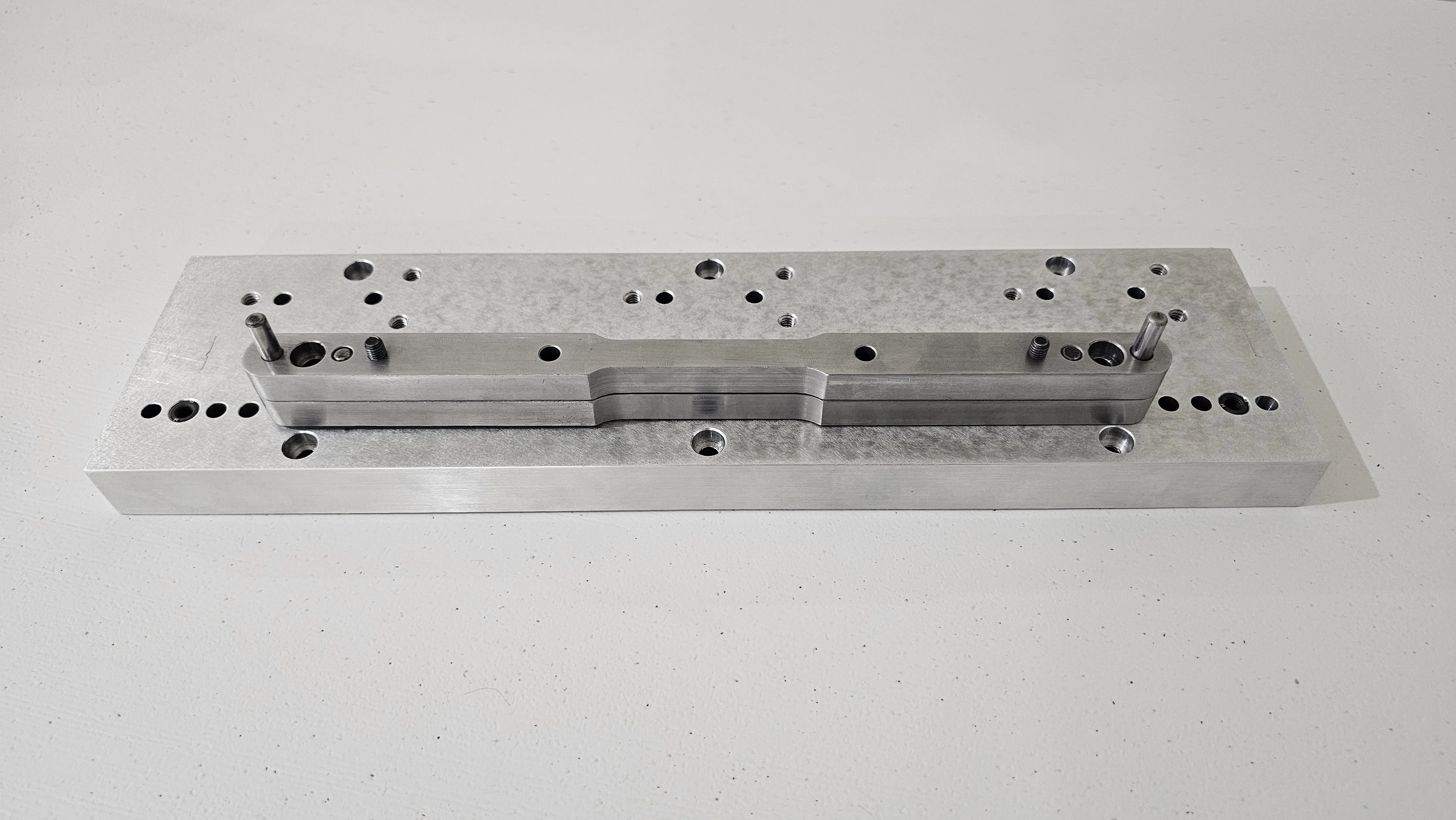

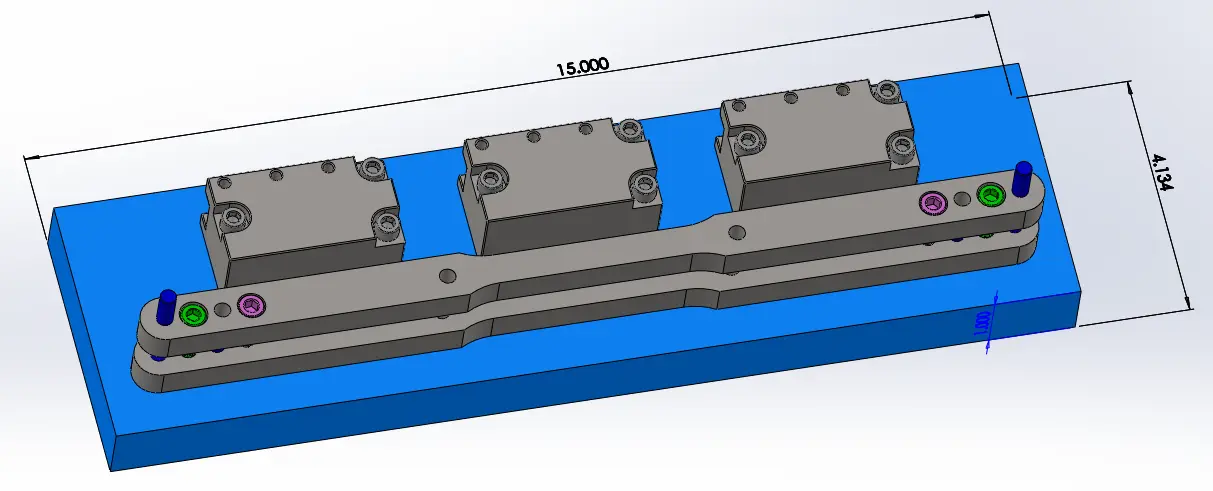

As a turnkey system, the TensileMill CNC MICRO is supplied with a dedicated flip-jig fixture for flat tensile and impact specimen preparation. The operator clamps the blank once, machines one side, then rotates the jig when prompted by the touchscreen to complete the second side—without re-aligning the specimen.

Out of the box, you can expect:

One flip-jig size matched to your chosen specimen length (4", 8", or 12")

A base fixture mounted on the machine table designed specifically for flat tensile coupon milling

Optional additional jigs and inserts available for different standards or custom geometries

Impact integration:

The MICRO platform can be equipped with Impact Jig fixtures, with space for up to three Impact Jigs on the table.

This allows you to prepare up to three impact specimens in a single setup, improving throughput for Charpy/Izod notching workflows.

Because impact samples often have stricter geometry constraints, we strongly recommend confirming your impact specimen dimensions and standards (ASTM, ISO, etc.) with a TensileMill consultant to ensure the fixtures are configured correctly for your test method.

The result is a fixture system that minimizes setup time and maintains consistent alignment of the gauge section, supporting repeatable, audit-ready tensile and impact sample preparation.

To explore flip-jig options, impact fixtures, or confirm compatibility with your standards, visit the

TensileMill CNC MICRO page.

Is it possible to upgrade to the CNC Unlock function after the purchase of the main unit?

Yes. The TensileMill CNC MICRO can be upgraded to the Carbon CNC interface (“CNC Unlock”) at any time after installation. This software upgrade turns the MICRO from a dedicated tensile/impact coupon mill into a hybrid specimen preparation and general-purpose CNC machining center.

With the Carbon upgrade, users typically:

Keep using the guided TensileSoft workflow for flat tensile and impact specimen preparation

Add the ability to run custom G-code programs for additional machining tasks, fixtures, and auxiliary components

Expand beyond standards-based coupons into R&D coupons, small brackets, and light prototyping work

The upgrade process is:

Software-driven – normally performed remotely via activation keys and configuration

Non-invasive – no major hardware modifications are required when the machine is already Carbon-ready

Reversible in workflow – operators can still rely on the simple tensile interface for routine specimens while advanced users tap into the full CNC environment

This is especially useful for labs where engineering teams want to consolidate equipment: one MICRO can handle both routine ASTM/ISO specimen milling and occasional CNC jobs without taking space for a second mill.

If you’re considering the CNC Unlock/Carbon upgrade for hybrid machining, you can request full details on the

TensileMill CNC MICRO page.

What are the common consumables for the TensileMill CNC MICRO? Are these readily available?

The most common consumables for the TensileMill CNC MICRO are specialty end mills and coolant. The machine ships with a recommended end mill selected according to your primary material (e.g., aluminum, carbon steel, stainless, Inconel, plastics or composites), and you can reorder tooling as your volumes grow.

Typical consumables include:

Carbide end mills with coatings selected for tensile coupon milling

Coolant concentrate for the recirculating flood system

Occasionally, fixture inserts or clamping hardware when changing specimen formats

Key points for labs:

End mills are optimized for tensile sample preparation, not generic routing—so you get longer life and more consistent edge quality.

For most labs, keeping a small inventory of spare end mills on site prevents unexpected downtime during high-priority test runs.

Consumables can be ordered either directly from TensileMill CNC or via your preferred local tooling distributor, using the specifications recommended by our engineering team.

To review available consumables and request pricing for MICRO-specific tooling kits, visit our Tensile Sample Preparation Consumables, Fixtures, and Spare Parts

page.

What are the common spare parts for the TensileMill CNC MICRO? Are these readily available?

For routine operation, the main “spares” you’ll interact with are end mills and coolant. Over a longer time horizon, other components—especially the spindle—may eventually require replacement depending on how intensively the machine is used.

Common spare/replaceable items include:

End mills and ER collets

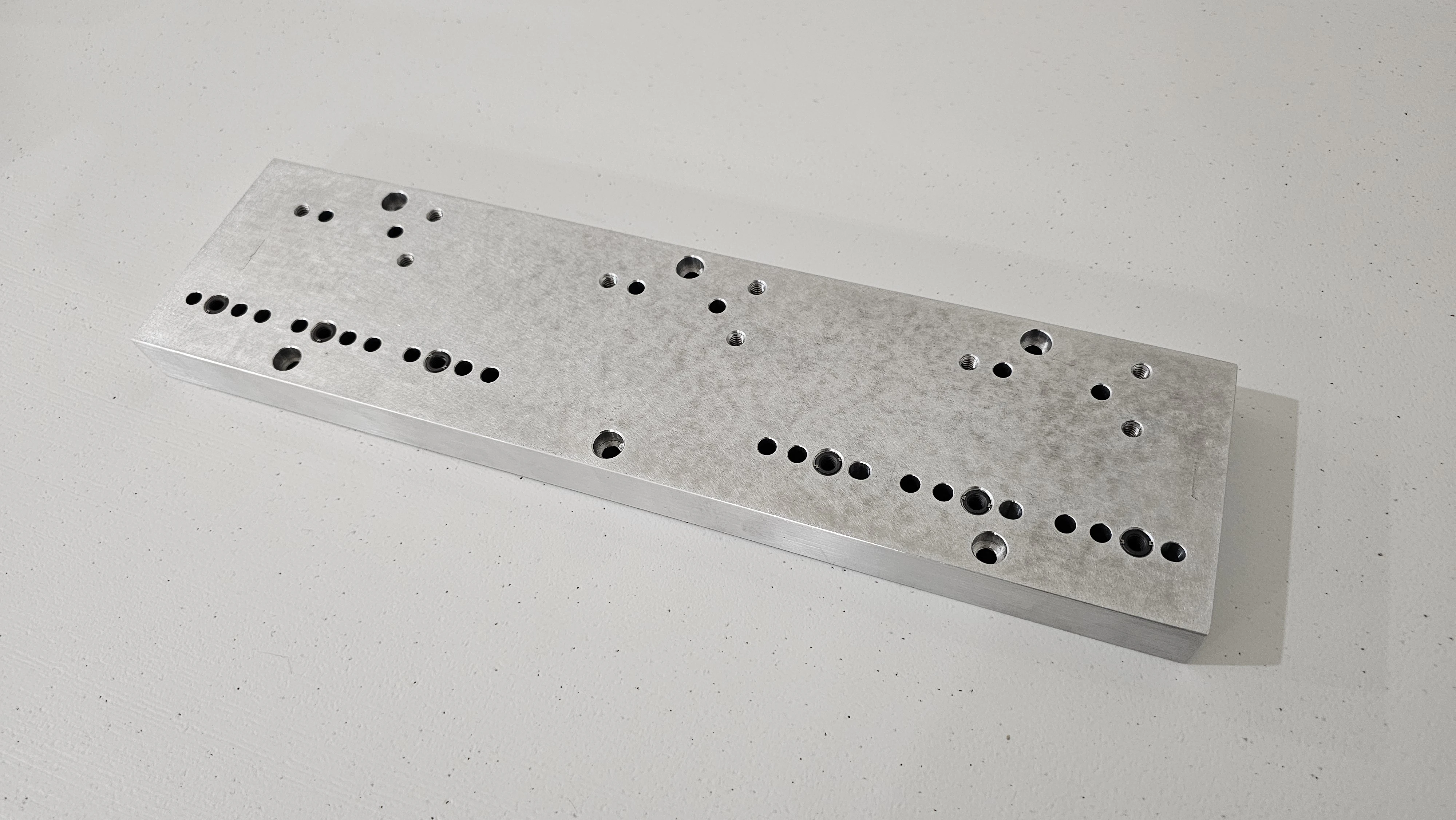

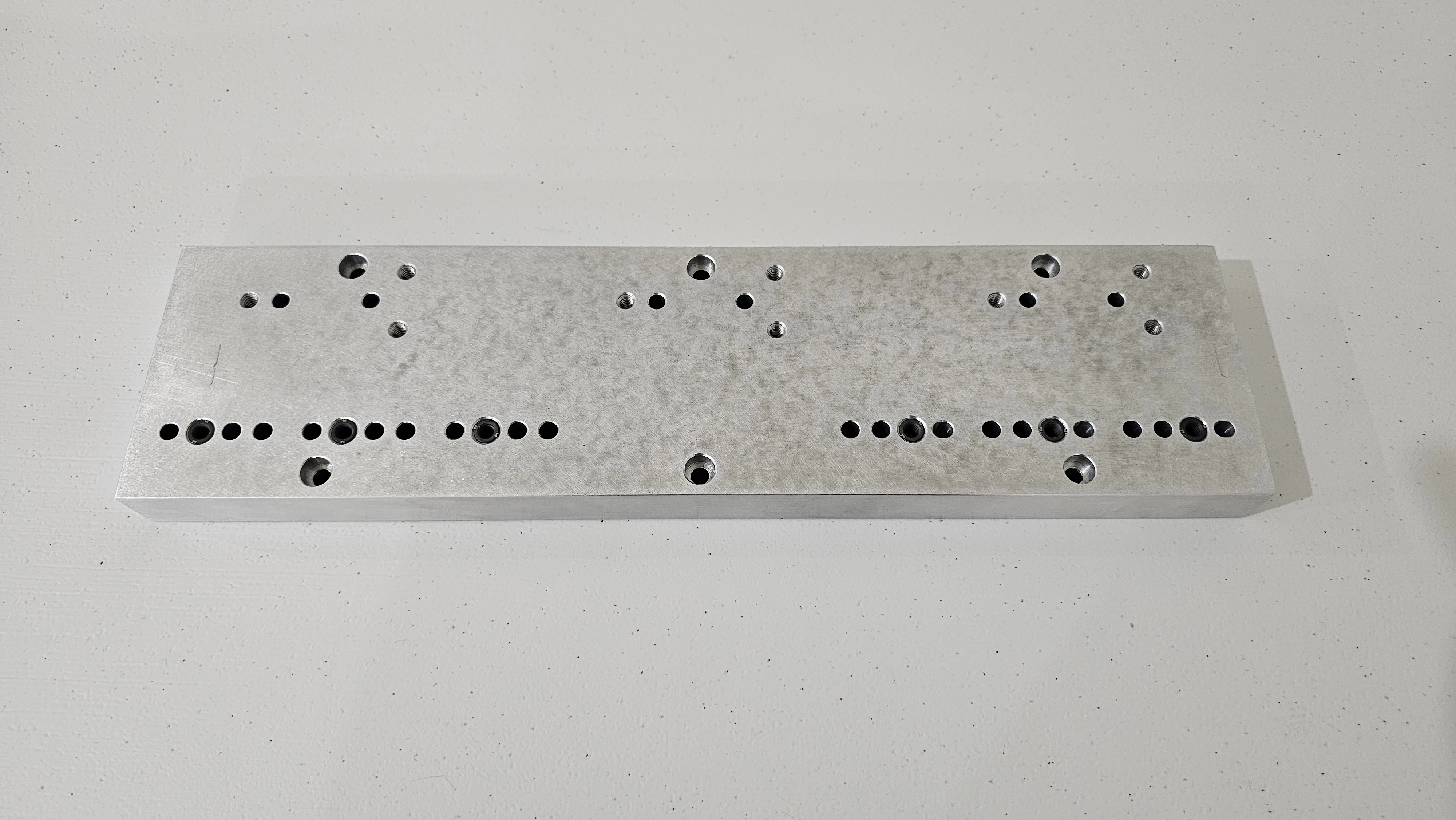

Custom Fixtures and Baseplates

Controllers

From a support perspective:

TensileMill CNC maintains strategic stock of critical replacement parts to minimize downtime.

Most standard parts can be shipped within a short lead time, often within a few business days depending on region.

When you submit a support or parts request, the service team will help confirm part numbers, compatibility, and any installation guidance.

For help selecting the right spare parts package for your MICRO or placing a replenishment order, visit the

TensileMill CNC MICRO page.

What are the common spare parts for MICRO? Are these readily available?

For routine operation, the main “spares” you’ll interact with are end mills and coolant. Over a longer time horizon, other components—especially the spindle—may eventually require replacement depending on how intensively the machine is used.

Common spare/replaceable items include:

Coolant for the recirculating system

Spindle assemblies (long-term wear item under heavy use)

Servo drives, control boards, and interface components, if ever needed to recover from an unexpected failure.

From a support perspective:

TensileMill CNC maintains strategic stock of critical replacement parts to minimize downtime.

Most standard parts can be shipped within a short lead time, often within a few business days depending on region.

When you submit a support or parts request, the service team will help confirm part numbers, compatibility, and any installation guidance.

If you’d like support confirming replacement part compatibility or long-term service planning, you can request details through the

TensileMill CNC MICRO page.

What are the power and amperage requirements for TensileMill CNC MICRO?

The TensileMill CNC MICRO operates on single-phase 220 V power and draws approximately 15 A, within a recommended 200–240 V input range. The machine must not be connected to 110 V, as this is below the minimum operating threshold and can prevent components from functioning correctly.

In practical terms, for most facilities this means:

A dedicated 220 V, 20 A single-phase circuit with a standard 3-prong 20 A receptacle

Adequate breaker sizing and grounding following local electrical codes

Avoiding shared circuits with other high-draw devices (ovens, compressors, etc.) to minimize voltage drop

A typical installation workflow:

Your facilities or maintenance team confirms availability of a 200–240 V single-phase supply near the planned MICRO location.

They install a 20 A receptacle or disconnect within reach of the machine’s power cable.

The machine is connected and powered up during commissioning, with voltage and phase confirmed as part of the startup checklist.

To verify power compatibility for your facility and review the full electrical specifications, visit the

TensileMill CNC MICRO product page.

What service and technical support do you provide for Flat Tensile Sample Preparation machines?

You receive rapid-response technical support from CNC consultants and application engineers for installation, applications, and day-to-day operation. We respond by phone, email, or live video, with same-business-day acknowledgment for most requests.

Support covers programming and machining for standard-compliant flat specimens, including common geometries used for ASTM E8 metals and ISO 527 plastics when applicable. We help with post-processor setup, G-code verification, cutter and tooling selection, recommended feeds and speeds across aluminum, steel, and polymers, and workholding alignment to maintain parallelism and target gauge length. Remote diagnostics can review controller parameters, tool and work offsets, probing routines, and surface finish outcomes. On request, we provide templated CAM files and sample toolpaths to speed first-article approval and increase throughput.

For ongoing operations, we offer operator training, preventive maintenance schedules, and spare parts assistance for cutters, belts, fixtures, and other wear items. Most consumables ship from North America to keep downtime low. When needed, on-site visits can be scheduled for advanced troubleshooting or calibration checks.

If you would like to plan service and training for your lab, you can review options on the

Flat Tensile Test Sample Preparation Machines page.

Will burrs remain on tensile specimens after the cutting cycle on a TensileMill CNC sample preparation system?

Edge condition after machining depends on material type, cutter or insert condition, feed and speed, coolant, and toolpath strategy. With the supplied starter tooling and tuned parameters, burr can typically be minimized to a negligible edge or eliminated. Good practices include matching the cutter or insert grade to the alloy, keeping cutting edges sharp, using adequate coolant, and programming climb milling with a light finishing pass of about 0.005 to 0.010 in (0.13 to 0.25 mm) stock. Adding a small edge break of roughly 0.005 in (0.13 mm) with a chamfer or deburr pass helps reduce handling nicks before testing.

If some burr remains, quick secondary methods are common in tensile labs: hand files, deburring blades, small countersinks, tube deburring tools for round gage sections, fine flap wheels, and nonwoven abrasive pads. Remove only the raised edge so gage width or diameter is not altered, then verify dimensions and surface quality prior to testing. Our team can recommend tooling and parameters for both flat and round workflows to help you hit your required finish with minimal rework.

If you would like to source deburring media, end mills, inserts, and related supplies, you can review options on the

Consumables and Spare Parts page.

How do I determine the optimal spindle speed and feed rate for machining tensile specimens in a specific material?

Optimal speed and feed depend on the material, cutter geometry, coating, and the specimen’s gauge geometry. Start with tooling matched to your alloy or polymer, then validate with a brief trial. TensileMill CNC offers complimentary dog-bone preparation where our engineers cut your samples on flat and round specimen systems such as the TensileMill CNC MICRO or MINI for flat blanks and the TensileTurn CNC series for round bars, typically converging on stable parameters by the second or third cycle. During installation and training, our technicians also tune speeds, feeds, coolant strategy, and toolpaths at your site so production runs are repeatable and surface finish in the gauge section aligns with your testing needs.

A practical workflow is to begin with the cutter manufacturer’s conservative chip load, a shallow axial depth per pass such as 0.050 to 0.100 in (1.27 to 2.54 mm), and moderate radial engagement. Make a short 1 to 2 in (25 to 50 mm) test pass outside the gauge length, then review chip form, temperature at the gauge, spindle load, and finish. Increase feed in small steps until chatter or rising load appears, reduce by about 10 percent, and adjust rpm to stabilize the cut. Use climb milling for flat specimens, sharp inserts on round specimens, and flood coolant or MQL to keep the gauge section smooth, which supports ASTM E8 or ASTM D638 geometry requirements when applicable. Save the final recipe in the controller for repeatable throughput.

If you would like parameter guidance for your material or a complimentary dog-bone trial, you can connect with our team on the

Contact Us page.

What tensile specimen geometries and dimensions can TensileSoft prepare?

TensileSoft supports both standard straight-edge and tapered-edge flat tensile specimens. Operators can select common dog-bone geometries from ISO 527 and ASTM D638 or input custom sizes. On compact systems such as the TensileMill CNC MINI, tapered-edge profiles are typically produced up to 0.50 in (12.7 mm) thickness.

In practice, you choose a template or define gauge length, grip width, fillet radius, overall length, and thickness, then clamp the blanks and start the cycle. The software creates the profile and edge transitions, applies optimized toolpaths, and accommodates single-part or stacked cutting to increase throughput. Final size ranges depend on machine travel, fixturing, material, and cutter selection, so your achievable envelope is governed by the specific flat specimen system installed. The same workflow applies across the MICRO, MINI, Classic Upgrade, and XL flat machines, giving plastics and metals labs a fast path to repeatable edges for standard-compliant tensile testing.

If you would like to compare flat-specimen systems and software workflows, you may review details on the

Flat Specimen Preparation Equipment Lineup page.

How Many Flat Tensile Specimens Can I Prepare Per Cycle?

Throughput per cycle depends on the machine configuration, workholding, blank size, and material hardness. Standard flat-specimen setups typically machine one coupon at a time, while optional multi-station and triple-clamp fixtures allow multiple blanks or stacked sets in a single program.

On compact systems, a single-station clamp is common for one-part cycles. Larger or upgraded setups can use multi-station fixtures. With a triple-clamp configuration, operators may load up to three stacked blanks, subject to total stack height, cutter reach, and part rigidity. As a practical reference, many labs run stacks totaling about 1.0 in (25.4 mm), and individual coupons up to 0.5 in (12.7 mm) thick on select models. The achievable part count also varies by alloy and starting thickness, since harder materials and wider gauge sections call for more conservative feeds and additional passes. If you share your material grade, starting thickness, and target geometry, our team can recommend a cycle plan and fixture package that balances part count, surface finish, and tool life.

If you would like to discuss throughput and fixturing for your application, you can connect with our team on the

Contact Us page.

Can I Stack Multiple Blanks for Faster Tensile Sample Preparation?

Yes. Our flat-specimen systems support stacked machining using a dedicated clamping device that accommodates a combined stack height up to 1.0 in (25.4 mm). The clamp grips the full pack so the mill can rough and finish several specimen profiles in one program with stable holding and repeatable alignment.

Stacking is commonly used for metals and polymers to raise throughput while maintaining final geometry. Use uniform blank thickness, register the edges, and verify cutter reach across the full 1.0 in (25.4 mm) height. Apply toolpaths, feeds, and coolant suited to the material to manage heat and burr formation. After machining, separate the coupons, deburr, and measure according to the applicable standard, for example ASTM E8 for metallic flats or ISO 527 for plastics, so each specimen meets the required dimensions and radii. This approach reduces handling time per part without changing compliance, since every coupon is inspected individually.

If your workflow calls for taller packs, unusual geometries, or abrasive alloys, specialty clamps and tooling packages are available to match your specimen design and production rate.

If higher throughput is a priority, you may review model compatibility and fixturing details on the

Flat Tensile Test Sample Preparation Machines page.

What Additional Maintenance Steps Extend the Life of a Tensile Sample Preparation Machine?

Routine preventive maintenance and a clean workspace go a long way. Keep the lubrication reservoir topped with the recommended oil, wipe down exposed surfaces, and remove chips after each shift to reduce wear on moving components and guarding.

For daily care, vacuum chips instead of blowing them into seals, clear the chip tray, and dry any coolant residue on the table, vises, and fixtures. Confirm that the automatic lubrication system is cycling and that lines are intact. Inspect the spindle taper and tool holders for debris, then lightly clean and re-seat them to protect runout. Keep the coolant or mist system clean by using approved fluids and replacing filters as needed. Periodically check way covers, door interlocks, cable carriers, and the condition of belts, fasteners, and guarding. Verify that the air supply is clean and dry to protect valves and actuators. Back up machine parameters and software, and record service actions in a simple log so you can spot trends. Train operators to run a brief warmup program at start of day, handle specimens and tooling carefully, and report any unusual noise, heat, or vibration immediately.

If you would like maintenance guidance tailored to your setup or a recommended service interval, you can connect with our team on the

Contact Us page.

How Many Tensile Specimens Can Be Prepared Per Cycle?

Throughput per cycle varies by material, specimen geometry, and workholding. On flat CNC tensile systems, you can machine a single coupon in one setup or run a batch using multi-station clamps, fixture plates with nesting, or stacked blanks when thickness and rigidity allow.

The achievable count depends on thickness and hardness, which influence cutter engagement, pass strategy, and allowable stack height. Standards such as ASTM E8 or ISO 6892 define gauge length and width, which dictate part spacing and fixture pocket layout. Tough alloys and thicker stock increase cycle time and often favor one-up machining with separate rough and finish passes, while thinner sheet and softer metals suit nested batches that deliver higher parts per hour. Tool diameter, corner radii, coolant delivery, and changeover method also affect real-world yield. If you share your alloy, initial blank size, thickness, and target standard, our team can provide an application-specific parts-per-cycle and hourly throughput estimate.

If you would like to compare batch fixturing and table sizes, you can review models and options on the

Flat Tensile Test Sample Preparation Machines page to learn more about throughput planning.

What Types of Base Fixtures Are Available for Tensile Sample Preparation Machines?

Flat tensile preparation systems from TensileMill CNC are supplied with a stainless steel base fixture tailored to the specimen geometry in your method library. Optional clamping fixtures expand the holding envelope for different blank lengths, covering approximately 15 in down to 4 in (381 mm to 102 mm). Each package also includes an ER collet and carbide end mills, with only the cutters considered routine consumables.

The base fixture is built for long service life and resists wear in high-throughput labs. It is configured to support common flat specimen profiles used in standards such as ASTM E8 for metals, ISO 6892-1, and ASTM D638 for plastics when applicable to your workflow. When your starting blank length changes, selecting the matching clamping fixture maintains full contact and stable clamping, which helps hold gauge-width tolerance and finish quality during milling. End mill life ranges from weeks to months based on part volume, material hardness, and blank thickness, so keeping a small stock of our coated carbide tools helps prevent unplanned downtime.

If you would like to compare fixture options or check current availability, you can review details on the

Tensile Sample Preparation Consumables, Fixtures, and Spare Parts page.

What Is the Typical Lifespan of End Mills for TensileMill CNC Milling Machines?

Tool life varies because it depends on material hardness, blank thickness, toolpath strategy, coolant use, and spindle setup. Our systems ship with specialty carbide end mills in bright finish or Alcrona Pro coating that are engineered for tensile specimen machining. In production labs, these cutters commonly deliver extended service across multiple batches, including high-throughput programs, but there is no single hours-or-parts figure that applies to every application.

For the longest life, match the geometry and coating to the workpiece: bright finish for aluminum and other nonferrous materials, AlCrN-type coatings such as Alcrona Pro for steels, stainless, and nickel alloys. Use conservative radial engagement, climb milling on profiles, ample coolant, and rigid fixturing. Keep spindle runout at or below 0.001 in (0.025 mm). Replace a cutter when surface finish begins to dull, burrs increase, spindle load trends upward, or edge wear and micro-chipping become visible under magnification. Keeping a spare set of identical tools on hand helps maintain consistent specimen quality and uptime.

If you would like application-specific tooling guidance or to review stocked options, you may explore the

Consumables and Spare Parts page for end mills matched to our sample preparation machines.

What Is the Primary Purpose of the TensileMill CNC MICRO for Flat Tensile and Impact Specimen Preparation?

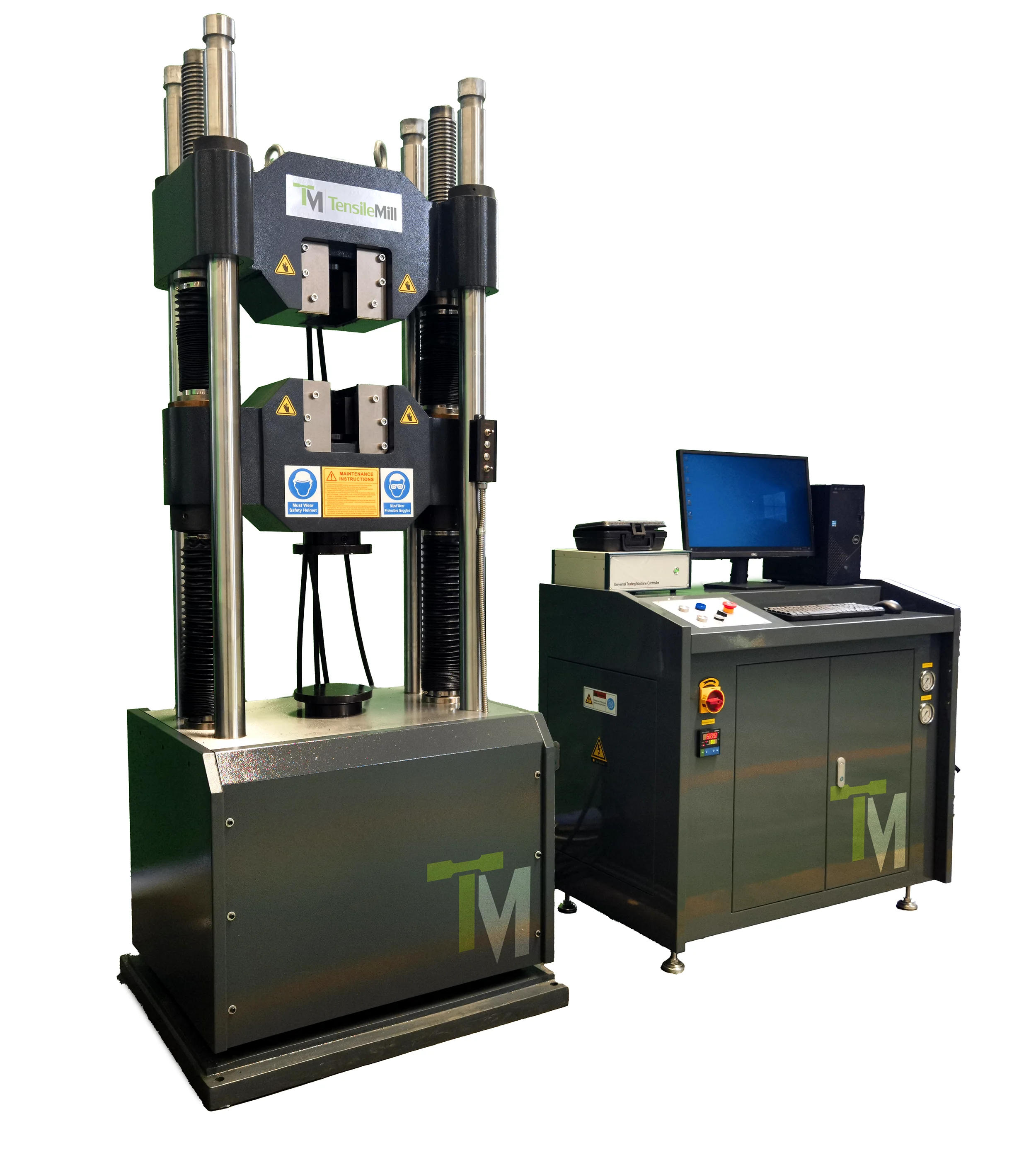

The MICRO is a compact CNC machining system built to produce flat tensile coupons and impact-test blanks in-house with controlled, repeatable geometry.

By replacing manual routing and outsourced jobs, the machine keeps gauge width, shoulder radii, and overall profile consistent from lot to lot, which supports comparable test results over time. Operators load blanks, choose a preprogrammed specimen profile or enter custom dimensions, and the guided interface runs optimized toolpaths to deliver uniform coupons. Typical workflows include metals to ASTM E8 and ASTM A370, plastics to ASTM D638 and ISO 527, and milling of Charpy or Izod blanks prior to notching per ASTM E23. Integrated fixturing and an enclosed cutting area help non-CNC staff achieve stable dimensional accuracy and a suitable surface finish for testing. The in-house approach gives QC labs, production teams, and R&D groups tighter control of turnaround, scheduling, and batch repeatability, while reducing variability tied to different subcontractors or handheld methods.

If you would like a closer look at the workflow and options, you can review technical details on the

TensileMill CNC MICRO product page.

How Does the TensileMill CNC MICRO Differ From a Standard CNC Milling Machine for Tensile Specimen Preparation?

The MICRO is a dedicated tensile and impact specimen preparation system, engineered for lab workflows rather than general machining. Instead of CAM programming and manual G-code edits, it uses a guided TensileSoft MICRO touchscreen interface with prevalidated motions, dedicated fixturing, and lab-focused safety and chip management.

In a conventional CNC mill, operators must program toolpaths, set work offsets, align fixtures, and prove out every geometry. With the MICRO, the operator selects the required standard profile, such as ASTM E8, ISO 527, ASTM D638, or ASTM E23, or enters custom dimensions, loads a blank into the included flip-jig, and starts a preconfigured cycle. The flip-jig preserves the datum through the flip, reducing side-to-side drift and maintaining gauge width and radius continuity across both faces. Pre-engineered motion profiles minimize setup time, programming errors, and operator-to-operator variation, which supports consistent, standard-compliant results.

A compact enclosure with recirculating coolant, integrated chip control, and a mobile base makes the MICRO easy to position next to a UTM and polishing station. The outcome is predictable throughput and repeatable flat specimens that move directly to polishing and testing without the overhead of a general-purpose CNC environment.

If you would like to compare this dedicated workflow with traditional CNC approaches, you can review technical details on the

TensileMill CNC MICRO product page.

Can the TensileMill CNC MICRO Be Operated Without CNC Programming or G-Code Experience?

Yes. Routine operation is template driven, so no CNC programming or G-code is required for day-to-day specimen preparation.

A typical cycle runs as follows: on the touchscreen, the operator selects a standard specimen template or enters custom dimensions, secures the blank in the flip-jig using the basic alignment guides, then starts the cycle. The machine completes the first-side cut, pauses automatically, and prompts the operator to flip the blank. After the flip, the program resumes and finishes the second side. On-screen messages call out each action, which helps new users build confidence quickly.

Template options cover common dog-bone and subsize geometries for flat specimens used with ASTM E8 for metals, plus ISO 527 and ASTM D638 for plastics. Custom fields for gauge length, radius, and width allow labs to match internal drawings when required, and frequently used profiles can be saved for repeat work. The flip-jig supports common specimen lengths such as 4 in, 8 in, and 12 in (102 mm, 203 mm, and 305 mm). This behavior reduces setup variability, supports consistent throughput across shifts, and keeps training focused on safe handling, material identification, and fixturing rather than programming.

If you would like to review the touchscreen workflow, flip-jig process, and specimen template options, you can learn more on the

TensileMill CNC MICRO page.

Which Materials Can the TensileMill CNC MICRO Machine for Flat Tensile Specimens?

The MICRO machines flat tensile specimens from three categories: metals, engineering plastics, and composite laminates processed as sheet or strip. One workflow supports all three, with cutter geometry and coating selected during setup. A matched cutting tool set is supplied with the system.

Common metal jobs include aluminum, structural steels, stainless grades, and nickel or titanium alloys prepared to ASTM E8 or ISO 6892 geometries. Polymers such as ABS, nylon, polycarbonate, PEEK, and reinforced plastics are machined to ASTM D638 or ISO 527 dog bone patterns. Composite laminates, including carbon fiber and fiberglass, are milled for ASTM D3039 or ISO 527-4 coupons. In mixed-material labs, operators load the appropriate program template, install the designated cutter, and run batches without changing fixtures, which supports steady throughput, consistent gauge width, and smooth fillet transitions while managing burr and heat. Typical tool choices include TiAlN-coated carbide for ferrous and nickel alloys, polished single O flute for plastics to reduce chip welding, and diamond-cut or PCD routers for fiber laminates to control fray.

If you would like a concise overview of compatible materials, tooling packages, and example workflows, you can review technical details on the

TensileMill CNC MICRO product page.

Does the TensileMill CNC MICRO Support ASTM and ISO Standard Specimen Geometries?

Yes. The MICRO includes a preloaded library of standard flat tensile and impact blank geometries aligned with common ASTM and ISO methods. Through the TensileSoft interface, the operator selects the required profile and size, then runs the program without writing toolpaths.

The library covers dog-bone and sub-size shapes used in ASTM E8 and ISO 6892 for metals, plastics formats from ASTM D638 and ISO 527, and flat blanks referenced by ASTM A370 for impact testing. If Charpy testing is needed, the notch is typically added on a dedicated notching unit after the blank is machined. For lab-specific tolerances, you may adjust parameters such as gauge width, reduced-section length, shoulder radii, and overall length to match internal procedures while staying within the target method. Saved templates support batch work and repeat orders.

The guided workflow prompts clamping and flip steps for two-sided machining and automatically generates paths for the chosen geometry. This behavior helps teams maintain consistent shapes across runs without CNC programming experience, even when minor dimensional updates are required by internal specifications or audit feedback.

If you would like to see how the geometry library works in practice, you can review technical details on the

TensileMill CNC MICRO product page.

Can Custom Tensile Specimen Dimensions Be Programmed on the MICRO?

Yes. Beyond its preset libraries, the MICRO lets you enter fully custom geometry on the touchscreen. Operators can key in gauge length, reduced section width, grip width, shoulder radius, and transition radii, then save the set as a named profile. Saved profiles can be recalled, edited, or duplicated for variant trials. This is valuable for R&D or proprietary work, or when a standard shape needs adjustments beyond ASTM E8 or ISO 527 presets.

A typical workflow looks like this: open the TensileSoft geometry menu, enter the required dimensions, for example 2.00 in (50.0 mm) gauge length and 0.50 in (12.5 mm) gauge width, preview the toolpath, assign cutters and feeds, then store the profile. On repeat jobs, select the profile, mount blanks in the flip-jig fixture, and start the cycle. The software applies the saved offsets and transitions consistently from run to run, which supports stable specimen geometry across batches and reduces programming time when sizes change frequently.

If you would like a closer look at the workflow, you may review technical details on the

TensileMill CNC MICRO product page.

How Do Flat Tensile Specimen Machines Keep the Gauge Section Centered During Two-Sided Machining?

Symmetry is achieved with a one-setup flip process that keeps the blank registered to the same clamping faces for both passes. The machine completes the first side, pauses, and the operator rotates the fixture while the work offset and datums remain unchanged. The second operation runs a mirrored toolpath around the same centerline, so the gauge section stays centered and thickness remains uniform.

Dedicated reference surfaces in the fixture control X and Y location, while the clamping stack maintains Z datum, preventing drift that commonly appears when parts are reindicated on manual equipment. Matching step-downs, cutter paths, and feed strategies for both sides keep cutting forces balanced, which helps avoid taper, bow, or offset shoulders. The same workflow applies to multi-part fixtures or stacked blanks, so every coupon in the set carries the same geometry. For labs preparing flat specimens to ASTM E8 or ISO 6892, this approach supports gauge section alignment and parallelism requirements without extra setup time.

If you would like to compare fixturing and workflow options, you can review model details on the

Flat Specimen Preparation Equipment Lineup page.

What Does the Flip-Jig Fixture Do in Two-Sided Tensile Specimen Machining?

The flip-jig is a dedicated workholding fixture that clamps the specimen blank for two-sided milling, keeps the centerline aligned, and preserves the work offset during rotation. By holding the blank in a consistent datum, it allows the part to be rotated when prompted by the software without changing the machining origin.

In practice, you clamp the raw blank, machine the first side, then rotate the part 180 degrees within the same fixture when the program prompts a flip. Because the datum remains constant, the controller continues from the same zero, which reduces thickness mismatch, shoulder radius offset, and gauge-section runout compared with manually re-centering on a general-purpose CNC. The result is tighter correlation between faces, faster changeovers, and stable parallelism across batches.

One flip-jig is supplied with the system and is selected to match expected specimen length. Available sizes include 4 in (101.6 mm), 8 in (203.2 mm), and 12 in (304.8 mm). Selecting the correct size matches the clamping span to the blank, improving stability and surface finish on thin or long samples.

If you would like to compare compatible systems and fixturing options, you can review details on the

Flat Tensile Test Sample Preparation Machines page.

How Does the TensileSoft MICRO Interface Guide the Operator During Tensile Specimen Preparation?

TensileSoft MICRO presents a guided workflow on a 15.6 in (396 mm) touchscreen, moving the operator through each stage of flat specimen preparation. The user selects the target geometry, including templates commonly used for standards such as ASTM E8 or ISO 527 when applicable, then aligns the blank using the fixture’s locating features. Machining starts from on-screen prompts, without any G-code entry.

During cutting, the software signals required actions and pauses automatically for interventions, such as flipping the jig, verifying clamp position, or changing a cutter. Clear confirmation buttons resume the cycle from the correct step, which helps prevent missed operations and scrap. Real-time status bars display the active pass, remaining steps, and spindle feed conditions so an operator can track progress at a glance.

Profiles can be saved with geometry, speeds and feeds, step counts, and offsets. Recalling a profile reproduces the same workflow for repeat batches, improving consistency across shifts and shortening onboarding for new team members.

If you would like to review interface highlights and technical details, you can explore the

TensileMill CNC MICRO product page for a closer look at the workflow and options.

How Many Steps Are Required to Prepare One Flat Tensile Specimen on a TensileMill CNC?

Most users complete one flat tensile specimen in five steps. Select the standard or custom profile on the touchscreen, clamp the blank in the flip fixture against the alignment stop, start the first-side program, rotate the flip fixture when prompted without re-centering, then resume the cycle to machine the second side.

The built-in library covers common profiles such as ASTM E8 or ISO 527, so dimensions are loaded once and stored for repeat runs. Toolpaths, spindle speed, and motion control are automated, which keeps operator involvement to alignment and the single flip. The fixture datum preserves registration between sides, producing consistent gage width and surface finish for reliable tensile results across batches.

If you would like to compare model options for flat specimen machining, you can review capabilities on the

Flat Specimen Preparation Equipment Lineup page.

Can I Save and Reuse Tensile Specimen Geometry on the TensileMill CNC MICRO?

Yes. With the TensileSoft MICRO interface, you can store both standard and custom tensile specimen profiles and recall them for future runs.

Each saved profile captures the geometry fields used in flat-specimen machining, including gauge width, gauge length, shoulder transition size or radius, and overall specimen length. Profiles are named and listed in the geometry library, so operators can select them at the machine, apply them to new workpieces, or duplicate a profile when a small variation is required. This workflow shortens setup, reduces manual data entry, and supports consistent preparation between operators and across shifts. Labs that regularly prepare specimens to common methods such as ASTM E8 for metals, ISO 527 for plastics, or ASTM D638 can move from one material lot to the next with minimal reprogramming during qualification, production testing, and recurring research cycles.

If you would like to see how saved profiles fit into daily throughput, you can review technical details on the

TensileMill CNC MICRO equipment page.

What Cutting Tools Does the MICRO Use and How Often Should They Be Replaced?

The MICRO uses non-proprietary solid carbide end mills for machining flat specimens from metals, plastics, and composite materials. Each system ships with a starter tooling set matched to your primary material group, so you can begin producing specimens immediately without special adapters or custom holders.

Replacement is condition-based. For metals, operators typically switch tools when edge polish dulls, burrs increase, or the milled surface loses brightness. For plastics and composites, change tools at the first signs of haze, edge feathering, or heat-related melting marks. Material hardness, feed rate, coolant use, and total specimen count drive actual life. Many labs keep two sets in rotation, a working set and a freshly sharpened set, to keep finish quality consistent during higher-throughput shifts.

Because the feed paths and parameters are controlled automatically on the MICRO, tool wear trends are predictable. A simple routine of inspecting the cutting edges at setup and reviewing surface finish after each batch helps maintain steady results and budgeting. For most workflows, 3- or 4-flute coated cutters are common for metals, while 1- or 2-flute polished cutters are preferred for plastics to reduce heat and improve chip evacuation.

If you would like to review tooling compatibility and workflow details, you can explore the

TensileMill CNC MICRO product page for an overview of the system and its specimen preparation process.

How Is the Flood Coolant System Maintained and Refilled?

Our flat-specimen machining systems use a recirculating flood coolant housed in the machine base, so all plumbing, filtration, and return flow stay inside the enclosure. Routine care focuses on fluid level, concentration, and chip control to keep cut quality and pump life stable in a lab setting.

To refill, open the sump access inside the enclosure and add premixed water-soluble coolant until the sight gauge or fill mark is reached. Typical lab units hold about 10 gal (37.9 L). After filling, run the pump briefly to verify steady return flow to the tank. For day-to-day operation, top off with the same premix rather than straight water to avoid diluting the blend.

Maintenance includes checking concentration with a refractometer and adjusting with concentrate or water per the coolant manufacturer’s chart, cleaning the intake screen and return tray so chips do not starve the pump, and skimming tramp oil as needed. Plan full tank cleanouts on a usage-based interval, for example every few months, which includes draining, wiping sediment, flushing lines, and replacing disposable filters if fitted. No external coolant supply is required, which keeps service simple for laboratories and small production cells.

If you would like a model-by-model look at coolant features for our flat specimen mills, you can review details on the

Flat Tensile Test Sample Preparation Machines page.

What Are the Electrical Power Requirements for the TensileMill CNC MICRO?

The MICRO operates on 220 V, 60 Hz, single-phase power. This single circuit supports the machine controller, spindle drive, and the integrated coolant recirculation system. Three-phase service is not specified for this model.

For installation planning, route a properly grounded single-phase supply to the machine location, confirm breaker and wiring are sized per local electrical code, and avoid extension cords or power strips. Position the receptacle so the factory power cable can connect directly, which helps minimize electrical noise to the controls. If your facility documents require an electrical load summary, the configuration is a single-phase 220 V, 60 Hz feed for the complete system.

If you are reviewing compact tensile sample preparation systems, you can read the power details and other specifications on the

TensileMill CNC MICRO product page.

Does the TensileMill CNC MICRO need external ventilation, a water line, or other facility infrastructure?

No. The TensileMill CNC MICRO operates as a self-contained system and does not require external ventilation, a water connection, or a separate chiller. Power is via a single-phase 220 V, 15 A circuit.

A full safety enclosure contains chips and coolant, while the recirculating flood-coolant tank is integrated into the mobile base. The spindle is air-cooled, so there is no coolant plumbing beyond the onboard reservoir. Typical lab installations place the machine using its mobile stand, with approximate dimensions of 20.5 in × 24 in × 59 in (52 × 60 × 150 cm) and a weight of 1500 lb (680 kg). Facilities may keep standard access clearance around the unit for service and coolant maintenance.

Compressed air is optional and used only if your workflow calls for chip blow-off or pneumatic fixturing. If your environmental, health, and safety policies specify auxiliary mist collection, a third-party unit may be added according to local requirements, but it is not a built-in requirement for operation.

If you would like to review footprint, power, and installation details, you can read the technical information on the

TensileMill CNC MICRO product page.

Is the TensileMill CNC MICRO Easy to Move Within a Laboratory or Production Facility?

Yes. The MICRO machine is supplied on a mobile stand with lockable casters and a built-in recirculating coolant tank, so it can be rolled into position for setup and then stabilized by locking the wheels for machining.

Its self-contained base keeps the coolant reservoir and lines inside the cabinet, which streamlines moves between test bays and reduces disconnect steps. The compact footprint and full enclosure help it fit beside existing UTMs or polishing stations without adding new infrastructure. Typical overall size is 20.5 in × 24 in × 59 in (52 cm × 60 cm × 150 cm), and the unit weight is about 1,500 lb (680 kg), so facility staff can reposition it using the casters or standard material handling equipment according to site safety practices. Because the spindle is air cooled and the tank is internal, there is no external water hookup to manage during relocation.

If you are planning lab layout changes, you can review mobility details and specifications on the

TensileMill CNC MICRO product page.

Is In-House Tensile Specimen Preparation More Cost-Effective Than Outsourcing?

For labs with steady testing, in-house preparation typically reduces total cost after the initial equipment purchase, because the marginal cost per specimen becomes far lower than paying per batch externally. For occasional or sporadic testing, outsourcing can be practical since there is no upfront capital spend.

Outsourcing carries variable charges that repeat with every order: setup and machining fees, packaging, two-way shipping, potential rush charges, and idle time while parts are in transit. Those costs scale directly with demand and can rise with tighter tolerances or special profiles for standards such as ASTM E8 or ISO 527. If rework is needed, the cycle repeats.

In-house shifts spending to a fixed asset plus predictable items like cutters, inserts, coolant, and routine maintenance, along with operator time. Once a flat or round specimen system is installed, the next sample mainly reflects tool wear and minutes of machine time, and adjustments happen immediately without courier delays. Facilities running regular production checks, R&D iterations, or academic coursework usually see per-specimen cost drop as throughput increases, especially when using batch cycles or multi-part fixtures to machine multiple blanks in one run.

If you would like to discuss throughput, staffing, and payback for your lab, you can connect with our team on the

Contact Us page.

How Do I Choose Between Flat and Round Tensile Specimen Preparation Systems?

Start with your material form and the target geometry required by your test method. Flat preparation is ideal for sheet, plate, or molded panels, commonly used for ASTM E8 metals or ISO 527 plastics. Typical flat dog-bone sizes include 0.25 to 1.00 in (6 to 25 mm) gauge width with 1.00 to 2.00 in (25 to 50 mm) gauge length and 0.125 in (3.2 mm) fillet radii. Round preparation suits bar, rod, wire, or cast buttons, with frequent sizes of 0.250 to 0.500 in (6 to 13 mm) diameter and 2.00 to 4.00 in (50 to 100 mm) gauge length. Target tolerances often hold ±0.001 in (±0.025 mm) in the gauge section and 0.001 in TIR (0.025 mm) concentricity for round specimens.

Consider throughput and handling. For high coupon volumes across multiple alloys, a fixtured flat CNC system supports repeatable nesting and quick changeovers. For rounds, a programmable lathe-style machine with tailstock support and center drilling maintains straightness on longer pieces, for example 6 to 12 in (152 to 305 mm) overall length, while flood or mist coolant protects both metals and polymers.

Confirm UTM and grip compatibility early. Flats pair well with wedge or pneumatic grips using 1 to 2 in (25 to 50 mm) jaw widths. Rounds may require collets, shoulders, or threaded ends such as 0.500-20 UNF, with shoulder perpendicularity within 0.002 in (0.05 mm). Surface finish affects results, so polish the gauge section longitudinally to Ra ≤ 32 µin (0.8 µm), or to 16 µin (0.4 µm) for notch-sensitive materials, and verify dimensions against the selected standard during first-article inspection.

If you are comparing flat and round preparation solutions, you can explore the

TensileMill CNC Homepage to review product families on the page.

How Do I Choose Between Flat and Round Tensile Specimen Preparation Systems?

Selection depends on your product form, the governing standard, and downstream gripping. For sheet, plate, and extrusions, a milling-based system produces flat coupons to ASTM E8/E8M or ISO 6892-1 for metals, and ASTM D638 or ISO 527 for polymers. For bar, rod, and forged stock, a lathe-style system machines round specimens, typically 0.500 in (12.5 mm) nominal diameter with 2.00 in (50 mm) gauge length for ASTM E8, or subsize options when thickness limits the section.

Consider precision and finish. Flat machining supports tight edge tolerance around ±0.001 in (±0.025 mm) and surface finish near 32 µin Ra (0.8 µm) when tooling is sharp. Turning round specimens makes concentricity and straightness easier to control, often within 0.001 in (0.025 mm) TIR, which reduces bending errors. If your lab needs a mirror finish for strain extensometers, plan on a polishing pass to achieve 16 µin Ra (0.4 µm) or better.

Throughput and fixturing also matter. Flat systems can fixture multiple blanks per cycle, which is efficient for sheet from 0.020 to 0.250 in (0.5 to 6.0 mm) thickness. Round systems suit continuous runs from 0.125 to 1.000 in (3.2 to 25.4 mm) diameter bar. Verify your UTM grip style, wedge grips for flat widths like 0.500 in (12.5 mm) or collet or threaded holders for round shoulders, and confirm overall length, for example 6.0 to 10.0 in (152 to 254 mm), matches the machine and standard.

For additional guidance, you can connect with our team on the

Contact Us page.

How Do I Choose the Right Flat Tensile Sample Preparation Machine for ASTM E8, ASTM D638, or ISO 527 Work?

Start with your material range and blank size. If most coupons come from sheet, a compact work envelope such as 12 in × 12 in (305 mm × 305 mm) is efficient. For plate cutting or multiple-up nesting, consider larger travels, for example 24 in × 36 in (610 mm × 914 mm). Match spindle power and tooling to your thickness, such as 0.020 in to 1.50 in (0.5 mm to 38 mm), and plan for tool diameters from 0.0625 in to 0.375 in (1.6 mm to 9.5 mm).

If you would like to compare sizes, options, and workflows side by side, you can review model details on the

Flat Tensile Test Sample Preparation Machines page.

How Do I Choose the Right Flat Tensile Specimen Preparation System for My Throughput and Materials?

Start by quantifying volume and changeover frequency. If one profile takes about 3 minutes of cut time plus 1 minute of handling, stacking 3 blanks per cycle yields roughly 45 specimens per hour. Look for rigid fixturing that supports stacked thickness targets, for example 0.50 in (12.7 mm) total, and verify chip evacuation so buried layers do not overheat or burr.

Match cutting strategy to material. Typical starting surface speeds are 600–1000 SFM (183–305 m/min) for aluminum, 150–300 SFM (45.7–91.4 m/min) for carbon steel, 100–200 SFM (30.5–61.0 m/min) for stainless, and 80–120 SFM (24.4–36.6 m/min) for hardened alloys with TiAlN-coated carbide. Use 0.0015–0.004 in (0.038–0.102 mm) per-tooth feed and shallow stepdowns of 0.02–0.06 in (0.50–1.50 mm) to control heat and edge quality on the gauge section.

Select software that locks in specimen geometry from a standards library and exports a run record. For metals reference ASTM E8 or ISO 6892-1, and for plastics reference ASTM D638 or ISO 527. Aim for a uniform gauge finish of 63 µin Ra (1.6 µm) or better, and plan a light final pass of about 0.005 in (0.13 mm) to remove tool marks and minimize burrs. For thin sheet, a vacuum table with a sacrificial backup of 0.25 in (6.35 mm) improves flatness and edge integrity.

For labs with frequent size changes, an automatic tool changer and quick-swap jaws reduce cycle losses, while larger work envelopes support multi-up fixtures that increase hourly output without adding operators.

If you want a side-by-side look at compact and full-size options, you can review model details on the

Flat Specimen Preparation Equipment Lineup page.

How Do I Select the Right Flat Tensile Specimen Preparation Machine for Metals, Composites, and Polymers?

Start by matching expected material range and blank size to the work envelope and clamping options. For typical flat coupons, ensure the machine accommodates blank thickness from 0.02 to 0.50 in (0.5 to 12.7 mm) with rigid parallel clamping. If you process hard alloys, confirm cutter stability and spindle torque suitable for up to 60 HRC, plus coolant delivery and effective chip evacuation for stainless and nickel grades. For composites and polymers, prioritize dust extraction and heat control.

Define accuracy targets based on your lab’s method. Many teams aim for gauge width tolerance of ±0.002 in (±0.05 mm), shoulder radius within ±0.005 in (±0.13 mm), and edge burr less than 0.002 in (0.05 mm) to reduce notch effects. When preparing metals to ASTM E8 or ISO 6892, or plastics to ASTM D638 or ISO 527, verify that the software can call standard geometries, edit dimensions, and lock feeds to prevent operator deviation.

Evaluate throughput and automation that actually save minutes per coupon. Look for a probing routine to locate blanks, a tool changer with finishing and roughing tools, and fixtures that allow stacking within the travel area, for example 8 in × 12 in (203 mm × 305 mm). A practical workflow includes a rough pass, a finish pass at reduced step-over, and a light deburr or polish to reach an Ra near 63 µin (1.6 µm) for metals, while using lower surface speeds on polymers to avoid heat-affected edges.

If you would like to compare sizes, controls, and automation options, you can review detailed options on the

Flat Specimen Preparation Equipment Lineup page.

What Dimensional Tolerances And Surface Finish Are Recommended For Flat Tensile Specimens Prepared By CNC Milling?

For metallic coupons prepared to ASTM E8/E8M or ISO 6892-1 geometry, most laboratories target reduced-section width and gauge length within ±0.002 in (±0.05 mm), overall length within ±0.010 in (±0.25 mm), and gauge flatness within 0.002 in (0.05 mm). Aim for a surface finish of 32–63 µin Ra (0.8–1.6 µm) on the gauge section to support stable extensometer contact and consistent strain. Break all edges lightly, about 0.005–0.010 in (0.13–0.25 mm), and remove burrs without narrowing the net width. Shoulder radii should follow the selected standard; where custom, hold radius mismatch under 0.002 in (0.05 mm).

Use stable fixturing on a rigid sacrificial backer, then rough and finish. A typical finishing pass removes 0.010–0.020 in (0.25–0.50 mm) per side with climb milling to minimize recast and burr formation. Keep the work below 150 °F (65 °C) with flood coolant or MQL so temper or residual stresses are not altered. Fresh carbide end mills around 0.250 in (6.35 mm) handle shoulders efficiently, with smaller tools near 0.125 in (3.18 mm) for tight radii.

Verify width at three locations in the gauge using a micrometer with 0.0005 in (0.01 mm) resolution, confirm straightness and parallelism with a granite square or indicator, and document actual dimensions on the traveler before polishing. For plastics per ASTM D638 or polymers to ISO 527, use the same approach, but prioritize lower heat input and gentler edge breaks to avoid notch sensitivity.

If you would like to compare capacities, controls, and footprints, you can review model details on the

Flat Specimen Preparation Equipment Lineup page.

How Do I Choose The Right Flat Tensile Specimen Preparation Machine For ASTM E8 Or ISO 527 Workloads?

Start by matching your material mix and blank thickness to the equipment class. For sheet and thin plate in the 0.020–0.060 in (0.5–1.5 mm) range, a compact system with vacuum workholding and a built-in template library efficiently mills subsize coupons with 2.0 in (50 mm) or 1.0 in (25 mm) gauge lengths. For thicker sections up to 1.00 in (25 mm), a rigid floor machine with higher torque and an automatic tool changer maintains stable cycle times and tool life.

Confirm the machine can hold the tolerances your method requires. Flat tensile coupons for metals and polymers commonly target width and thickness within ±0.002 in (±0.05 mm), straightness within 0.004 in per 6 in (0.10 mm per 150 mm), and a smooth gauge section that avoids notch initiation. A finish of 63 µin Ra (1.6 µm Ra) or better in the gauge length is a practical benchmark. Preloaded libraries for ASTM E8, ISO 527, or ASTM D638 reduce programming risk while still allowing custom geometries.

Evaluate fixturing and process controls. Vacuum or magnetic fixtures excel for thin stock under 0.080 in (2.0 mm); mechanical vises or step clamps suit thicker blanks up to 1.00 in (25 mm). Use appropriate coolant to manage heat and burrs in stainless or nickel alloys, and sequence roughing, semi-finish, then finish passes so final dimensions settle before the contour cut.

If you would like to compare models and review specifications, you can explore options on the

Flat Specimen Preparation Equipment Lineup page.

What Tolerances and Surface Finish Are Achievable on Flat Tensile Coupons with a Micro CNC System?

With a rigid micro CNC platform, properly selected tooling, and stable workholding, labs routinely hold width and thickness within ±0.001 in (±0.025 mm) across a batch. With a spring-pass or light finish pass, ±0.0005 in (±0.013 mm) is attainable on critical sections such as the reduced area and fillet transitions when the blank is fixtured correctly and the machine is thermally stable.

As-milled surface finishes of 32–63 µin Ra (0.8–1.6 µm Ra) are common using sharp carbide, climb milling, and flood or MQL coolant. To support requirements seen in ASTM E8/E8M for metallic flats or ISO 527-type geometries for plastics, minimize cold work and heat by using low radial engagement, for example 5–10 percent of tool diameter, stepdowns of 0.010–0.020 in (0.25–0.50 mm), and a final finish pass of about 0.005 in (0.13 mm). Edge integrity improves with a sacrificial backing, often reducing exit burr to under 0.001 in (0.025 mm).

Verification should include micrometers with 0.0001 in resolution (0.0025 mm), an optical comparator for fillet radius, and a roughness tester to confirm Ra targets. Document tool lot numbers, coolant concentration at 6–10 percent, and fixture torque values. For sheet below 0.040 in (1.0 mm), a vacuum fixture or adhesive-backed 0.125 in (3.2 mm) sacrificial plate controls chatter and preserves parallelism before gauge-length measurement and final conformity checks to the chosen standard.

If you are evaluating compact machining solutions for flat specimens, you can review technical details and options on the

TensileMill CNC MICRO product page.

Can This Compact Machine Prepare Both Tensile And Impact Specimens To ASTM And ISO Requirements?

Yes. The MICRO prepares flat tensile and impact specimen blanks from metals, plastics, and composites within a compact working envelope of 8.27 in × 4.72 in × 0.79 in (210 mm × 120 mm × 20 mm). A guided interface and a flip jig support two-sided machining without reindicating, which helps maintain symmetry on thin sections and small radii common in standardized coupons.

For tensile coupons, the software library covers common geometries for ASTM E8 and ISO 527, as well as custom inputs. To achieve test-ready edges, use a roughing pass followed by a 0.008–0.012 in (0.20–0.30 mm) finish pass, climb milling, and recirculating flood coolant. Labs typically target ±0.001 in (±0.025 mm) on gauge width and thickness with burr height under 0.002 in (0.05 mm). Fillet transitions should be smooth and free of nicks, then verified with radius gauges and digital calipers before testing.

For impact testing, the system machines straight, square blanks to size. U or V notches are normally produced on a dedicated notching unit per ASTM E23 or ISO 148. The enclosed machine operates on single-phase 220 V, ~15 A, through a 20 A receptacle, and requires no water connection due to its integrated coolant tank.

If you are comparing compact machining systems, you can review capabilities and specifications on the

TensileMill CNC MICRO equipment page.

What Tolerances And Specimen Sizes Can The Compact System Achieve For ASTM E8 And ISO 527 Flat Samples?

The machine holds tight geometric control suitable for flat specimens governed by ASTM E8 and ISO 527 when appropriate cutters and toolpaths are used. Positioning accuracy is ±0.0012 in (±0.03 mm) and repeatability is ±0.0008 in (±0.02 mm), which supports consistent gauge widths, radii, and transitions. A light finishing pass typically brings dogbone profiles into their tolerance window while maintaining edge quality for reliable extensometer gripping.

Within the working envelope of 8.27 in × 4.72 in × 0.79 in (210 mm × 120 mm × 20 mm), most subsize and many standard coupon formats are practical. Typical flip-jig options support overall specimen formats of 4 in, 8 in, and 12 in (102 mm, 203 mm, and 305 mm), enabling two-sided machining without re-centering. This approach keeps the neutral axis aligned through the gauge section, which helps maintain parallelism and symmetrical fillets.

For best results, rough close to net, then apply a finishing allowance of 0.005–0.010 in (0.13–0.25 mm). Use ER25 tooling with cutter diameters that match your smallest internal radius, for example 0.250 in (6 mm) for common fillets. Flood coolant supports metals, and polished single-flute, O flute cutters help prevent melting in plastics. Saving validated profiles in the interface allows operators to reproduce the same geometry across batches with minimal variation.

If you would like to compare capabilities or confirm fit for your lab, you can review specifications on the

TensileMill CNC MICRO product page.

What Are the Space, Work Envelope, Power, and Coolant Requirements for the TensileMill CNC MICRO?

The MICRO fits lab spaces with a footprint of 20.5 in × 24 in × 59 in (52 cm × 60 cm × 150 cm) on a mobile base, and weighs about 1500 lb (680 kg). The working envelope is 8.27 in × 4.72 in × 0.79 in (210 mm × 120 mm × 20 mm), optimized for flat tensile and impact blanks. A flip jig supports common blank formats of 4 in, 8 in, or 12 in (102 mm, 203 mm, 305 mm) while maintaining alignment after rotation. The software library covers typical subsize geometries used in ASTM E8 for metals and ASTM D638 for plastics.

Electrical requirements are single-phase 220 V within 200–240 V at approximately 15 A. A standard 3-prong 20 A receptacle is recommended, or the unit may be hardwired to a disconnect according to local code. Do not connect to 110 V service. Provide clearance for power entry and safe cable routing.

Cooling is self-contained. The machine includes a recirculating flood coolant tank in the base, so no external water line is required. The spindle is air cooled. Compressed air is optional for chip clearing or fixture actuation. For routine care, refresh or replace the coolant about every 6–12 months depending on duty cycle and material, and use a water-soluble coolant formulated for aluminum and ferrous alloys to protect surface finish and extend tool life.

If you are evaluating compact flat-specimen machining options, you can review technical details on the

TensileMill CNC MICRO equipment page.

How Should Cutting Parameters And Fixturing Be Set For Small Flat Tensile Coupons On A Compact CNC?

Stabilize thin stock first. For sheets around 0.020–0.125 in (0.50–3.20 mm), a vacuum pallet or full-support sacrificial plate about 0.25 in (6.40 mm) thick keeps the gauge section flat. Use low-profile clamps outside the coupon profile, add two or four micro-tabs about 0.06 in (1.50 mm), then remove them after finishing. Set a repeatable datum and probe thickness at multiple points to compensate for real material variation.

Select tool sizes to match geometry and standard radii. General-purpose profiles machine well with 0.125–0.375 in (3.20–9.50 mm) carbide end mills. Rough at 40–60 percent stepover, then finish at 5–10 percent with 0.02–0.04 in (0.50–1.00 mm) stepdowns. Leave 0.005 in (0.13 mm) stock for a final contour pass at reduced feed to minimize burrs in the gauge region. Corner-radius or ball tools help maintain the transition radius defined by ASTM E8 or ISO 6892 for metals, and ASTM D638 or ISO 527 for plastics.

Aim for clean edges and controlled heat. Use climb milling, sharp tools, and air blast or minimum-quantity lubrication. Target an edge and face finish of 63 µin Ra (1.60 µm) or better in the gauge section when standards require it. Verify thickness and width within your method’s tolerance using calibrated calipers or a micrometer, for example within ±0.001 in (±0.025 mm) for small metallic coupons. Document the CAM template so the machine, tooling, and inspection steps repeat without adjustment drift.

If you are comparing compact machining systems for precision coupons, you can review technical details on the

TensileMill CNC MICRO equipment page.

How Should Labs Choose Between Flat-Specimen and Round-Specimen CNC Equipment For ASTM E8 and ISO 6892 Programs?

Start with your incoming material and governing standard. Sheet, strip, and plate typically drive a milling-type system for dog-bone coupons, while bar, rod, and machined components favor a lathe-style system for round bars. If the specification calls for a proportional round sample or threaded ends, a round-specimen machine is the efficient path. When standards permit either form, choose the geometry that best represents the product form and simplifies measurement for your team.

Match machine capability to tolerances and finish targets. A good benchmark for flat coupons is ±0.002 in (±0.05 mm) on width and thickness with smooth fillet transitions. For round bars, plan for diameter control within ±0.0015 in (±0.04 mm) and concentricity near 0.001 in (0.025 mm). Many labs target Ra 32–63 µin (0.8–1.6 µm) in the gauge, achieved with sharp tooling, proper coolant, and light finishing passes. Common dimensions include 2.00 in (50 mm) gauge length for flat sub-size coupons and 0.505 in (12.83 mm) diameter round specimens where allowed by ASTM E8/E8M.

Consider throughput and features. If you produce many round bars, a rigid lathe with tailstock support, threading cycles, and optional bar feed improves cadence. For varied flat work, look for travels around 12 in × 6 in × 6 in (305 mm × 152 mm × 152 mm), fast workholding, and an automatic tool changer. Labs that routinely test both sheets and bars often deploy one of each style to keep schedules predictable and results consistent.

If you would like to review configuration options for both flat and round systems, feel free to connect with our team on the

Contact Us page.

How Should Labs Choose Between Flat-Specimen CNC Mills and Round-Specimen CNC Lathes?

Start with incoming stock and the governing standard. Sheet, strip, and plate are most efficiently machined as flat dog-bones on a milling platform, while rods and bars are best prepared as round specimens on a lathe. For metals, ASTM E8/E8M and ISO 6892 outline proportional geometries, so select the machine that matches the required coupon form. If thickness is limited, flat coupons are often the practical path. When both are allowed, round bars can simplify stress calculations and reduction-of-area measurements.

Build your quality targets into the program and inspection plan. Common lab goals are diameter within ±0.001 in (±0.025 mm) for round gauges, width and thickness within ±0.0015 in (±0.04 mm) for flat gauges, and fillet radii within ±0.002 in (±0.05 mm). Aim for 32 to 63 µin Ra (0.8 to 1.6 µm) on the gauge section. Leave finish stock of 0.030 to 0.060 in (0.8 to 1.5 mm) for final passes, use sharp tooling, and apply coolant to avoid altering the surface layer. Deburr lightly, then polish only as needed to remove tool marks without changing dimensions.

Match the machine to throughput and workflow. A benchtop mill can produce a flat coupon in a few minutes, while a lathe with a tailstock and proper centers keeps TIR under 0.002 in (0.05 mm) across the gauge. For mixed workloads, many labs pair a flat system from the TensileMill CNC line with a round-prep TensileTurn unit to cover all materials efficiently.

If you would like to discuss selection criteria for your materials and standards, feel free to connect with our team on the

Request a Quote page.

How Should I Set Up CNC Tooling, Fixturing, And Tolerances For Flat Versus Round Tensile Specimen Preparation?

For flat coupons, use a rigid vise or dedicated plate fixture that supports the gauge and fillet regions, and verify parallelism of the work surface within 0.001 in (0.025 mm). Keep clamp pressure low near the gauge to avoid distortion. For round bars, hold in a precision collet or soft-jaw chuck with a live tailstock center, and keep total indicated runout at or below 0.001 in (0.025 mm). Add 60° center holes with an entrance diameter near 0.10 in (2.5 mm) to maintain concentric support, and limit unsupported overhang to 3–4 in (75–100 mm).

Tooling differs by geometry. Flat specimens respond well to carbide end mills, 3/8–1/2 in (10–12 mm) diameter, with a light finishing pass of about 0.010 in (0.25 mm) per side using climb milling. Deburr edges minimally, about 0.005 in (0.13 mm). For round specimens, use finishing inserts with 0.016–0.032 in (0.4–0.8 mm) nose radius, depth of cut 0.004–0.008 in (0.10–0.20 mm), and feed 0.003–0.006 in/rev (0.08–0.15 mm/rev). Face ends square and add a 0.010 in × 45° (0.25 mm × 45°) chamfer. In both cases, apply flood coolant at 5–10 percent concentration to control temperature.

As practical targets, hold width or diameter within ±0.002 in (±0.05 mm), straightness within 0.002 in per 6 in (0.05 mm per 150 mm), and surface finish in the gauge section between 32–63 μin Ra (0.8–1.6 μm). Verify geometry against the selected standard, such as ASTM E8/E8M or ISO 6892 for metals and ASTM D638 or ISO 527 for plastics. Measure round diameters at three axial locations, and for flat coupons measure width and thickness in the necked region. Avoid cold work by keeping the part under 120°F (50°C), then, if needed, apply a light longitudinal polish to remove tool marks.

If you would like to review equipment options and sizing for your lab, you can connect with our team on the

Contact Us page.

What Tolerance, Concentricity, and Surface Finish Targets Should We Use for Flat vs Round Tensile Specimens?

For flat coupons prepared to ASTM E8/E8M or ISO 6892, labs commonly hold width and thickness within ±0.002 in (±0.05 mm) and keep fillet radii within ±0.005 in (±0.13 mm). Cut edges should be smooth, typically 63–125 µin Ra (1.6–3.2 µm), with machined faces, if required, at about 32–63 µin Ra (0.8–1.6 µm). Break sharp edges lightly, about 0.005–0.015 in (0.13–0.38 mm), and ensure the gauge section is uniform through thickness. Verify at multiple points across the reduced section, not just at mid-length.

For round bars, diameter control drives data quality. A practical target is ±0.001 to ±0.002 in (±0.025 to ±0.05 mm) on the gauge, total indicated runout at or below 0.001 in (0.025 mm), and straightness within about 0.002 in over 6 in (0.05 mm over 150 mm). Surface finish on the gauge is typically 32–63 µin Ra (0.8–1.6 µm). If threaded grips are specified by the standard, cut threads after finishing the gauge to avoid distortion, and use 60° center holes to support the work during turning.

Process tips help you achieve these targets. On flat systems, use full-face fixturing, finish with a light climb-mill pass around 0.005 in (0.13 mm) radial, apply coolant, then deburr without rounding the gauge. On round systems, use a collet or soft jaws with a live center, finish in multiple light passes of 0.002–0.004 in (0.05–0.10 mm), and polish longitudinally. Preloaded templates in TensileMill CNC and TensileTurn CNC equipment help enforce geometry and compliance checks.

If you would like to discuss your testing requirements, feel free to connect with our team on the

Contact page.

How Do I Choose Between Flat and Round Tensile Specimen CNC Systems for ASTM E8 and ISO 6892 Work?

Start with material form and the governing standard. Sheet, strip, and plate, typically 0.04–0.50 in (1.0–12.7 mm) thick, are prepared on a flat-specimen CNC mill per ASTM E8/E8M or ISO 527. Bars and rods, often 0.25–1.00 in (6.4–25.4 mm) diameter, are turned on a round-specimen CNC lathe for ASTM E8 or ISO 6892 work. When a material could be tested either way, follow the product form specified by the standard to keep results comparable.

For flat coupons, hold width and thickness uniformly, probe stock before cutting to minimize taper to under 0.0008 in (0.02 mm), and program the correct shoulder radii from the selected method. Use sharp carbide end mills, climb milling, and flood coolant to avoid cold work. Many labs target edge quality that deburrs to a smooth finish near 32–63 µin Ra (0.8–1.6 µm).

For round bars, center-drill each end, support with a live center, and limit total indicated runout to 0.001 in (0.025 mm) across the gauge length. A 0.015 in (0.40 mm) insert nose radius and light finishing passes help achieve a uniform surface and stable diameter. If your workload regularly includes both sheets and bars, the most efficient path is one dedicated machine of each type. If you must pick one first, select the platform that covers at least 80 percent of your daily specimens.

If you would like to compare round-specimen options, you can explore details on the

All Round Sample Preparation Products product page.

What Tolerances And Surface Finish Should Flat Tensile Specimens Meet Before UTM Testing?

For metallic dog-bone coupons per ASTM E8/E8M or ISO 6892-1, hold gauge width and thickness within about ±0.001 to ±0.002 in (±0.025 to ±0.05 mm). Keep shoulder transitions smooth to the specified radius, and target a gauge-section roughness of 32 micro-in Ra or better (0.8 µm). For plastics under ASTM D638 or ISO 527, dimensional limits are typically wider, yet edge quality and uniform thickness across the gauge length, often 2 in (50 mm), remain critical.