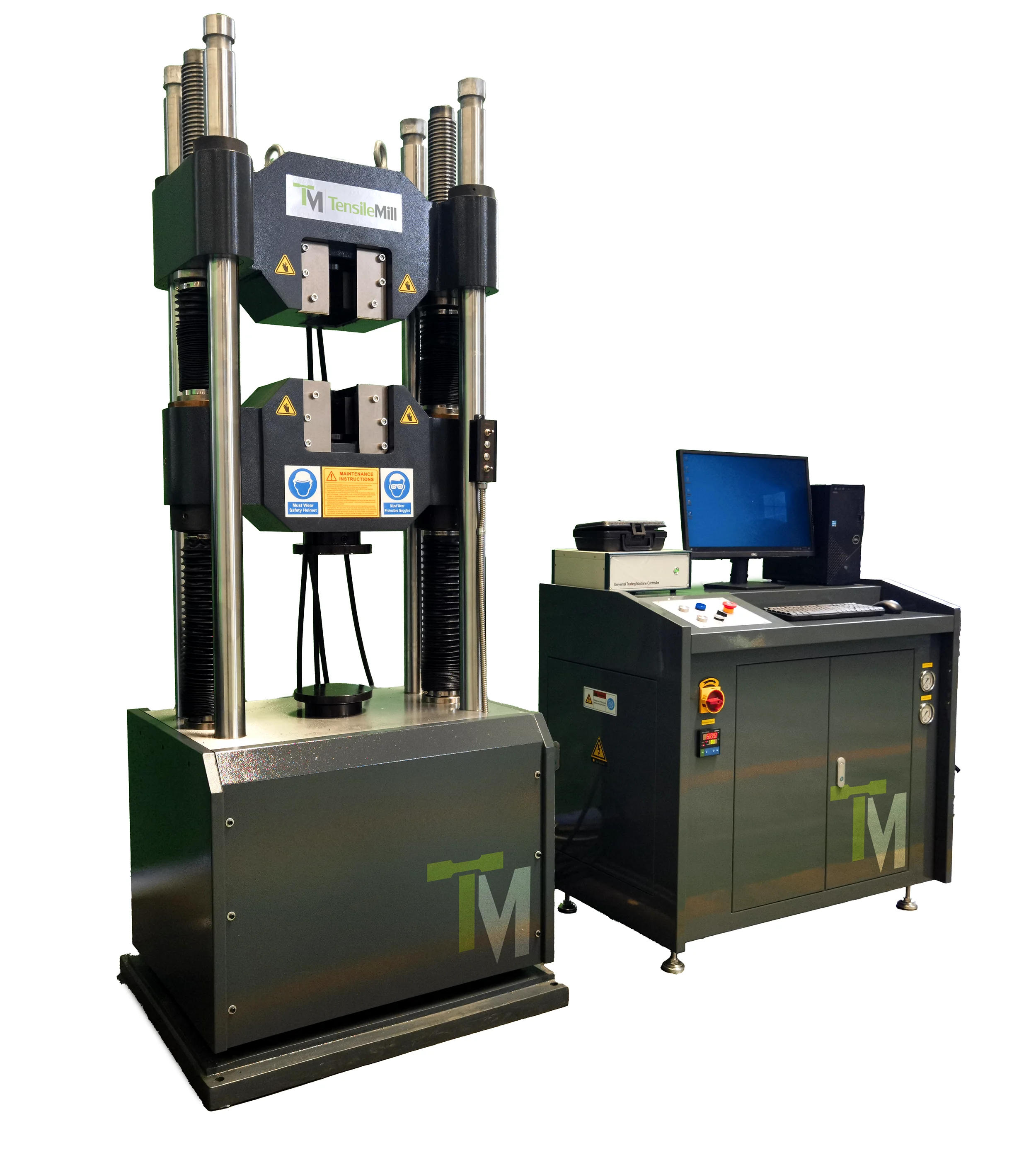

Grips and Fixtures for TensileMill Universal Testing Machines

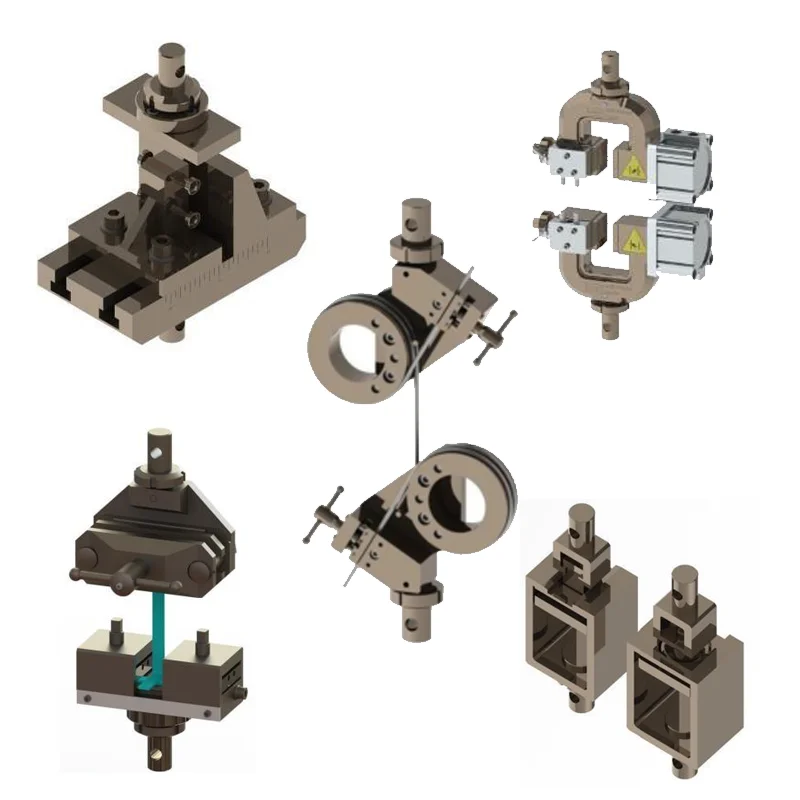

Grips and fixtures are essential components used with universal testing machines (UTMs). They hold the specimen in place and transfer the applied load during tensile, compression, flexural, shear, peel, and puncture tests. Proper gripping helps maintain specimen geometry and supports testing according to ASTM, ISO, and other relevant standards.

TensileMill CNC provides a selection of grips and fixtures for both electromechanical and servo-hydraulic UTMs. Each configuration is matched to the material and test method, covering applications from films and elastomers to metals and composite laminates. Options include wedge grips for high-strength metals, pneumatic grips for frequent test cycles, and flexural fixtures for 3-point and 4-point bending setups.

The available designs accommodate different specimen shapes and sizes. Many models support interchangeable jaw faces, such as smooth, serrated, or rubber-coated surfaces. Certain mechanisms increase clamping force with rising load, helping the specimen stay secured without crushing or slipping during testing.

Selecting appropriate grips and fixtures allows the UTM to function as a versatile testing platform for research, production, and standards-based quality control. These accessories are used in test methods such as ASTM E8 for tensile properties, ASTM D695 for compression, and ISO 178 for flexural evaluation, supporting consistent measurements under controlled testing conditions.

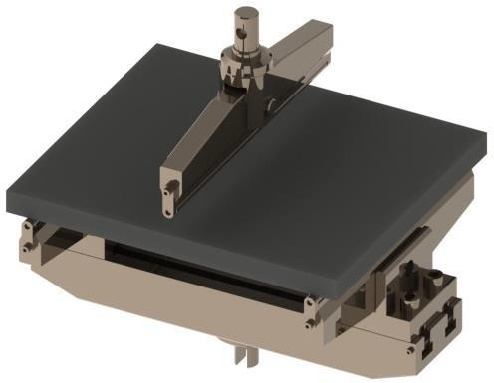

Side Action Tensile Grips for General Clamping Applications

Side action tensile grips are mechanical clamps used for tensile testing of plastics, metals, textiles, rubber, and composite specimens. These grips apply lateral pressure through two jaws that are tightened manually with a screw or lever mechanism. This method allows for controlled clamping without leaving marks on the specimen's surface.

These grips are commonly used in medium-load testing environments such as quality control labs and research facilities. Interchangeable jaw faces, including smooth, serrated, and rubber-coated options, help match the clamping surface to the material being tested, which supports consistent gripping and reduces the chance of specimen movement during the test.

Side action grips are practical for standardized tensile testing where a stable holding force and straightforward setup are needed. They offer a simple and economical clamping method without the additional components required for pneumatic or hydraulic gripping systems.

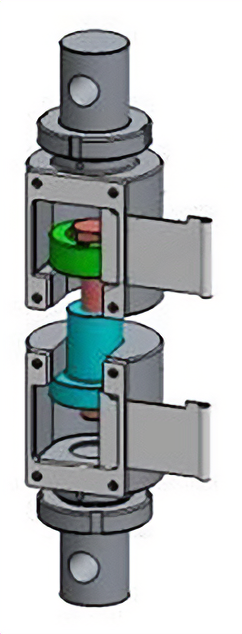

Snubbing Grips for Wire and Cable Tensile Testing

Snubbing grips, also known as capstan grips, are used for tensile testing of wires, ropes, fiber bundles, and electrical cables that tend to slip during loading. The specimen is wrapped around a curved mandrel or capstan to create friction along its length. This distributes the load and avoids concentrating stress at a single point.

This setup makes it possible to accurately measure the tensile strength of materials like steel cables, braided conductors, and reinforced wire products. The free end of the specimen is commonly secured with a clamp or wedge insert to maintain stable loading throughout the test.

Snubbing grips are used in cable manufacturing, laboratory testing, and quality control for structural and infrastructure applications. They are selected for specimens that require secure holding without surface damage and are suitable for testing procedures performed under ASTM, ISO, and related standards.

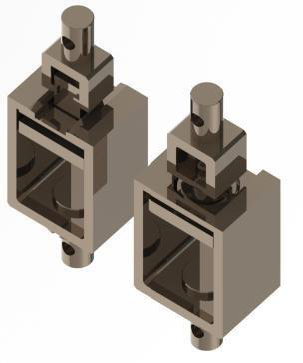

Self-Tightening Grips for Deformable and Elastic Materials

Self-tightening grips increase clamping force as tensile load is applied. They are used for specimens that stretch or reduce in thickness during testing, such as elastomers, thin plastics, foams, textiles, and biomedical materials. The gripping mechanism adapts to changes in specimen dimensions without requiring manual adjustment during the test.

Common configurations include scissor-type grips, eccentric cam grips, and lever-actuated jaw systems. As the load rises, the jaw movement provides additional holding force, which helps maintain contact with the specimen and limits surface slipping at higher elongation levels.

These grips are used in quality control labs, textile and rubber production, and research settings, performing standardized tensile tests on soft or flexible materials. They support consistent clamping conditions throughout the loading cycle and are practical for materials with low friction or high elongation behavior.

Eccentric Roller Grips for Thin and Flexible Samples

Eccentric roller grips are self-tightening fixtures used for tensile testing of thin films, rubber sheets, flexible plastics, and other low-strength materials. The design uses an off-center roller that presses the specimen against a fixed surface. As the tensile load increases, the roller rotates and adds clamping force.

This mechanism maintains contact with the specimen as it elongates or reduces in thickness, helping prevent slipping or tearing during the test. To support delicate materials, the gripping surfaces are commonly coated with rubber or other non-marking materials.

Eccentric roller grips are used in research labs, quality control environments, and manufacturing lines that work with soft or flexible specimens. Their lever-operated design allows quick specimen setup while maintaining steady clamping throughout loading. These grips are compatible with ASTM and ISO test methods for films, elastomers, and similar materials.

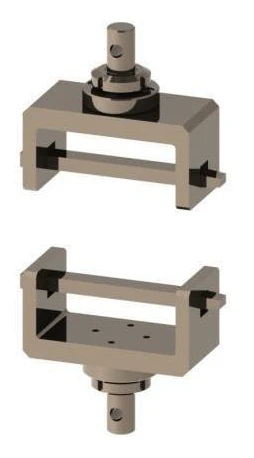

Bending Fixtures for Standard 3-Point Flexural Testing

Bending fixtures, also referred to as flexural test fixtures, are used with universal testing machines to carry out 3-point and 4-point bend tests. These tests are performed to evaluate flexural strength, modulus of elasticity, and related bending properties in plastics, metals, wood, and composite materials.

A typical setup includes two lower support anvils and one or two upper loading noses or rollers. The span length can be adjusted to suit the specimen dimensions and geometry. These fixtures are commonly applied in testing procedures such as ASTM D790 for plastics and ASTM C393 for sandwich panel structures. The fixture layout supports stable alignment and reduces unwanted friction during loading.

Bending fixtures are used in manufacturing, research, and laboratory environments to create controlled flexural loading conditions. They are produced from rigid steel or aluminum to maintain shape under load, helping the applied force transfer directly through the specimen during the test.

Compression Fixtures for Axial Load Testing of Rigid Specimens

Compression fixtures are used with universal testing machines to apply axial compressive loads in a controlled and aligned setup. The standard configuration uses flat compression platens made from precision-machined steel, which support even force transfer across the specimen surface.

For higher accuracy or high-force applications, one of the platens may include a spherical seat to help align the loading surface with the specimen and reduce off-axis loading. Additional fixture formats, such as compression cages or four-post assemblies, are used for testing larger specimens, including foam blocks, packaging materials, and structural components, where specimen stability during loading is important.

These fixtures are produced in various sizes and capacities for use with plastics (ASTM D695), concrete cubes, metals, composites, and paperboard materials. They are commonly used in materials testing laboratories, construction quality control, and packaging evaluation to support consistent compressive strength measurements.

Shoulder Grip Fixtures for Pull-Off and Component Strength Testing

Shoulder grip fixtures are used for testing specimens that have an enlarged head, flange, or formed end that cannot be held with standard jaw clamps. These fixtures support pull-off, push-out, and component strength evaluations where force must be applied through the shoulder of the part to reflect how it is used in service.

Typical applications include bolt head retention tests, cable termination pull tests, syringe plunger withdrawal tests, mechanical anchors, buttons, bottle caps, and fastener hold strength assessments. The specimen is supported by a recessed ledge or collar, while the axial load is applied from the testing machine.

These fixtures are used in medical device testing, automotive and mechanical component assessment, packaging evaluation, and construction anchoring validation. They help distribute the load across the shoulder region to reduce bending and maintain alignment. The fixtures are produced in multiple sizes and configurations to meet ASTM, ISO, and related test procedures.

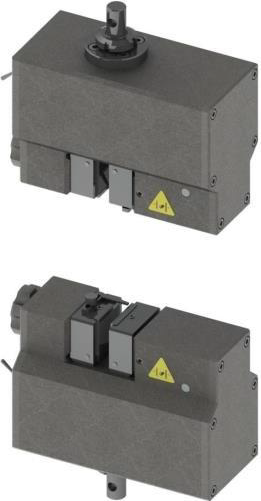

Pneumatic Clamping Grips for Consistent Specimen Holding

Pneumatic grips use controlled air pressure to apply stable and repeatable clamping force to the specimen. They are operated by a hand switch or foot pedal, and the integrated air cylinders close the jaws with adjustable pressure that can be set according to the material being tested. This helps maintain surface integrity while holding the specimen securely during tensile loading.

These grips are commonly used for rubber, plastics, textiles, and other flexible or soft materials where controlled clamping is important. The applied pressure can be adjusted to help limit crushing or slipping during standardized tensile procedures.

Due to their quick operation, pneumatic grips are used in high-throughput testing environments such as quality control labs and production settings. Variants including pneumatic side action designs are suited for mid-range test forces, often up to 20 kN, and support centered specimen alignment during loading.

Pneumatic grips are compatible with testing performed under ASTM, ISO, and similar standards, making them suitable for routine testing and development work across materials that benefit from adjustable, repeatable clamping conditions.

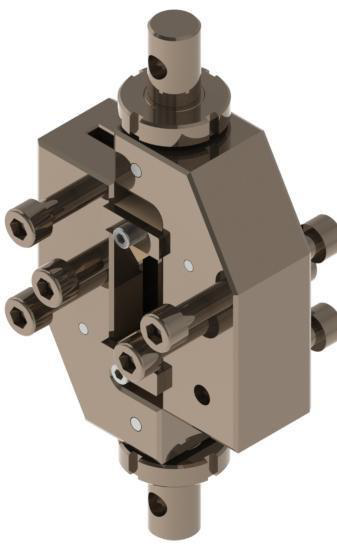

Wedge Clamping Grips for High-Strength Metal and Composite Specimens

Wedge clamping grips use a wedge-based jaw mechanism that increases holding force as the tensile load rises. The internal wedge slides against serrated or knurled jaw surfaces, which continue to tighten on the specimen during loading.

These grips are used for high-strength materials such as structural metals and composite laminates, where high load capacity and firm holding are required. They are produced in manual and hydraulic versions and support force levels ranging from moderate test loads to capacities exceeding 500 kN.

Wedge clamping grips are used in materials testing laboratories, aerospace and automotive component evaluation, and research settings where standardized tensile tests are performed. They support testing practices such as ASTM E8 and ISO 6892 by maintaining axial load alignment and steady clamping conditions for hard, rigid specimens.

3-Point and 4-Point Bending Fixtures for Uniform Moment Flexural Testing

3-point and 4-point flexural fixtures are used with universal testing machines to evaluate the bending properties of materials under controlled loading conditions. In a 4-point configuration, two loading rollers apply force at equal distances from the supports, producing a constant moment region between the load points. This method is used to measure flexural modulus and deformation behavior with as little effect from shear loading in the middle section as possible.

These fixtures are suitable for brittle materials, plastics, composites, and concrete beams where even stress distribution is important. Common reference standards include ASTM D6272 for plastics and ASTM C78 for concrete flexural testing.

The fixture assembly includes two upper loading rollers and two adjustable lower supports. The support span can be set to match specimen size and testing requirements. These flexural fixtures are used in construction material testing, composite manufacturing, and research environments to study bending performance and fracture characteristics under stable and repeatable loading conditions.

Grips and Fixtures for Tensile, Shear, and Flexural Testing of Wood Specimens

Wood testing grips and fixtures are designed to work with the directional structure and variable density of wood and timber specimens. These setups are used for mechanical tests referenced in standards such as ASTM D143 and ASTM D4761, including tensile, shear, compression, nail and screw withdrawal, and flexural evaluations.

For tensile testing parallel to the grain, flat or serrated jaw grips or shoulder-type clamps are used to hold dogbone specimens without crushing the loaded section. For tests that are perpendicular to the grain, fixtures with bonded support plates are used to keep the specimen stable. Block shear fixtures are used to measure shear strength along the grain under tension or compression. Nail and screw withdrawal fixtures apply axial force to fasteners embedded in wood to determine withdrawal resistance.

Compression testing is performed using large-area or self-aligning platens to support uniform load applications. Flexural properties such as modulus of rupture and modulus of elasticity are measured using 3-point or 4-point bending fixtures for lumber, beams, and engineered wood products.

These fixtures are used in wood products manufacturing, construction materials testing, and furniture and fastener development. Their designs help maintain proper specimen support and load transfer while accounting for material variability typical of natural wood.

Composite Testing Grips and Fixtures for Tensile, Shear, and Delamination Evaluation

Composite testing grips and fixtures are designed for the mechanical testing of carbon fiber reinforced polymers, fiberglass laminates, and other layered composite materials. Because composites can fail prematurely from gripping pressure or misalignment, the fixtures are configured to support controlled load application across the intended failure region.

For tensile testing, hydraulic wedge grips with surface-treated jaws are used to maintain hold on composite laminates without crushing or slipping. Compression testing commonly uses Combined Loading Compression (CLC) and IITRI-style fixtures, where side supports or end tabs help produce the correct failure mode.

Interlaminar and in-plane shear evaluations are performed using short-beam shear fixtures (ASTM D2344), Iosipescu shear fixtures (ASTM D5379), and rail shear devices (ASTM D7078). Delamination and fracture toughness assessments include double cantilever beam setups for Mode I (ASTM D5528) and end-notch or mixed-mode bending fixtures for Mode II.

Additional configurations include picture frame fixtures and bias extensometer arrangements for fabric in-plane shear, as well as floating roller peel (ASTM D3167) and climbing drum peel (ASTM D1781) fixtures for adhesive and bonded laminate peeling tests.

Specialized Fixtures and Grips for Tear, Peel, and Puncture Testing

Specialized grips and fixtures are used for tear, peel, puncture, pull-through, buckle, and other non-standard mechanical tests where conventional tensile or compression grips are not suitable. These configurations are designed to match specific material behaviors and specimen shapes.

Peel testing setups include 90-degree peel fixtures and climbing drum peel fixtures for evaluating bond strength in adhesives, laminates, tapes, and layered assemblies. Tear testing grips are used for plastic films, fabrics, and other flexible sheet materials to study tear propagation. Puncture testing fixtures include systems for geomembranes under ASTM D4833 and ball burst devices for textiles in accordance with ASTM D3787.

Additional configurations include eyelet pull-through grips, buckle testing fixtures, and custom shear fixtures such as adhesive lap joint setups following ASTM D4501. These fixtures are used in packaging development, textile and film manufacturing, materials testing laboratories, and product engineering environments that require controlled testing beyond standard tensile or compression methods.

TestStar® Series Grips and Fixtures for Hydraulic UTM Systems

TestStar® series grips and fixtures are designed for use with TestStar® hydraulic universal testing machines. These accessories fit the machine's mounting points, can handle the right amount of force, and help apply loads steadily during strong pulling, pushing, and bending tests.

The series has different types of grips and fixtures, including capstan-style grips for wires and cables, side action grips for general pulling tests, wedge clamping grips for strong metals and composite materials, and fixtures for testing plastics, metals, and composites under compression and bending. 3-point bending assemblies are available for structural flexural evaluation.

TestStar® grips and fixtures are used in materials testing laboratories, industrial production facilities, and research environments where larger specimens or elevated load requirements are common. Hydraulic configurations are available for high-capacity loading and continuous test operation.

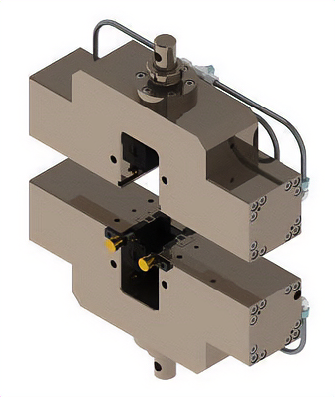

Dual-Action Hydraulic Wedge Grips for High-Force Tensile Testing

Dual-action hydraulic wedge grips are used for high-capacity tensile testing where stable clamping and controlled jaw movement are required. In side-action mode, the jaws close from both sides under hydraulic pressure, providing even clamping across flat or wide specimens. This helps maintain alignment during loading.

In wedge-action mode, angled jaw slides increase gripping force as the tensile load rises. This configuration supports large metal specimens, steel rods, fasteners, and other high-strength materials used in structural or industrial applications. The hydraulic system allows pressure to be set before the test, supporting consistent specimen engagement.

These grips are used with servo-hydraulic universal testing machines in construction materials labs, metal processing facilities, and industrial manufacturing environments. Their heavy-duty construction supports high load capacities, making them suitable for testing rebar, bolts, and structural metals under elevated tensile forces.

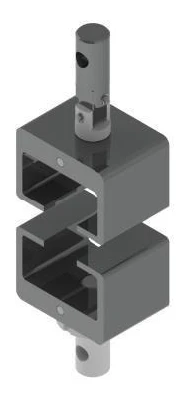

Threaded Fastener Grips for Bolt and Nut Tensile Testing

Threaded fastener grips are used for axial tension testing of bolts, screws, studs, and nuts. Instead of clamping the specimen externally, these fixtures use threaded adapters or holders that engage directly with the part’s threads. This setup applies load through the fastener in a way that reflects how it is used in service.

These grips are used to evaluate tensile strength, yield characteristics, and proof load requirements for fasteners in accordance with standards such as ASTM F606. In proof load testing, a nut is installed on a hardened threaded mandrel and loaded to a specified tension to confirm thread integrity and load-bearing capability without failure. Interchangeable threaded inserts are available to match different thread sizes.

Threaded fastener grips are used in automotive, aerospace, construction, and mechanical testing environments. They are manufactured from high-strength steel to support elevated load capacities, often exceeding 100 kN. These grips provide consistent test alignment and measurable data for quality control and certification of structural and mechanical fasteners.

Hydraulic UTM Grips and Fixtures for High-Force Tensile Testing

Hydraulic UTM grips and fixtures are used in high-force tensile testing to ensure that the materials are held securely and that the force is applied accurately. This category includes hydraulic side action grips and hydraulic wedge grips for pulling metal coupons, bars, rods, and other structural specimens. It also includes tensile shear fixtures, which apply tension to joints or bonded assemblies to evaluate shear strength, and proof load fixtures for fastener testing.

A typical nut-proof load setup uses a hardened threaded mandrel to hold the nut while axial load is applied to confirm that the threads can withstand the specified tension without stripping. These fixtures are built to support very high forces, as large fasteners and structural components may require testing at loads measured in hundreds of kilonewtons. Many hydraulic grips also incorporate interchangeable jaw inserts and reinforced clamping surfaces to support different specimen geometries and diameters.

The purpose of these fixtures is to apply high tensile forces with controlled alignment. Maintaining vertical load alignment is critical in hydraulic systems, since off-axis loading at high force can introduce bending stresses. With the right grips and setups for a hydraulic frame, users can carry out regular tests like ASTM E8 for metals and ASTM A370 for rebar, along with proof load tests for fasteners and tension-based shear tests. Each fixture is made to meet the specific test standards and works with powerful load cells and hydraulic systems.