Are Training and Installation Mandatory for Class A, B, and C Tensile Testing Systems?

No. Training and installation are optional for our universal testing machines. Class A, B, and C systems ship with all required cabling and a step-by-step setup guide, so most labs complete installation independently.

A typical startup includes positioning the frame, making power and controller connections, attaching the load cell and any extensometer, installing the testing software, running the built-in self-check, confirming crosshead travel and safety circuits, and performing a trial test to validate data flow. The process is designed for technicians who may be new to UTMs, reducing ramp-up time without sacrificing measurement quality.

If you would like assistance, a qualified engineer can host a remote onboarding session to walk through connections, software configuration, grip selection, and your first live test. Onsite services can also be quoted on request. When your quality program calls for third-party verification, we can coordinate accredited calibration to ISO 7500-1 or ASTM E4 after the machine is operational.

If you would like to review capabilities by system class, you may explore specifications on the

Tensile Testing Equipment page.

Why Perform Material Fatigue Testing?

Fatigue testing quantifies how a material behaves under repeated loading across thousands to millions of cycles. It provides fatigue life, the number of cycles to failure at a given stress or strain, and helps define fatigue strength or an endurance limit. Laboratories use these results to compare heat lots, validate heat treatment or weld quality, evaluate notch sensitivity and crack initiation behavior, and select designs that match expected duty cycles and safety factors.

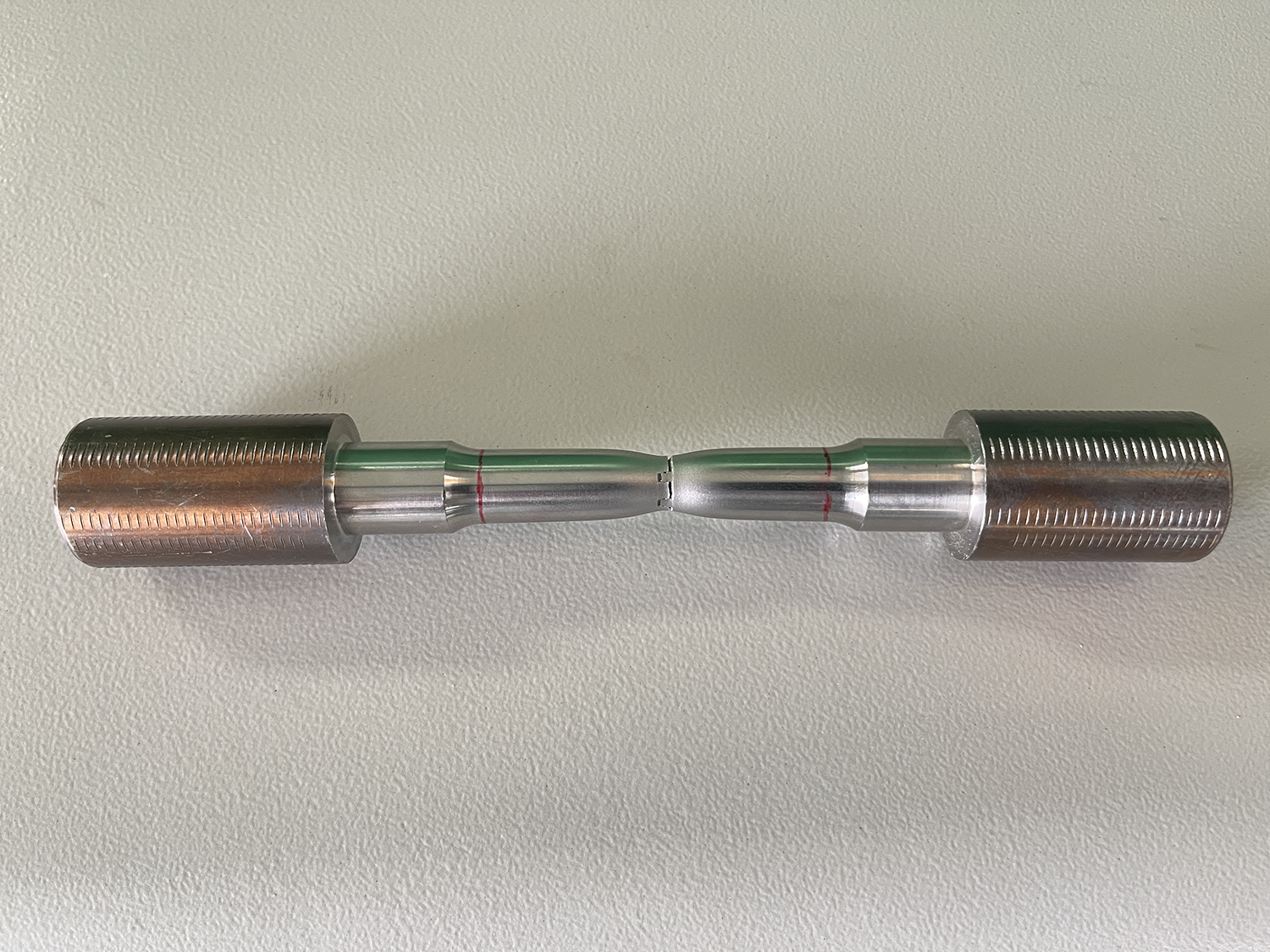

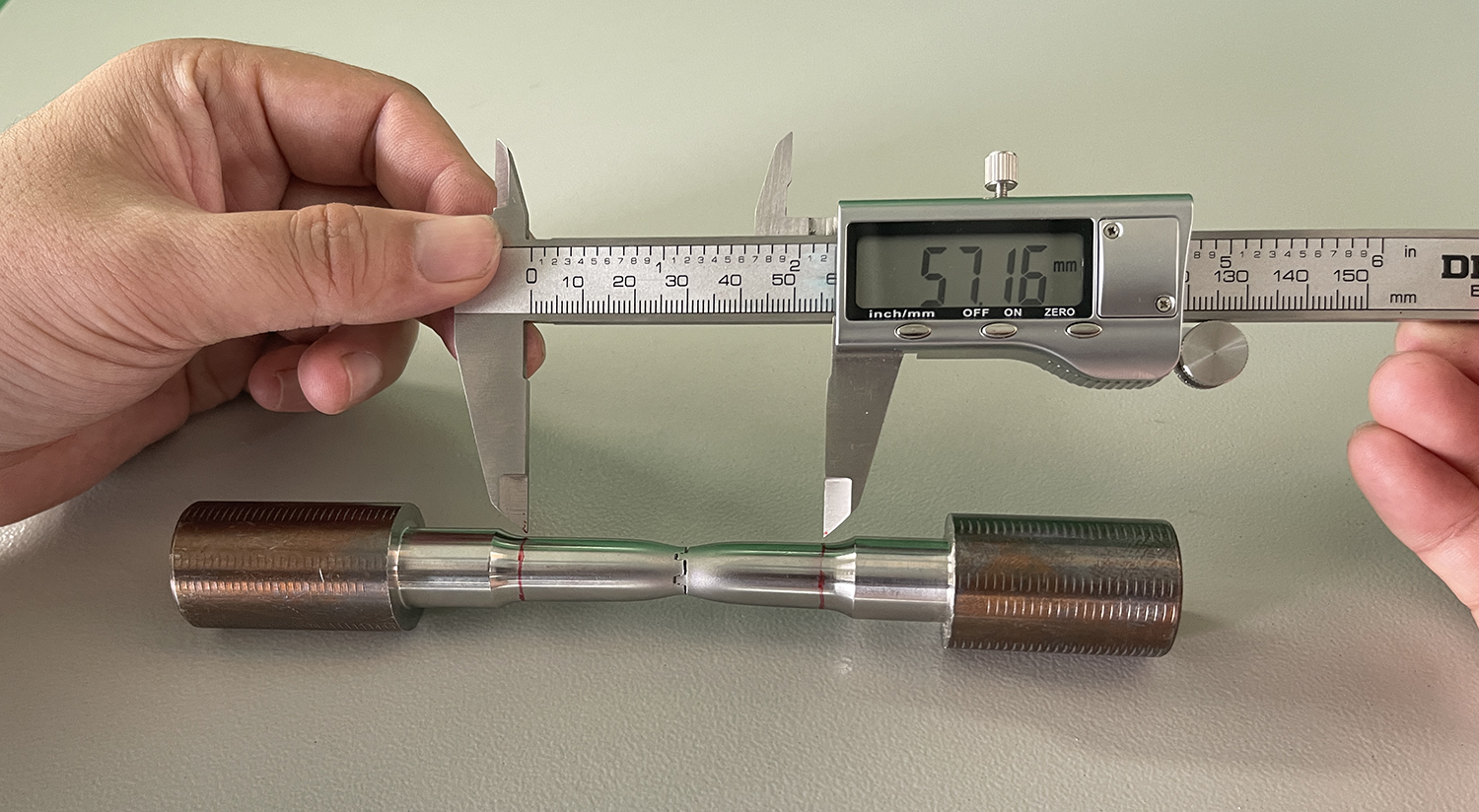

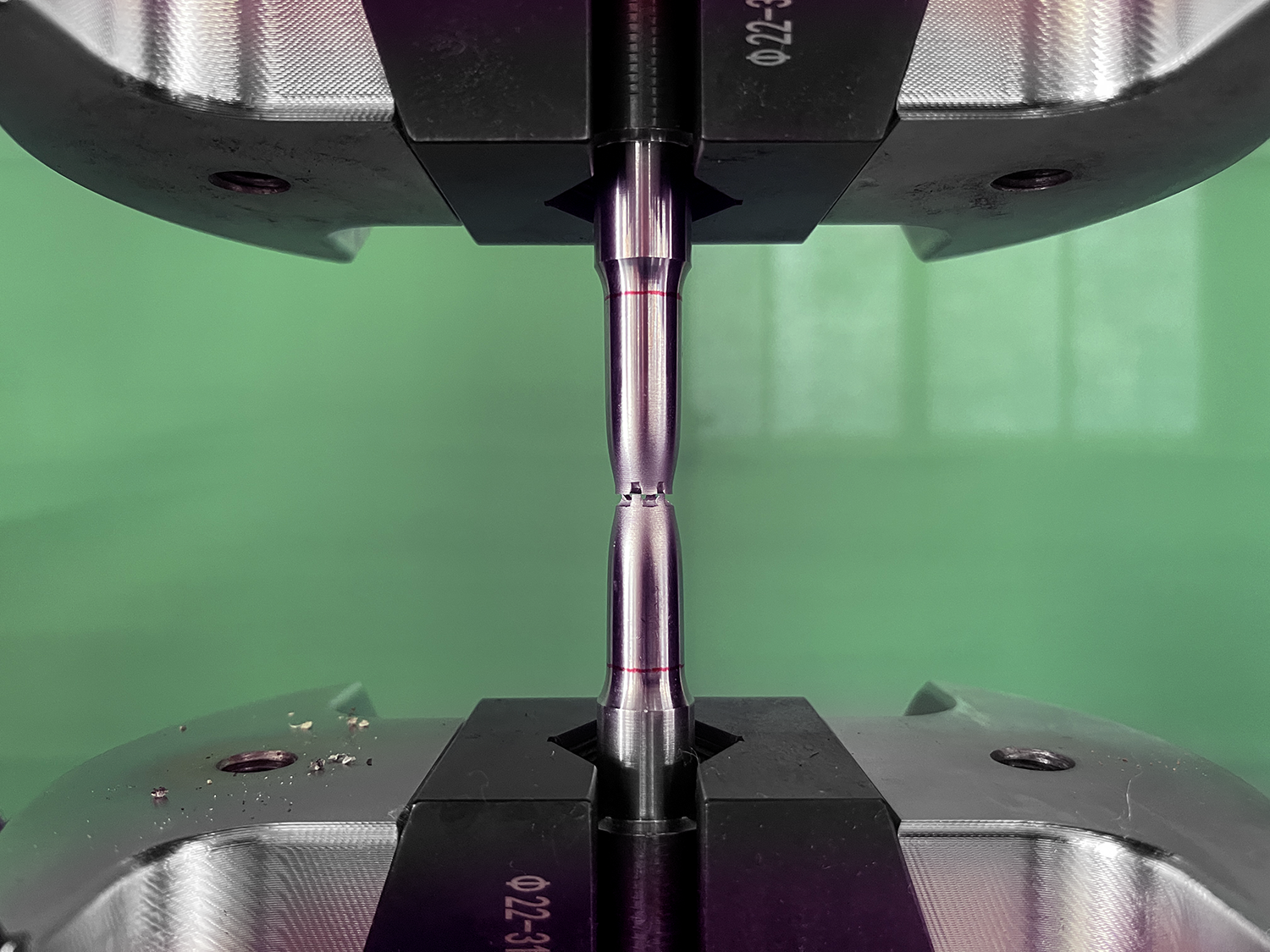

In a typical program, the specimen is cycled at a defined amplitude and mean level under force or strain control with a specified R ratio. Instruments track peak load, stiffness changes, and crack growth to produce S–N curves and, where applicable, strain-life or crack-growth data. Common references include ASTM E466 for force-controlled axial fatigue of metals, ASTM E606/E606M for strain-controlled fatigue, and ISO 1099 for metallic materials. Because loading fluctuates rather than remaining static, fatigue testing better reflects service conditions than single-pull tensile, bend, or compression checks, leading to more reliable durability predictions for real components.

If you would like to review system options for cyclic testing along with compatible accessories, you can explore available platforms on the

All Tensile Testing Equipment page.

What After-Sales Support Is Available for Your Universal Testing Machine (UTM)?

Our post-sale program covers installation guidance, commissioning assistance, remote diagnostics, calibration coordination, annual preventive maintenance, software updates, and priority ticketing. You also receive direct phone and email access to our technical team for troubleshooting and application support.

For laboratories testing metals, polymers, or composites, we can coordinate verification to ASTM E4 or ISO 7500-1 as applicable, advise on load cell selection, and schedule on-site service to keep daily throughput consistent. Typical activities include crosshead alignment checks, controller and PC software updates, safety interlock tests, and new-operator training. High-capacity frames, including systems around 450,000 lbf (2,000 kN), are supported with the same resources. To reach support or open a ticket, call 877-672-2622 ext. 3, email support1@tensilemillcnc.com, or submit an online request for priority routing. Replacement grips, fixtures, and spare parts are available to reduce downtime.

If you would like to discuss service options or schedule calibration, you can connect with our team on the

Contact Us page.

How Does TensileMill CNC Reduce Downtime on 135,000 lbf and 225,000 lbf UTM Systems (600 kN and 1000 kN)?

High capacity frames, 135,000 lbf and 225,000 lbf (600 kN and 1000 kN), are supported by a rapid-response service program that keeps test queues moving. You can reach support by phone 877-672-2622 ext. 3, by email support1@tensilemillcnc.com, or through an online ticket. Most cases are triaged and corrected remotely within 4 hours. When parts or field work are needed, typical restoration targets are 24 to 48 hours based on scope.

Downtime is limited through proactive diagnostics, log-based fault analysis, and guided video sessions, so operators resume testing without waiting for a site visit. Field-replaceable assemblies and stocked consumables, grips, and electronics are available for expedited shipment, and advance-exchange options reduce waiting for repairs. Our team pre-verifies replacement components before dispatch, provides step-by-step installation coaching, and follows up with a quick verification pull to confirm load, extension, and data acquisition are back within specification. For labs with continuous throughput, we can schedule preventive checks and keep a recommended spares list tailored to 135,000 lbf and 225,000 lbf frames.

If you would like to review service options and performance details, you can learn more on the

TM-EML Series D UTM page.

Which Grips and Fixtures Are Available for TM-EML Series Universal Testing Machines?

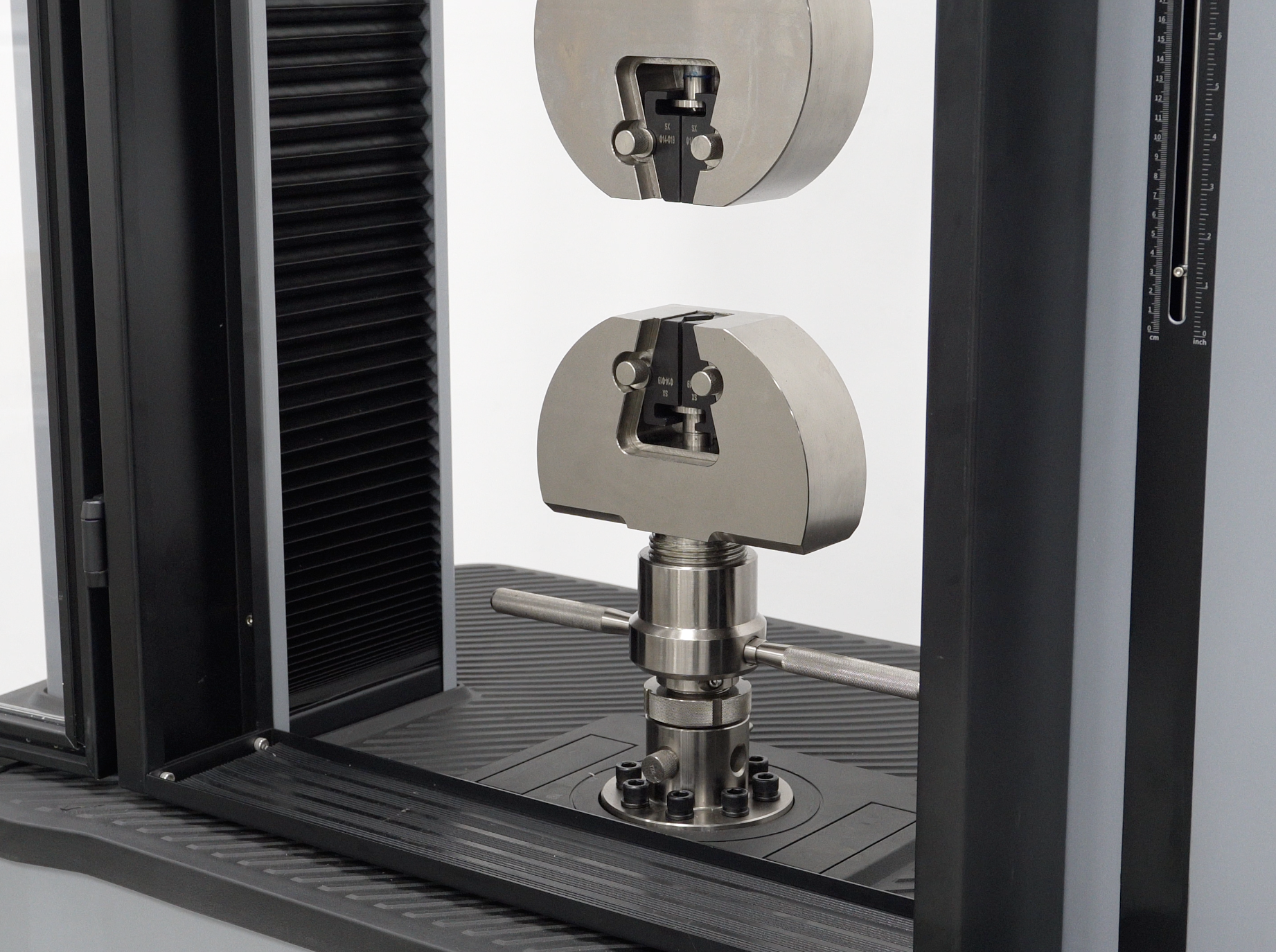

TensileMill CNC offers a broad catalog of grips and fixtures for TM-EML Series load frames to support tension, compression, flexure, peel, tear, puncture, and fastener testing across metals, plastics, elastomers, films, cables, and composites. Common options include wedge grips for flat and round metallic specimens used with ASTM E8 and ISO 6892 methods, pneumatic grips for rapid, repeatable clamping of soft or flexible materials, and side-action grips with interchangeable jaw faces for general lab workflows. Self-tightening and eccentric roller styles address wires, thin films, and deformable specimens. Flexural fixtures are available in 3-point and 4-point configurations for plastics and laminates per ASTM D790 and ISO 178, while compression platens support axial loading per ASTM D695. Threaded adapters and proof fixtures cover bolts, studs, and nuts per ASTM F606, and specialized peel, tear, and puncture fixtures serve films, laminates, bonded assemblies, and packaging.

All accessories interface directly with the TM-EML crosshead and load cell to promote coaxial loading, stable clamping, and repeatable results. Quick-change adapters, a wide range of jaw surfaces, and optional pneumatic regulators streamline throughput, and fixtures integrate cleanly with the system software for limit settings and method templates. Application-specific jaws and custom fixtures can be supplied to match specimen geometry or surface finish requirements.

If you would like to compare available jaws, adapters, and fixture styles for your TM-EML frame, you can review options on the

Grips and Fixtures page.

Do You Offer On-Site Installation, Operator Training, and Calibration for TM-EML Series Universal Testing Machines?

Yes. Our field service team provides on-site installation, operator training, and calibration for all TM-EML Series Universal Testing Machines.

Visits can be scheduled at commissioning or as part of routine verification. A typical service includes force verification of load cells with NIST-traceable standards to ASTM E4 or ISO 7500-1, verification of extensometers and displacement channels to ASTM E83 or ISO 9513, alignment checks in line with ASTM E1012, functional testing of crosshead motion and safety circuits, and software setup for your test methods. Following service, you receive calibration documentation with traceability and stated measurement uncertainty for audit records.

Laboratories operating under ISO 9001 or ISO/IEC 17025 commonly calibrate every 12 months, with shorter intervals based on throughput or customer audits. Remote support is available between visits for interim checks and software updates. Each TM-EML system includes manufacturer warranty coverage; regional terms and duration can be included with your quotation.

If you would like to review a representative model and related service options, you can read more on the

TM-EML Series C UTM product page.

Do You Offer On-Site Installation, Operator Training, and Calibration for TM-EML Series Universal Testing Machines?

Yes. Our field service team provides on-site installation, operator training, and calibration for all TM-EML Series Universal Testing Machines.

Visits can be scheduled at commissioning or as part of routine verification. A typical service includes force verification of load cells with NIST-traceable standards to ASTM E4 or ISO 7500-1, verification of extensometers and displacement channels to ASTM E83 or ISO 9513, alignment checks in line with ASTM E1012, functional testing of crosshead motion and safety circuits, and software setup for your test methods. Following service, you receive calibration documentation with traceability and stated measurement uncertainty for audit records.

Laboratories operating under ISO 9001 or ISO/IEC 17025 commonly calibrate every 12 months, with shorter intervals based on throughput or customer audits. Remote support is available between visits for interim checks and software updates. Each TM-EML system includes manufacturer warranty coverage; regional terms and duration can be included with your quotation.

If you would like to review a representative model and related service options, you can read more on the

TM-EML Series C UTM product page.

Do TM-EML Series Universal Testing Machines Meet ASTM and ISO Standards?

Yes. TM-EML Series universal testing machines are built and validated to comply with widely used international requirements for tensile and compression work. Force accuracy is verified in accordance with ASTM E4 and ISO 7500-1. Extensometer performance can be verified to ASTM E83 and ISO 9513, and load-train alignment can be checked per ASTM E1012. Method templates support metal tensile testing to ASTM E8 and ISO 6892-1.

For production QC environments, preloaded methods, operator prompts, and automatic certificates help maintain method control across shifts. For accredited or audited laboratories, TensileMill CNC can coordinate ISO/IEC 17025 calibration through partner labs and supply alignment fixtures, verification records, and gage-length documentation matched to your grips and specimen geometry.

Systems cover 11 lbf to 224,800 lbf (50 N to 1000 kN), supporting low-force polymers and high-strength metals within the same software environment. Documentation options include machine conformity statements, traceable load cell certificates, extensometer verification summaries, and alignment data. Verification intervals can be configured to follow your internal QMS or customer requirements.

If you would like to review capacities, accuracy classes, and software workflows, you can explore details on the

TM-EML Series C UTM.

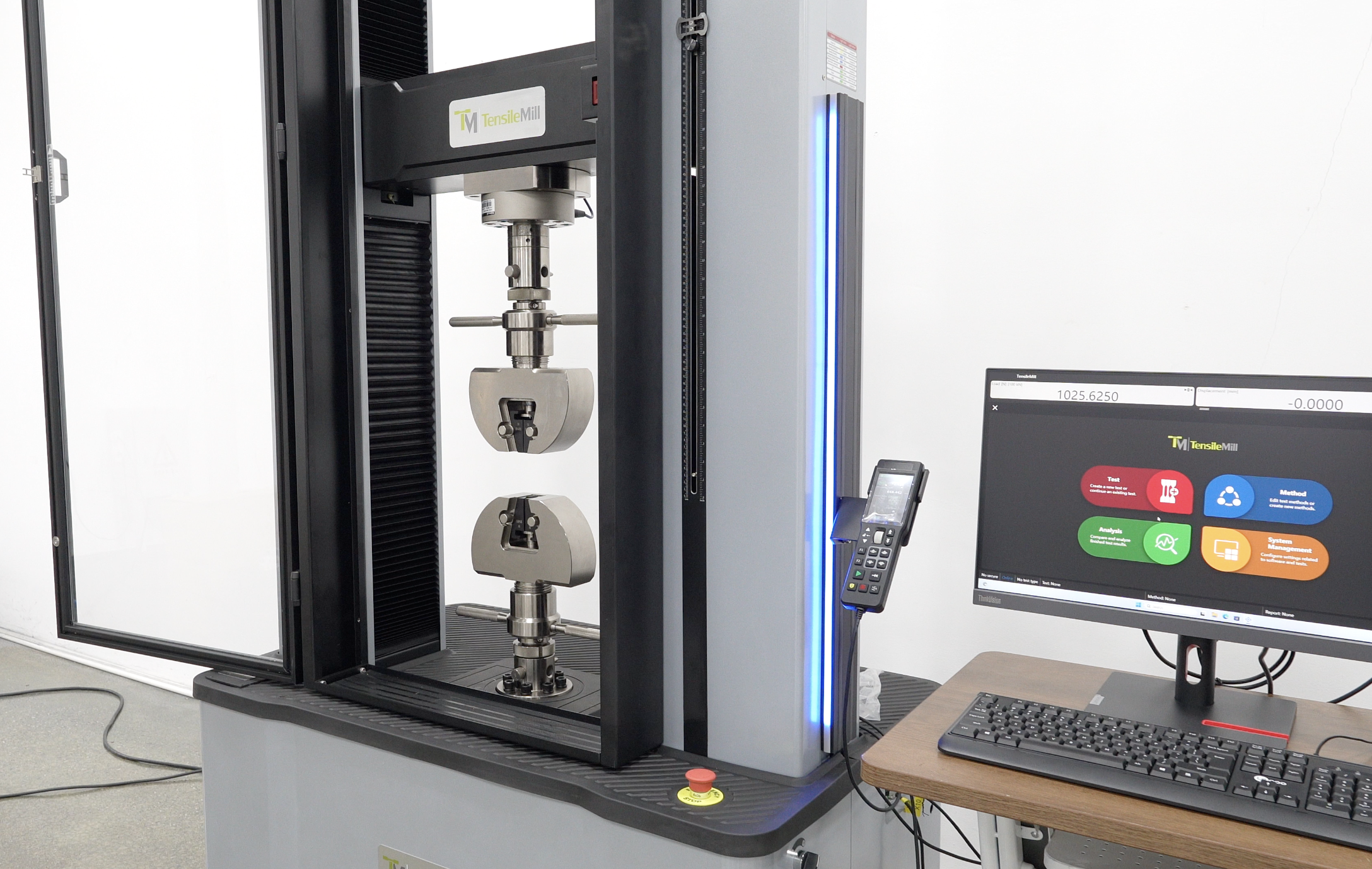

What Software Runs the TM-EML Series Universal Testing Machines and What Capabilities Does It Include?

TM-EML Series systems operate with GenTest, TensileMill CNC’s test control and data acquisition platform designed for routine QA and advanced laboratory workflows. The interface is straightforward for new operators and includes deeper controls for method development.

GenTest provides a library of tensile and compression templates aligned with common procedures such as ASTM E8 for metals and ISO 527 or ASTM D638 for plastics, with built-in prompts for grips, extensometers, and test speeds. During a run, the software displays live force, extension, and stress–strain plots while computing yield, ultimate strength, modulus, elongation, and other result parameters with pass or fail limits. Users can build custom methods for non-standard geometries, apply specimen protection logic during setup, and automate sequences for batch testing. Reports are configurable with company branding and can be exported to PDF, Excel, CSV, and image formats. Integration paths are available for clip-on or non-contact extensometers, environmental or thermal chambers, and pneumatic grip actuation. If you would like a look at the workflow or example outputs, a remote demonstration can be arranged.

If you would like to explore software workflow and accessory options, you can review technical details on the

TM-EML Series C UTM product page.

Are Consumables and Spare Parts In Stock for TM-EML Series Universal Testing Machines?

Yes. TensileMill CNC keeps a stocked inventory of consumables and replacement components for TM-EML electromechanical frames to keep labs running and minimize downtime.

Frequently supplied items include grips and jaw sets in manual, pneumatic, and specialty formats, extensometer accessories and cable assemblies, calibrated load cells across multiple capacity ranges, and common wear parts such as bearings, seals, and belts. Control boards and electronic modules are available in versions compatible with GenTest, and assemblies are shipped preconfigured for the intended TM-EML model.

Most parts are plug-and-play, so typical replacements can be completed in-house without a technician visit. For consumables with predictable wear, such as jaw inserts, grip pads, and seals, you may select multi-pack reorder options to support internal stocking programs for QC labs or 24/7 production lines. If a non-standard or legacy item is required, our team can coordinate sourcing and shipment to keep lead times tight.

If you would like to review stocked items and ordering options, you can explore the

Tensile Sample Preparation Consumables, Fixtures, and Spare Parts page for availability and compatible components.

What Post-Purchase Technical Support and Service Do TM-EML Series Universal Testing Machines Include?

TM-EML Series testing machines are backed by ongoing technical assistance from TensileMill CNC. Most operational or configuration questions are handled through guided remote support that covers GenTest software setup, method creation, data export, and safety logic. The team advises on grip and fixture selection and helps integrate extensometers, chambers, and other accessories. Remote diagnostics address motion control, electronics, and load-cell communication, and software updates are provided when applicable. When force verification or alignment is required, the team coordinates calibrated services in line with ASTM E4 or ISO 7500-1 for force and ASTM E1012 for alignment.

If an on-site visit is needed, certified regional partners perform diagnostic checks, system adjustments, functional testing, and operator coaching tailored to your sample types and throughput goals. TM-EML systems include standard manufacturer warranty coverage, and terms can vary by configuration and region. Replacement parts, grips, fixtures, and consumables are available to support uptime across routine QA work and research programs.

If you would like to review service options or confirm warranty terms for your system, you may connect with our team on the

Contact Us page.

How User-Friendly Are TM-EML Series Universal Testing Machines for New Operators?

The TM-EML Series is designed to be approachable for first-time users. GenTest software guides setup and execution with a structured workflow that reduces steps and lowers the chance of operator error.

Operators select a preloaded method template, such as ASTM E8 for metals or ISO 527 for plastics, then follow on-screen prompts to enter specimen dimensions, choose grips, and set gauge length and speed. Live graphs for force and extension display during the run, while built-in limits manage crosshead travel and overload conditions. When the test finishes, the system calculates key results automatically and produces reports that can be exported to common formats for LIMS or quality records.

Day-to-day tasks are straightforward: swap grips or add an extensometer using quick, tool-efficient connections; stored calibration factors and accessory profiles load from the software when selected. A multilingual interface is available depending on configuration. Typical onboarding covers method selection, specimen installation, running the cycle, and reviewing or exporting results, allowing consistent production testing with minimal adjustment.

If you would like to preview the software workflow and see model options, you can explore operation details on the

TM-EML Series D UTM product page.

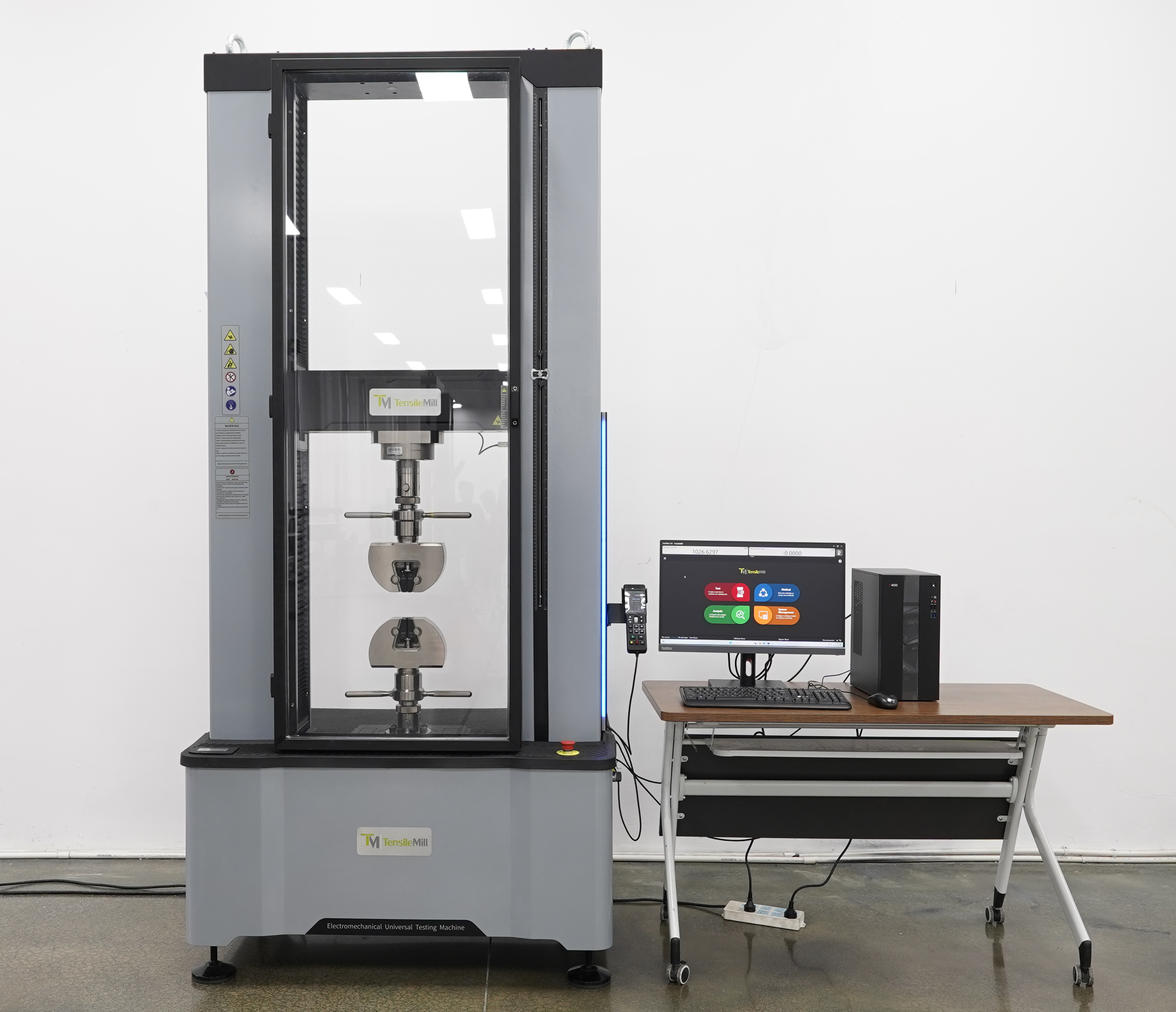

What Installation Space and Mounting Requirements Apply to TM-EML Series UTMs for Benchtop and Floor Models?

Benchtop units in the TM-EML Series should sit on a rigid, low-vibration workbench rated to carry the machine plus tooling. Typical footprints are 22.8 in × 20.4 in (580 mm × 520 mm) and about 238 lb (108 kg) for Series A, and 30 in × 25 in (770 mm × 640 mm) and about 595 lb (270 kg) for Series B. Leave 6–8 in (150–200 mm) behind the frame for cable routing and routine service, and keep both sides open to simplify grip and fixture changes.

Floor-standing Series C and Series D machines perform best on a flat, level concrete surface with vertical clearance for full crosshead travel and for load cell or grip changes. Larger Series D frames weigh roughly 2,200–13,000 lb (1000–6000 kg), so a reinforced slab is preferred. Bring the frame level and square using the leveling points or shims, and consider anchor bolts where the lab has floor vibration or when high-frequency cycling is planned. Provide front access for specimen loading, a safe path for a lift or pallet jack during placement, and space for the main power disconnect and cabling. If you are planning a first installation or relocating a unit, our team can review a floor plan to validate fit and workflow.

If you would like to review frame sizes and site planning notes, you can explore specifications on the

TM-EML Series D UTM page.

What Are the Power and Voltage Requirements for TM-EML Series UTM Models?

TM-EML Series A, B, and benchtop C operate on single-phase 220 V ±10%, 50/60 Hz. Typical input load is about 600 W for Series A, and roughly 1.0 to 1.5 kW for Series B and C depending on motor size and installed accessories. High-capacity Series D requires a three-phase 220 V ±10%, 50/60 Hz supply, with frame-dependent power from approximately 2 kW up to 11 kW.

For planning, Series A commonly suits a dedicated 15 A branch circuit, while Series B and C are often paired with 15 A to 20 A circuits. On Series D, estimated current draw spans about 6 A to 36 A per phase across the 2 kW to 11 kW range; actual values depend on drive settings, duty cycle, and power factor. Verify that the delivered voltage at the machine location is within 198 V to 242 V, and size the disconnect and overcurrent protection according to local electrical rules. If your facility provides 208 V or 240 V services, they fall within the stated tolerance band.

If you would like a deeper look at capacities and electrical ratings, you can review the specifications on the

TM-EML Series D UTM product page.

What Temperature, Humidity, Vibration, and Altitude Conditions Are Recommended for Stable Operation of TM-EML Series UTMs?

TM-EML systems perform best in a controlled laboratory. Keep room temperature stable at 60 to 77 °F (15 to 25 °C) during testing to reduce drift in force and displacement readings. Maintain low to moderate relative humidity, typically below 70 percent, and avoid any condensation within the test area.

Minimize vibration at the installation site. Benchtop frames operate well on a rigid laboratory bench, while large Series D frames should be mounted on a stable concrete floor slab. Separate the tester from heavy machinery and other sources of shock, particularly when using high-resolution extensometers or low-force load cells, which are more sensitive to ambient disturbance. If site vibration cannot be avoided, consider isolation pads or relocating the machine to a quieter room. Altitude is not usually a limiting factor for measurement accuracy, though labs at higher elevations may notice minor changes in pneumatic accessory response. In those cases, a small regulator adjustment typically restores expected grip timing and pressure behavior. If your facility has atypical conditions, our team can confirm compatibility with your setup.

If you would like to review specifications and options, you can read more on the

TM-EML Series C UTM product page.

What Utility Requirements Apply to TM-EML Universal Testing Machines With Pneumatic Grips or Environmental Chambers?

TM-EML load frames operate on electrical power only. The base machine does not need compressed air or external ventilation for motion control, data acquisition, or routine testing.

Air and ventilation are required only for certain accessories. Pneumatic grips run from a typical laboratory air line at 80 to 100 psi (5.5 to 7 bar). If plant air is not available, a compact oil-free compressor can be used, and clean, dry air is recommended for consistent clamping performance.

Environmental chambers carry their own utility needs. Depending on the model, a separate electrical connection and, in some cases, an exhaust pathway may be specified by the chamber supplier. These utilities belong to the chamber, not the TM-EML frame. If you plan to add pneumatic grips, a temperature chamber, or other powered accessories, share your accessory list and test range with our team so we can confirm utilities for your exact configuration.

If you would like to review frame capabilities and compatible accessories, you can learn more on the

TM-EML Series C UTM equipment page.

What Safety Features and Optional Protective Enclosures Are Available for TM-EML Universal Testing Machines?

TM-EML electromechanical UTMs include layered safeguards for routine tensile, compression, and flexural work. Standard protections include an emergency-stop button, upper and lower travel limits, motor overload protection, and automatic force shutoff when a specimen breaks unexpectedly. Optional guarding surrounds the test area with impact-resistant panels and allows safe, clear access to grips and fixtures; door interlocks and remote operation options are available when added risk reduction is desired.

During a test, the controller monitors load and position. If a sudden force spike or loss of load indicates a break, motion stops and the load path is protected, reducing the chance of shock to the load cell. Mechanical limit switches prevent crosshead over-travel, while overload logic pauses drive power before components are overstressed. Protective enclosures are recommended for brittle materials, sharp fragments, or high-energy failures. Clear panels maintain visibility, and hinged or sliding access keeps specimen changes practical. When equipped with an interlock, opening the enclosure halts crosshead motion and disables start commands until the guard is closed, helping operators maintain a safe standoff without sacrificing throughput.

If you would like to review safety functions and protective guarding options, you can learn more on the

TM-EML Series C UTM product page.

How Do TM-EML Universal Testing Machines Use Digital Closed-Loop Control and High-Speed Data Acquisition?

TM-EML load frames run a fully digital control loop that continuously reads force, crosshead displacement, and motor position, then updates drive output in real time. The high-speed data stream is time-aligned with GenTest software so you get live stress–strain curves, smooth transitions between control modes, and reliable results without waiting for buffers to catch up.

Measurement feedback comes from precision load cells and high-count encoders routed through high-resolution electronics. The controller applies tuned PID and feed-forward profiles to hold a commanded speed, load, or strain, which supports rate-sensitive methods such as ASTM E8 for metals or ISO 527 for plastics. When material behavior changes abruptly, for example at yield or during necking, the loop reacts immediately to stabilize the setpoint. The same control architecture is calibrated across the family, so Series A low-force machines and Series D high-capacity frames respond with consistent logic. Operators can set triggers, switch from displacement to load or strain at a defined event, and capture synchronized data for export without gaps.

If you would like a mid-range reference for capacities and controls, you can review technical details on the

TM-EML Series C UTM page.

How Do TM-EML Universal Testing Machines Use Digital Closed-Loop Control and High-Speed Data Acquisition?

TM-EML load frames run a fully digital control loop that continuously reads force, crosshead displacement, and motor position, then updates drive output in real time. The high-speed data stream is time-aligned with GenTest software so you get live stress–strain curves, smooth transitions between control modes, and reliable results without waiting for buffers to catch up.

Measurement feedback comes from precision load cells and high-count encoders routed through high-resolution electronics. The controller applies tuned PID and feed-forward profiles to hold a commanded speed, load, or strain, which supports rate-sensitive methods such as ASTM E8 for metals or ISO 527 for plastics. When material behavior changes abruptly, for example at yield or during necking, the loop reacts immediately to stabilize the setpoint. The same control architecture is calibrated across the family, so Series A low-force machines and Series D high-capacity frames respond with consistent logic. Operators can set triggers, switch from displacement to load or strain at a defined event, and capture synchronized data for export without gaps.

If you would like a mid-range reference for capacities and controls, you can review technical details on the

TM-EML Series C UTM page.

Do TM-EML Series UTMs Integrate with LIMS, MES, and Third-Party Analysis Software?

Yes. TM-EML universal testing machines interface with external systems through GenTest export functions. Results, raw curve data, and calculated parameters can be written to CSV, Excel, or PDF, allowing straightforward transfers into LIMS, MES, or third-party reporting tools without custom programming.

GenTest can also produce tailored exports that match your file naming rules or batch structure, so receiving systems can map specimen IDs, lot numbers, and test metadata consistently. Many laboratories use automated import utilities on the LIMS or analytics side to ingest these files after each test run. If your workflow requires a specific column layout or additional identifiers, our team can help configure the export profile and confirm compatibility with your existing platforms.

If you would like to explore software and connectivity options, you can review capabilities on the

TM-EML Series D UTM product page.

Do TM-EML Series UTMs Integrate with LIMS, MES, and Third-Party Analysis Software?

Yes. TM-EML universal testing machines interface with external systems through GenTest export functions. Results, raw curve data, and calculated parameters can be written to CSV, Excel, or PDF, allowing straightforward transfers into LIMS, MES, or third-party reporting tools without custom programming.

GenTest can also produce tailored exports that match your file naming rules or batch structure, so receiving systems can map specimen IDs, lot numbers, and test metadata consistently. Many laboratories use automated import utilities on the LIMS or analytics side to ingest these files after each test run. If your workflow requires a specific column layout or additional identifiers, our team can help configure the export profile and confirm compatibility with your existing platforms.

If you would like to explore software and connectivity options, you can review capabilities on the

TM-EML Series D UTM product page.

How to Relocate a TM-EML Series Universal Testing Machine Within a Lab or Between Facilities, and What to Prepare First

Relocation depends on frame size. Benchtop TM-EML units such as Series A and Series B can be moved within a lab on a rated cart or with a controlled two-person lift. Floor-standing frames like Series C and Series D should be handled by trained riggers using certified lifting equipment, with the load frame secured to a pallet or base.

Before moving, power down, back up any test methods, lower and mechanically secure the crosshead, then remove grips, load cells, extensometers, fixtures, and any environmental chambers. Isolate electrical and pneumatic lines, cap ports, protect connectors, and wrap guide columns and screws to avoid contamination. Verify pathway clearances, doorway and elevator limits, and tie-down points, then stabilize the machine for transport to prevent tipping or frame shock. At the destination, place the system on a level surface, reconnect services, reassemble accessories, and confirm ambient conditions are suitable for testing. Perform a verification of force and alignment before resuming production testing, for example a force check to ASTM E4 or ISO 7500-1 and an alignment check to ASTM E1012, and record results for your quality program.

If you would like additional setup details and configuration options, you can review technical information on the

TM-EML Series C Universal Testing System page.

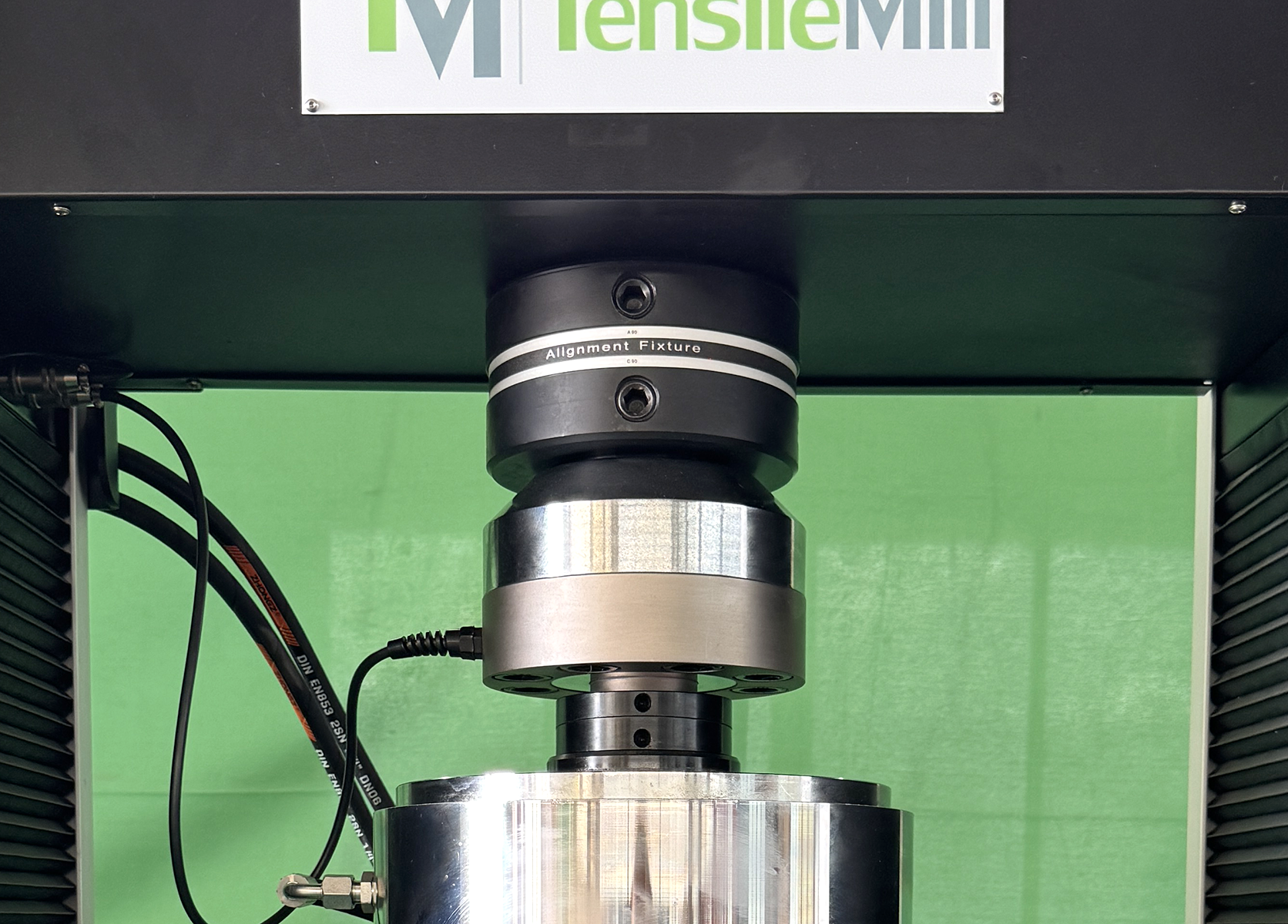

Which Alignment Tools and Procedures Prepare TM-EML Series UTMs for NADCAP or Similar Accreditation?

TM-EML testing frames support formal alignment workflows used for NADCAP and comparable audit programs. Operators can verify axiality with alignment fixtures compatible with ASTM E1012 and with ISO-aligned practices. These tools measure load-string symmetry, bending strain, and force distribution so you can adjust grips, adapters, and crosshead centering before a calibration visit. GenTest software guides stepped loading and captures alignment data, then generates a traceable report for auditors.

In practice, select an alignment bar or multi-gage fixture that matches your grip type, install it between the upper and lower adapters, and zero the sensors. Run a controlled tension profile in GenTest, add compression if required by your audit scope, and watch live axiality and bending indicators. If readings show eccentricity, correct grip parallelism, change or reface worn jaw faces, confirm adapter concentricity, and recenter the crosshead, then repeat the sequence until bending falls within your program limits. Save the GenTest protocol with operator ID, instrument serial numbers, and calibration references to document the alignment state. Our team can help match the correct alignment fixture to your frame and jaw style for a smooth audit.

If you would like to review compatibility and reporting features, you can read more on the

TM-EML Series C UTM product page.

What Comes Standard With a TM-EML Series Universal Testing Machine, and Which Options Are Most Popular?

Each TM-EML order ships ready to test with the load frame, a closed-loop AC servo controller, a precision load cell matched to the selected capacity, and the GenTest software package. Basic tensile grips or compression platens are supplied according to the methods specified on the order, and the machine includes safety features such as an emergency-stop circuit, travel limit switches, and motor protection.

If you would like to compare capacities and accessory choices, you can review technical details on the

TM-EML Series C UTM page.

What Comes Standard With a TM-EML Series Universal Testing Machine, and Which Options Are Most Popular?

Each TM-EML order ships ready to test with the load frame, a closed-loop AC servo controller, a precision load cell matched to the selected capacity, and the GenTest software package. Basic tensile grips or compression platens are supplied according to the methods specified on the order, and the machine includes safety features such as an emergency-stop circuit, travel limit switches, and motor protection.

If you would like to compare capacities and accessory choices, you can review technical details on the

TM-EML Series C UTM page.

How Does the Pneumatic Grip Control Module Work on the TM-EML Series C UTM and What Are the Workflow Benefits?

The optional pneumatic grip control module provides closed-loop, digital pressure regulation for the upper and lower grips on the TM-EML Series C. Operators set and monitor clamping pressure from the handheld console or directly in GenTest software, with independent channels for each grip. An integrated electronic regulator maintains the target pressure during the test, and quick-connect air ports make it straightforward to attach pneumatic side-action grips or other air-operated fixtures for tensile or compression work.

For routine testing, this module improves repeatability by applying the same clamping force every time, which reduces operator-to-operator variation and helps protect delicate or compliant specimens from over-tightening. Preset profiles let labs switch materials or jaw faces without re-tuning pressure, which shortens changeovers and speeds batch throughput. Built-in safety logic ties grip actuation to machine state, so clamping remains disabled until the test space is clear and the frame is ready, helping prevent unintended jaw movement during setup.

If you would like to review control options, pressure presets, and compatible pneumatic grips, you can learn more on the

TM-EML Series C Universal Testing System page.

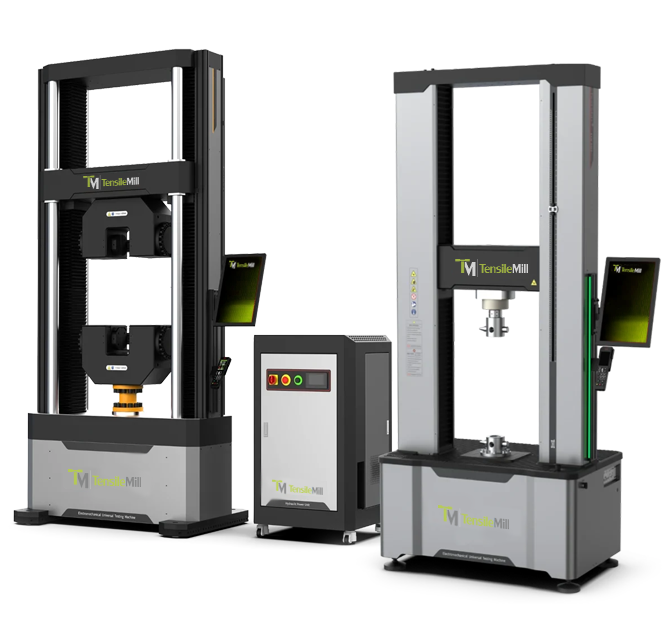

What Is the TM-EML Series D Universal Testing Machine and Which Applications Is It Built For?

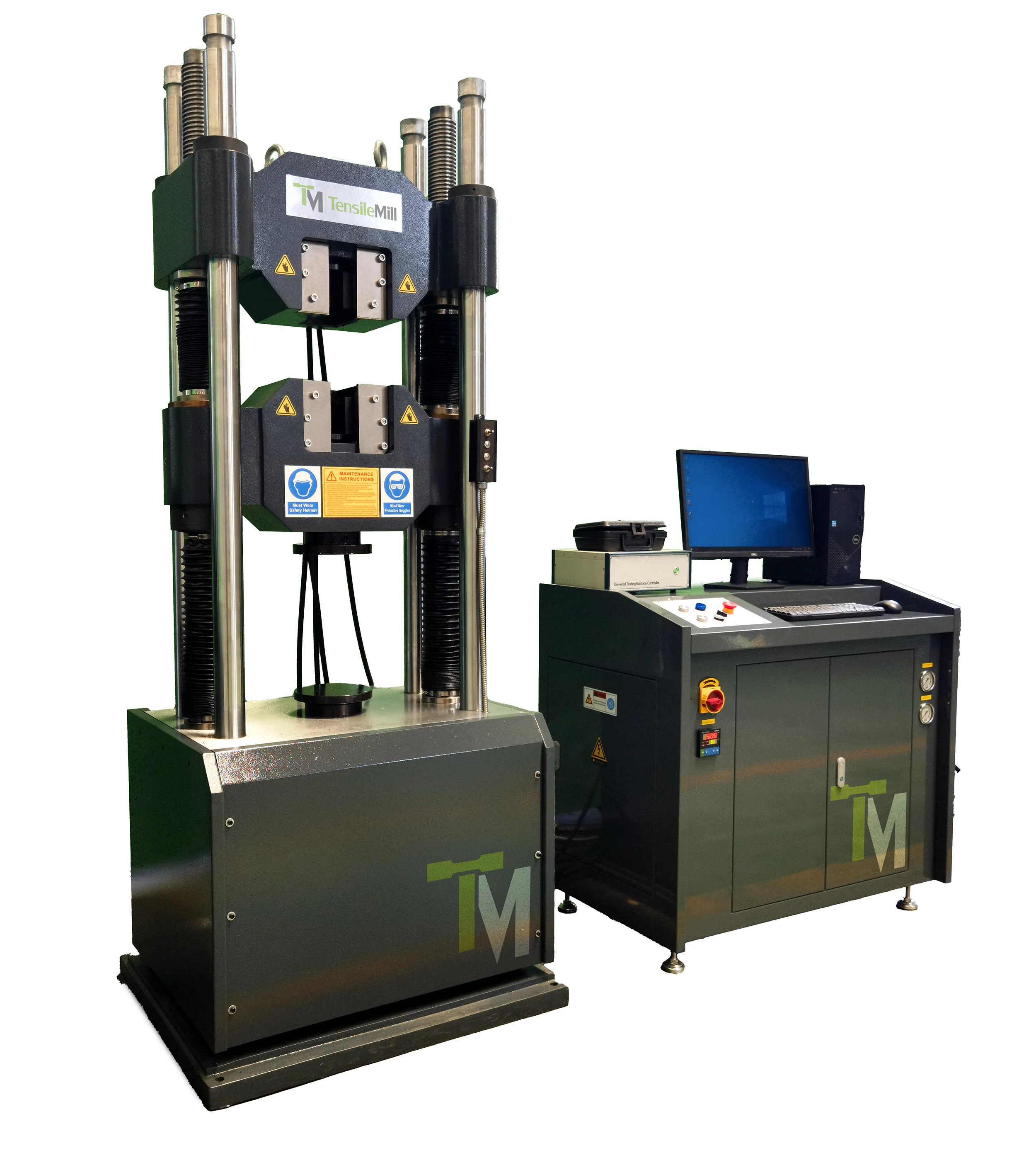

The TM-EML Series D is a high-capacity, dual-column, floor-standing electromechanical universal testing system for tensile, compression, flexural, and low-frequency cyclic work. It covers force capacities from 11,240 to 224,800 lbf (50 to 1,000 kN) and uses a rigid frame, direct-drive actuation, and high-resolution feedback to deliver precise control at heavy loads with stable strain-rate and repeatable results.

Typical use cases include testing high-strength steels, structural alloys, engineered composites, and other advanced materials that demand controlled rate profiles or high force. Laboratories apply this platform for routine quality control and research programs across standards such as ASTM E8 and ISO 6892-1 for metallic tension, ASTM E9 for compression, and ASTM D790 or ASTM D3039 for flexure and composite tension. The system supports ramp, hold, and waveform-based loading for tension, tension-compression, creep, and stress-relaxation studies, while accommodating a broad range of grips, fixtures, and extensometry to match specimen geometries and throughput needs.

If you would like deeper specifications and configuration options, you can review details on the

TM-EML Series D Universal Testing Machine page.

Which Industries And Testing Environments Commonly Use The D-Class High-Force UTM?

The D-Class high-force universal testing machine is widely used in industrial laboratories, aerospace and automotive R&D centers, quality control departments, steel and foundry operations, and advanced manufacturing groups working with composites and high-temperature alloys. It is also adopted by universities, national laboratories, and certification-driven test facilities that manage long-duration or methodical study programs.

Teams deploy this platform for routine lot release, process validation, and materials qualification where high loads and traceable results are required. Typical workflows include metallic tensile per ASTM E8 and ISO 6892-1, elevated-temperature tensile per ASTM E21, and compression per ASTM E9, often with environmental chambers, furnaces, and high-capacity grips. With available force ranges from 11,240 to 224,810 lbf (50 to 1,000 kN), the system covers plate and bar stock, heavy fasteners, weldments, forgings, castings, and large-section additive builds. Research environments use the same machine for strain-rate studies, thermal exposure programs, and other long-term investigations, supported by precise closed-loop control and extensometry.

If you would like a deeper look at capacities, frame layouts, and compatible accessories, you can review technical details on the

TM-EML Series D UTM equipment page.

Which Specimen Types Suit High-Capacity Testing on the TM-EML 11.2 to 224.8 Kip (50 to 1000 kN) Platform?

High-strength metallic and large-section parts are ideal candidates for high-capacity work on this platform. Typical specimens include steel bars and plate, forged components, structural fasteners, wire rod, reinforced composites, and high-temperature alloy coupons. The frame also supports environmental chambers or furnaces, oversized fixtures for thick cross sections, and programs that require very low strain-rate control.

Labs commonly run tensile, compression, flexural, shear, and cyclic methods on components used in construction, transportation, energy, aerospace, and heavy manufacturing. When applicable, metals are often evaluated to ASTM E8 or ASTM A370, fasteners to ASTM F606, high-temperature alloys to ASTM E21, and composites to ASTM D3039 or ISO 527. Selecting suitable wedge or hydraulic grips, high-capacity compression platens, bend fixtures, or custom adapters helps maintain alignment and throughput with long bars or wide plate. For workflows that include thermal exposure or slow loading, the system’s precision drive and closed-loop control deliver stable low-rate operation while protecting the specimen and tooling.

If you would like to compare capacities, fixtures, and thermal options, you can review technical details on the

TM-EML Series D UTM product page.

What Force Capacities Are Offered for the TM-EML Series D UTM, and How Do I Choose the Correct Range?

Series D is available in 11,240, 22,480, 44,960, 67,440, 112,400, 134,890, and 224,810 lbf (50, 100, 200, 300, 500, 600, and 1000 kN). These ratings cover mid-capacity metals and composites through ultra-high load applications. All models share a common digital control and software platform, with differences in frame size, stiffness, motor power, and crosshead travel that match the rated capacity.

To select the right range, calculate the expected peak load using specimen cross-sectional area multiplied by anticipated tensile strength, for example using materials data aligned with ASTM E8 or ISO 6892-1 for metals. Add practical headroom for grip mass, preloads, and occasional overloads, then choose a frame where your highest expected load falls between 10 and 90 percent of the machine capacity. If your estimate lands near the upper third, move to the next capacity to protect data quality and reduce wear. Also consider future material programs, long fixtures, or environmental chambers, since these may favor a stiffer frame with longer travel.

If you would like to compare capacities, frame options, and software features, you can review technical details on the

TM-EML Series D UTM product page.

What Are the Differences Between the 50 to 100 kN, 200 to 300 kN, 500 to 600 kN, and 1000 kN UTM Configurations?

All configurations share the same control electronics and GenTest software platform. The differences come from the load frame design, which drives stiffness, crosshead travel, movement speed, and usable test-space dimensions. As capacity increases, the structure becomes heavier and stiffer, travel and top speed are moderated, and adapters, couplings, and bases scale to handle higher forces and larger tooling.

50 to 100 kN units deliver about 11,240 to 22,480 lbf (50 to 100 kN). They use a dual-column layout with longer travel, the quickest crosshead speeds, and a compact footprint for high-throughput lab work. 200 to 300 kN systems cover roughly 44,960 to 67,410 lbf (200 to 300 kN). Frames are reinforced, stiffness rises, and the test space shortens to reduce deflection when running thicker sections or larger wedge grips. 500 to 600 kN models reach about 112,400 to 134,800 lbf (500 to 600 kN). These add thicker columns, extended crosshead guidance, and slower maximum speeds to keep alignment stable under high loads. The 1000 kN configuration provides about 224,800 lbf (1000 kN) with maximum stiffness, a larger base, reinforced couplings, reduced travel speed, and optional dual test spaces for long or bulky specimens. Choose the lowest capacity that still covers your peak test loads to maintain resolution, speed, and operator throughput.

If you would like to compare capacities and frame options, you can review configuration details on the

TM-EML Series D UTM page.

How Does Frame Stiffness Scale Across TM-EML Series D UTM Capacities From 50 kN to 1000 kN?

Stiffness in the TM-EML Series D frames increases with each higher force class. Larger guidance columns, a heavier crosshead and base structure, and reinforced load paths limit frame deflection under axial and side loading. This behavior improves modulus repeatability, reduces bending effects, and preserves grip-to-grip alignment when using large wedge grips, environmental chambers, or furnaces.

At 11,240 to 22,480 lbf (50 to 100 kN), stiffness supports mid-strength metals and composites for routine QA. At 44,960 to 67,440 lbf (200 to 300 kN), thicker columns and a stronger crosshead raise lateral rigidity for higher yield materials and larger fixtures. At 112,400 to 134,900 lbf (500 to 600 kN), reinforced load structures provide substantial rigidity for heavy industrial alloys and large-section specimens. At 224,800 lbf (1000 kN), the frame offers the highest stiffness in the series to maintain alignment during extreme loads, long holds, or cyclic profiles. These characteristics help meet bending and alignment requirements in standards such as ASTM E8 and ISO 6892-1 when paired with appropriate fixturing and alignment practices.

If you would like capacity-specific details, you can review frame and test-space specifications on the

TM-EML Series D Universal Testing System page.

What Are the Dimensions, Working Height, and Weight of TM-EML Series D Universal Testing Machines?

Frame dimensions, working height, and approximate weight for TM-EML Series D electromechanical UTMs vary by capacity and whether you choose the standard or extended test space. Typical footprints by capacity are: 50–100 kN and 200–300 kN models, about 46.3 in × 28.0 in × 100.4–126.8 in (1175 mm × 710 mm × 2550–3220 mm), usable crosshead travel roughly 49.2–76.8 in (1250–1950 mm), weight about 2205–3307 lb (1000–1500 kg). 500–600 kN frames, about 56.3 in × 33.5 in × 108.7–123.6 in (1430 mm × 850 mm × 2760–3140 mm), crosshead travel roughly 25.6–41.3 in (650–1050 mm), weight about 6528–7654 lb (2960–3470 kg). 1000 kN units, about 61.8 in × 39.4 in × 122.0–139.8 in (1570 mm × 1000 mm × 3100–3550 mm), crosshead travel roughly 19.7–35.4 in (500–900 mm), weight about 12,082–13,621 lb (5480–6180 kg).

Working height refers to the usable crosshead travel within the selected test space. Labs running longer grips, high-temperature furnaces, or large extensometer frames often select the extended-height configuration to simplify changeovers and keep travel available for both tensile and compression modes. When planning installation, consider ceiling clearance, floor loading, and door widths that correspond to the footprints and weights above, then size the frame for your highest expected test load and accessory stack-up.

If you would like a deeper look at frame sizes, travel options, and compatible fixtures, you can review technical details on the

TM-EML Series D UTM product page.

What Single-Space and Dual-Space Frame Configurations Are Available for the TM-EML Series D?

The Series D universal testing machine is offered in single-space and dual-space frames. Single-space provides one primary test area, suited for labs running mostly tensile or compression work with standard grips and fixtures. Dual-space adds a second test area above or below, allowing tensile and compression setups to remain installed, which cuts changeover time and preserves alignment-sensitive accessories.

For approximately 11,200 to 22,500 lbf (50 to 100 kN) and about 44,900 to 67,400 lbf (200 to 300 kN) models, you can select standard height or extended-height versions of plus 11.8 in (plus 300 mm) and plus 23.6 in (plus 600 mm) in either single-space or dual-space layouts. The roughly 112,000 to 134,900 lbf (500 to 600 kN) and 224,800 lbf (1000 kN) platforms are available as standard or extended-height dual-space frames, supporting long specimens, large compression platens, or high temperature chambers to stay mounted between tests, which helps increase throughput and measurement repeatability.

If you would like additional configuration details, you may review frame layouts and options on the

TM-EML Series D UTM product page.

How Does the Dual-Column Floor-Standing UTM Frame Improve Alignment and Long-Term Rigidity?

A dual-column floor-standing frame carries the load symmetrically on both sides of the crosshead, so the force path stays coaxial with the specimen. This architecture reduces bending moments, side loading, and frame deflection during high-force tensile, compression, or flex tests.

On the TM-EML Series D, reinforced guide columns, preloaded ball screws, and high-stiffness linear rails keep the crosshead tracking straight under eccentric fixtures or heavy grips. Frame stiffness rises from about 1,540,000 lbf/in (270 kN/mm) in models around 11,240 to 22,480 lbf (50 to 100 kN), up to about 7,420,000 lbf/in (1300 kN/mm) in the 224,800 lbf (1000 kN) frame. The added rigidity supports accurate modulus and yield determination on high-strength steels or large cross-section specimens, where even small misalignment can skew strains and create premature necking.

Finite element optimization of the D-class structure, combined with zero-clearance mechanical interfaces, limits micro-slip at joints. As a result, axial alignment remains stable over years of daily operation with minimal re-verification drift. For labs that perform alignment checks, improved coaxiality also helps meet the intent of alignment verification practices such as ASTM E1012.

If you would like to explore frame design details and capacity options, you can review technical information on the

TM-EML Series D UTM product page.

What Crosshead Travel Options Are Available Across TM-EML Series D Models?

Crosshead travel varies by capacity and frame height. For 50 to 100 kN and 200 to 300 kN units, typical travel is about 49.2 to 76.8 in (1250 to 1950 mm) depending on standard or extended frames. The 500 to 600 kN machines provide roughly 25.6 to 41.3 in (650 to 1050 mm). The 1000 kN system offers around 19.7 to 35.4 in (500 to 900 mm). Extended-height packages add up to 11.8 or 23.6 in (300 or 600 mm) for longer specimens and tall accessories.

Selection comes down to specimen gauge length, maximum jaw separation during failure, and accessory stack-up. Environmental chambers, long wedge grips, compression platens, or multi-axis fixtures consume vertical clearance, so additional travel helps maintain working space while keeping operators out of pinch points. Labs running high-elongation metals or polymers benefit from the extended frame because it reduces regripping and shortens changeovers when alternating between tensile, compression, and flex setups. If your workflow includes oversized grips or elevated-temperature testing, the extended travel option gives the headroom to mount instrumentation and still reach the required displacement range.

If you would like to review frame sizes and travel options in detail, you can explore specifications on the

TM-EML Series D Universal Testing Machine page.

What Is the Usable Test Width on the TM-EML Series D UTM?

Usable test width varies by capacity group. Frames rated 11,240 to 67,440 lbf (50 to 300 kN) offer about 23.6 in (600 mm). Higher capacity frames at 112,400 to 134,900 lbf and 224,800 lbf (500 to 600 kN and 1000 kN) provide approximately 29.5 to 35.0 in (750 to 890 mm).

This is the clear distance between columns, which sets the maximum width for fixtures or environmental chambers and governs the largest specimen geometry that can pass without contact. When planning a setup, consider the full installed width of grips, adapters, alignment devices, cable routing, and chamber wall thickness, not just the nominal grip face size. Wider hydraulic wedge grips, split furnaces, or cryogenic chambers can reduce effective working width by several inches or millimeters. For high-throughput workflows or automation where accessories move in and out of the load string, confirm the required between-column width during configuration to maintain safe clearances.

If you would like a deeper look at frame dimensions and options, you can review technical details on the

TM-EML Series D UTM page.

What Crosshead Speed Range Do TM-EML Series D UTMs Support, and How Does It Vary by Capacity?

Across the TM-EML Series D lineup, the minimum crosshead speed is 0.00000197 in/min (0.00005 mm/min). Maximum speed depends on frame capacity: 33.46 in/min (850 mm/min) for 11,240 to 22,481 lbf (50 to 100 kN), 23.62 in/min (600 mm/min) for 44,962 to 67,443 lbf (200 to 300 kN), 12.99 in/min (330 mm/min) for 112,404 to 134,885 lbf (500 to 600 kN), and 11.81 in/min (300 mm/min) for 224,809 lbf (1000 kN). Return speed on lighter models reaches up to 47.24 in/min (1200 mm/min), with proportionally lower values on higher mass frames.

This range supports fine strain rate control for metals and composites, creep dwell segments, and micro-displacement work, while higher peak speeds reduce nonproductive positioning between tests. Heavier capacity frames use larger screws, gear ratios, and motor tuning that prioritize force authority and stiffness, which is why their maximum traverse and return speeds are lower. If your method targets a constant nominal strain rate, select a frame where your required speed sits within roughly 20 to 80 percent of the listed maximum, which maintains servo headroom under load and stabilizes velocity near yield.

If you would like to compare capacities and speed options in more detail, you can review the specifications on the

TM-EML Series D UTM product page.

What Ultra-Low Strain-Rate Capabilities Are Available for Creep and Stress Relaxation Testing?

The TM-EML Series D electro-mechanical UTM supports ultra-low deformation work with a minimum crosshead speed of 0.00000197 in/min (0.00005 mm/min). Class 0.5 load accuracy and position feedback resolution down to 0.000000374 in (0.0095 µm) allow the system to track very slow creep strain and gradual force relaxation with stable feedback. Closed-loop control with 1200 Hz acquisition keeps force, displacement, and extensometer signals synchronized during extended holds and ramps.

With appropriate extensometry, including clip-on, video, or high-temperature gauges, strain-rate control can reach approximately 0.00007 s^-1, supporting long-duration tests on high-strength metals, polymers, and high-temperature alloys. The control architecture maintains steady load or displacement holds for multi-hour or multi-day sequences, supports user-defined logging rates, and applies programmable limits to protect specimens and tooling. Optional high-temperature fixtures and environmental chambers may be used when thermal stability is required.

If you would like to review ultra-low rate capabilities and specifications, you can explore the

TM-EML Series D Electro-Mechanical Universal Testing System on the product page.

How Does Return Speed Vary Across the Force Capacity Range on Electromechanical UTM Frames?

Return speed scales with frame capacity to balance throughput and stability. On electromechanical frames in the 11,240 to 22,481 lbf (50 to 100 kN) and 44,962 to 67,443 lbf (200 to 300 kN) ranges, the maximum return speed is about 47.2 in/min (1200 mm/min). This clears the test space quickly between specimens while keeping motion smooth for setup and grip changes.

For heavier systems, the motion is moderated to protect the load frame, grips, and long-travel accessories. Frames rated 112,405 to 134,885 lbf (500 to 600 kN) return at up to roughly 19.7 in/min (500 mm/min). The 224,809 lbf (1000 kN) platform returns at up to about 15.7 in/min (400 mm/min). Lower return speeds on high-capacity machines reduce vibration, prevent overshoot during long crosshead moves, and help operators maintain alignment on consecutive tests, which supports steady sample throughput without shock to the structure.

If you would like capacity-specific details, you can review speed ranges and configuration options on the

TM-EML Series D Universal Testing System product page.

How Does the TM-EML Series D Protect Load Cells From Overload and Lateral Forces?

The TM-EML Series D combines software safeguards with a mechanically aligned load train to protect the load cell during high-force testing. An overload cutoff trips at roughly 103 percent of the load cell’s rated capacity and immediately stops crosshead travel when that threshold is exceeded, which helps prevent shock damage during sudden specimen fracture or setup mistakes.

Mechanically, the load cell stack uses centered mounting faces, rigid couplers, and tight-fit interfaces that keep the force line on the column centerline. By maintaining coaxial loading, side forces, bending moments, and other off-axis stresses are diverted away from the sensing element. Real-time spike detection in the control loop adds another layer of protection by halting motion when abnormal force changes appear. This integrated approach reduces the chance of overload or lateral damage and supports long-term calibration stability and sensor life in high-capacity applications.

If you would like a deeper look at protective features and capacity options, you can review technical details on the

TM-EML Series D UTM product page.

Does the TM-EML Series D UTM Support IEEE 1451.4 TEDS Auto-Recognition for Load Cells?

Yes. TM-EML Series D supports IEEE 1451.4 TEDS auto-recognition. When a TEDS-capable load cell is connected, the controller reads the embedded memory and applies the correct capacity, calibration constants, engineering units, and sensor ID without manual entry.

In daily use, this enables rapid changeovers between lower and higher capacity sensors, with the correct force range and scaling applied as soon as the load cell is installed. The system also sets polarity and zero for tension or compression, activates appropriate protective limits, and records the load cell identification for traceability in test results. This workflow reduces setup time, helps avoid configuration mistakes, and keeps results consistent when labs switch frequently between different test programs or materials.

If you would like to review related specifications and controller features, you can explore details on the

TM-EML Series D UTM product page.

How Does the D-Class Electromechanical UTM Protect Brittle or High-Strength Specimens During Gripping and Preload?

The D-Class electromechanical UTM reduces the chance of cracking or grip marks during setup by combining low-speed jog control, adjustable approach parameters, and high-rate force feedback. Operators bring the crosshead into contact gradually, apply only a seating load, and the closed-loop controller samples force at 1200 Hz, halting motion if a sudden load spike appears.

For brittle or high-strength specimens, the frame supports pneumatic or mechanical grips that apply controlled, repeatable clamping pressure. With pneumatic grips, a regulator and gauge let staff set pressure that matches the material and surface finish; with mechanical grips, torque-limited actuation helps avoid localized overstress. Alignment features and seating routines keep bending low before the test, and preload ramps with short dwells stabilize the load prior to the programmed strain rate. These practices align with common methods used for metallic tension testing, such as ASTM E8 and ISO 6892-1, when applicable. The result is uniform gripping, predictable preload behavior, and fewer damaged samples across production and R&D workflows.

If you would like to review gripping options, seating control, and load feedback features, you may explore the details on the

TM-EML Series D UTM product page.

What Built-In Safety Features Protect Operators and Equipment on the TM-EML Series D UTM?

The TM-EML Series D uses multi-layer safety logic that tracks force, crosshead displacement, and motor status in real time. Overload protection activates at approximately 103 percent of rated capacity, stopping motion and removing drive torque to protect the load cell and frame. Collision detection monitors rapid force spikes, then halts the crosshead to avoid secondary damage during sudden specimen breaks.

Hardware and software limits work together: mechanical limit switches define the physical travel bounds, while programmable stroke limits and soft limits confine test travel within user-set windows. Sensor-range protection blocks data channels from exceeding their calibrated range, preventing over-range conditions that can corrupt results or stress components. A dedicated emergency-stop circuit cuts power to drives independently of the control PC, giving operators a fast way to stop the test during fixturing, pre-load, or unexpected behavior.

If you would like a deeper look at the protection logic and system ratings, you can review specifications on the

TM-EML Series D UTM product page.

Does the TM-EML Series D UTM Offer an Optional Full Protective Safety Enclosure?

Yes. The Series D can be supplied with a full protective enclosure featuring an aluminum-reinforced frame and impact-resistant polycarbonate panels. It surrounds the test zone to help contain debris from specimen breaks, grip releases, or hardware fragments during high-force work.

The enclosure integrates a safety interlock that ties directly into the motion controls. When the door is open, crosshead movement is inhibited and a test cannot start; motion is restored only after the door is closed and latched. Clear panels maintain visibility for monitoring and camera use, while the rigid frame supports routine grip changes and fixture swaps without removing the shield. Labs running high-strength metals, thick composite laminates, brittle materials, or tests at elevated load or temperature often add this option to reduce risk exposure and comply with internal EHS policies. The design supports daily throughput by allowing fast access to the workspace without compromising operator protection.

If you would like to review the enclosure option and other safety features, you can explore details on the

TM-EML Series D UTM product page.

What Extensometer And Strain Measurement Options Are Recommended For High-Force Testing On The TM-EML Series D UTM?

For high-force tensile and compression work on the TM-EML Series D, recommended options include clip-on strain-gauge extensometers for metals, long-travel clip-ons for large-strain materials, high-temperature clip-ons for chamber use, and non-contact video or optical systems that interface through available analog and digital channels.

Selection depends on specimen behavior, temperature, and the target method. For rigid metals and high-strength alloys to ASTM E8 tension or ASTM E9 compression, low-mass axial clip-ons with appropriate knife edges provide stable readings across 11,240 to 224,800 lbf (50 to 1,000 kN). When elevated temperature or thermal cycling is required, furnace-rated extensometers pair with environmental chambers for strain tracking consistent with ASTM E21. For applications with localized necking, very stiff setups, or where contact is undesirable, video extensometers and digital image correlation systems capture strain without adding mass and can synchronize through the Series D controller I/O. Where elongation is large, long-travel units avoid overrun while maintaining resolution, and for compression on short gauges or thick sections, bonded strain-gauge extensometers or high-resolution displacement with specimen correction are practical options.

If you would like to review compatible strain measurement options, capacities, and software integration, you can learn more on the

TM-EML Series D Universal Testing System equipment page.

Does the TM-EML Series D UTM Support High-Temperature Extensometers for Furnace and Thermal Testing?

Yes. The Series D frame integrates with high-temperature clip-on and furnace-mounted extensometers used inside environmental chambers for elevated-temperature tensile work. These devices maintain accuracy at heat, allowing reliable modulus, yield, and elongation measurement when testing metals, superalloys, or composites.

The controller delivers stable, low-noise strain tracking during thermal expansion, slow strain-rate segments, and long-duration profiles. When paired with an appropriate chamber and grips, the system supports elevated-temperature tension per methods such as ASTM E21 and ISO 6892-2, with extensometer performance classified to ASTM E83. For time-dependent behavior, the platform accommodates creep and stress-rupture routines consistent with procedures like ASTM E139.

Integration options include side-entry or through-chamber feedthroughs, rigid or spring-loaded mounting, and high-temperature cabling routed to minimize thermal drift. Software tools provide strain-channel selection, gauge length input, and drift correction, so labs can run controlled ramp, dwell, and creep sequences with consistent strain control across repeated cycles.

If elevated-temperature testing is part of your program, you may review integration details and accessory options on the

TM-EML Series D UTM equipment page.

Are Non-Contact or Video Extensometers Compatible With the TM-EML Series D UTM?

Yes. Non-contact and video extensometers integrate with the Series D electro-mechanical frame for applications where clip-on gauges are impractical due to gripping marks, high elongation, or thermal conditions.

The rigid column design maintains a clear optical line of sight to the gauge section, and the controller accepts synchronized strain signals from most video-based systems via analog or digital I/O. This lets your test setup capture real-time strain without mass loading the specimen, which is valuable for brittle coupons, thin sections, polymers with wide strain ranges, and work inside environmental enclosures. Operators typically apply gauge marks or a speckle pattern, set lighting, and run a quick calibration so the video extensometer tracks axial strain throughout loading.

When the chosen video extensometer meets the required accuracy class per ASTM E83 or ISO 9513, the Series D can be used to generate compliant results for metals and plastics tests, such as ASTM E8, ISO 527, or ASTM D638. The non-contact approach also supports waveform-driven or strain-controlled profiles by providing stable, high-resolution strain feedback without mechanical attachment.

If you would like to review interface options and optical access details, you can learn more about the

TM-EML Series D UTM on the product page.

How Do Servo Direct-Drive and Synchronous Belt Transmission Improve Motion Control on the TM-EML Series D UTM?

The direct-drive servo couples the motor to the ball screw without a gear reducer, which cuts compliance, lowers vibration, and minimizes mechanical backlash. Paired with a high-rigidity synchronous belt, the drive holds commanded velocity and position tightly, so the crosshead tracks small setpoints at 0.00000197 in/min (0.00005 mm/min) and remains stable up to the model’s top speed.

During fast ramps, waveform or cyclic profiles, and high-load transitions, the belt’s torsional stiffness and the servo’s closed-loop response deliver clean acceleration and predictable deceleration, reducing overshoot and hunting. This helps maintain uniform strain-rate control that labs target for metals testing under methods such as ASTM E8 and ISO 6892-1. The result is smooth, repeatable motion on heavy-capacity frames, consistent crosshead positioning under large inertial loads, and reliable displacement control across the full capacity range, including high-force configurations up to 11,240 lbf to 224,800 lbf (50 kN to 1000 kN).

If you would like a deeper look at motion-control features and capacities, you can review technical details on the

TM-EML Series D Universal Testing Machine product page.

What Is the Position Resolution of the TM-EML Series D Optical Encoder?

The TM-EML Series D uses a high-resolution optical encoder that delivers micro-displacement position resolution down to 0.000000374 in (0.0095 µm), depending on the load frame capacity.

Typical values are approximately 0.000000374 in (0.0095 µm) on 11,240 to 22,480 lbf frames (50 to 100 kN), 0.000000264 in (0.0067 µm) on 44,960 to 67,440 lbf frames (200 to 300 kN), and 0.000000433 in (0.011 µm) on 112,400 to 134,900 lbf and 224,800 lbf frames (500 to 600 kN and 1000 kN). This resolution is available across the usable crosshead speed range, supporting precise strain-rate ramps, very small crosshead increments, and consistent positioning during high-force tensile or compression work. In daily operation, the feedback helps with specimen alignment, seating preloads, low-travel compression steps, and return-to-gauge moves without overshoot. The encoder signal ties directly into the closed-loop servo drive so commanded micro-moves translate into repeatable crosshead displacement across all capacities.

If you would like to review full specifications and model options, you can explore the

TM-EML Series D UTM page for details on encoder performance and displacement control.

What Are the Sampling Rate and Closed-Loop Control Frequency for the TM-EML Series D UTM?

The Series D controller operates at a closed-loop control frequency of 1200 Hz with a real-time data sampling rate of 1200 Hz. Force, crosshead displacement, and extensometer signals are captured and updated at this rate across all frame capacities.

A 24-bit A/D front end on multiple analog channels, paired with dedicated high-speed digital inputs, feeds the control loop for tightly synchronized acquisition. At these rates, the machine follows sharp load or strain ramps, maintains steady setpoints during holds, and reproduces sine or trapezoid waveforms for static or cyclic work. Labs gain crisp yield-point identification on metals, stable strain-rate control for polymers, and reliable modulus, yield, and break calculations from clean, time-aligned data. This behavior is consistent from low to high capacity configurations within the Series D lineup.

If you would like to review controller and data acquisition details, you can explore the

TM-EML Series D Universal Testing Machine page to read more on the product page.

How Does GenTest Handle ASTM, ISO, EN, and GB/T Methods on the Series D High Capacity UTM?

GenTest is delivered with a structured method library that is organized by standard and by test type for the Series D frame range of 11,240 lbf to 224,800 lbf (50 kN to 1000 kN). When you select a method such as ASTM E8, ISO 6892-1, EN metals, or GB/T 228, the software loads the appropriate control mode, speed or strain-rate profile, data sampling, and required result items for high-force tensile, compression, bend, or elevated-temperature testing. Calculations include modulus, offset yield, ultimate tensile strength, elongation, and reduction of area, with report fields matched to the selected specification.

For day-to-day work, operators can duplicate any base method, edit specimen dimensions, gauge length, grip separation, speed ramps, strain control, and acceptance limits, then save the setup as a reusable template for a specific alloy, heat treatment, or product family. Accessory profiles, such as clip-on or video extensometers and furnaces, can be tied to the template so the correct channels and safety limits load with each run. This approach keeps standardized procedures consistent across shifts and labs, supports audit traceability, and shortens setup time when switching between material groups or temperature regimes.

If you would like to review software workflows and high-load capabilities, you can read more on the

TM-EML Series D UTM page.

What Reporting, Graphing, and Data Export Options Does the TM-EML Series D with GenTest Provide?

GenTest on the TM-EML Series D delivers real-time plotting of force versus displacement, stress versus strain, and time-based channels at 1,200 Hz. During a run, you can zoom, autoscale, add cursors, overlay multiple tests, and view up to 12 live channels, including force, crosshead position, extensometer strain, strain rate, and temperature when equipped.

Reports generate automatically with modulus, offset yield, ultimate tensile strength, elongation at break, and other results commonly used in ASTM E8 and ISO 6892 workflows. You can export numeric data as CSV or Excel, and save publication-ready graphs as PDF, PNG, or SVG. Exports capture both raw and calculated values, so labs can archive full datasets, review curves, or process results in external software without losing context.

If you would like a deeper look at data handling features, you can review technical details on the

TM-EML Series D UTM product page.

Does GenTest Support Waveform-Based, Cyclic, and Multi-Stage Test Sequences on Series D UTM?

Yes. GenTest lets you build waveform-based, cyclic, and multi-stage profiles on Series D universal testing systems.

Operators can assemble segment-by-segment programs using sine or trapezoidal waveforms, ramp and dwell segments, loops, creep, relaxation, and hold ramps. Each segment can run under force, displacement, strain, or extension control, with seamless transitions between control modes during the same test. You can set targets such as amplitude, rate, hold time, and cycle count, then trigger the next segment by time, limit value, or an event such as break detection. Closed-loop control supports stable tracking for long holds and low-rate segments, which helps with method development as well as repetitive production testing. Custom sequences can be saved as reusable templates, applied across batches, and shared among users to keep results consistent and setup time low.

If you would like to review advanced sequencing options within our software, you can explore details on the

TM-EML Series D UTM product page.

Which External Sensors, Environmental Chambers, and High-Temperature Fixtures Are Compatible With the TM-EML Series D UTM?

The Series D frame accepts direct integration with high-temperature furnaces, environmental chambers, liquid-bath fixtures, and thermal conditioning units used for tensile, compression, and creep workflows. External devices such as clip-on extensometers, high-temperature extensometers, bonded strain gauges, auxiliary load transducers, temperature probes, and video or laser extensometers connect through the system’s analog channels and high-speed digital inputs. Ethernet and USB interfaces support synchronization with third-party data acquisition hardware and custom R&D accessories.

In practice, labs pair the Series D with elevated-temperature chambers and extensometry for metallic tension tests aligned with ASTM E21 or ISO 6892-2, and with long-duration thermal setups for creep programs consistent with ASTM E139. Analog inputs accept conditioned strain or displacement signals, while digital inputs and encoder taps capture high-rate events during yield, fracture, or dwell segments. This connectivity lets you correlate chamber temperature, specimen strain, and force in a single dataset without separate logging. If you are migrating existing fixtures, standard mechanical adapters and signal breakouts make it straightforward to bring legacy extensometers, thermocouples, or DAQ racks onto the same test profile.

If you would like to review connection options and interface details, you may explore integration guidance on the

TM-EML Series D UTM product page.

How Do I Select Load Capacity and Test Speed for an Electro-Mechanical Universal Testing Machine?

Start with the highest expected specimen load. Estimate peak force by multiplying ultimate tensile strength by the smallest cross section, then choose a frame rated 2 to 3 times higher. Common ranges are 10 kip, 30 kip, and 60 kip (45 kN, 135 kN, and 267 kN). For thin plastics, elastomers, or biomedical parts, 225 lbf to 1,000 lbf (1 kN to 4.4 kN) often suffices.

Match control mode and speed to materials and methods. For metals to ASTM E8 or ISO 6892-1, prioritize strain or strain-rate control with an extensometer, not crosshead speed alone. A practical speed envelope is 0.002 to 20 in/min (0.05 to 500 mm/min); labs running plastics to ASTM D638 or ISO 527 often need up to 40 in/min (1,000 mm/min). Verify rate accuracy of ±0.5 percent and position resolution near 0.00004 in (1 µm) for consistent results.

Use interchangeable load cells so routine tests fall between 10 percent and 90 percent of capacity. For example, pair a 10 kip (45 kN) cell for structural metals with a 500 lbf (2.2 kN) cell for thin polymers or adhesives. Select grips rated above the expected test load and an extensometer with the correct gauge length, such as 1.0 in or 2.0 in (25 mm or 50 mm), to meet specimen geometry and relevant standards.

If you would like specification guidance tailored to your lab, you can review options on the

UTM Electro Mechanical equipment page and connect with our team for configuration details.

How Do I Select Load Capacity, Travel, and Speed for an Electromechanical UTM?

Start by estimating the highest force your specimens will require, then size the frame at 1.2 to 1.5 times that peak. For example, if trials show 8,000 lbf (35.6 kN), a 10,000 to 15,000 lbf (44.5 to 66.7 kN) machine provides headroom for tough batches, larger cross sections, or future programs. Verify the load cell meets Class 1 or better accuracy per ASTM E4 or ISO 7500-1, and confirm resolution is adequate for low-force segments like yield-by-offset.

Match speed and control to your methods. A practical range is roughly 0.002 to 20 in/min (0.05 to 500 mm/min), with stable closed-loop control at very low speeds for modulus, creep, or stress-relaxation work. If you run strain-rate or crosshead-rate procedures in ASTM E8, ISO 6892-1, or ISO 527, ensure the controller supports constant strain rate and easy transitions between method steps. Choose travel that accommodates grips, extensometers, and anticipated elongation; 20 in (510 mm) covers most metals and plastics, while high-elongation materials may need 30 to 40 in (760 to 1,020 mm).

Evaluate the ecosystem. Confirm data acquisition at 1,000 Hz or higher for clean stress-strain curves, compatibility with clip-on or non-contact extensometry, and the availability of tension, compression, and flexure fixtures. Consider safety, power, and lab footprint, for example 120 V single-phase or 230 V single-phase, and plan for calibration and verification intervals aligned to your quality system.

If you would like to review configuration options for electromechanical universal testing frames, you can connect with our team on the

Contact Us page.

How Do I Choose the Right Electromechanical UTM Capacity and Speed?

Start with capacity. Estimate the highest failure load for your specimens, then select a frame rated at 1.2 to 2.0 times that value to preserve measurement linearity and accommodate grips or chambers. Size the primary load cell so typical peaks fall between 50 and 90 percent of capacity. If you also test thin plastics or small wires, add a secondary load cell, for example 50 lbf to 500 lbf (220 N to 2.2 kN). As a reference, if most metal samples break near 8,000 lbf (35.6 kN), a 10,000 to 20,000 lbf (44.5 to 89 kN) frame with a 10,000 lbf (44.5 kN) load cell is a practical choice.

Confirm speed and travel next. A crosshead speed range covering 0.002 to 20 in/min (0.05 to 500 mm/min) addresses common plastics methods in ASTM D638 and ISO 527, and metals preloads or modulus ramps. Plan for at least 30 in (760 mm) vertical travel when using long extensometers, temperature chambers, or long-specimen grips. Look for closed-loop control in force, displacement, and strain, along with high-resolution position feedback and adequate data rates for your material behavior.

Validate compliance and accessories. For metals, verify force calibration to ISO 7500-1 Class 1 or Class 0.5 and ASTM E4, and consider an alignment device per ASTM E1012 for ASTM E8 or ISO 6892-1 testing. Match grips to the application, such as wedge or hydraulic grips for metals and pneumatic grips for thin plastics, and select a clip-on or automatic extensometer meeting ASTM E83 Class B-1 or better.

If you would like personalized guidance on sizing and configuration, you can connect with our team on the

Contact Us page.

How Do I Select Load Capacity, Speed, and Extensometry for an Electromechanical UTM?

Start with the highest expected failure load and specimen dimensions. Choose a frame capacity that covers your peak load with 20 to 30 percent headroom. Use interchangeable load cells so routine tests run between 10 and 90 percent of the cell’s capacity. For example, if aluminum coupons fail near 12 kip (53 kN), a 22 kip (100 kN) machine with a 22 kip cell plus a secondary 2 kip (10 kN) cell delivers both headroom and fine resolution. Typical electromechanical systems span about 225 lbf to 220 kip (1 kN to 1000 kN).

Match speed capability to your methods. For metals guided by ASTM E8, prioritize low-speed stability and closed-loop strain control for yield and modulus work. For plastics under ASTM D638 or ISO 527, ensure the controller holds constant rates across roughly 0.2 to 20 in/min (5 to 500 mm/min), with speed accuracy near ±0.5 percent of setpoint and smooth transitions between preload, approach, and test segments.