A major component of material testing is tensile testing, which is used to determine the strength and performance of materials. However, the financial implications of such testing are quite substantial. For example, the average cost per tensile test is approximately $155. Moreover, investing in a universal testing machine (UTM) can range from $10,000 to $160,000, depending on its capabilities. Considering these substantial expenditures, organizations should critically evaluate their testing strategies.

To better assist you, TensileMill CNC introduces the ROI calculator for an in-house tensile testing solution. This tool was created to provide a comprehensive comparison between the costs associated with outsourcing tensile testing and those incurred when conducting tests in-house. By inputting specific parameters, users can obtain a detailed financial analysis, enabling informed decision-making aimed at cost reduction and operational efficiency.

The purpose of this article is to explore why tensile test costs matter, how in-house testing compares with outsourcing, and how the calculator for in-house tensile testing works. We will also discuss who can benefit from the use of this tool and how it can be used to optimize material testing processes using data-driven decisions.

Why Tensile Testing Costs Matter

For a long time, manufacturers had no way to compare outsourcing versus in-house tensile testing. Building a dedicated lab was considered too expensive, with equipment costs and technical barriers making it unrealistic for most businesses. As a result, companies relied on third-party testing, assuming it was the only cost-effective option.

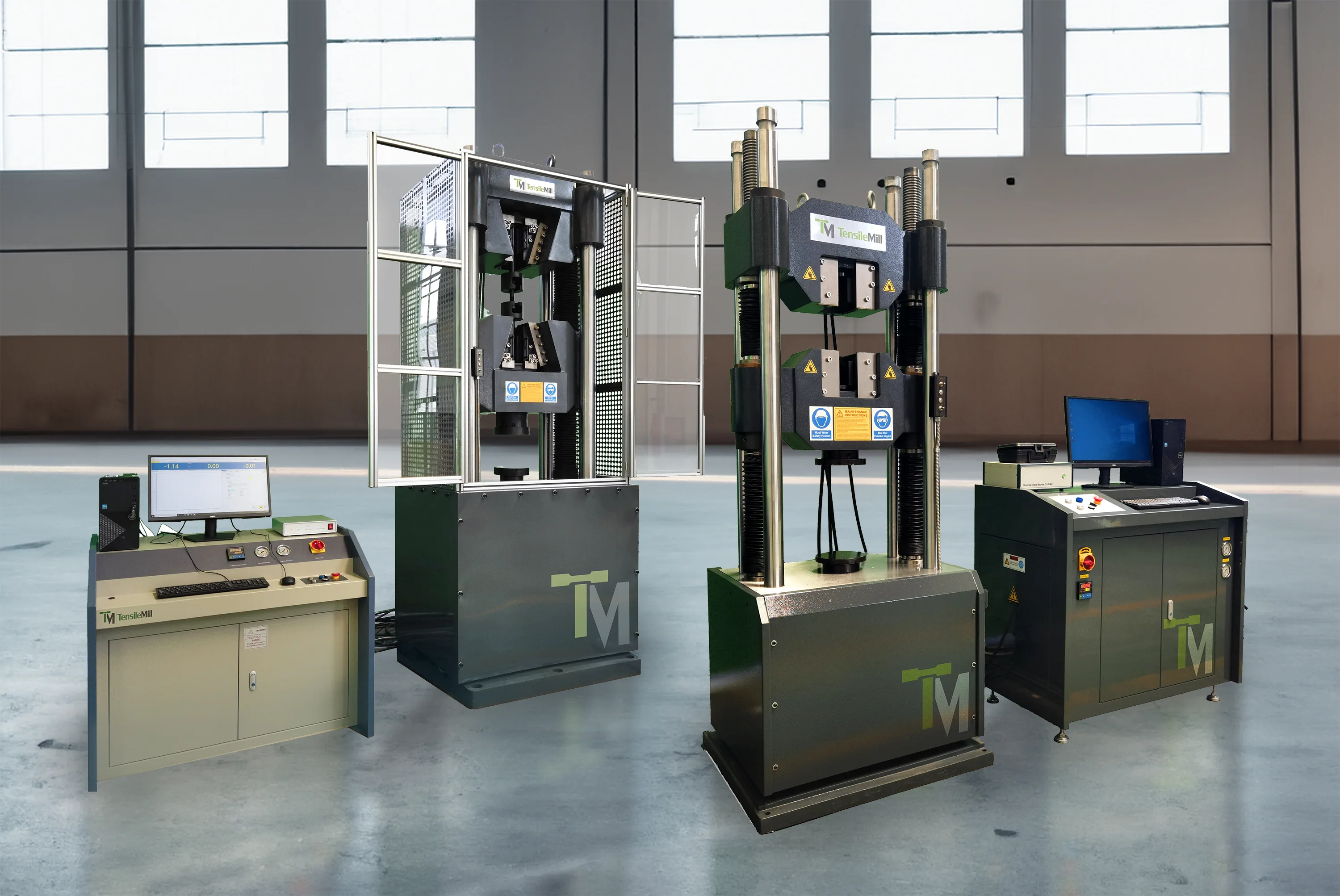

However, the industry is changing. Advances in affordable CNC tensile sample preparation machines and universal testing equipment now allow businesses to perform their own tests efficiently and at lower costs. Many companies are unaware that in-house testing is now a realistic and scalable alternative, offering significant savings and operational advantages.

The ROI calculator for in-house tensile testing helps businesses break outdated assumptions about lab costs. With this tool, companies can quickly calculate their own savings, proving that in-house testing can be financially smarter than outsourcing. For those who prefer expert guidance, we can even prepare a full presentation—so you do not need to do anything yourself.

The Financial Impact of Outsourcing Tensile Testing

Outsourcing tensile testing has hidden costs beyond the per-test fee. The price per test can range from $55 to $280 per sample, but shipping, lead times, and delayed production schedules further increase expenses. Companies often overlook how material holding costs and external lab timelines affect efficiency.

With more affordable equipment now available, outsourcing is no longer the only option. Businesses can now take control of their own testing process, avoiding logistical challenges and unnecessary expenses.

Investing in In-House Tensile Testing Equipment

Previously, in-house tensile testing was reserved for large-scale operations due to high equipment costs. Now, with compact and cost-effective testing solutions, companies of all sizes can set up their own labs. Entry-level machines start at $2,500 to $6,000, while advanced UTMs range from $10,000 to $160,000, offering a more accessible path to in-house testing.

The latest devices require minimal operator training, making it easier to integrate tensile testing without disrupting production workflows. The result is faster test cycles, better control, and long-term savings.

Balancing Costs and Benefits

Until now, many companies assumed in-house labs were too expensive, but with new technology, that is no longer the case. The ROI calculator for in-house tensile testing allows businesses to run their own cost analysis and see exactly how much they can save.

The world is changing, and testing changes with it. Companies that implement cost-effective solutions will not only reduce expenses but also gain a competitive advantage in speed, efficiency, and operational control.

How the ROI Calculator for In-House Tensile Testing Works

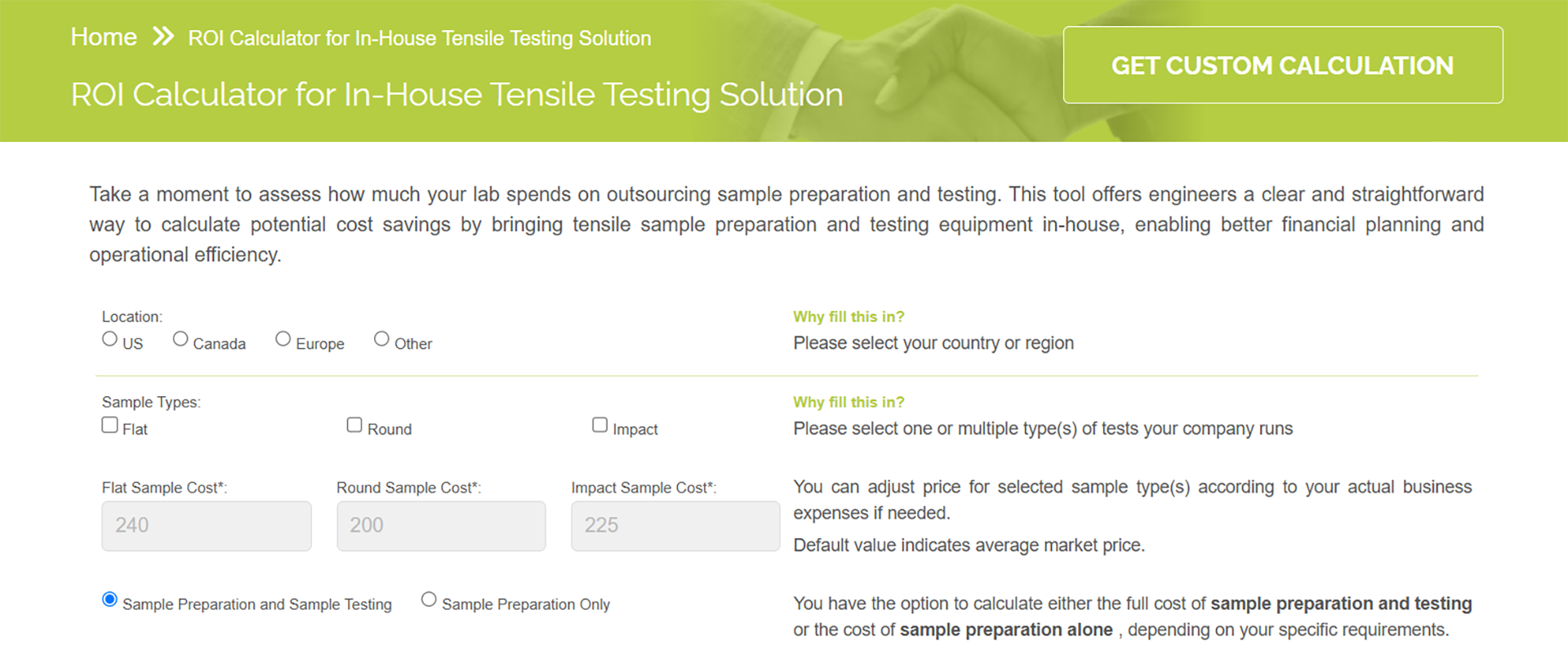

Using the calculator for in-house tensile testing solutions allows manufacturers and laboratories to accurately compare outsourcing costs to in-house sample preparation and testing. By entering key operational parameters, businesses can identify cost savings, improve financial planning, and optimize material testing workflows.

Step 1: Enter Key Testing Parameters

To generate a detailed cost analysis, users enter specific details about their tensile testing process:

- Location Selection – Choose between the United States, Canada, Europe, or Other regions to confirm that cost estimates align with regional market trends.

- Sample Type – Select one or multiple tensile sample types: flat, round, or impact specimens.

- Sample Cost Inputs – The default values are:

- Flat sample cost: $240 per sample.

- Round sample cost: $200 per sample.

- Impact sample cost: $225 per sample.

- These values can be adjusted based on actual business expenses.

- Testing Scope – Calculate the cost of sample preparation only or both sample preparation and tensile testing.

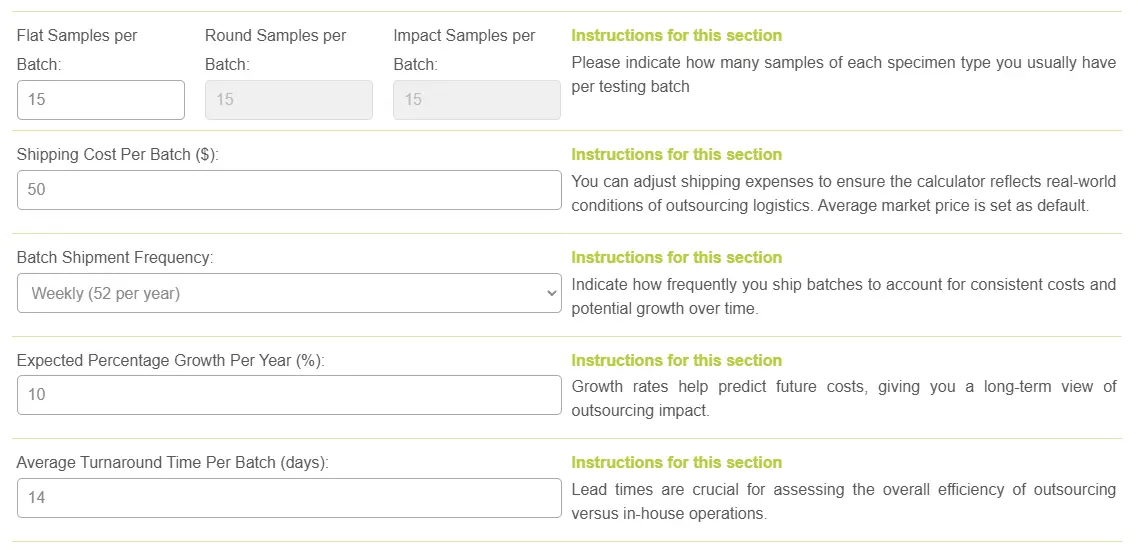

- Batch Size – Input the number of samples tested per batch for each sample type.

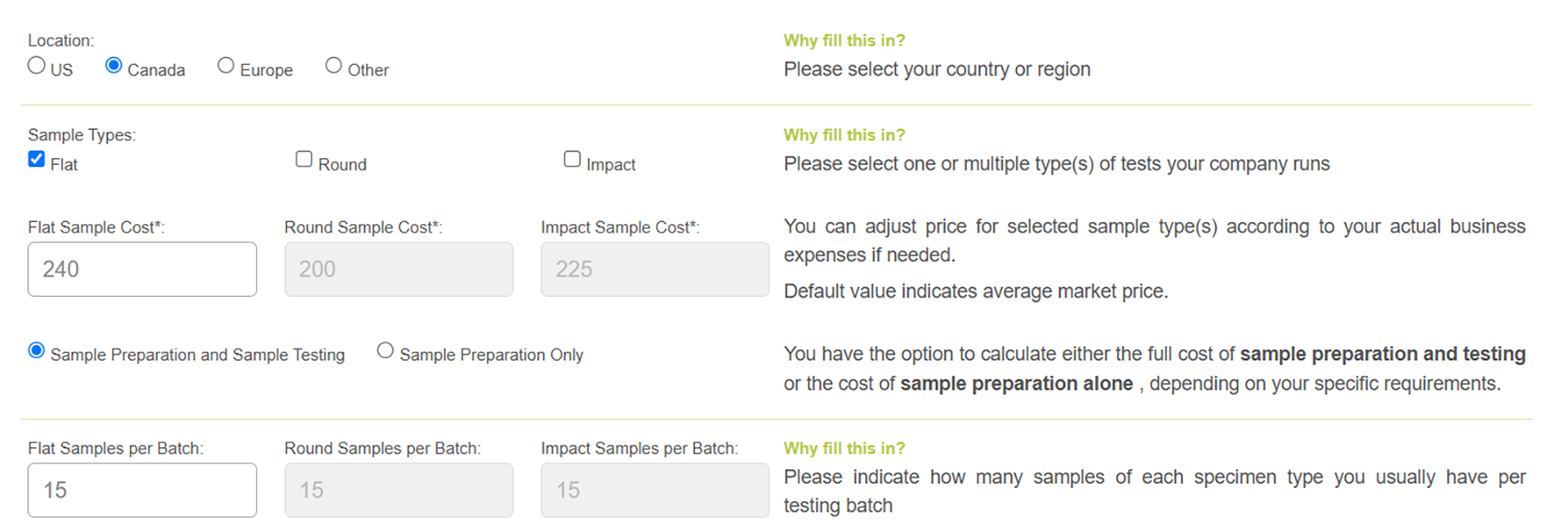

Step 2: Include Additional Cost and Operational Factors

Beyond sample costs, the calculator also accounts for logistics, growth projections, and lead times:

- Shipping Cost Per Batch – The default value is $50 per batch, which can be modified according to real-world shipping expenses.

- Batch Shipment Frequency – Users select shipment intervals, such as weekly, to reflect outsourcing schedules.

- Annual Growth Rate – The expected cost increase per year is set at 10%, helping businesses predict future expenses.

- Turnaround Time Per Batch – The default value is 14 days, showing how outsourcing testing affects production schedules.

Step 3: Generate a Cost Comparison Report

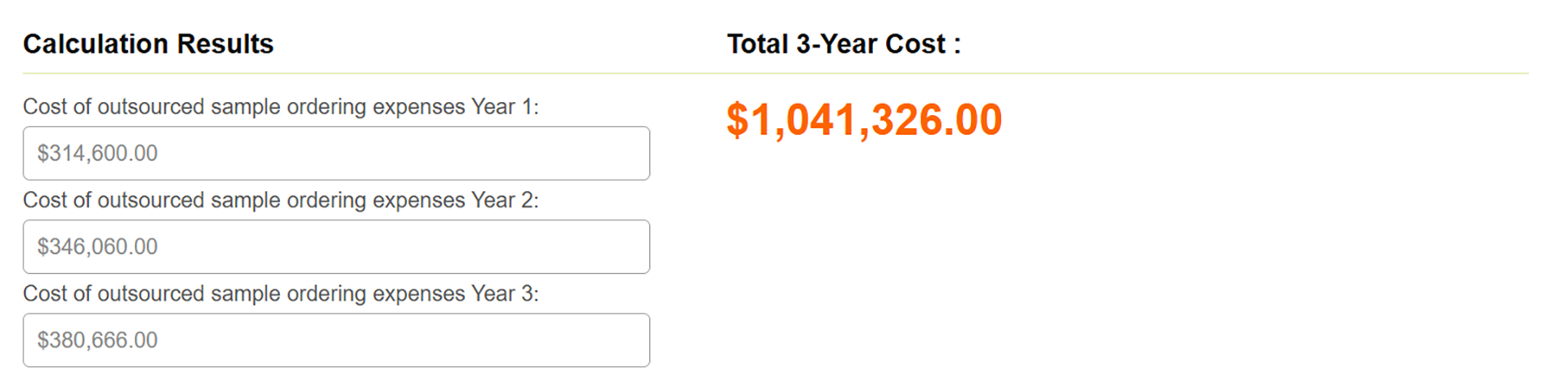

Once all data is entered, the calculator processes the information and provides a detailed financial projection. As an example, here are some numbers:

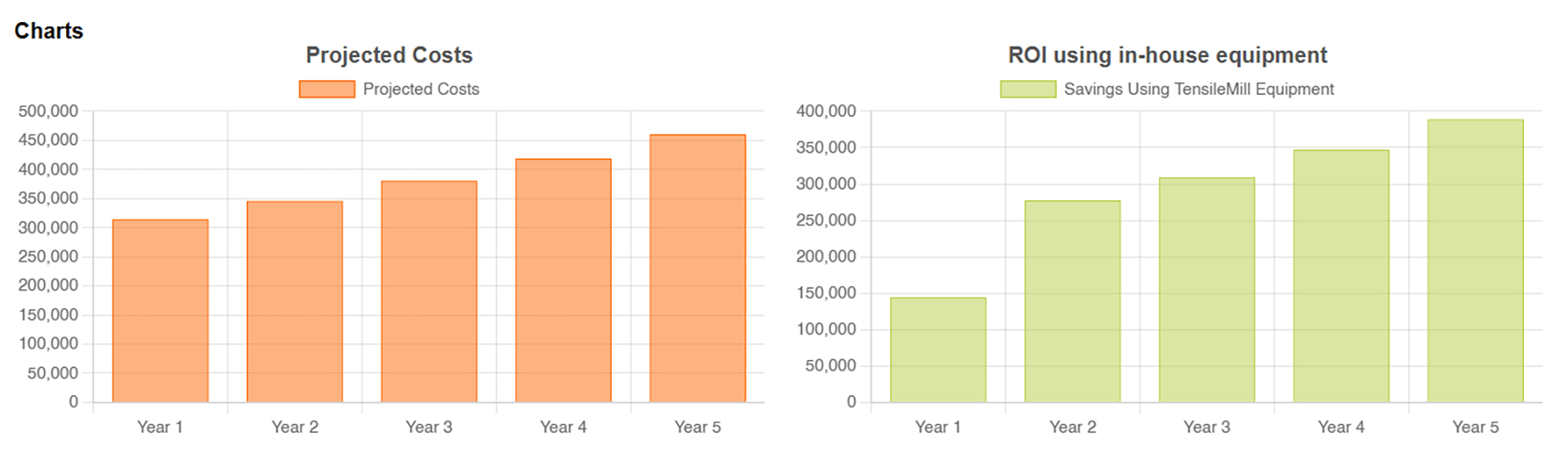

As part of the report, businesses will also be able to view graphical cost projections over time:

Who Benefits from the Calculator for In-House Tensile Testing Solutions?

The ROI calculator for an in-house tensile testing solution is a valuable tool for quality control, manufacturing, financial decision-making, and research and development professionals. Businesses can assess costs, optimize operational efficiency, and make informed investment decisions by comparing outsourcing and in-house testing. Take a look at how different industries and roles can benefit from our calculator.

Quality Control and Testing Laboratories

For quality control and testing laboratories, frequent outsourcing of tensile testing can create delays, increase expenses, and introduce variability. Having a way to calculate the financial impact of in-house testing allows laboratories to evaluate whether investing in their own CNC tensile sample preparation machines is a better long-term solution. By reducing dependency on external testing providers, laboratories can accelerate testing cycles, improve accuracy, and maintain tighter control over material evaluation processes.

Manufacturing and Engineering Companies

Manufacturing and engineering companies in industries such as aerospace, automotive, construction, and metallurgy often require the testing of tensile strength as a routine part of product validation and quality assurance. The ability to quantify the cost of outsourcing versus in-house testing enables them to determine whether bringing sample preparation and tensile testing in-house will reduce overall expenses while maintaining operational efficiency. By shifting to internally managed testing, companies can avoid unexpected outsourcing costs, minimize lead times, and improve workflow integration. For businesses experiencing growth, the calculator also allows them to project long-term cost savings as their testing needs increase over time.

Financial Decision-Makers and Procurement Teams

From a financial and procurement perspective, investing in tensile testing equipment requires justification based on measurable cost savings and return on investment. The calculator provides a structured financial overview, allowing decision-makers to assess when in-house testing becomes economically reasonable. By analyzing both immediate cost reductions and long-term financial benefits, procurement teams can make strategic purchasing decisions that align with company goals and budget allocations.

Research and Development (R&D) Departments

Research and development departments benefit significantly from in-house tensile testing capabilities. Companies focused on material innovation and product development often need to test prototypes and novel materials under different conditions. Outsourcing these tests can slow down development timelines and introduce confidentiality concerns. The calculator helps quantify the cost-effectiveness of internal testing resources. Thus, making it certain that companies maintain faster R&D cycles, better intellectual property security, and greater flexibility in material testing.

Regarding industry or business size, the calculator for an in-house tensile testing solution can assist any organization looking to optimize testing expenses without compromising accuracy or efficiency. With this tool, businesses can analyze testing expenditures, predict long-term savings, and gain a better understanding of how in-house tensile testing equipment can contribute to overall cost reduction and operational efficiency.

Maximizing Cost Efficiency in Tensile Testing

Testing for tensile strength is an integral component of material evaluation, but the associated costs can be quite high, especially for businesses that rely on frequent testing. By comparing outsourcing expenses with in-house testing investments, the ROI calculator for an in-house tensile testing solution provides a clear financial roadmap for laboratories, manufacturers, and decision-makers. Businesses can assess sample preparation costs, shipping expenses, and long-term savings projections, helping them determine whether investing in CNC tensile sample preparation equipment is the right move.

With the ability to reduce turnaround times, avoid third-party expenses, and improve operational efficiency, in-house tensile tests can be a cost-effective solution for companies aiming for increased control over material evaluation. The calculator serves as a practical tool for informed decision-making, allowing businesses to optimize budgets, increase testing efficiency, and optimize quality assurance processes.

If you require assistance or additional information, please do not hesitate to contact us or request an online quote. Our goal is to help you obtain quality tensile testing at a reasonable price.