Universal Testing Machines (UTMs) are multipurpose devices used to evaluate materials' mechanical properties, including tensile, compression, bending, and shear strengths. These machines are indispensable in many industries, from manufacturing to research, making certain that materials comply with necessary standards and specifications. Particularly, UTMs are critical in tensile testing—a method that measures strength and ductility by stretching it until it breaks.

In today's market, the range of available testing machines is vast, from basic models suitable for small-scale applications to advanced systems capable of handling complex and high-capacity tests. However, not all of these machines meet the high standards required for precise and reliable testing. Finding a truly dependable and capable machine that consistently delivers accurate results is extremely important.

Thus, we are excited to introduce you to our top selection of testing machines, renowned for their outstanding quality and performance. With decades of experience, TensileMill CNC understands the critical importance of reliable tensile testing equipment. In this article, we will present our top three testing machines, helping you find the right solution customized to your specific needs.

Types of Universal Testing Machines for Tensile Testing

Understanding the differences between the primary types of universal testing machines used specifically for tensile testing is very important. You need to fully understand the main differences before exploring the product details.

Electromechanical Universal Testing Machines

Electromechanical UTMs are commonly used for tensile testing because of their precision. These machines use an electric motor to control the crosshead movement, which applies force to the test specimen. They are ideal for a broad range of materials and applications, offering accurate control over test speed and force. Due to their precision and ease of use, electromechanical UTMs are commonly applied to testing materials with high accuracy, such as plastics, textiles, and composites.

Servo-Hydraulic Universal Testing Machines

Servo-hydraulic universal testing machines, on the other hand, are better suited for testing materials that require higher force applications, such as metals and alloys. These devices use hydraulic systems to apply force, making them capable of handling large test loads. They are often used in industries like aerospace, automotive, and construction where high-strength materials are tested. While they may not offer the same speed control as electromechanical systems, their ability to generate high forces makes them indispensable for certain applications.

Both types of machines are multifunctional and can perform a number of tests, including tensile, compression, bending, and shear tests. The choice between an electromechanical or a servo-hydraulic UTM often depends on the specific requirements of the material being tested, such as the force needed and the precision required in the results.

Understanding the Force Capacities of Universal Testing Machines

Universal testing machines come in a range of force capacities, typically from 10 kN to 5000 kN or more. When choosing a universal testing machine, you must consider its capacity as it directly impacts the types of materials you can test and the applications to which it is suited.

Low-Capacity Universal Testing Machines - 10 kN to 100 kN

UTMs in the range of 10 kN to 100 kN are generally used for testing smaller, less rigid materials such as plastics, rubber, textiles, and other soft materials. These machines are ideal for industries like consumer goods, packaging, and textiles, where precise control of small forces is necessary. For instance, a 10 kN UTM might be used to test the tensile strength of packaging films or rubber materials used in everyday products. These machines are typically electromechanical, providing high-precision force application and measurement.

Medium-Capacity Universal Testing Machines - 100 kN to 1000 kN

Machines with capacities from 100 kN to 1000 kN are versatile and widely used across many industries, including automotive, aerospace, and construction. A UTM with a 100 kN to 250 kN capacity is often used to test metals, composites, and reinforced plastics—materials that require higher forces to achieve deformation or failure. This makes them suitable for testing structural components like beams, metal sheets, and automotive parts. These machines might be electromechanical or hydraulic, depending on the required precision and force.

High-Capacity Universal Testing Machines - 1000 kN and Above

Universal testing machines with capacities of 1000 kN and above are necessary for the heaviest and most demanding applications. These machines are typically hydraulic and used to test high-strength materials such as steel and large metal components. Industries like civil engineering, infrastructure, and heavy manufacturing rely on these machines to perform critical tests on materials that must withstand significant forces, such as those used in bridges, buildings, and large machinery. For example, a 2000 kN UTM might be used to perform tensile tests on large metal beams, making sure they meet structural integrity requirements for use in high-stress environments like bridges or skyscrapers.

The Best Universal Testing Machines from TensileMill CNC

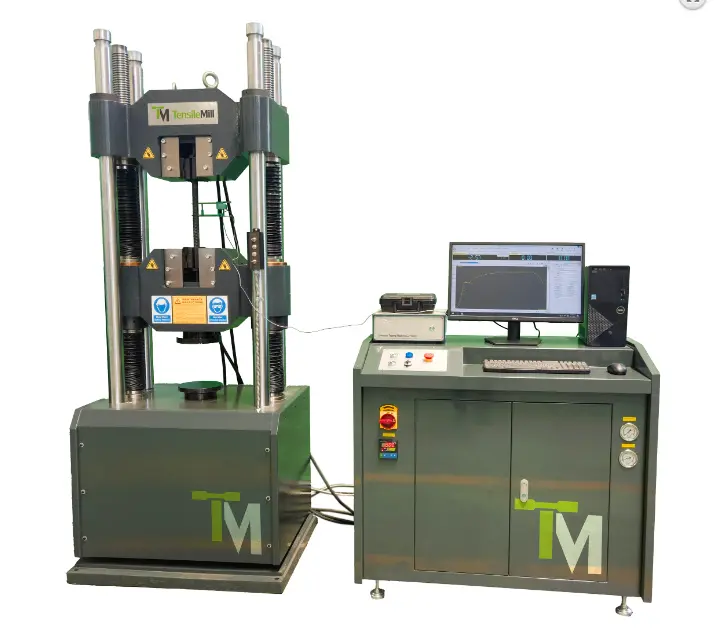

TensileMill CNC is proud to offer a range of high-quality testing machines engineered to meet the diverse needs of many industries. We will highlight three of our most advanced models:

- The TM-EML Series - Dual-Column Floor-Standing Universal Testing System (50kN to 600kN)

- The NG-SHM Series - Servo-Hydraulic Universal Testing System with Precision Load Cell (600kN / 1000kN)

- The TM-SHM2000 Class A - Servo-Hydraulic Universal Testing Machine (2000kN)

The TM-EML Series - Dual-Column Floor-Standing Universal Testing System

The TM-EML Series - Dual-Column Floor-Standing Universal Testing System is a high-precision solution designed to meet diverse metal testing needs. This multi-purpose machine offers a force capacity ranging from 50kN to 600kN (11,200lbf to 135,000lbf), enabling it to test a wide range of materials and components, including metals, building components, large fasteners, composites, and wood products.

Key Features:

- Robust Design: The dual-column, floor-standing configuration ensures stability and durability, accommodating heavy-duty testing requirements.

- High Accuracy: The system achieves a force accuracy of ±0.5% of the reading, making it ideal for applications where precision is critical.

- Wide Force Range: With a capacity from 50kN to 600kN, this machine can handle small to medium-sized materials, providing flexibility in testing different specimens.

- Comprehensive Testing Capabilities: The TM-EML Series supports tensile, compression, bending, and shearing tests, along with extensive extensometer solutions for in-depth material analysis.

- Advanced Control System: Featuring USB 2.0 communication, the control system facilitates seamless data exchange, real-time monitoring, and precision control during testing procedures.

- Efficient Performance: Equipped with high-speed, low-vibration electromechanical drives and pre-loaded ball screws, the machine offers optimal performance and superior alignment during testing.

Technical Specifications:

- Force Capacity: Models available in 50kN, 100kN, 200kN, 300kN, 500kN, and 600kN.

- Calibration Standard: ISO 7500, Class 1 / Class 0.5.

- Crosshead Speed: Variable from 0.001 to 500 mm/min, depending on the model.

- Power Requirements: Range from one-phase 220V to three-phase 380V, with power consumption between 2 kW and 5.5 kW.

- Weight: Depending on the model, the system's weight ranges from 1200 kg to 2000 kg.

The TM-EML Series is designed for laboratories and industries that demand accurate, reliable testing of materials under varying forces, as well as compliance with global standards like ASTM, ISO, DIN, EN, and BS. With its high-resolution digital closed-loop controls and versatile software, this machine is a valuable asset to any testing environment.

The NG-SHM Series - Servo-Hydraulic Universal Testing System with Precision Load Cell

The NG-SHM Series - Servo-Hydraulic Universal Testing System from TensileMill CNC is engineered to provide exceptional performance in high-force mechanical testing applications. With capacities of 600kN and 1000kN, this system is suitable for a broad range of materials and industries, from metals and composites to construction materials and large fasteners. The multi-column design, combined with the precision of hydraulic operation, provides reliable, accurate results even under the most demanding conditions.

Key Features:

- Robust Load Frame Structure: The four-column and two-lead screw design offers maximum durability and stability during testing. This structure is critical for maintaining test integrity, particularly in high-force applications. The dual testing zones provide flexibility, with the upper zone dedicated to tensile testing and the lower zone configured for compression, bending, and shearing tests.

- High Precision Load Cell: Central to the NG-SHM Series is its high-precision load cell, which offers a testing accuracy of ±0.5% of the reading value. This direct measurement method surpasses traditional systems that rely on oil pressure sensors.

- Advanced Measurement Systems: The system includes an optical encoder for precise displacement measurement and a high-precision electronic extensometer for deformation measurement.

- Comprehensive Software Solutions: The EVOTest software provides a user-friendly interface with a broad array of testing functions. It supports multiple control modes such as constant force, constant displacement, and continuous deformation.

- Multi-Layer Protection: The system is equipped with advanced protection mechanisms, including overload protection, position-limit protection for the piston and lower crosshead, and a clearance elimination mechanism between the tensile nut and the leading screw.

- Additional Features: The NG-SHM Series also includes a hydraulic-operated tensile grip, essential for secure clamping of specimens, and a clearance-sealed cylinder piston system that minimizes wear and tear, extending the machine's operational life.

Technical Specifications:

- Capacity: Available in 600kN (134,885 lbf) and 1000kN (224,809 lbf) configurations.

- Testing Accuracy: ±0.5% of the reading value.

- Control Range: Stress rate from 1-60 MPa/S, with a strain rate adjustment range of 0.00025/S-0.0025/S.

- Displacement Rate: Adjustable between 0.5mm/min and 70mm/min.

- Test Spaces: 850mm tensile space, 700mm to 750mm compression space.

- Clamping Capabilities: Clamps round specimens with diameters from φ13-φ60mm and flat specimens with thicknesses from 0-40mm.

The NG-SHM Series is designed to comply with a number of international standards, making it suitable for global applications. These standards include A615, BS 4449, ISO 6892, ASTM E8, ISO 15579-2000, ISO 679, ISO 7438-1985, and JIS Z2241. It is important that the test results are universally recognized and that the materials tested comply with all regulatory requirements.

The NG-SHM Series is an exceptional choice for any organization requiring high-capacity, precise, and reliable testing. Whether in research, development, or quality control, this system provides the advanced features and robust construction needed to meet the most stringent testing demands.

The TM-SHM2000 Class A - Servo-Hydraulic Universal Testing Machine

The TM-SHM2000 Class A represents the pinnacle of our universal testing machines, offering the highest capacity in our lineup at 2000kN (449,617 lbf). This machine is engineered for the most demanding testing applications, where exceptional force and precision are required. This is particularly true in testing high-strength materials like bolts, nuts, and other fasteners.

Key Features:

- High-Capacity Load Frame Structure: The TM-SHM2000 is built with a robust four-column and two-leading-screw structure, ensuring maximum durability and stability during tests requiring high force. The dual testing spaces, with the upper zone dedicated to tensile testing and the lower zone configured for compression and bending tests.

- Precision Hydraulic Operation: The machine features a hydraulic-operated tensile grip system, designed to securely hold specimens and prevent slippage during testing. This grip system, coupled with the precision load cell, ensures that the force applied is measured directly and accurately, achieving a testing accuracy of ±0.5% of the reading value.

- Advanced Measurement Capabilities: Equipped with a displacement encoder and a high-precision load cell, the TM-SHM2000 offers precise force and displacement measurement. The system supports various measurement tools, including clip-on extensometers and large-travel extensometers.

- Cutting-Edge Software Integration: The TM-SHM2000 is equipped with the MaxTest software, a powerful tool capable of supporting multiple load cells and extensometers. The software provides real-time data display and analysis, including multiple curve plotting (e.g., load-time, load-displacement, stress-strain), and highlights critical points such as yield strength and modulus of elasticity. The control system is based on DSP technology with a PCI-E control card, offering three-closed-loop control for load, displacement, and strain.

Technical Specifications:

- Maximum Testing Force: 2000kN (449,617 lbf).

- Tensile and Compression Space: 700mm tensile space and 250mm piston stroke, with clamping capacities for round specimens ranging from φ10-70mm and flat specimens up to 120mm in width and 800mm in length.

- Hydraulic Power Pack: The system is powered by an Italian ATOS servo valve and a Japanese NACHI oil pump.

- Environmental Requirements: Designed to operate effectively at room temperatures up to 40°C with relative humidity levels up to 80%.

- Dimensions and Weight: The load frame measures 1100x1190x3150 mm, and the control cabinet measures 1150x870x650 mm, with a total system weight of 9,000 kg.

The TM-SHM2000 meets many international standards. These standards include ASTM E4 and ISO 75001 for load accuracy, as well as ISO 898-1:1999, ISO 898-2:1992, ISO 898-6:1994, and ASTM F606-07 for testing bolts and fasteners.

This machine is the ultimate tool for laboratories and industrial quality control sectors that require the utmost in testing precision and reliability. With its high capacity, advanced hydraulic system, and comprehensive software, the TM-SHM2000 stands as a critical asset for evaluating the mechanical properties of high-strength materials under extreme conditions.

Choosing the Right Universal Testing Machine for Your Needs

At TensileMill CNC, we pride ourselves on delivering top-notch equipment, particularly our universal testing machines. These machines represent the best of what we offer, designed to meet a broad spectrum of material testing needs. Whether you require precision in metal testing, high-force testing for industrial applications, or versatile equipment that can handle multiple test types, our lineup has the right tool for you.

To recap, the TM-EML Series is ideal for testing metals, building components, and other materials requiring a force range between 50kN and 600kN. This product is perfect for laboratories and industries where precision and flexibility are paramount. The NG-SHM Series is suited to high-force applications, offering capacities of 600kN and 1000kN, and is particularly effective at testing metals, composites, and large fasteners. Lastly, the TM-SHM2000 Class A is designed for the most demanding testing scenarios, providing a 2000kN capacity that makes it ideal for testing high-strength materials like bolts, nuts, and structural components under extreme conditions.

If you are interested in any of these machines, have questions, or want to learn more, please do not hesitate to request an online quote or contact us directly. Additionally, if you are looking for other equipment, such as CNC machines for tensile specimen preparation or sample polishing machines, please explore our related product pages. We are here to help you find the right solutions to your material testing needs.