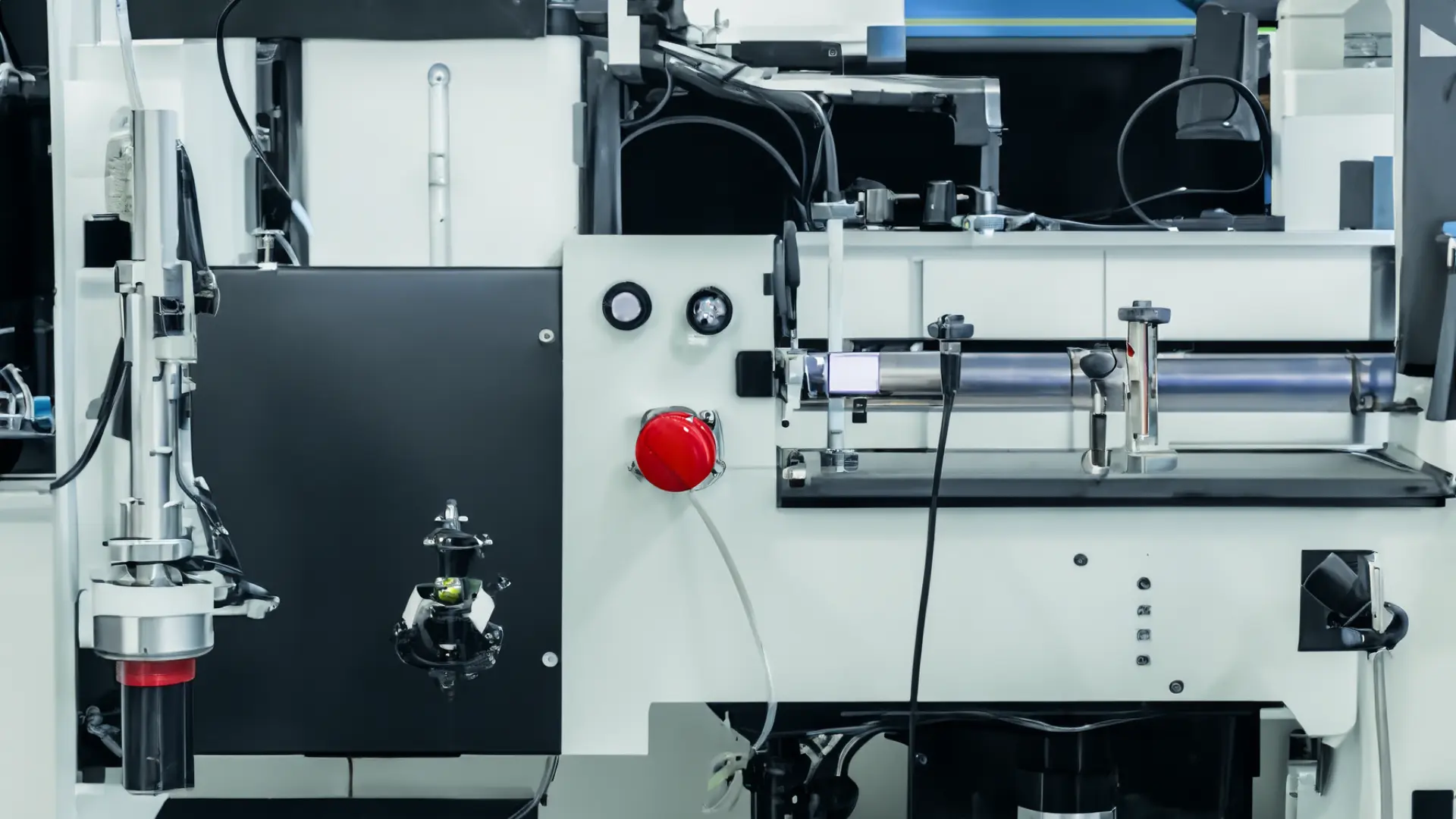

Servo Hydraulic Universal Testing Machines, often abbreviated as UTM, are advanced pieces of equipment designed to test materials' mechanical properties. They determine the tensile, compression, flexural (bending), and shear strength of both raw materials and finished products.

The main principle of these machines is to apply controlled force or displacement to a sample. They monitor its response and analyze the results to determine specific mechanical properties. It provides valuable data about the material's ultimate tensile strength, yield strength, stretch, and index of elasticity. Tensile testing, which refers to stretching a specimen until it breaks, is one of the most commonly conducted tests.

Industries ranging from construction and aerospace to automotive and biomedical actively utilize these machines to ensure materials reliability and safety. By evaluating materials' properties under various conditions, businesses can ensure the quality and longevity of their products. The process is performed in accordance with international standards and regulations.

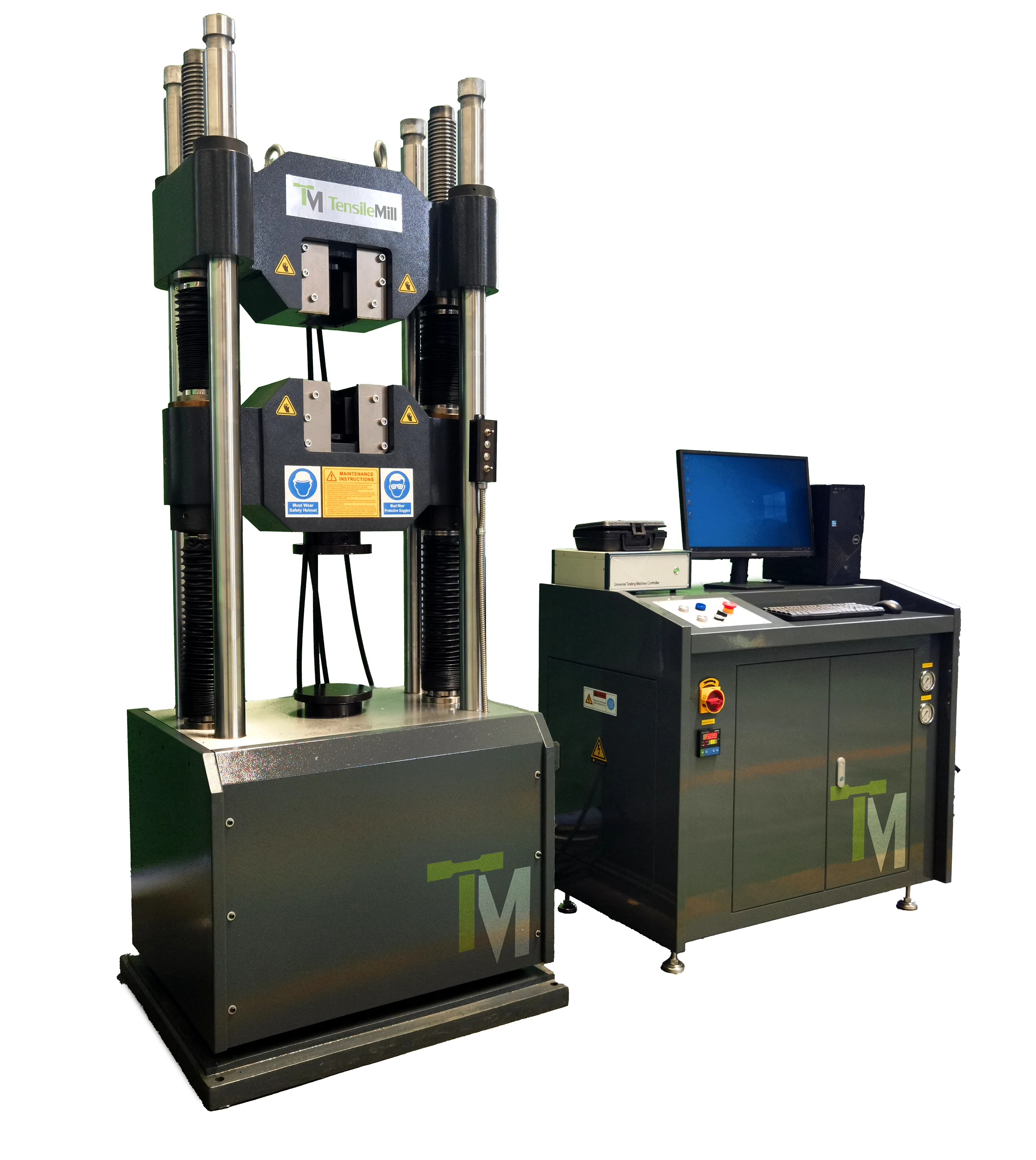

Here in this blog we will provide a comprehensive review of the new NG-SHM Series Servo Hydraulic Universal Testing Machines from TensileMill CNC Inc., detailing its specifications, applications, and unique features related to the field of material testing.

Testing Capabilities of a Servo Hydraulic Universal Testing Machines

Tensile Testing

Let's begin with tensile testing, one of the primary tests conducted using this machine. It provides a comprehensive analysis into the material's ability to withstand forces that stretch, elongate, or pull it in different directions. Tensile testing is crucial for many industries, as it provides data on the material's tensile strength, yield strength, ductility, and modulus of elasticity.

For instance:

- Automotive Industry: Components like seat belts, which are crucial for passenger safety, undergo tensile testing to ensure they won't snap under stress. According to the National Highway Traffic Safety Administration (NHTSA), seat belts, the results of which from tensile testing were high, reduce the risk of fatal injury to front-seat passenger car passengers by 45%.

- Aerospace Industry: The materials used in aircraft wings or turbine blades are also subjected to tensile tests. These materials must endure high tensile loads without failure, ensuring aircraft safety.

- Biomedical Field: Tensile testing is crucial in evaluating surgical sutures' integrity, ensuring their capacity to maintain wound closures effectively. The World Health Organization (WHO) emphasizes that the robustness and reliability of these sutures directly influence the success of surgeries and patient recovery speed.

In addition to tensile testing, Servo Hydraulic Universal Testing Machines offer a broad testing range that includes:

Compression Testing

This test evaluates a material's behavior under forces that reduce its size. Industries such as construction heavily rely on compression tests, especially for materials like concrete and brick.

Flexural (Bending) Testing

Materials like beams or semi-finished products often undergo bending tests to assess their flexibility and resistance to breaking when deformed.

Shear Testing

This test is essential for materials like adhesives and welded joints, gauging their ability to resist forces that aim to slide one layer of the material over another.

Health and Safety Compliance

Health and safety standards are a top priority in all industries. Machines like NG-SHM Series play a significant role in this field. From the food packaging industry, where the integrity of the package is crucial for food safety, to the pharmaceutical field, where pill casings need to maintain their form and operation without degrading, Servo Hydraulic Universal Testing Machines deliver the assurance industries need.

Standardization of Testing Machines

Testing equipment, including models like the NG-SHM Series, must follow internationally accepted standards to establish reliability and credibility in the international market. These standards, developed and maintained by recognized organizations, ensure that the equipment functions within specified parameters and delivers consistent results. The compliance of these standards not only confirms the accuracy and precision of the equipment but also builds trust among industries that depend on such machinery for quality assurance.

Standards of the Servo Hydraulic Universal Testing Machine 2000kN

This powerful testing machine aligns with some of the most stringent international standards, making it an excellent choice for a broad range of industries and tasks. Let's take a look at the list of these standards:

International Standards

- ASTM E4: Specifies machine calibration to measure force. It provides procedures for ensuring that a testing machine accurately reads the force being applied.

- ISO 750001: This and all ISO standards were developed by the International Organization for Standardization to ensure consistency and quality across industries.

Test Standards

- ISO 898-1: 1999, ISO 898-2: 1992, ISO 898-6: 1994: These standards relate to the mechanical properties of fasteners made of carbon steel and alloy steel. They define performance criteria such as tensile strength, yield strength, elongation, and hardness.

- ASTM F606-07: Tests mechanical fasteners' performance criteria like tensile strength, yield strength, and elongation.

- GB/T 1231-2006: Relating to high-strength bolt specifications and quality requirements.

Standards of the Servo Hydraulic Universal Testing System 600kN / 1000kN with Precision Load Cell

International Standards

- A615: Specifies the requirements for deformed and plain carbon steel bars in concrete reinforcement.

- BS 4449: A British standard detailing the specification for carbon steel bars for concrete reinforcement.

- ISO6892: This is a method for tensile testing at room temperature, mainly applicable to metallic materials.

- ASTM E8: Covers the tensile testing of metallic materials defining methods for determining yield strength, elongation, and tensile strength.

- ISO679: Determines the setting time and stability of cement.

- ISO7438-1985: Specifies a method for bend testing of metallic flat materials of thickness up to 3 mm.

- JIS Z2241: A Japanese industrial standard that outlines the method of tensile testing for metallic materials.

The 600kN / 1000kN Servo Hydraulic Universal Testing Systems with a Precision Load Cell

Let's begin our overview of the NG-SHM Series with the 600kN and 1000kN systems. Engineered with incredible attention to detail, they have an accuracy level refined to ±0.5% of the reading value. Truly a benchmark in its category, the NG-SHM Series seamlessly addresses a wide range of testing requirements, from tensile and compression to shearing and bending, highlighting its adaptability and significance in diverse industrial contexts.

600kN & 1000kN Servo Hydraulic Universal Testing Systems

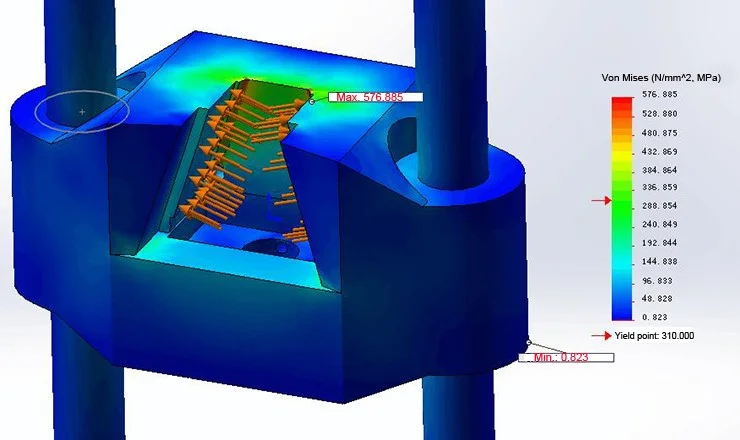

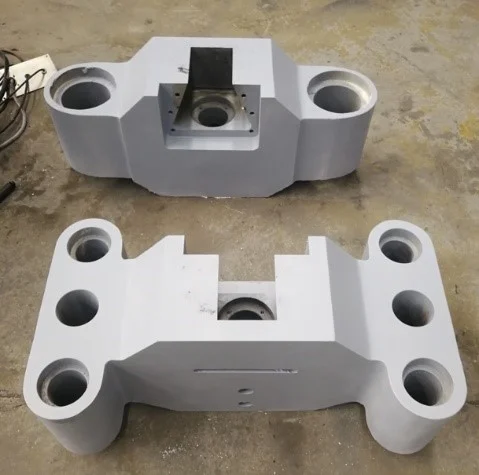

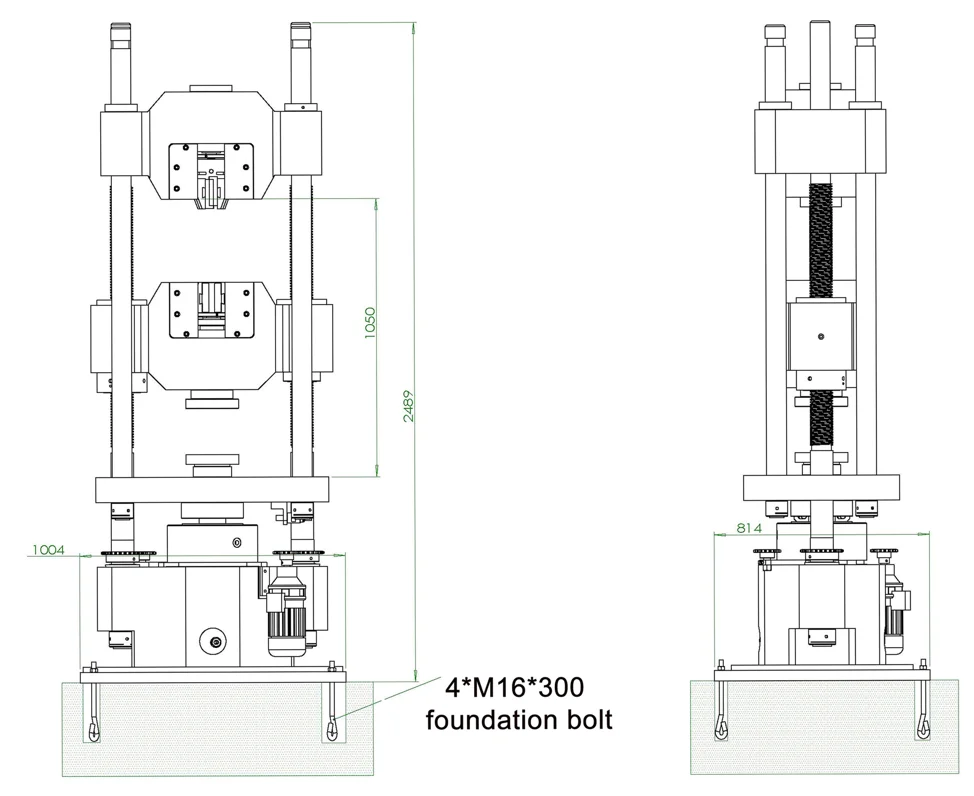

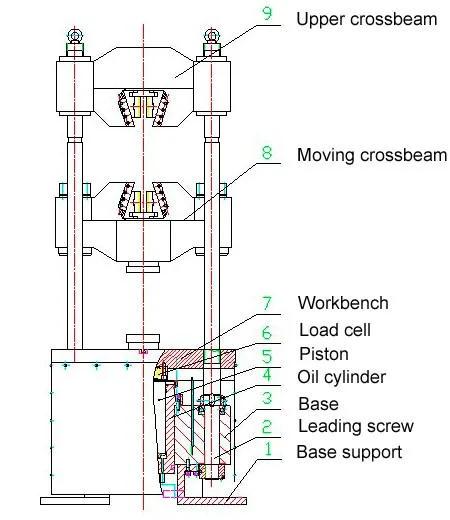

At the heart of the system lies the load frame. Robustly constructed from cast steel, its design is defined by a four-column and two-leading screw structure, which guarantees high stiffness and ultimate safety. This unique design offers dual testing spaces. While the upper section is primarily used for tensile tests, the lower section is adept at compression, bending, and shearing tests. To provide increased flexibility during tensile testing, the upper space is adjustable.

A key component of this system is the hydraulic-operated tensile grip. It features a high-stiffness wedge-type grip. The grip's feature is its unique structure, which ensures stability during tests, allowing materials to be held securely.

There is no place for uncertainty in the measurement process. The load measurement utilizes a high-precision load cell that promises unwavering accuracy, reliability, and consistency. In addition to this, the displacement measurement employs a state-of-the-art optical encoder known for its precision, while the deformation measurement relies on a high-tech electronic extensometer.

Safety and precision are integrated into the system's features, which is very important. The multi-protection system prevents overloads, safeguards against problems, and ensures that the piston and lower crosshead are locked in place. Adding to the equipment's efficiency is the clearance-eliminating mechanism, which removes any clearance between the tensile nut and the leading screw, promoting consistent loading throughout the test.

Lastly, at its operational core, the machine has a control system that integrates a fully digital closed-loop control mechanism. This system opens the way for fluid transitions between control modes, such as load, displacement, and extension. Supporting this seamless operation is the environmentally-conscious power pack, which is designed to be low-noise and reduces both energy consumption and heat generation, protecting the oil way and promoting long-term efficiency.

Load Frame Structure for Servo Hydraulics Universal Testing Systems 600kN / 1000kN

A key component of the Servo Hydraulic Universal Testing System 600kN / 1000kN is its load frame. It's worth dedicating a section of our discussion to its complexity. At the core of its structure are four columns paired with two leading screws for different testing scenarios.

Ease of operation is assured with a hydraulic-operated tensile grip, which streamlines the testing process. Specifically, the system is divided into two main parts: an upper test space and a lower test space. The former, located between the upper crossbeam and the moving crossbeam, is dedicated to tensile testing. In contrast, the latter, located between the moving crossbeam and the workbench, is designated for compression and bending tests.

The integration of a load cell stands out as a crucial feature, directly measuring the testing force to guarantee accuracy during every phase of testing. In addition to this precision, the system utilizes chain-type transmissions, which are robust and streamline maintenance efforts, making overall upkeep easier and more efficient.

High Precision Load Cell (0.5 class)

Further ensuring the longevity of the system, the clearance seal of the oil cylinder has been designed without the typical O seal ring. This decision helps prevent potential aging or wear-related issues. Lastly, the load frame employs a half-open tensile jaw seat, an improvement over the fully-open type. This configuration guarantees no deformation at the mouth of the tensile jaw seat and ensures no slippage during tensile tests.

Tensile Jaw Seat

As we already mentioned, one of the main features of the Servo Hydraulic Universal Testing System 600kN / 1000kN is its tensile jaw seat. This innovative design is specifically targeted at preventing any deformation by improving the strength around the jaw "mouth". By doing so, the system ensures consistent and high-quality test results and contributes to long-term operational cost savings, emphasizing efficiency and effectiveness.

High-Quality Tensile Jaw for Rebar Tensile Test

The machine employs a wedge-type hydraulic operated tensile grip, which simplifies the testing process, allowing for easy control with just the press of a button. Furthermore, the tensile jaw, a crucial component, is crafted from high-strength alloy steel, specifically 20CrMnTi material. Its manufacturing process is meticulously planned and executed, involving stages like blanking, forging & hammering, carburizing, milling, grinding, sawing, quenching, blueing, and more.

Jaws are notable for their "teeth". They undergo a dual carburization process, achieving a layer thickness of 1.7-2.2mm and a hardness level of 61-65 HRC. Such specifications don't just assure the quality of the component but also promise an extended lifespan, maximizing value for users.

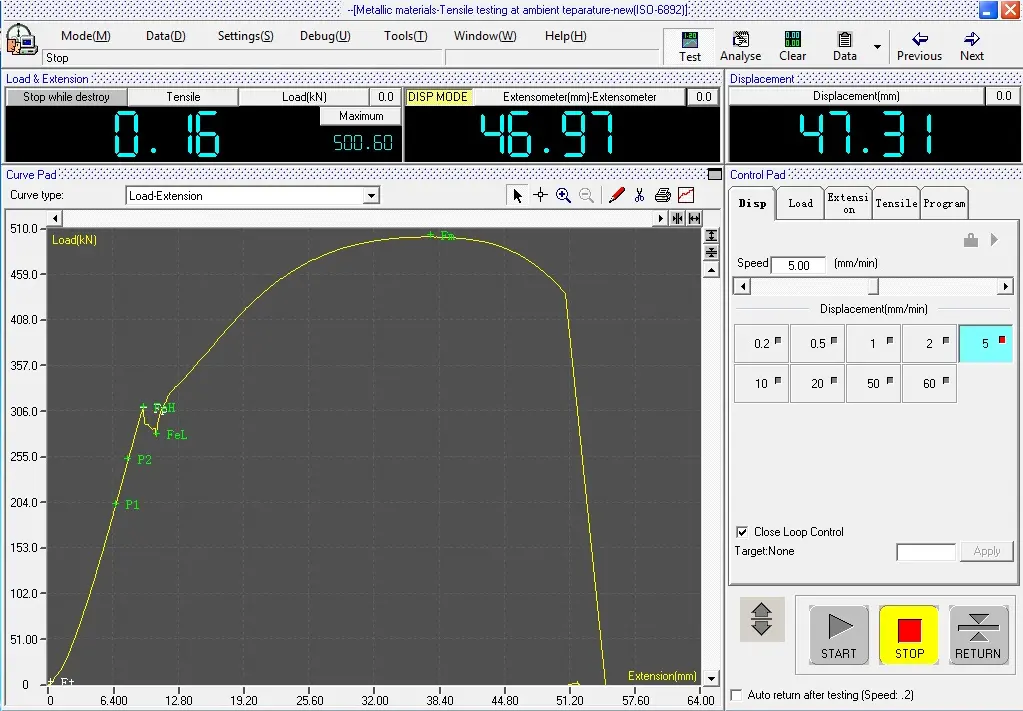

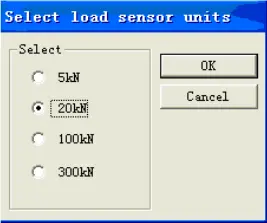

Software Features of the Servo Hydraulic Universal Testing System 600kN / 1000kN

Now, let's take a closer look at the software capabilities of the Servo Hydraulic Universal Testing System 600kN, which are key components in its operation and user experience.

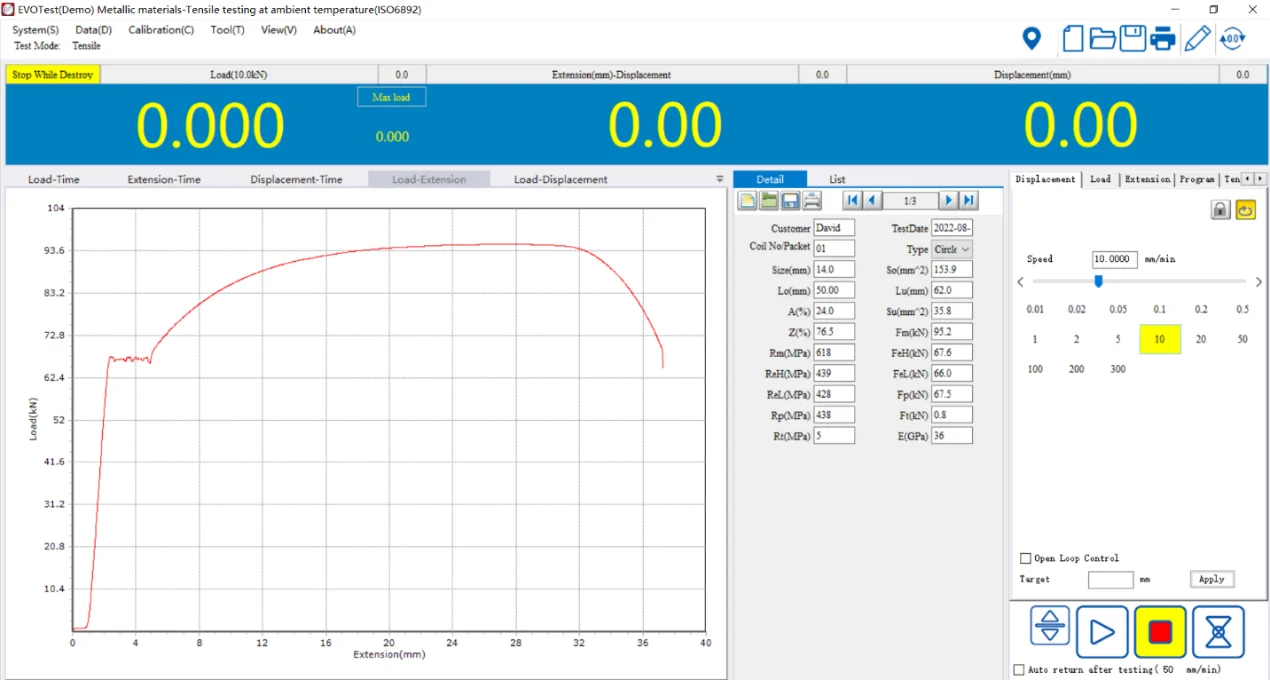

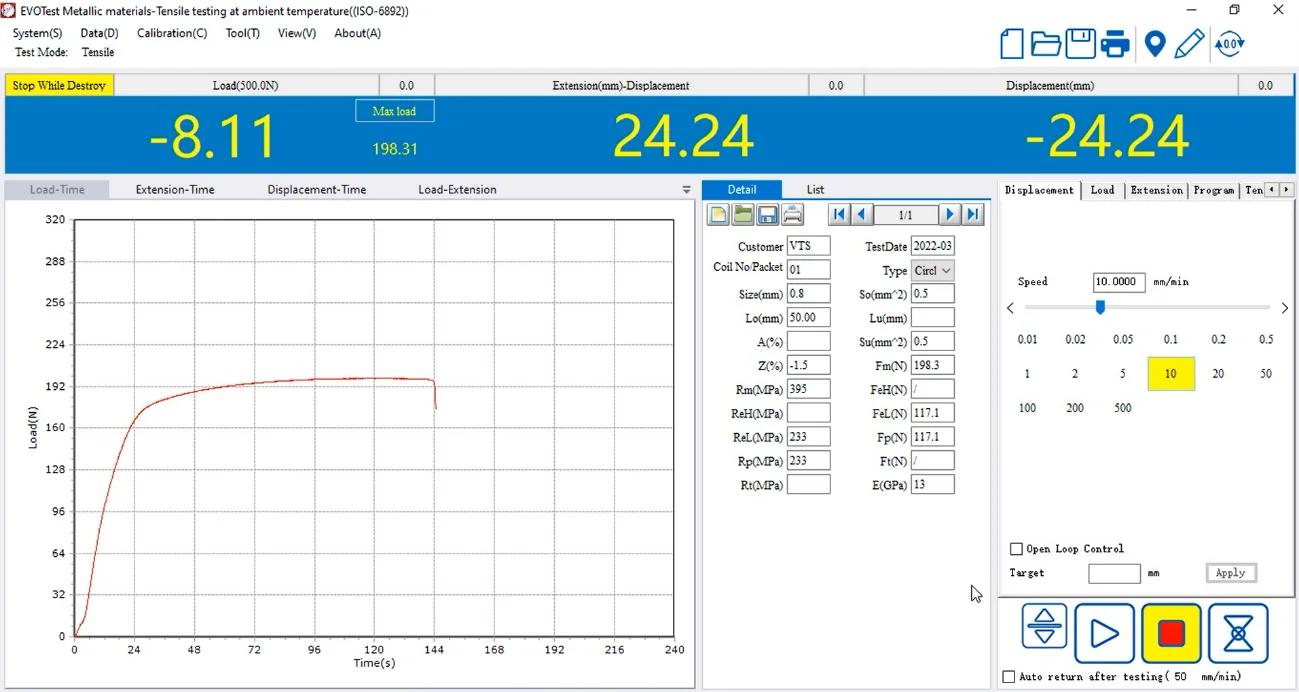

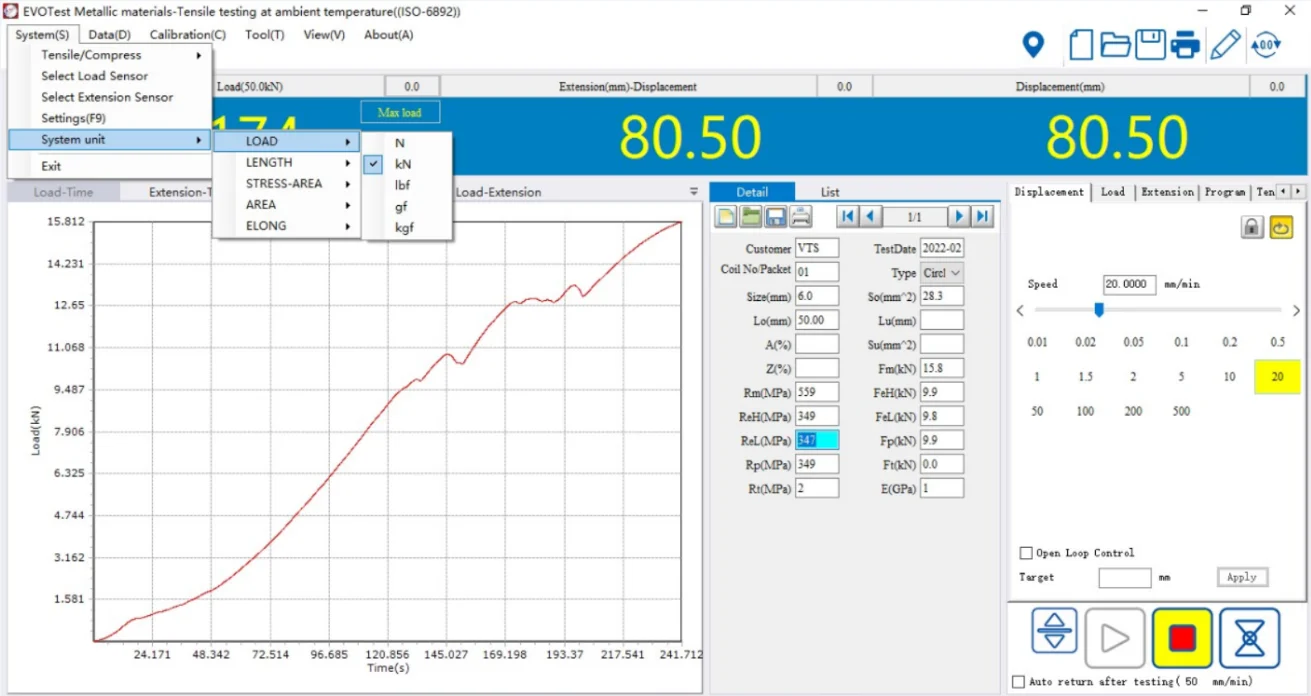

To begin with, the testing system employs user-friendly software named EVOTest. This platform is packed with essential testing functions that streamline the entire process. Operating seamlessly on Windows, it is compatible with Windows 10 and previous versions. A standout feature of this software is its comprehensive library encompassing a vast array of international testing standards, from ISO and ASTM to JIS and BS.

The versatility of EVOTest is evident in its multi-modal control, offering options such as constant force, constant displacement, and variable deformation, to name a few. As tests progress, users are presented with dynamic graphical representations like force-displacement and stress-strain curves. Such visualizations facilitate intuitive understanding, and the software allows users to switch between these visuals for easy observation and comparison.

Moreover, EVOTest introduces an innovative test module, empowering users to set up new tests individually or in batches, according to their requirements. The curve analysis module is another noteworthy feature, allowing users to explore in depth into test curves. It allows specific curve points to be identified using a mouse. Furthermore, for data retrieval, the software's data inquiry module is indispensable. It helps users determine the test data they need, once they input the relevant parameters.

Safety and precaution have not been overlooked either. In situations where the load surpasses 2%-10% of the load sensor's maximum measuring capacity, the software instantly activates an overload protection mechanism. This causes the machine to halt operations automatically. For the user's convenience, the software is equipped with an alert system. This reminds operators to detach the extensometer before a specimen breaks.

Analysis of Tensile Test Curve and Results

In analyzing tensile test outcomes, there are various metrics and units to consider. These units, such as Newtons (N), kiloNewtons (kN), pounds-force (lbf), gram-force (gf), and kilogram-force (kgf), measure the testing force. For length measurements, both inches and millimeters can be used.

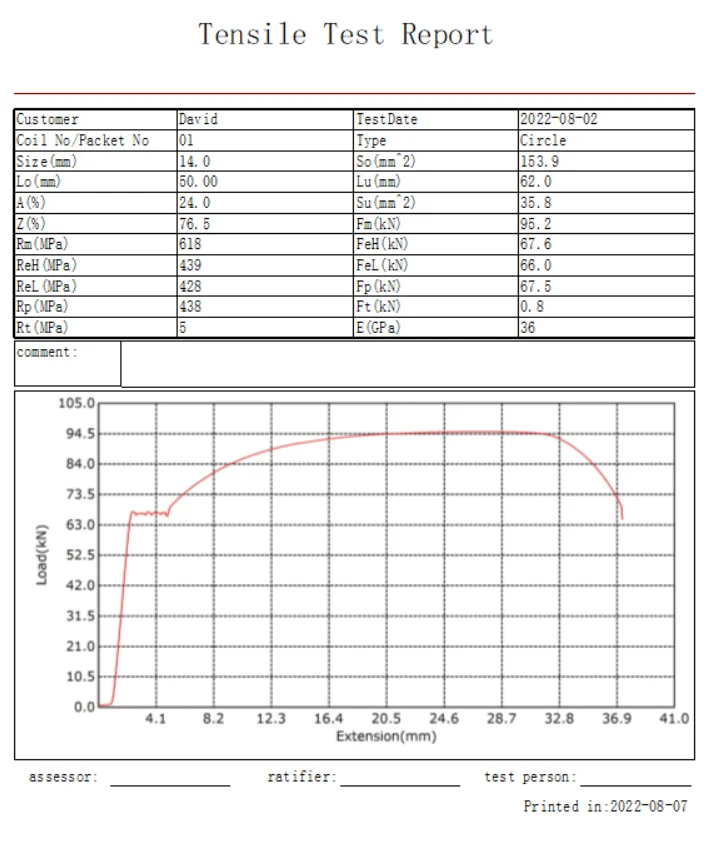

Sample Test Report:

To fully understand these results, it's crucial to define what each metric signifies:

- Lu (mm): Represents the final gauge length post-fracture.

- A (%): Indicates the percentage elongation following a fracture.

- Su (mm²): Denotes the smallest cross-sectional area post-fracture.

- Z (%): Highlights the percentage reduction in the initial area.

- Fm (kN): Stands for the peak testing force applied.

- Rm (MPa): Refers to the tensile strength recorded.

- FeH (kN) and FeL (kN): These represent the upper and lower yield forces, respectively.

- ReH (MPa) and ReL (MPa): These measure the upper and lower yield strengths, respectively.

- Fp (kN): This is the force that has been recorded.

- Rp (MPa): Signifies proof strength, expressed as Rp0.2.

- Ft (kN): Denotes the entire proof force.

- Rt (MPa): Represents the total proof strength measured.

A Closer Look at the Technical Specifications

Let's examine the technical specifications of these systems. For convenience in viewing and comparing between models, we will present data in a table:

|

NG-SHM600 Class A |

NG-SHM1000 Class A |

|

|

Class |

A |

A |

|

Capacity |

600kN |

1000kN |

|

Measure Range Accuracy |

1% to 100% |

1% to 100% |

|

Testing force accuracy |

±0.5% of reading value |

±0.5% of reading value |

|

Control range of stress rate |

1-60MPa/S |

1-60MPa/S |

|

Adjust range of test strain rate |

0.00025/S-0.0025/S |

0.00025/S-0.0025/S |

|

Precision of deformation measurement |

±0.5% |

±0.5% |

|

Precision of displacement measurement |

±1% |

±1% |

|

Control range of displacement rate |

0.5mm/min-70mm/min |

0.5mm/min-70mm/min |

|

Tensile space |

850mm |

850mm |

|

Compression space |

750mm |

700mm |

|

Clamping diameter of round specimens |

φ13-φ40mm |

φ13-φ60mm |

|

Clamping width of flat specimens |

90mm |

120mm |

|

Clamping thickness of flat specimen |

0-30mm |

0-40mm |

|

Diameter of upper and lower plate |

φ200mm |

φ210mm |

|

Piston stroke |

250mm |

250mm |

|

Power supply |

3-phase 4-wire 220V, 60 Hz |

3-phase 4-wire 220V, 60 Hz |

|

Dimension |

Main Unit: 36.22x25.60x90.55-inches / 920x650x2300(mm) Power Box: 43.3x25.2x39.4-inches 1100x640x1000 (mm) |

Main Unit: 39.76x32.00x98.42-inches / 1010x815x2500(mm) Power Box: 43.3x25.2x39.4-inches / 1100x640x1000 (mm) |

|

Weight |

Main Unit: 6614 lbs / 3000kg Power Box: 441 lbs / 200kg |

Main Unit :7716 lbs / 3500 kg Power Box: 441 lbs / 200kg |

The 1000kN model offers slightly more robust features in terms of capacity and specimen handling, while both models are designed specifically for different testing needs.

Standard Accessories of the 600kN / 1000kN Testing Systems

The Heart of the System - Control Units

At the core of the Servo Hydraulic Universal Testing System lies a reliable control PC provided by Dell. This is complemented by the servo control box which operates on a 3-close loop control mechanism. Together, they ensure seamless operation and real-time monitoring.

Valve and Hydraulic Mechanism

Sourced from ATOS, Italy, the hydraulic servo valve is a testament to global standards. The incorporation of an Italian valve ensures quality and precision in fluid control, a crucial aspect of testing equipment of this nature.

Tensile Test Accessories

To facilitate tensile testing on a diverse range of samples, the system comes equipped with two grip sets. For round specimens, there are grips catering to diameters from Φ13-Φ26mm and Φ26-Φ40mm. When it comes to flat specimens, the grips can hold materials ranging from 0-15mm to 15-30mm. These accessories ensure that a large variety of samples can be analyzed without additional equipment.

Compression Test Accessories

Compression testing is facilitated by 200mm platens. This standardized size ensures uniform testing and accurate results, irrespective of the sample in question.

Measuring Units for Accuracy

A high-precision 0.5 class load cell is an integral part of the testing system, ensuring accuracy. Moreover, the photoelectric encoder, designed to measure piston strokes, offers a fine resolution of 0.01mm.

Extensometer for Elongation Measurements

The clip-on extensometer, with a gauge length of 100mm and a maximum extension capability of 25mm, is a valuable accessory for those keen on understanding material elongation.

The 2000kN Servo Hydraulic Universal Testing Machine

Among the NG-SHM series, the Servo Hydraulic Universal Testing Machine 2000kN is the most powerful system. Designed for the most rigorous and demanding tests, this machine is specifically designed to assess the ultimate strength parameters of fasteners. It focuses mainly on bolts and nuts.

Its primary function focuses around evaluating fasteners' maximum testing force and tensile strength. Given the critical role that bolts and nuts play in a multitude of applications, ranging from construction to machinery, the reliability and strength of these fasteners are essential.

One of the defining features of this system is the integration of the precision Italian ATOS servo valve hydraulic power pack. The choice of an Italian ATOS valve underscores our commitment to quality but also guarantees accurate and consistent loading. Coupled with a high-precision load cell, it ensures impeccable testing force measurement.

The product differs from other testing machines because this model has a three-closed-loop control mechanism, encompassing constant load, displacement, and strain. Such a complex control mechanism ensures that testing conditions remain consistent and controlled, leading to consistently accurate results.

The machine tests bolts of varying grades, namely 8.8, 10.9, and 12.9. This encompasses a comprehensive range, catering to various application needs. Additionally, it can handle bolts ranging in size from M6 to M56.

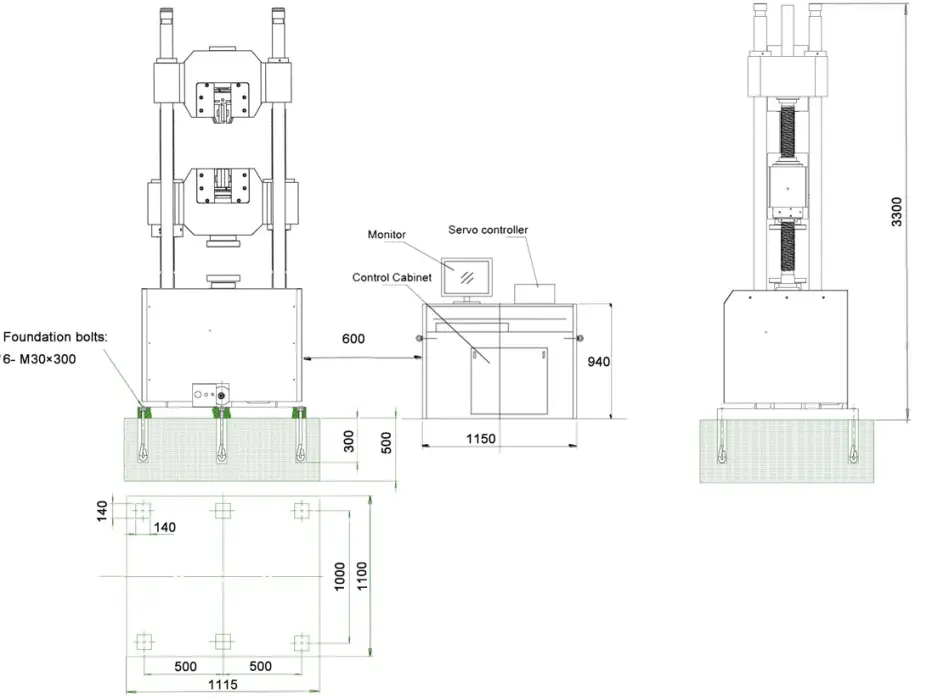

Load Frame Structure of the 2000kN Servo Hydraulic Universal Testing Machine

The Servo Hydraulic Universal Testing Machine 2000kN is unique by its crafted structure, integrating a robust four-column and two-lead screw configuration. This ensures exceptional parameters, providing an excellent foundation for testing scenarios. The incorporation of a hydraulic-operated tensile grip is a key feature, designed to increase simplicity of operation, making it an adaptable piece of equipment for tensile testing.

Strategic designation of testing spaces enhances machine functionality. The upper test space, positioned between the upper and moving crossbeams, is specifically used for tensile tests. In contrast, the lower space, situated between the moving crossbeam and the workbench, is well-suited to perform compression and bending tests. This logical structure ensures each test is conducted in an environment customized to its specifications.

With its high-precision load-measuring device, accuracy is a primary concern in the design of this machine. This direct measurement adds reliability to the testing process. Furthermore, the machine employs a simple chain-type transmission system, simplifying maintenance and ensuring longevity.

The design also extends to the oil cylinder's clearance seal, which does not use O-seal rings to prevent aging and wear issues. Additionally, the inclusion of a half-open tensile jaw seat is a significant enhancement over the fully-open type. It maintains the tensile jaw seat remains straight and securely prevents sliding during tensile testing.

Software Operation of the Servo Hydraulic Universal Testing Machine 2000kN

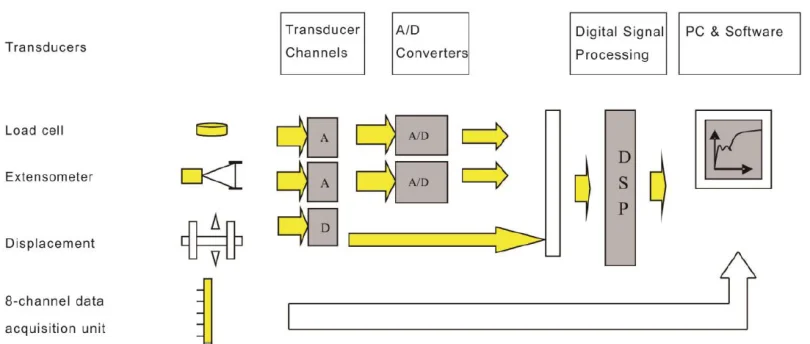

The testing software plays a vital role in devices like these, and there are reasons for that which we will now explain to you. Maxtest testing software, integral to the Servo Hydraulic Universal Testing Machine 2000kN, is a versatile platform compatible with a diverse range of material testing machines. Whether you're dealing with electromechanical UTM, hydraulic servo UTM, screen display hydraulic UTM, or horizontal tensile testing machines, Maxtest software adapts through configuration adjustments.

This software stands out due to its robust interface with four distinct load cells and eight different extensometers. Such diversity allows compatibility with a broad range of extensometers, from clip-on types to video extensometers and large travel variants.

The underlying control system is fortified with DSP technology and incorporates a PCI-E control card, ensuring three-closed loop control that spans load, displacement, and strain. This enables precise execution of various controls such as constant loading rate, displacement, strain, and programmable controls.

For real-time analysis, the software provides live load, displacement, and extension displays. Users can also access multiple curves encompassing metrics like load time, load displacement, and stress strain, among others. Crucially, specific points of interest, including the yield point, Rp, Rm, and elastic modulus, can conveniently be marked directly on the curve for in-depth analysis.

Technical Specifications of NG-SHM2000 Class A Universal Testing Machine

Let's take a look at this list to understand the technical specifications:

|

NG-SHM2000 Class A |

|

|

Class |

A |

|

Max. testing force (kN) |

2000 |

|

Accuracy of testing force |

φ15-φ70 |

|

Round specimen diameter range (mm) |

10-70 |

|

Flat specimen thickness range (mm) |

120 |

|

Flat specimen width range (mm) |

800 |

|

Tensile space (mm) |

700 |

|

Compression space (mm) |

8.8 grade ≤M56 10.9 grade ≤M52 12.9 grade ≤M48 |

|

Bolt test specification |

250 |

|

Max. piston stroke (mm) |

φ15-φ70 |

|

Power supply |

220V / 480V ±10%, 50Hz, three phase |

|

Work environment |

Room temperature~ 40℃ Relative humidity≤ 80% |

|

Dimension of load frame |

43.30x46.85x124.00-inches 1100x1190x3150 mm |

|

Dimension of control cabinet |

45.27x34.25x25.60-inches 1150x870x650 mm |

|

Weight |

19,840 lbs / 9,000 kg |

Standard Configuration of the 2000kN Servo Hydraulic Universal Testing Machine

Main Machine

- Load Frame: This dual space, class 0.5 frame serves as the primary structure for testing operations.

- Load Cell: Conveniently built into the load frame to ensure precise force measurements.

- Displacement Encoder: Essential for tracking and measuring displacement during tests.

- Motor and Speed Reducer: Provides the necessary power and speed adjustments for effective testing.

Power Pack

- Servo Valve: A trustworthy Italian ATOS brand ensures precision hydraulic flow control.

- Oil Pump: Featuring the Japanese NACHI brand.

- Oil Pump Motor: Powers the hydraulic pump to maintain system pressure.

- Solenoid Valves and Filter: Vital components for the hydraulic control system.

- Cooling Fan: Ensures optimal operating temperatures.

- High-Pressure Oil Hoses: Secure conduits for hydraulic fluid, ensuring smooth operation.

Grips and Fixtures

- Bolt and Nut Tensile Holder: Specifically designed according to the customer's bolt and nut's grade and diameter, ensuring an accurate fit for testing.

- Compression Platen: Measuring 210x210mm, it's the primary surface for compression tests.

Controller

- Model: AD-18000. A robust and reliable controller ensures smooth operations and test accuracy.

Software

- MaxTest: A comprehensive testing software that integrates seamlessly with machine operations.

Additional Accessories

- Operation Manual: Provides a thorough guide to machine setup and operation.

- Software Manual: Details the ins and outs of MaxTest software.

- Warranty Card: Offers customers assurance of the quality and longevity of their purchase.

- Quality Certificate: Proof of the high standards maintained during manufacturing.

The NG-SHM Servo Hydraulic UTM Series - the Right Choice for Testing

In the field of material testing, the Servo Hydraulic Universal Testing Machine series which includes the 600kN, 1000kN, and 2000kN model stands out as an example of engineering excellence. These machines, each designed to specific testing capacities, together represent the highest level of precision and versatility in the industry.

Beginning with the Servo Hydraulic Universal Testing Machine 600kN model, it provides an ideal platform for testing tasks requiring moderate force levels. The Servo Hydraulic Universal Testing Machine 1000kN model scales up this capability, handling more robust materials without compromising precision. Last is the NG-SHM Series Servo Hydraulic Universal Testing Machine 2000kN model. Built for the most demanding tensile tests, it has a dual space load frame, a class 0.5 designation, and an integrated load cell. This ensures that even the most intense testing procedures are conducted with maximum accuracy.

Across the series, there's a consistent emphasis on integrating only the finest components. The machines are fitted with world-class parts like the Italian ATOS servo valve and the Japanese NACHI oil pump, each carefully selected to uphold the highest standard.

Our machines offer more than impressive technical specifications. Designed with the complexities of tensile testing in mind, they can handle various bolt and nut grades and sizes, ensuring accurate testing specific to the specific material.

For professionals in need of a comprehensive solution that meets a range of tensile testing requirements, the Servo Hydraulic Universal Testing Machine series offers a combination of precision, durability, and versatility. If you're looking to further understand their capabilities or consider them for your operations, connect with TensileMill CNC Inc. We are here to guide you through every detail and provide you with our tools to achieve success.