Many facilities face several common challenges when searching for a reliable partner in tensile testing. These often include overly complex equipment interfaces that require extensive training, delayed deliveries that disrupt production timelines, and limited technical support that leads to downtime during critical operations. In some cases, equipment arrives incomplete or without proper calibration, making it difficult to meet required testing standards from the start.

At TensileMill CNC, we provide precision equipment and complete solutions for the preparation of flat and round tensile specimens. Our systems are developed to support laboratories, manufacturing plants, and research institutions by offering in-house tensile sample preparation solutions that align with international standards such as ASTM, ISO, CSA, and JIS. We supply CNC milling and turning machines, universal testing machines, and related accessories, including fixtures and tooling. In addition to the equipment, we offer installation support, operator training, calibration services, and lifetime technical assistance. Our goal is to deliver practical tools that help our clients maintain efficient, accurate, and consistent tensile testing processes.

Precision, Simplicity, and Support—Built into Every System

Our equipment is engineered for usability and operational efficiency. Each system is equipped with an intuitive interface that allows operators of all experience levels to perform sample preparation with confidence. This significantly reduces training time and helps prevent common operating errors.

We understand that delivery delays can impact production or research schedules. That is why we maintain efficient lead times and organized logistics to help make sure that equipment arrives on schedule, ready for implementation.

To support long-term performance, we offer reliable calibration services and ongoing technical assistance. From installation through routine maintenance, our team provides continued support, including remote software updates and optional on-site service through our North American partner network.

Every system we deliver is complete with all necessary components, including fixtures, software, setup support, and initial training. This allows our clients to begin testing with minimal delay or additional investment.

Our equipment is engineered to deliver a high return on investment by minimizing outsourcing, reducing operator time, and keeping ongoing operating costs low. Durable construction and the availability of non-proprietary parts further contribute to cost-effective long-term use.

All of our systems comply with international testing standards, including ASTM, ISO, CSA, and other relevant frameworks. Consequently, clients in regulated industries are able to produce accurate, audit-ready results.

Our Equipment Lineup: Purpose-Built for Every Need

At TensileMill CNC we offer a complete range of equipment developed specifically for material testing laboratories and production environments. Our product categories are intended to support the preparation and testing of a range of specimen types in accordance with international standards. Here is our category breakdown:

Flat Specimen Preparation Systems

Our flat specimen preparation machines accurately mill tensile samples from metal and composite blanks. These systems feature a guided interface, enabling consistent preparation with minimal operator input. The equipment supports multiple standard profiles and is suitable for routine testing and high-throughput applications.

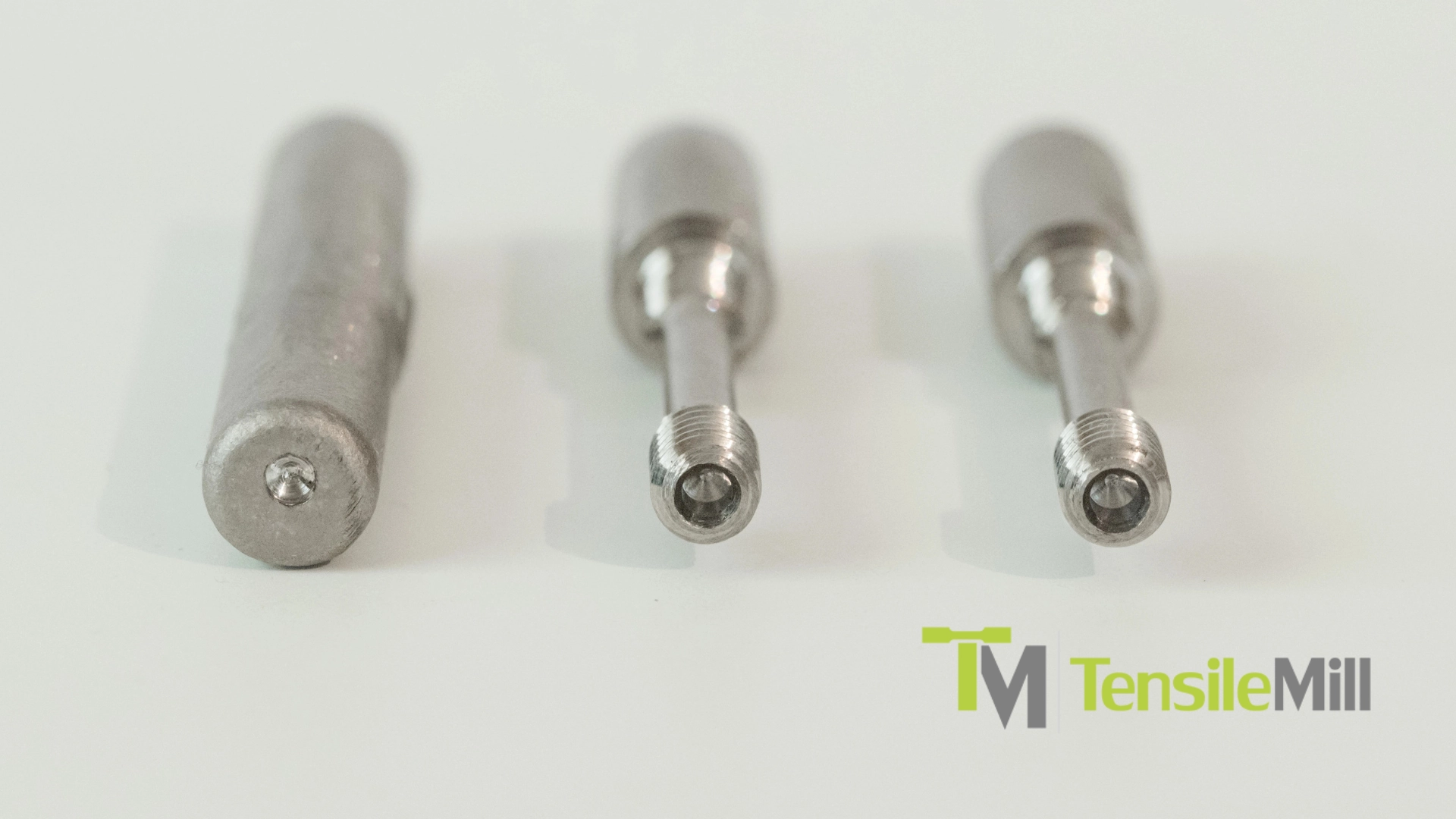

Round Specimen Preparation Tools

We provide CNC lathe-based systems for preparing round tensile specimens. These machines are built for precision and repeatability, allowing users to produce samples that meet strict dimensional and geometric tolerances. The software interface supports standard and custom specimen parameters, offering flexibility across industries.

Impact Specimen Preparation Systems

Our impact specimen preparation equipment enables fast and compliant notching of specimens for Charpy and Izod testing. Engineered for safety and ease of use, these systems help laboratories meet impact testing standards by delivering uniform notch profiles and surface finishes.

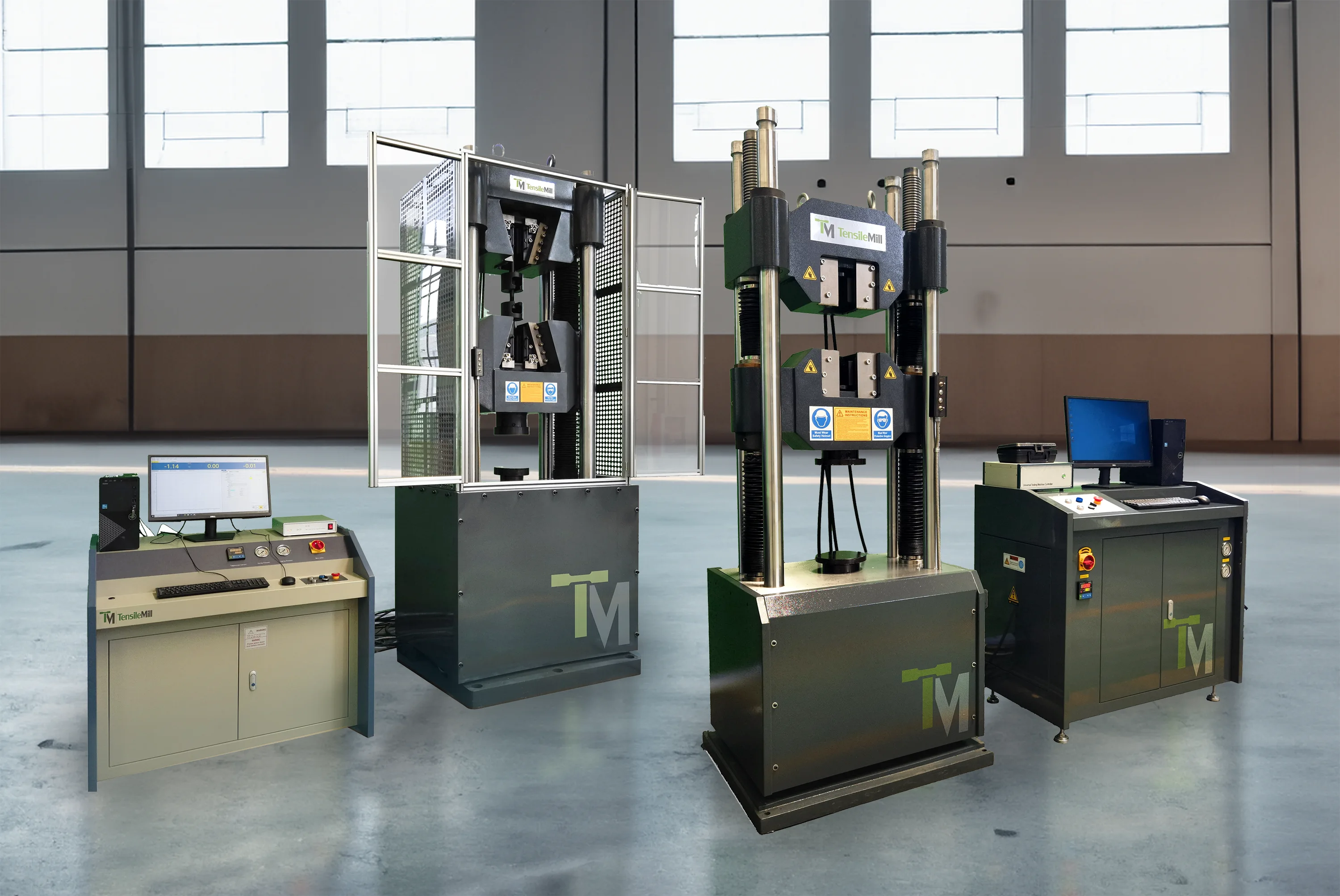

Universal Tensile Testing Machines

Our tensile testing systems evaluate material properties such as strength, elongation, and elasticity. Available in an array of force capacities, these machines are designed for tensile, compression, and flexural testing. They are suitable for both production control and research applications.

Surface Preparation and Polishing Equipment

We also provide polishing systems used to refine tensile and metallographic specimens. These machines contribute to test accuracy by delivering a clean and consistent finish, supporting both visual inspection and mechanical measurement requirements.

Consumables and Spare Parts

To support your continued operation, we offer a range of consumables and spare parts, including cutting tools, clamps, fixtures, and jaws. All components are selected for compatibility and durability, helping to maintain performance while reducing maintenance and downtime.

Smart Solutions for Flat and Round Specimen Preparation

We offer targeted solutions for both flat and round tensile specimen preparation. Our systems are engineered to improve precision, streamline operations, and reduce reliance on external machining services. We help testing facilities save time, lower costs, and improve results consistency by integrating intuitive software and automation features.

As previously mentioned, our machines are equipped with a built-in library of international tensile testing standards, including ASTM, ISO, JIS, and DIN. This allows operators to prepare specimens by the most recognized testing protocols without manual calculations or programming. Simply entering the required measurements or selecting a predefined template enables automatic milling or turning process generation.

By managing the entire specimen preparation process in-house, laboratories can reduce outsourcing delays and gain greater control over sample quality. This results in a faster testing cycle and more predictable timelines for both production and research environments. Additionally, our systems are capable of handling many types of materials, including soft metals, hardened alloys, and difficult-to-machine options such as Inconel and titanium.

In order to give you a better understanding of what we have available in terms of machines for tensile specimen preparation, let us show you two of our bestsellers:

TensileMill CNC MINI – Compact Flat Specimen Preparation Machine

The TensileMill CNC MINI is a compact yet powerful solution for preparing flat tensile specimens under international standards. Despite its small footprint, this system delivers high machining performance. It features a 24,000 RPM water-cooled spindle, a cast iron frame for stability, and a touchscreen interface operated through TensileSoft™. The machine can be optionally upgraded to a full Carbon software package, transforming it into a hybrid CNC milling center.

The MINI is specifically designed for environments where space is limited but high output and precision are required. It supports the preparation of specimens from various materials, including aluminum, brass, heat-treated steel, and Inconel. The standard package includes a complete turnkey setup, enabling immediate use without separate integration or tooling. In quality control departments with shifting personnel, operators with limited or no CNC experience can prepare specimens within hours.

TensileTurn CNC – Industrial Upgrade for Round Specimen Preparation

The TensileTurn CNC - Industrial Upgrade model is a compact CNC lathe system for the efficient preparation of round tensile specimens. Aimed at consistent accuracy, it supports both standard and custom specimen geometries, including threaded ends, button heads, and fatigue test bars. The system features a touchscreen interface with built-in standard libraries, as well as full Carbon software for advanced CNC functions.

Equipped with an 8-position tool turret, automatic center drilling, and a stainless-steel enclosure, the machine is capable of preparing specimens from round, square, or irregular blanks. Its granite base and precision ballscrew contribute to long-term stability and machining accuracy. With a maximum spindle speed of 3,500 RPM and support for various automation functions, the TensileTurn CNC is a practical solution for laboratories and production environments requiring fast, reliable specimen preparation.

Both systems come with comprehensive service plans, preventive maintenance options, and lifetime software updates. Keeping up with evolving testing standards over time allows facilities to maintain consistent performance.

Trusted by Leaders in Every Industry

TensileMill CNC systems are used by a large number of organizations that require accurate and repeatable tensile specimen preparation. Our clients include materials testing laboratories, research and development centers, educational institutions, government bodies, and industrial manufacturers. These facilities rely on precise tensile data to support quality control, product development, and industry compliance.

Our equipment is used to prepare flat and round specimens for tensile, impact, fatigue, and hardness testing. Many facilities produce anywhere from a few dozen to several hundred samples per week, depending on the volume of testing and the material types involved. Our systems support both low- and high-throughput environments.

Over the years, our equipment has been selected by recognized names in the aerospace, automotive, and energy sectors, as well as numerous departments of transportation and leading universities. The decision to use TensileMill CNC systems is often based on the need for reliable performance, ease of operation, and the ability to meet international testing requirements.

At TensileMill CNC, our responsibility does not end with equipment delivery. We provide a complete support structure to guarantee long-term operational reliability and continued alignment with industry requirements. From initial setup to ongoing service, our team remains available to assist with technical, calibration, and software needs.

Each system includes lifetime access to remote software updates. Through our support tools, we can connect directly to the machine interface to install the latest features, implement performance improvements, or assist with troubleshooting. This allows our clients to maintain up-to-date systems without disrupting workflows.

For calibration and maintenance, we offer service packages that include preventive maintenance plans and expert training. These options are designed to extend equipment life and maintain testing results consistency. When requested, on-site support is available through our network of qualified service partners located throughout North America.

Our equipment is built using non-proprietary components. This gives clients the flexibility to source replacement parts quickly from local providers or coordinate with our team for guided support. This approach minimizes downtime and allows laboratories to remain productive during routine service procedures.

Get Started with Confidence

Selecting the right equipment for tensile specimen preparation is an important step toward consistent, accurate, and standard-compliant test results. TensileMill CNC provides practical solutions that address common challenges in testing environments, from ease of use to reliable long-term support.

Our systems were created to simplify daily workflows, reduce preparation time, and support a broad spectrum of materials and testing standards. Each unit is delivered fully equipped and ready to operate, with training and support available from installation.

Whether you are managing routine quality control or conducting advanced research, our equipment is designed to integrate efficiently into your process. For more information on our available systems, service plans, or technical guidance, we invite you to contact our team. You can also request a detailed quotation based on your specific testing needs.