Many people who have heard of tensile testing, or even work around it, rarely think about how the test specimens are actually made. In manufacturing or research labs, the focus often falls on the testing machine itself, while the preparation step remains in the background. Yet this stage determines whether the final results are truly accurate.

In discussions about specimen preparation, CNC machines are often mentioned, yet few outside the testing field realize how different these systems can be. The process of preparing a tensile specimen depends heavily on the machine’s design. CNC systems can differ by geometry, tooling, and method of operation. The two main types are designed specifically for flat or round specimen preparation, and each follows a distinct machining approach.

Understanding how these machines differ helps laboratories produce consistent results and meet global standards. In this article, we will look at how CNC machines work in tensile specimen preparation, examine the unique characteristics of flat and round specimens, compare both types of machines, and discuss how to choose the right one for your testing needs.

What Is CNC Machining and How Does It Work

Before comparing flat and round specimen preparation, it helps to understand the basics of CNC machining. The principle behind these systems is simple: computerized controls guide the machine’s tools with high precision to shape raw material into a defined geometry.

In a CNC setup, a digital model created in CAD software is translated into machine instructions, known as G-code. The program directs the movement of cutting tools along multiple axes, forming parts with exact dimensions and clean surfaces. This automation allows laboratories to produce specimens that match international standards such as ASTM and ISO, with repeatable accuracy and smooth finishes.

One of the main strengths of CNC machining is repeatability. Once a program is set, the system can manufacture many identical specimens without variation. For material testing, this consistency is essential because even slight differences in geometry or surface quality can affect test results. Automated control also saves time: after initial setup, a CNC can machine several samples in sequence with minimal supervision, which helps laboratories maintain steady throughput.

There are different categories of CNC equipment, but two types are most relevant for tensile specimen preparation. A CNC milling machine shapes flat materials using a rotating cutting tool that moves along X, Y, and Z axes. A CNC lathe works differently: it spins the workpiece while a stationary or moving cutting tool forms the desired round geometry. Both are capable of fine tolerances but serve different specimen types.

Modern CNC systems are built for accessibility as much as for precision. Many models include intuitive interfaces with preloaded templates for common standards. An operator can simply select the required standard (ASTM, ISO, DIN, or another) and the machine executes the correct toolpath automatically. This combination of automation, precision, and simplicity is the reason CNC technology has become the preferred method for preparing tensile specimens in professional laboratories.

Standard Tensile Test Specimen Forms: Flat and Round

Before selecting a CNC system, it’s essential to understand how tensile specimens are classified. Most are produced in two main shapes: flat and round. Each follows international standards that define dimensions, tolerances, and preparation methods. The choice depends on the material’s form and the type of test required.

Flat tensile specimens, often called dog bone or dumbbell, have a rectangular cross-section with a narrow middle and wider ends for gripping. The reduced section, or gauge area, is the weakest point of the specimen and where the fracture is expected to occur. This geometry directs the stress toward the center and prevents premature failure at the grips.

Flat specimens are typically machined from sheet metal, plate, or other flat stock. Because of their shape, they are described mainly by width and thickness. Smooth radii connect the narrow gauge section to the wider ends, reducing stress concentration and keeping deformation uniform. Standards such as ASTM E8 and ISO 6892 define precise values for width, gauge length, and fillet radius, depending on material thickness and product form.

Round tensile specimens have a circular cross-section with a uniform diameter along the gauge length. They include a straight central portion and larger ends for gripping, which may be threaded or shaped for pin loading. These specimens are machined from bars, rods, or thick sections of metal where sufficient material is available for turning.

A round profile offers clear mechanical advantages. The stress distribution is uniform, no sharp edges exist, and only one parameter—the diameter—defines the cross-sectional area. This simplicity makes it easier to calculate stress and reduction of area during testing. Common standards, such as ASTM E8, describe several round specimen geometries. For example, the standard U.S. version uses a gauge length equal to four times the diameter, while the metric version ASTM E8M specifies a ratio of five to one. This proportional rule keeps elongation data consistent across different specimen sizes.

Both flat and round specimens must meet strict dimensional and surface-finish requirements. Standards specify exact tolerances for every key feature and often provide minimum or recommended values. They also highlight an important point: machining must not change the material’s properties. Heat-affected or cold-worked layers from cutting must be removed. To prevent this, technicians use sharp tools, controlled speeds, and cooling fluids. A brief polishing or finishing step may follow to achieve smooth surfaces free of burrs or tool marks.

CNC Machines for Flat Specimen Preparation

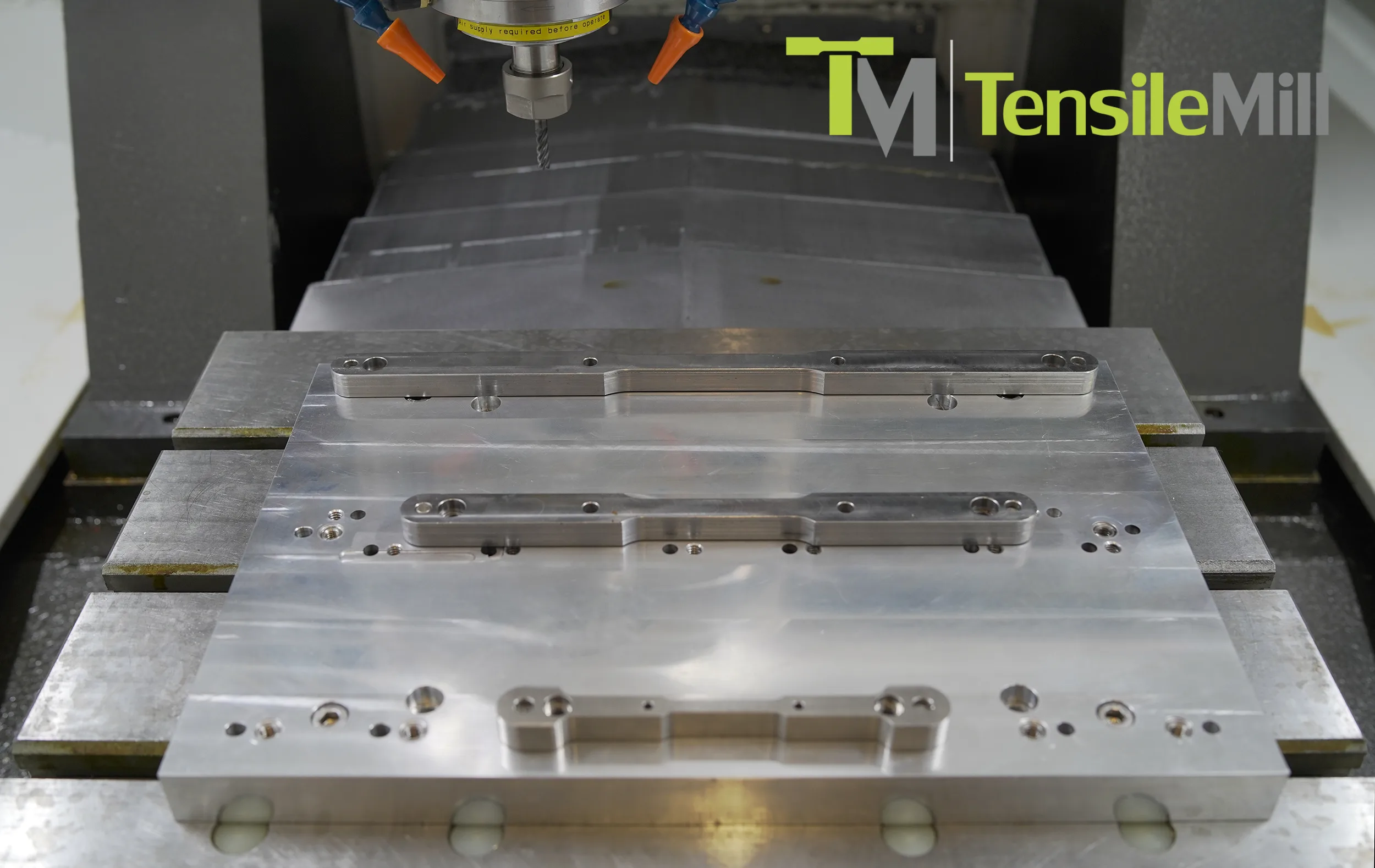

Let’s look in detail at the tools designed for flat tensile specimen preparation. These CNC systems are specialized milling machines built to produce flat tensile coupons with precision and consistency. The process begins with a strip or plate of material large enough for the required specimen shape. The CNC machine then mills the profile, cutting the narrow gauge section and shoulders, and, if necessary, surfacing the faces or adjusting the thickness to match the selected standard.

Flat specimen CNC machines use rotating cutting tools, such as end mills, to shape the sample with smooth edges and uniform geometry. The system’s automation simplifies the entire process, allowing laboratories to obtain clean and repeatable results without heavy manual involvement. Each specimen comes out within tolerance for width, thickness, and fillet radii, which is essential for reliable tensile testing.

Modern systems are equipped with dedicated software that includes pre-programmed templates for major standards like ASTM E8, ISO 527, ISO 6892, DIN, and JIS. Operation is straightforward: the user loads the material, selects the standard and specimen type on the touchscreen, and starts the cycle. The software automatically generates and executes the toolpath, producing the correct shape in minutes. This user-oriented design allows even non-machinists to create standard-compliant specimens in-house.

A typical flat specimen CNC machine holds the workpiece securely on the table using a vise or custom fixture. The spindle tool then follows the contour of the specimen, cutting the narrow and shoulder sections in several passes for maximum accuracy. Some models include automatic tool changers and digital probes to measure reference points, improving efficiency when switching between different specimen types. Despite the advanced setup, the workflow remains simple—load the blank, select the program, and start machining.

Precision and repeatability are the defining traits of these systems. They maintain tight dimensional control and achieve smooth edge finishes that require little to no post-processing. When configured correctly, the tolerance level stays within a few hundredths of a millimeter. Flat specimen machines can handle a wide range of materials, from soft plastics to hardened steels reaching roughly 60 HRC.

Producing specimens internally also saves time and reduces cost. Sending samples to external machine shops can cost a few hundred dollars per piece and often introduces long waiting periods. A dedicated in-house CNC system removes that dependency. Once programmed, it allows technicians to prepare specimens on demand, keeping testing schedules on track and lowering per-sample expenses.

CNC Machines for Round Specimen Preparation

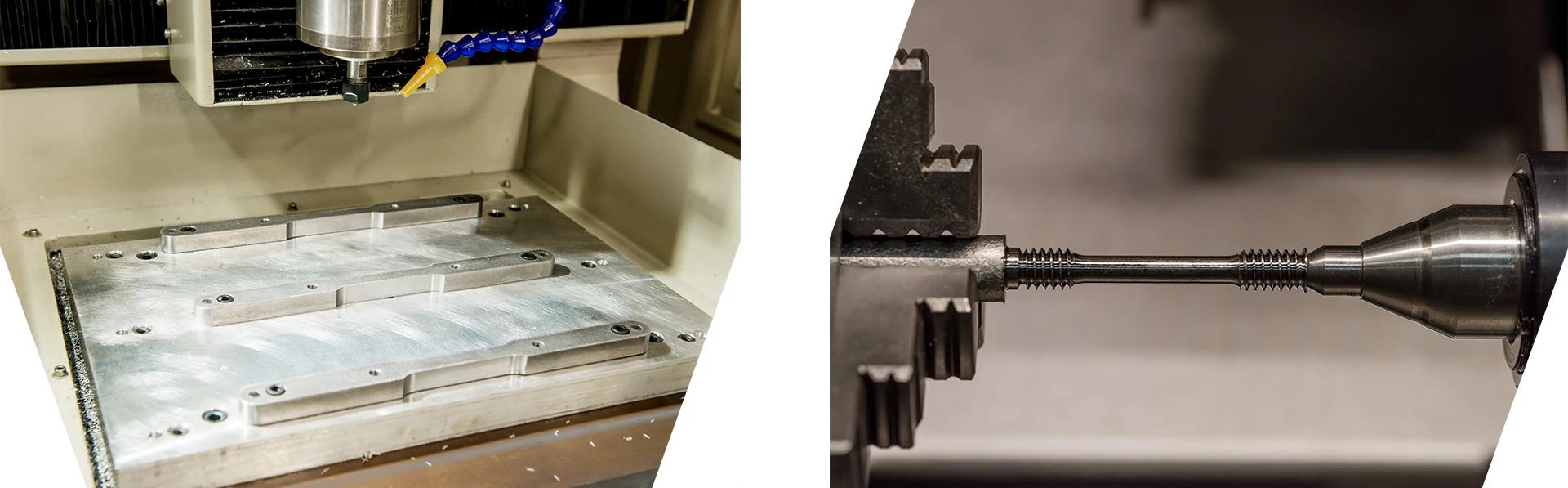

Now, let’s move on to the equipment used for round tensile specimen preparation. These CNC systems are precision lathes specifically configured to produce round tensile bars with accuracy and repeatability. The process relies on turning, where the specimen rotates in a chuck while the cutting tool removes material to form the correct diameter and shape.

The operator begins by mounting the raw sample, often a bar, rod, or even a square section, into the chuck. A tailstock center may support the opposite end to keep the piece stable. The CNC software then runs a predefined program that performs several operations in sequence: turning the gauge section to the target diameter, forming the filleted shoulders, and facing the ends so they are perfectly flat.

If a standard requires threaded grips, the machine can cut the threads automatically using a threading cycle. Some systems also automate center drilling, which creates small holes on each end. These holes allow the live center to support the workpiece during turning and prevent bending, which keeps the specimen perfectly concentric. Advanced systems can perform all these steps, including polishing, in one cycle, saving time and avoiding repositioning errors.

Round specimen CNC machines are built for simplicity as well as precision. Their interfaces include pre-programmed templates for popular standards such as ASTM E8 or ISO 6892. The operator selects the desired standard, loads the material, and starts the cycle. Within minutes, the system machines a fully finished tensile bar ready for testing.

Mechanical stability is essential in this process. The spindle and chuck must hold the specimen without vibration, and a rigid tailstock ensures straightness across the gauge section. Some high-performance models use heavy granite or cast-iron frames to minimize vibration during turning. The tooling inserts are designed to leave a smooth finish that often meets testing requirements without additional polishing.

Differences Between Flat and Round Specimen CNC Machines

Flat and round specimen CNC machines are designed for the same goal, but they differ in the way they operate, how they hold the material, and the geometry of the final specimen. Understanding these distinctions helps laboratories choose the right system for their materials and testing needs.

Let’s now take a closer look at the main differences between these two types of CNC machines and how each one performs its specific role in tensile specimen preparation.

Machining Method

Flat specimen CNC machines rely on milling, where the workpiece remains fixed while a rotating cutting tool, usually an end mill, removes material to create the dog-bone shape. Round specimen machines work through turning, where the specimen rotates in the chuck and a stationary or moving tool shapes it into a cylinder. This difference defines the core structure of each system: one resembles a milling center, the other a lathe.

Machine Configuration

Flat specimen CNC systems typically feature a flat bed or table where the sample is clamped, and a spindle that moves in multiple axes—X, Y, and Z—to carve the outline. Round specimen CNC systems consist of a headstock with a rotating chuck, a tailstock for support, and tooling that moves radially and axially. Their construction reflects the type of force applied: milling systems focus on spindle rigidity and linear precision, while lathes rely on strong, vibration-damping bases made of granite or cast iron.

Workpiece and Material Input

Flat CNC machines start with sheet or plate material, cutting the specimen directly from a flat piece. Round CNC lathes use rods, bars, or thick stock, and can even round off irregular or square material before machining the gauge section. The form of the material naturally determines the type of machine: flat stock goes to a mill, while rods and bars go to a lathe.

Specimen Geometry

Flat machines create rectangular cross-sections defined by width and thickness. Round machines produce cylindrical specimens defined by diameter. Each geometry requires its own dimensional checks: flat samples are measured by width and thickness, while round ones are verified by diameter. Both machine types achieve tight tolerances, but the measurement approach and tooling differ.

Tooling and Operations

Flat specimen systems use end mills or router bits for contouring, with possible tool changes between roughing and finishing passes. Round specimen systems use inserts for turning, facing, and threading. Milling involves high spindle speeds and moderate feed rates; turning relies on constant rotation of the workpiece with controlled feed of the cutter. Each machine is tuned to its own cutting dynamics.

Fixturing and Alignment

On flat CNC mills, the material is clamped horizontally with fixtures or vises. On lathes, the specimen is centered in the chuck, supported by the tailstock for straightness. A lathe inherently produces a specimen aligned to its central axis, while a milling system must maintain even material removal to keep the geometry symmetrical.

Throughput and Automation

Both machine types can operate quickly, but the workflow differs. Flat systems may machine several specimens from one plate by repositioning the material, while lathes can prepare multiple bars in sequence or from a single long rod using a bar feeder. In most labs, one specimen is produced per run, and the machining time, often a few minutes per piece, is rarely the limiting factor.

Surface Finish and Edge Quality

Flat CNC machines generate smooth edges but may leave corners along the thickness that require light deburring. The broad faces are usually the original sheet surface unless milled for thickness. Round specimens, on the other hand, have a continuous, fully machined surface that results in a smooth, polished finish. This uniformity is ideal for evaluating mechanical properties without surface inconsistencies.

Measurement and Data Consistency

After testing, measuring reduction of area is simpler for round specimens—only the final diameter is needed. For flat specimens, both width and thickness must be measured in the necked region, which introduces slightly more potential variation. Still, both geometries produce reliable and comparable tensile data when machined correctly.

Versatility

Flat specimen CNC mills can also perform general milling tasks, while round specimen lathes can be used for standard turning jobs. However, each is optimized for its own geometry, and one cannot substitute for the other. Laboratories that test both sheet and bar materials often use a combination of both machines to cover the full range of sample types.

When to Use Flat vs. Round Specimens and Their Machines

Selecting between a flat or round tensile specimen, and the corresponding CNC machine, depends on a few practical factors. The key points include the material’s form, the applicable standard, and the laboratory’s testing objectives. Let’s review when each type is most suitable.

Material Form

The simplest rule is based on the shape of the material. Thin materials such as sheet, strip, or plate are tested with flat specimens, while rods, bars, or thick sections are prepared as round specimens. For example, ASTM E8/E8M specifies flat coupons for sheet metal and round bars for bulk products. If the material thickness is insufficient to machine a round bar, a flat specimen must be used.

Testing Standards

Different testing standards clearly define the specimen type required for each product form. Specifications for steel bars, for instance, call for round specimens of fixed diameter, while sheet metal standards require flat strips of defined width. CNC machines should therefore match the geometry and tolerances specified in the chosen standard. Laboratories that test to multiple standards often benefit from having both flat and round CNC machines available.

Laboratory Focus

Consider what your lab tests most frequently. Facilities working with sheet metal, plastics, or composites need flat dog-bone specimens and will rely on a milling-type CNC. Labs testing rods, bars, or machined components will depend more on a lathe-style CNC for round specimens. Laboratories that handle both often operate one of each type to keep production consistent.

Sample Volume and Capacity

High-throughput environments should factor in the number of specimens produced daily. Industrial facilities may need heavy-duty round specimen lathes capable of handling multiple bars per shift, while smaller labs preparing only a few flat specimens per week can work efficiently with a benchtop CNC mill. Machine size, speed, and automation level should all align with workload demands.

Mechanical Property Considerations

If a material can be tested in either form, engineers often prefer round specimens for metals because they eliminate edge effects and simplify the calculation of the reduction of area. Flat specimens, however, may be better for evaluating surface conditions or coatings since they can retain one original surface from the sheet. Ultimately, the testing standard dictates which type to use, and that choice ensures consistent, comparable results.

Industry Practice

Industry norms also guide specimen choice. Automotive labs test mostly flat coupons from body panels and aluminum sheets. Aerospace facilities test both—flat for composite panels and round for high-strength alloy parts. Steel and metal producers rely heavily on round specimens, which represent the core material properties more accurately. Aligning with these conventions helps maintain compliance and customer confidence.

Lab Resources and Skills

If only one CNC machine can be purchased initially, choose based on the majority of your testing work. Some advanced CNC systems can switch between milling and turning using attachments, but most labs achieve better efficiency with dedicated equipment for each geometry. Operator familiarity also matters: while modern tensile CNCs are intuitive, turning and milling still require different setups and handling techniques.

Compliance and Quality

Accredited laboratories must follow the relevant testing standards exactly. Substituting specimen types without justification can invalidate results. Whichever CNC system is used must consistently hold the required tolerances and surface finish. Maintaining traceability in specimen preparation is part of good quality control practice.

In practical terms, the rule is simple: flat specimens for flat materials, round specimens for bar or bulk materials. The CNC choice follows naturally. Laboratories that handle diverse materials typically invest in both systems, while those testing a single product type can focus on the corresponding machine.

For instance, a lab analyzing both sheet steel and bolts would mill flat coupons from the sheet using a CNC milling system, while bolts would be turned into round specimens on a CNC lathe.

Precision in Every Step of Tensile Specimen Preparation

CNC technology has changed how laboratories prepare tensile specimens. Both flat and round CNC machines give the process the precision and consistency needed to meet strict international standards. Flat specimen systems mill accurate dog-bone shapes from sheet materials. Round specimen systems turn uniform bars from rods and thick sections. Each method follows the same principle of computer-guided accuracy, adjusted for the geometry and standard of the material.

At TensileMill CNC Inc., we provide CNC systems for preparing both flat and round specimens used in tensile testing. Our TensileMill CNC Series and TensileTurn CNC Series include dedicated models designed for different materials, specimen sizes, and workloads.

If you are selecting equipment for your testing facility or considering upgrading your preparation process, our team can assist you in finding the right CNC solution. Contact us or request an online quote to discuss your testing needs, material types, and expected throughput. We will help you choose the system that fits your workflow and testing standards, so your specimens are prepared correctly and efficiently every time.