Environmental conditions such as temperature and humidity influence the mechanical properties of different materials, particularly polymers and composites. While most studies focus on their effects during mechanical testing, growing attention has been placed on how these factors may affect specimens as early as the preparation stage. For instance, materials susceptible to moisture absorption can experience changes in ductility and dimensional stability when exposed to high humidity before testing. Similarly, temperature fluctuations in the preparation environment may lead to subtle thermal expansion or contraction, which can influence specimen geometry and preparation accuracy.

Tensile testing remains one of the most popular methods for evaluating material strength and structural reliability. However, the accuracy of these tests depends not only on the testing procedure itself but also on specimen preparation precision. Imperfections introduced during cutting, machining, or handling, especially under uncontrolled environmental conditions, can lead to inconsistencies, invalid data, or premature failure during testing.

While machine calibration and test parameters are frequently emphasized, the environmental context of specimen preparation is also important. Factors such as ambient temperature, moisture, airborne particles, and oxidation can all interact with the material's surface or internal structure during preparation, potentially negatively impacting test reliability.

The purpose of this article is to explore the factors that influence each stage in the preparation of tensile samples. Identifying and addressing these influences can greatly improve the consistency and credibility of laboratory tensile testing.

Understanding Tensile Sample Preparation

To discuss factors that influence tensile specimen preparation, it is first necessary to establish a basic understanding of the process. Tensile testing is a common method in materials science used to evaluate mechanical properties, such as strength, ductility, and elasticity. This process involves stretching a material specimen until failure to understand how it behaves under tensile (pulling) forces. Precision and reliability are heavily dependent upon the preparation of specimens for tensile testing.

Importance of Consistent Preparation

Consistent specimen preparation is crucial for accuracy and repeatability in tensile testing. Variations or imperfections in specimen geometry, surface finish, or alignment can lead to inconsistent stress distributions during testing, resulting in unreliable data. For instance, jagged edges or nicks introduced during preparation can act as stress concentrators, causing premature failure and skewing results. Therefore, following standardized preparation protocols is necessary to obtain meaningful and comparable data.

General Stages of Tensile Sample Preparation

The preparation process involves a series of standardized steps intended to produce specimens that reflect the true mechanical properties of the material under investigation. The following are the details:

1. Material Selection

Select a representative sample of the material that reflects its overall characteristics and condition.

2. Cutting/Machining

Shape the material into standardized specimens using precise cutting or machining techniques. This step is often performed using Computer Numerical Control (CNC) machines for accuracy.

3. Surface Finishing

Perform processes such as grinding, polishing, or milling to achieve the desired surface finish. A smooth surface is vital to prevent premature failure due to surface imperfections.

4. Storage Before Testing

Store prepared specimens in controlled environments to protect them from corrosion, contamination, or mechanical damage before testing.

Need for Precision During Each Step

Precision at each preparation stage is crucial to guaranteeing that the specimen's behavior under test conditions accurately reflects the material's true properties. For example, misalignment during machining can introduce unintended stresses, leading to erroneous conclusions about material performance. Similarly, inadequate surface finishing can mask inherent characteristics by introducing artificial points of failure.

Environmental Factors That Influence Sample Preparation

During the preparation phase, factors such as temperature, humidity, airborne contaminants, and oxidation may introduce variations that could compromise the integrity of the specimens and produce misleading results.

Temperature

Temperature fluctuations during specimen preparation can negatively affect material properties and the precision of the machining process:

- Dimensional Stability: Materials may undergo thermal expansion or contraction in response to temperature changes, leading to dimensional inaccuracies during cutting or machining. For instance, metals like aluminum exhibit notable thermal expansion, which can result in deviations from specified dimensions if not properly accounted for.

- Machining Precision: Ambient temperature can influence machining equipment, such as CNC machines. Thermal variations can cause machine components to expand or contract, potentially affecting cutting accuracy and surface finish quality.

Humidity

Humidity levels in the preparation environment can have profound effects, particularly on certain materials:

- Moisture Absorption: Polymers and composite materials absorb moisture from humid environments, leading to mechanical changes. This moisture uptake can result in swelling, reduced tensile strength, and ductility changes.

- Surface Corrosion: Metals exposed to high humidity levels are at risk of surface oxidation or corrosion, especially during the preparation stages. This degradation can compromise the material's integrity, leading to inaccurate tensile test results.

Airborne Contaminants

The presence of airborne particles and substances in the preparation area also can adversely affect specimen quality:

- Surface Quality: Dust, oil vapors, and chemical fumes can settle on specimen surfaces during preparation, leading to surface defects. These contaminants can act as stress concentrators, initiating premature failure during tensile testing.

- Adhesion Issues: For specimens requiring bonding or coating, airborne contaminants can interfere with adhesion processes, resulting in weak interfaces that may fail under tensile loads.

Oxidation / Air Exposure

Exposure to air, particularly oxygen, during preparation can cause surface oxidation:

- Surface Oxidation: Metals like steel and copper are prone to forming oxide layers when exposed to air, especially with moisture. These oxide layers can alter surface properties, affecting tensile test accuracy.

- Altered Mechanical Properties: Oxidation can lead to embrittlement or surface hardness changes, resulting in test data that does not accurately reflect the material's true properties.

The Role of Equipment in Minimizing Environmental Influence

It must also be noted that equipment is also critical in mitigating environmental conditions during tensile sample preparation, as even slight variations in temperature, humidity, or airborne contaminants can compromise specimen accuracy. Using advanced equipment and controlled environments is key to reducing these effects and to guaranteeing reliable test results.

High-quality CNC machines offer thermal stability and precise motion control, maintaining dimensional accuracy even when ambient temperatures vary. This helps prevent defects such as surface inconsistencies or geometric deviations that could affect test results.

Using enclosed CNC systems or operating in climate-controlled rooms limits exposure to temperature fluctuations, humidity, and airborne contaminants. These conditions are especially critical for composites and polymers, which absorb moisture or expand under heat.

Controlled laboratories with proper ventilation and integrated dust removal systems to maintain clean air, protect specimen surfaces, and assure consistent preparation. Additionally, these systems contribute to operator safety and reduce material loss.

CNC Solutions from TensileMill CNC

At TensileMill CNC we understand how important equipment is to maintaining tensile sample preparation integrity under different environmental conditions. Among our company's offerings are high-quality CNC systems specifically designed for flat and round tensile specimen preparation. If you are searching for equipment that combines accuracy, durability, and protection against environmental variables such as dust, temperature fluctuation, or humidity, we proudly introduce two of our flagship solutions:

TensileMill CNC MINI – Compact Flat Tensile Specimen Preparation Machine

The TensileMill CNC MINI is a compact yet powerful solution for flat tensile specimen preparation. Built on a cast iron frame with a small footprint, it is ideal for laboratories with limited space while maintaining exceptional accuracy and repeatability. Despite its size, this machine surpasses its predecessors with a larger table, stronger 2.2kW water-cooled spindle, and improved machining capabilities.

Equipped with a 10" touchscreen and our intuitive TensileSoft™ interface, users can input standard-specific specimen dimensions in seconds or select from a preloaded library of common standards like ASTM E8 and A370. For advanced users, the Carbon software upgrade transforms this model into a full CNC system capable of machining various soft, hard, and specialty materials. MINI offers easy operation even for untrained personnel, ensuring consistent results regardless of the testing conditions.

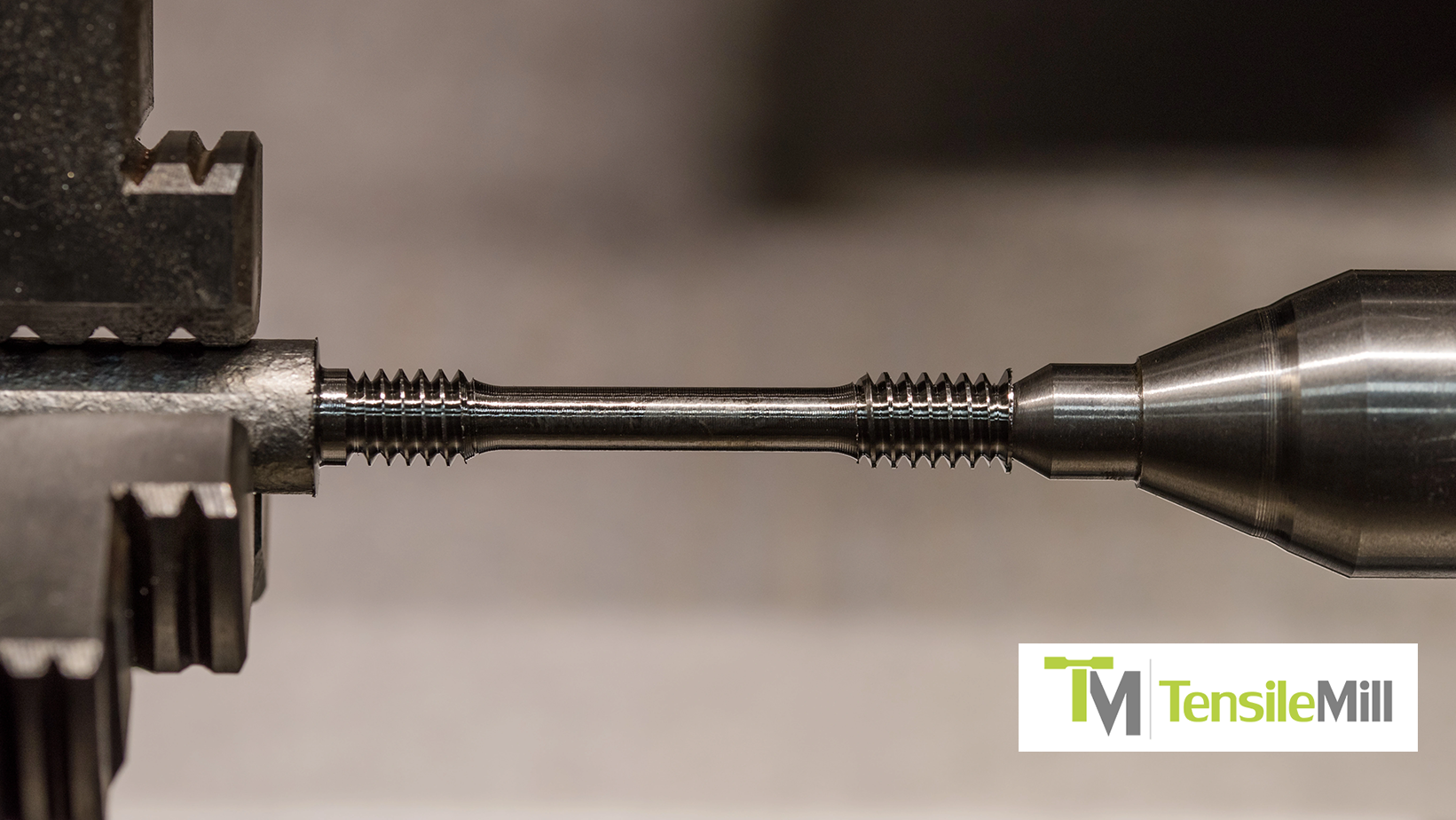

TensileTurn CNC – Industrial Upgrade – Round Tensile Sample Preparation Machine

The TensileTurn CNC – Industrial Upgrade is an automatic CNC lathe engineered for high-precision round tensile specimen preparation. Ideal for industrial environments, it also features a user-friendly touchscreen interface powered by TensileSoft™ and Carbon software, enabling both novice and experienced operators to produce standard and custom tensile specimens easily.

This upgraded model includes a powerful 2 HP motor, stainless steel enclosure, and granite frame for enhanced stability and vibration resistance. It supports automated center drilling and accommodates round, square, or irregular raw stock, delivering repeatable specimen production within minutes. The TensileTurn CNC is perfectly suited to environments where temperature control and contamination resistance are a necessity, thereby proving an invaluable asset for high-volume laboratories that place a high priority on quality and productivity.

Achieving Repeatable Results Starts with Proper Preparation

Tensile sample preparation is not merely a preliminary step before testing-it is a critical process that directly determines the accuracy and repeatability of mechanical test results. Environmental factors such as temperature, humidity, airborne contaminants, and oxidation can introduce subtle yet substantial changes in material behavior before testing even begins. Understanding how these factors influence each stage of the preparation process allows laboratories and manufacturers to better control conditions and improve test reliability.

Equally important is the use of proper equipment built specifically to reduce environmental exposure during machining and handling. CNC systems with thermal stability, enclosed workspaces, and intelligent control software serve as a protective barrier between sensitive materials and external variables. Organizations can maintain specimen integrity and produce accurate and reliable test results by combining environmental awareness with advanced technology.

If you need assistance selecting a CNC machine or other tensile testing equipment or if you have questions regarding it, please contact us through our online quote system or directly. We are here to assist you with all your tensile testing needs.