Why Choose the TensileTurn CNC for Round Tensile Specimen Preparation?

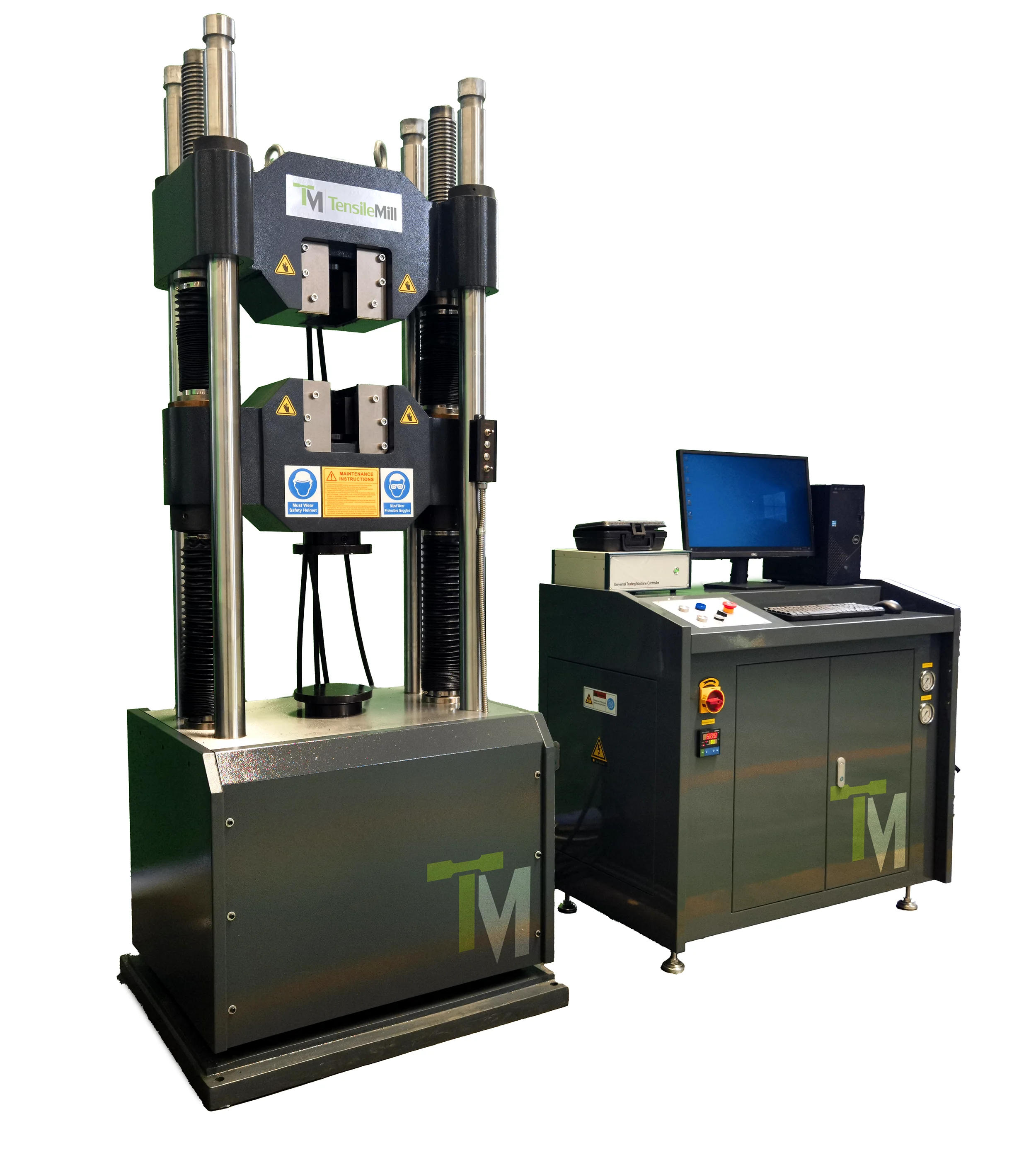

TensileTurn CNC brings round tensile specimen preparation in-house with consistent results and short cycle times. The TensileSoft interface lets operators pick ASTM E8, ISO 6892, or custom geometries on a 15 in (381 mm) touchscreen, so new users can run standard parts without G-code.

Built for labs and production cells, the lathe handles blanks up to 16 in long by 2 in diameter (406 mm by 51 mm) and supports stacking up to three blanks with a triple-clamping fixture to lift throughput. Accuracy and repeatability are maintained at X ±0.002 in and Z ±0.001 in (X ±0.05 mm, Z ±0.03 mm) with repeatability of ±0.0001 in (±0.0025 mm), producing smooth gauge sections and concentric shoulders for threaded or button-head specimens. Optional live tooling, custom workholding, and coolant capacity of 6.6 gal (25 L) support tough alloys and mixed material runs.

Moving preparation in-house reduces reliance on the main machine shop, cuts lead time from days to minutes, and makes it easier to document setups for audits. Each system ships with application support, remote training, and lifecycle software updates that keep workflows aligned as test plans evolve.

If you would like to explore specifications, videos, and workflow examples, you can review details on the

TensileTurn CNC – Classic Upgrade product page.

What After-Sales Support Is Included With the TensileTurn CNC?

Support spans the full lifecycle of your round specimen lathe, starting with application review to match materials, specimen diameters, and compliance needs such as ASTM E8 or ISO 6892. Our team helps select the right workholding, tooling, and programming templates for your target geometry and throughput.

After delivery, you receive guided installation, remote commissioning, and operator training. Topics include fixturing best practices, program selection for shoulder and gauge length profiles, surface finish targets, and cutting parameter tuning for different alloys. Training is structured so new staff can quickly produce consistent round specimens.

For ongoing assistance, you can reach the support team by phone at 877-672-2622 ext. 3, by email at support1@tensilemillcnc.com, or through our online ticket portal. Typical requests include troubleshooting, alignment checks, calibration guidance, and advice on tool paths or feeds and speeds. We also provide maintenance recommendations, spare parts and consumables sourcing, and help with software updates and remote diagnostics to keep day-to-day production steady.

If you would like additional details on capabilities and options, you can read more on the

TensileTurn CNC – Classic Upgrade page.

What Is the Typical Lead Time for the TensileTurn CNC Round Specimen Preparation Machine?

Typical build lead time for the TensileTurn CNC round specimen preparation machine is 2 to 6 weeks from order acknowledgment. The timing depends on your selected configuration and the shipping destination.

Standard builds and in-stock packages tend to ship toward the shorter end of the range. Schedules may extend when projects include custom fixturing, non-stock accessories, special acceptance testing, or export documentation. Freight method and transit time are additional to the build window. To keep projects predictable, our team provides milestone updates at order confirmation, assembly, factory test, and carrier booking. If you are targeting a specific installation window or have site requirements such as power availability, space clearance, or operator training, the project coordinator aligns the build and shipment accordingly.

If you would like current availability, accessory options, and specifications, you can review details on the

TensileTurn CNC – Classic Upgrade page.

Does the TensileTurn CNC Machine Round Tensile Specimens to ASTM E8 and ISO 6892 Standards?

Yes. The TensileTurn CNC is built to produce round tensile specimens that comply with ASTM E8, ASTM A370, ISO 6892, and comparable international standards.

Operators can choose preloaded geometries for full size, sub-size, threaded, and button-head bars, or enter exact gauge length, reduced section, and fillet radii. The touchscreen workflow applies the required profile while rigid workholding, tool libraries, and repeatable CNC cycles maintain dimensional accuracy and a testing-ready surface. With recommended inserts and feeds, typical turned finishes are near 63 µin Ra (1.6 µm Ra).

For audited environments, configuration records, setup sheets, and calibration documentation can be provided to support NADCAP and ISO requirements. Our team also offers certification services for our equipment and for third-party devices, helping your lab keep machining practices and paperwork aligned with standards.

If you would like to review standards-ready features and software templates, you can explore details on the

TensileTurn CNC – Classic Upgrade product page.

What Are the Typical Maintenance Costs for the TensileTurn CNC?

Routine upkeep is modest by design. The system uses a rigid base, industrial grade components, and an operator friendly layout, which keeps scheduled service focused on quick checks and periodic tooling inspection rather than recurring part replacements.

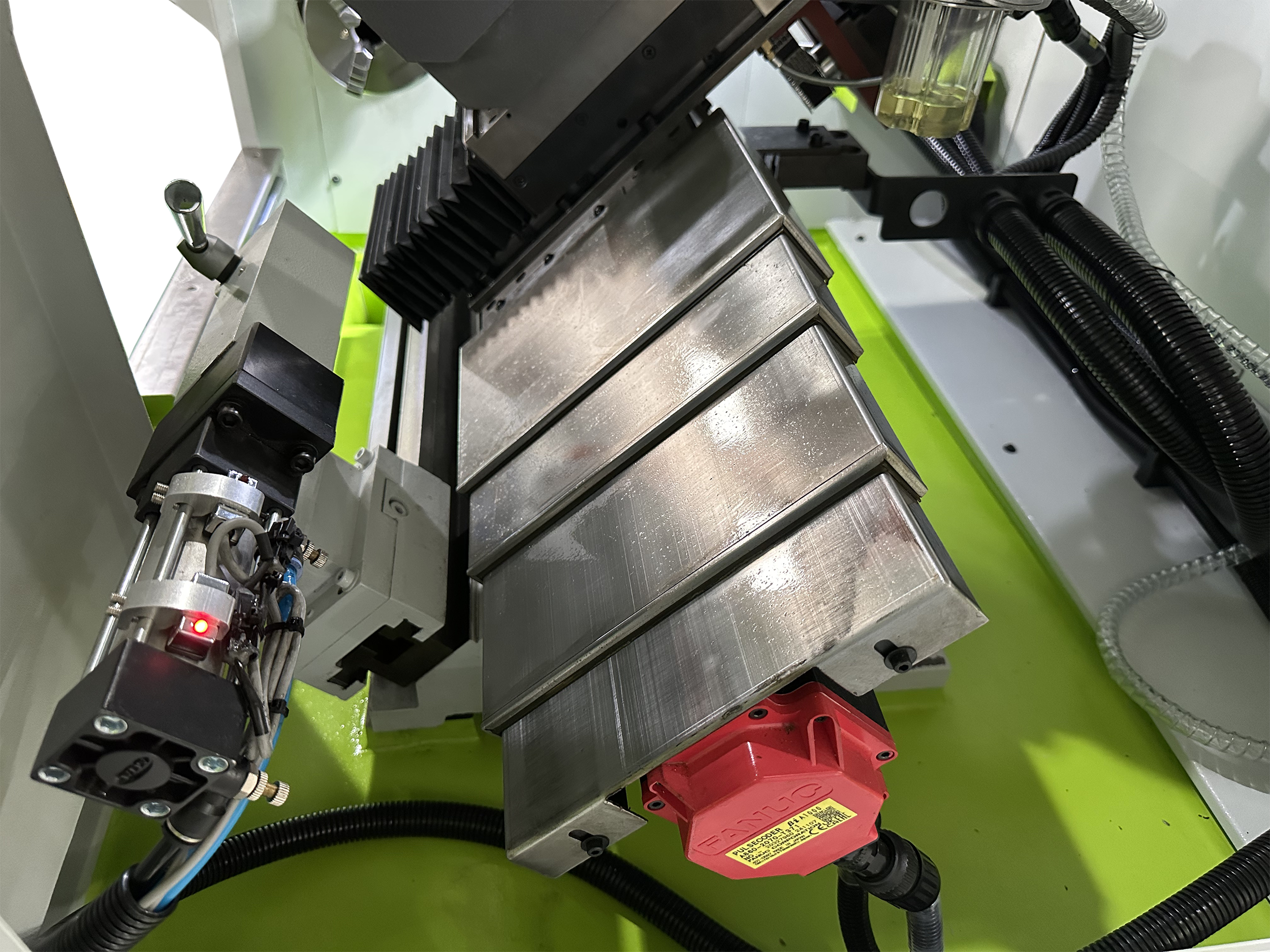

A standard preventative maintenance routine typically includes lubrication checks, coolant and chip management, cleaning of guards and way covers, verification of spindle and tailstock alignment, and inspection of chuck jaws, centers, belts, and cutting inserts. Many facilities choose our PM Service Packages to extend machine life and stabilize budgets. These visits include performance evaluations, thorough cleaning, alignment checks, and proactive replacement of common wear items to reduce unplanned downtime. With this approach, labs and production teams maintain high uptime and a predictable cost profile for round specimen preparation without outsourcing.

If you would like to explore service plan options or specifications, you may review details for the

TensileTurn CNC Classic Upgrade on the product page.

What Is the Average Cost Per Specimen for Round Tensile Preparation with TensileTurn CNC?

For machining-only preparation of round tensile specimens on a TensileTurn CNC, typical cost runs about $150 to $300 per specimen.

This estimate covers turning the grip and gauge sections, applying specified fillet radii, deburring or chamfering, and parting. It excludes raw material, polishing, etching, hardness or tensile testing, certification paperwork, and expedited fees. Actual pricing varies with alloy hardness and stock condition, tolerance and finish targets for standards such as ASTM E8 or ISO 6892, stepped or threaded features, quantity per run that spreads setup time, and tooling wear such as insert changes. Labs processing larger batches often land at the lower end because programs and fixtures are reused, while one-off jobs, tight tolerances, or difficult materials trend higher. The TensileTurn platform supports repeatable profiles and stable workholding, which helps maintain throughput and consistent geometry across batches. For an itemized quote based on your print and batch size, you can use the TensileMill CNC Calculator or connect with our product specialists.

If you would like to review capabilities and options, you can read more on the

TensileTurn CNC - Classic Upgrade product page.

What Is the Typical Cost to Machine and Test Round Tensile Specimens with TensileTurn CNC?

For most labs, the combined cost to machine round tensile specimens on a TensileTurn CNC and perform a single tensile test typically falls between $150 and $300 per specimen. This range assumes standard turning to final geometry, any light finish pass or polishing that may be required, and one pull on a calibrated universal testing machine.

Actual pricing varies with material hardness and machinability, target gauge diameter and tolerance, required surface finish, tooling life, and total cycle time. Batch size also matters, since setup time is distributed across the run; larger batches usually lower the per-piece figure. Work such as meeting tight tolerances like ±0.0005 in (±0.013 mm), applying a fine finish such as 32 µin Ra (0.8 µm Ra), or testing high-strength alloys can push costs toward the upper end. For metallic specimens produced to practices consistent with ASTM E8, additional steps like polishing or extensometer preparation may add minutes to the workflow. Many users see costs near $150 for common steels or aluminum in batches, and closer to $300 for nickel alloys or specialty requirements. If you would like a precise estimate, you can use our internal cost calculator parameters or request a tailored quote based on your throughput and specification details.

If you would like a closer look at cycle times, tooling options, and package pricing, you can review technical details on the

TensileTurn CNC – Classic Upgrade product page.

Why Is the TensileTurn CNC Known for Easy Round Tensile Specimen Machining?

It combines purpose-built tensile sample software with an integrated CNC control, so operators select a standard template, enter a few dimensions, and run guided cycles that produce repeatable round specimens with minimal steps and training.

Preloaded libraries for common standards such as ASTM E8 and ISO 6892, along with custom fields, let you generate necked geometries and threaded ends without manual programming. The software creates the toolpath for turning, facing, necking, and finishing, while canned cycles manage feeds and speeds. On-screen prompts cover stock setup, gauge length checks, and tool selection, and saved job profiles make repeat runs straightforward across shifts.

Because the tensile interface sits on a full-featured CNC platform, teams can switch from template-driven specimen work to conventional lathe operations when needed. Depending on configuration, systems are supplied with an industrial CNC such as Mach4 or FANUC, giving labs both simplicity and advanced control. The dedicated workflow reduces dependency on general-purpose machines, cuts programming time, and supports consistent surface quality for downstream testing.

If you would like to explore the software workflow and control options, you may review details on the

TensileTurn CNC – Classic Upgrade product page.

Which CNC Tensile Sample Preparation Machine Do You Recommend for Round Tensile Specimens?

For round tensile specimens, the recommended solution is the TensileTurn CNC round specimen preparation lathe. It includes a preloaded library of ASTM, ISO, DIN, and JIS geometries, and you can add, edit, or remove templates by entering new parameters. This gives labs a fast way to work to recognized standards while retaining the flexibility to support custom sizes.

Operators select a template such as ASTM E8 or ISO 6892 on the 15 in (381 mm) touchscreen, enter required dimensions like gauge length, reduced diameter, fillet radius, overall length, and any thread details, then start the cycle. Typical specimen capacity covers up to 16 in length × 2 in diameter (406 mm × 51 mm), which fits most standard round bars used for tensile testing. The editable standards library helps accommodate new internal specs or customer drawings without reprogramming from scratch.

Beyond tensile bars, the platform functions as a standard CNC turning center for general round work, so your team can perform routine facing, turning, drilling, and threading between tensile jobs. This combination of guided standards-based workflows and open CNC capability supports quick turnaround and consistent, repeatable specimen quality.

If you would like to compare capabilities and review specifications, you can explore the

TensileTurn CNC – Classic Upgrade on the product page.

Does the TensileTurn CNC Round Specimen Machine Accept Square Stock?

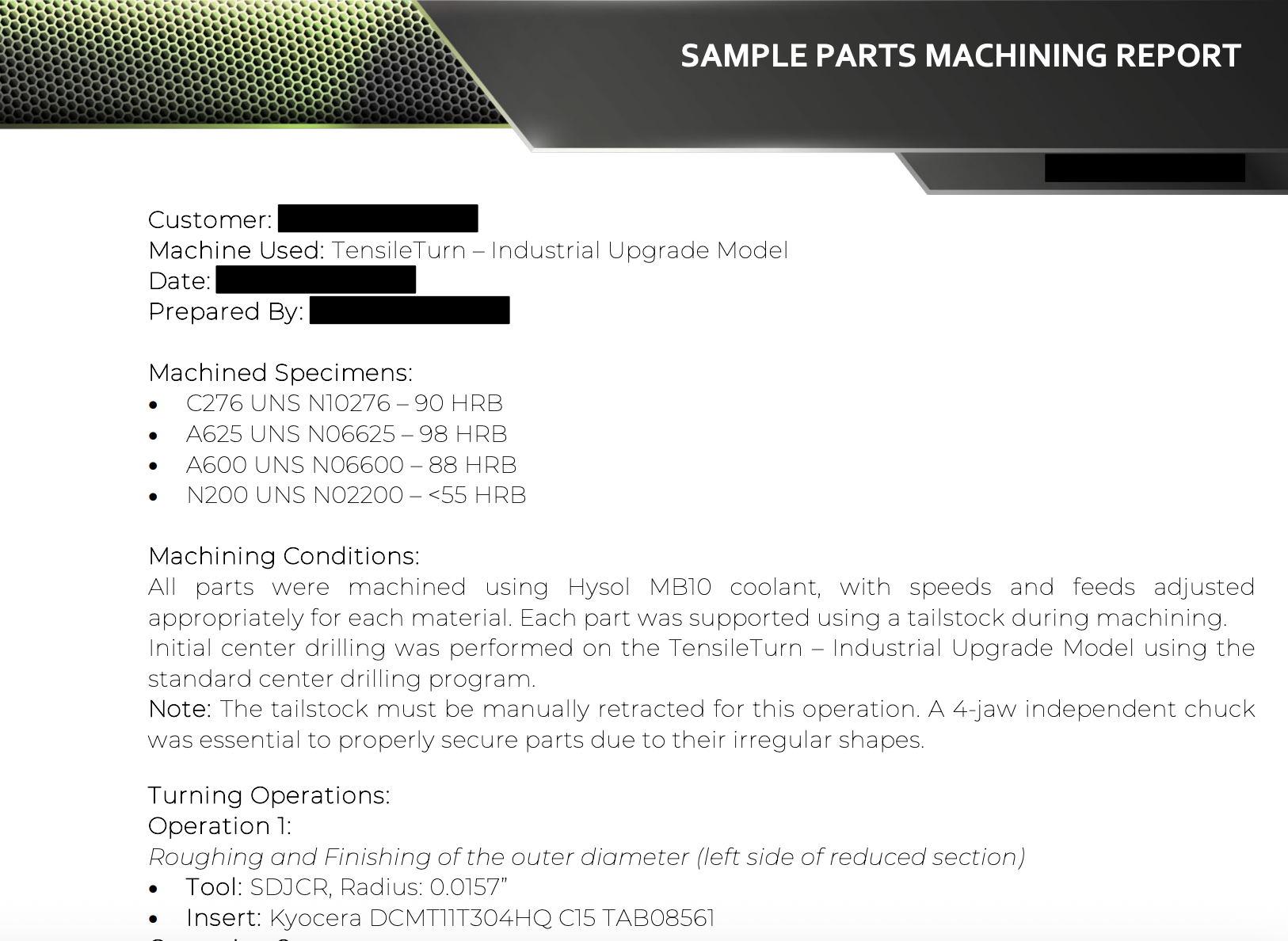

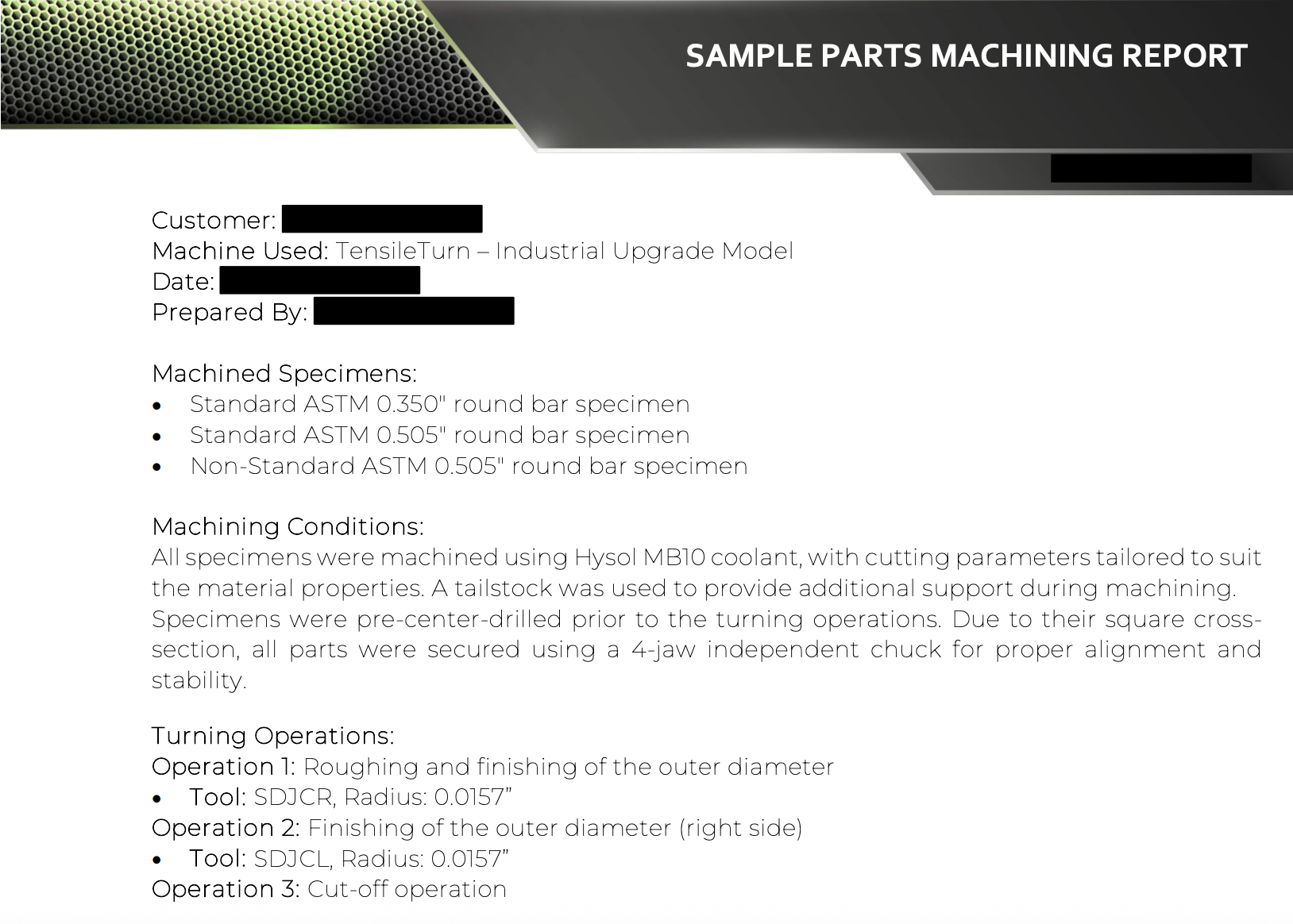

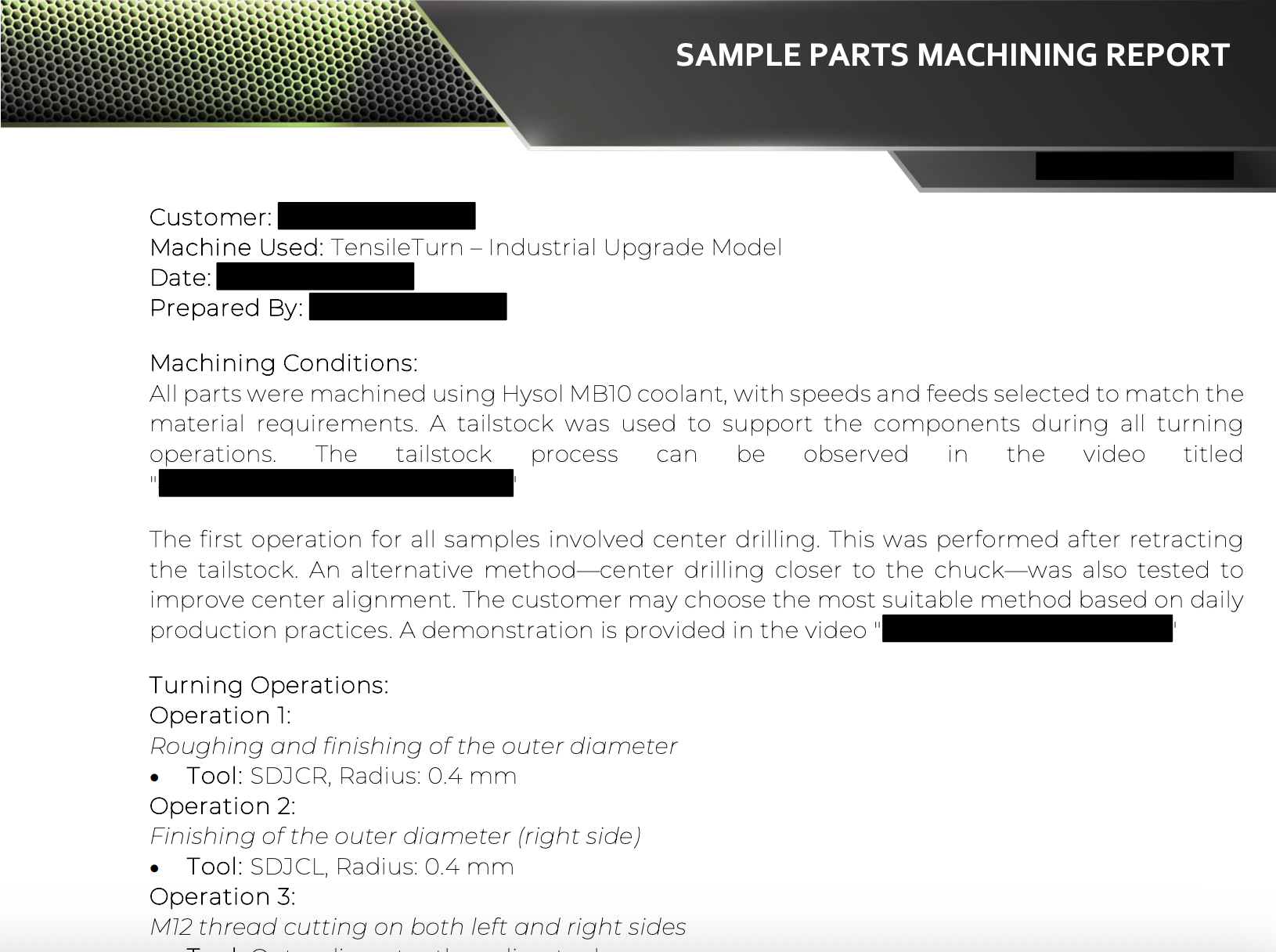

Yes. The TensileTurn CNC series can start from square or rectangular blanks as well as round bar when equipped with the optional 4-jaw manual scroll chuck. The chuck grips on the flats of the workpiece so you can center the blank quickly and turn concentric gauge sections for round tensile specimens.

Typical workflow is to face and center drill the blank, support it with the tailstock, then rough and finish turn the shoulders and gauge diameter. Many labs use soft jaws or thin brass shims to reduce clamping marks prior to final polishing, which helps when preparing metallic round specimens to ASTM E8 dimensional requirements. For longer pieces, tailstock support improves stiffness and surface finish, and balanced cuts help maintain runout control. The setup accommodates common square stock sizes within the machine’s chuck and spindle capacity, and the same accessory is helpful for machining irregular sawn blanks into round test samples.

If you would like to review accessory options and machining capabilities, you can learn more on the

TensileTurn CNC – Classic Upgrade product page.

How Should I Set Up Workholding and Cutting Parameters for ASTM E8 Round Tensile Specimens on the Classic Upgrade?

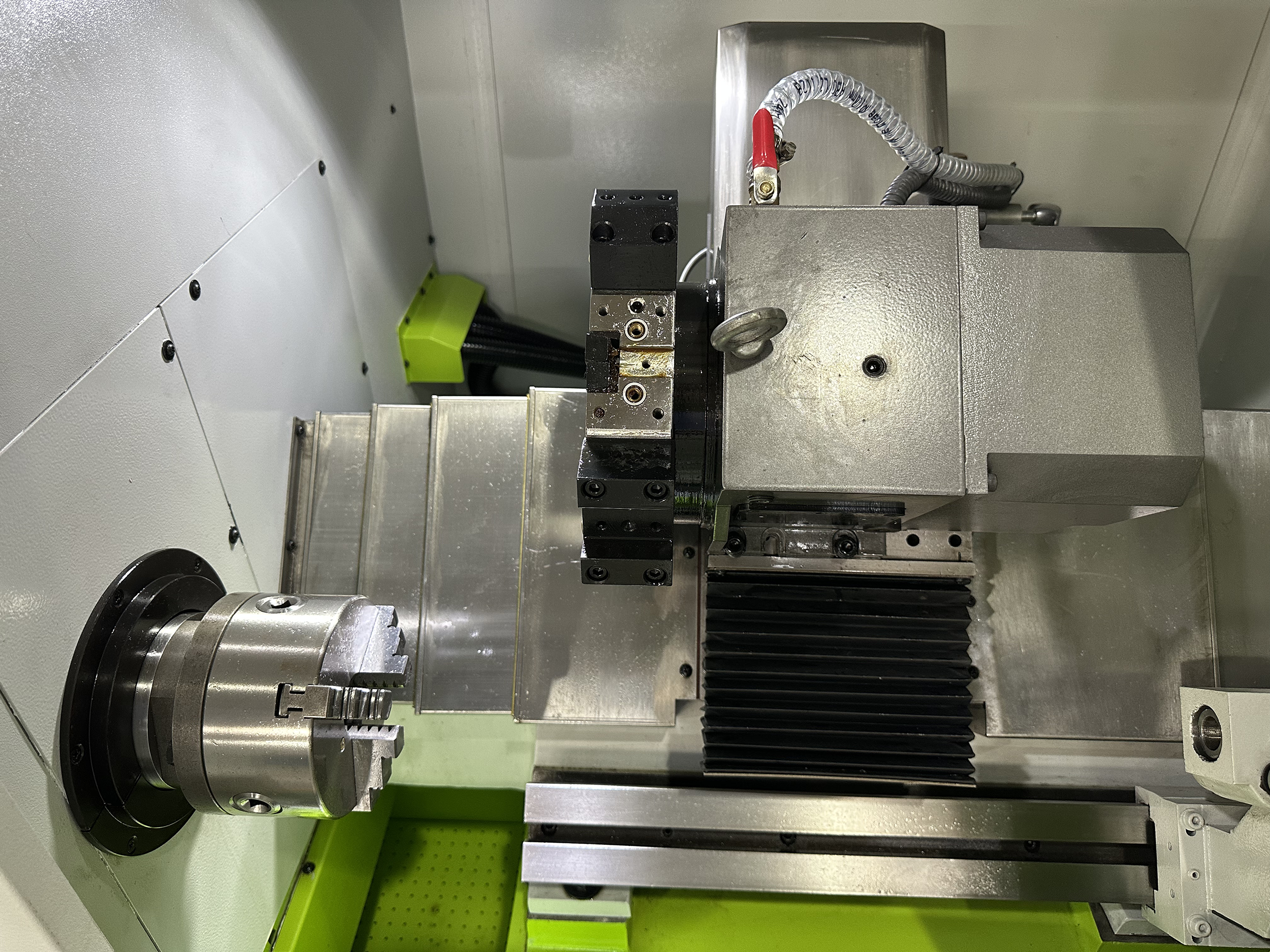

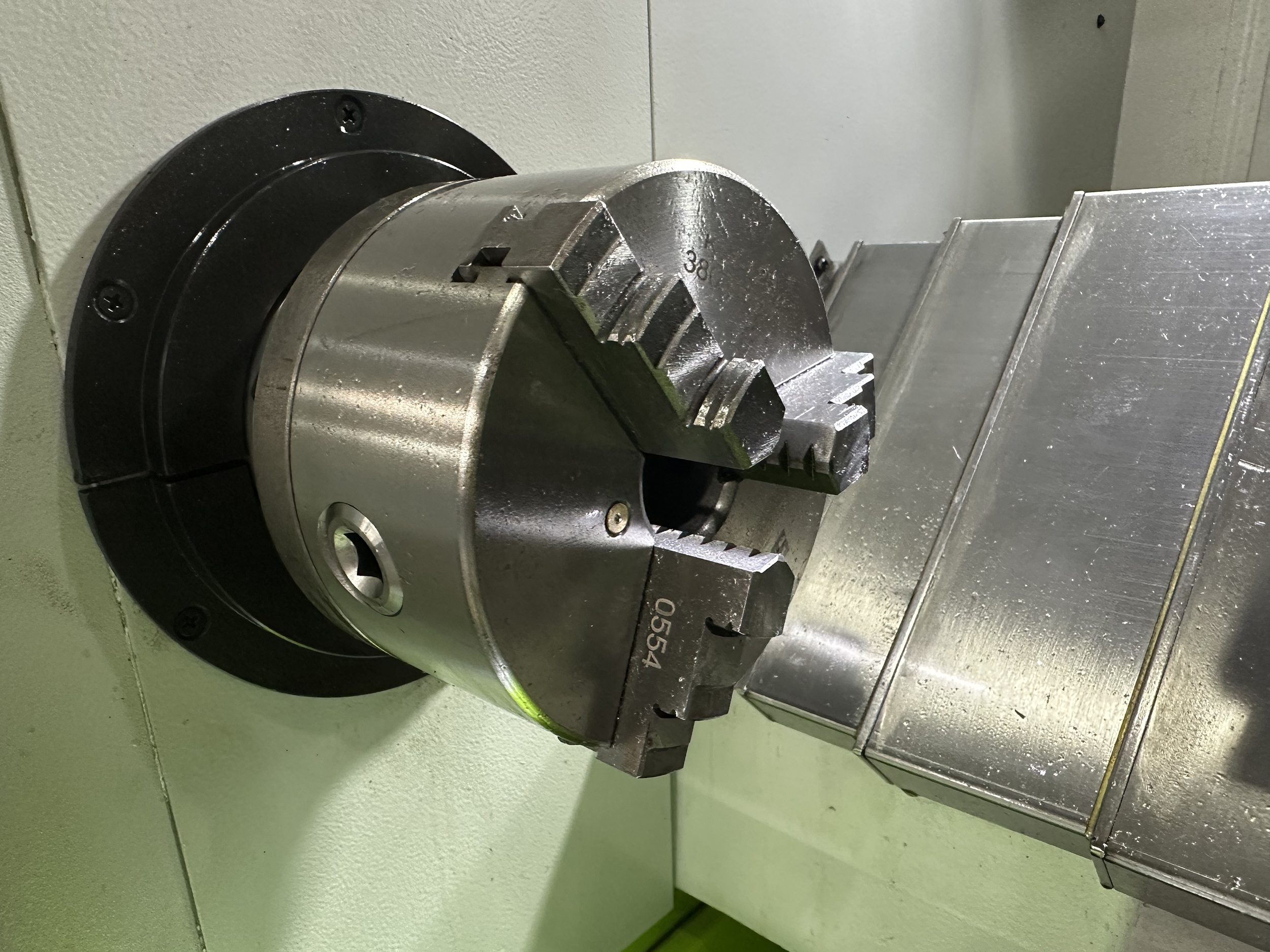

Use the 3-jaw chuck for round feedstock, or the optional 4-jaw for square or irregular blanks. Center-drill both ends and support with the tailstock live center. Minimize stickout, keeping unsupported length under about 6 in (152 mm) when practical. Indicate the bar and target 0.001 in (0.025 mm) TIR or better before cutting. Load the ASTM E8 geometry from the library, confirm gage length and transition radii, then set tool and work offsets accordingly.

For stable results, rough at 0.02–0.06 in (0.5–1.5 mm) radial depth of cut with 0.010–0.015 in/rev (0.25–0.38 mm/rev), leaving 0.010–0.015 in (0.25–0.38 mm) per side for finishing. Finish at 0.005–0.010 in (0.13–0.25 mm) radial depth of cut and 0.004–0.008 in/rev (0.10–0.20 mm/rev). Use a sharp carbide or CBN insert with about a 0.016 in (0.4 mm) nose radius for steels up to roughly 55 HRC. Apply flood coolant from the 6.6 gal (25 L) tank, and add a light spring pass to reach final size.

Verify the gage diameter and fillet radii against the ASTM E8 drawing, then check the finished gage section to ±0.001 in (±0.025 mm). Aim for 32–63 µin Ra (0.8–1.6 µm) to minimize stress risers. The equipment accommodates specimens up to 16 in × 2 in (406 mm × 51 mm), supporting most subsize and full-size bars. For button-head or threaded ends, call the appropriate cycle from the interface and maintain the same runout limit through final inspection.

If you would like to review specifications and options, you can explore details on the

TensileTurn CNC – Classic Upgrade equipment page.

How Can I Achieve ASTM E8 Concentricity And Surface Finish On Round Specimens With This Lathe?

Start with stable workholding. Use a precision collet when possible, or soft jaws trued in place, and support the free end with a live center to minimize runout. Keep stickout as short as the program allows and verify total indicator runout at both ends of the gauge section, targeting 0.001 in or better (0.025 mm). Turn the gauge length and fillet transitions in a single setup where feasible. Break edges with a light 0.02 in (0.5 mm) chamfer and apply specified fillet radii for button-head designs per ASTM E8 drawings.

For cutting parameters, use sharp, honed or wiper-style carbide with flood coolant. As starting points, run steels at 200 to 400 SFM (61 to 122 m/min) and aluminum at 600 to 1,000 SFM (183 to 305 m/min). Feed 0.004 to 0.008 in/rev (0.10 to 0.20 mm/rev) for roughing, then finish with 0.003 to 0.005 in/rev (0.08 to 0.13 mm/rev) at a light 0.005 to 0.010 in (0.13 to 0.25 mm) radial depth. For harder alloys, reduce SFM and depth to control heat. The machine capacity of 16 in length by 2 in diameter (406 mm by 51 mm) supports typical specimen sizes with tailstock rigidity.

ASTM E8 and ISO 6892-1 require smooth, defect-free surfaces but do not prescribe a specific roughness. Many labs target Ra 32 microinch (0.8 μm) or finer, and critical programs aim for Ra 16 microinch (0.4 μm). If needed, finish with light longitudinal polishing only to avoid circumferential scratches. Verify diameter to ±0.0005 to ±0.0010 in (±0.013 to ±0.025 mm) and gauge length within ±0.002 in (±0.05 mm), then confirm concentricity through the full gauge section.

If you would like additional setup guidance and specifications, you can review technical details on the

TensileTurn CNC - Classic Upgrade product page.

How Do I Prevent Taper And Maintain Concentricity On Round Tensile Specimens?

Start by facing and center-drilling both ends of the blank so the centers are coaxial. Grip the stock lightly in a 3-jaw chuck, support the free end with a live center, then indicate on the turned land and adjust until total indicated runout is at or below 0.001 in (0.025 mm). For long blanks, add a steady rest when the length to diameter ratio exceeds 10:1. Rough within 0.010 to 0.020 in (0.25 to 0.50 mm) of size, then finish in one or two equal passes to the target diameter, keeping tool nose radius and relief consistent at both shoulders to avoid taper.

Match speed and feed to the material. Typical starting points are: aluminum 600 to 1,200 SFM (180 to 365 m/min) at 0.002 to 0.006 in/rev (0.05 to 0.15 mm/rev); low-carbon steels 100 to 250 SFM (30 to 75 m/min) at 0.002 to 0.005 in/rev (0.05 to 0.13 mm/rev); heat-treated alloys 30 to 60 SFM (9 to 18 m/min) at 0.001 to 0.003 in/rev (0.03 to 0.08 mm/rev). Leave 0.002 to 0.004 in (0.05 to 0.10 mm) for the final finish pass. Use flood coolant, a sharp CNMG or VNMG tool for roughing, and a wiper-style or sharp finishing insert for the reduced section.

Verify reduced-section diameter, gauge length, fillet radii, and parallelism per ASTM E8/E8M or ISO 6892-1 as applicable. Aim for a uniform surface finish of about Ra 63 µin (1.6 µm) or better, remove burrs at the fillets, and recheck TIR before parting off to ensure concentric grips and consistent failure location.

If you would like deeper details on setup and best practices, you can review technical information on the

TensileTurn CNC – Classic Upgrade equipment page.

What Tolerances And Surface Finish Should Round Tensile Specimens Meet, And How Does This System Achieve Them?

For metallic round bars prepared to ASTM E8 or ISO 6892 drawings, many labs target a uniform gauge diameter within ±0.0005 in (±0.013 mm) to preserve compliance margin, with taper under 0.001 in (0.025 mm) across the gauge length. A smooth finish of 32 µin Ra (0.8 µm) or better limits stress raisers, and programs working with high-strength alloys often aim for 16 µin Ra (0.4 µm). Shoulders should blend smoothly with no undercut, and any button-head or threaded details must match the selected specimen drawing.

The machine holds these results through rigid workholding and controlled multi-pass turning. Use a live center in the tailstock, minimize stickout, rough the profile, then take one or two finish passes at 0.005–0.010 in (0.13–0.25 mm) depth of cut, 0.002–0.006 in/rev (0.05–0.15 mm/rev) feed, and about 800–2,400 rpm for typical 0.50 in (12.7 mm) carbon steel. Apply flood coolant, add a spring pass if mic checks show springback, and verify diameter every 0.50 in (12.7 mm) along the gauge with a 0.0001 in (0.0025 mm) micrometer before moving to polishing if required.

For capacity planning, the system accommodates specimens up to 16 in × 2 in (406 mm × 51 mm). For harder materials around 55 HRC, select sharp coated carbide or CBN, reduce feed toward the low end of the range, and confirm Ra prior to any optional polish to meet your finish target.

If you would like additional specifications and examples, you can review technical details on the

TensileTurn CNC - Classic Upgrade product page.

What Surface Finish And Dimensional Tolerances Should I Target For ASTM E8 Round Specimens On The TensileTurn CNC?

For most metals under ASTM E8 and ISO 6892, a practical target for the gauge section is 32 µin Ra (0.8 µm) or finer. Many labs pursue 16 µin Ra (0.4 µm) when testing high-strength alloys to reduce stress raisers. Aim for gauge diameter within ±0.001 in (±0.025 mm), total taper across the gauge length under 0.0005 in (±0.013 mm), out-of-round within 0.0005 in (±0.013 mm), and gauge-length straightness within 0.001 in over 2.0 in (0.025 mm over 50 mm). Use generous shoulder radii per the selected standard drawing and break edges lightly to remove burrs without changing the gauge length.

If you would like specification details and capacity notes, you can review the

TensileTurn CNC – Classic Upgrade on the product page.

How Does the Upgraded TensileTurn Classic Support ASTM E8 and ISO 6892-1 Round Specimen Tolerances?

Operators select an ASTM E8 or ISO 6892-1 template on the 15 in (381 mm) touchscreen, then enter target gauge diameter, gauge length, and fillet radii. The software builds toolpaths around those limits, and the operator sets tool offsets with a quick test cut and mic checks. A tailstock center and 3-jaw chuck hold the blank on axis, which keeps runout low across the gauge section.

A 3 hp (2.2 kW) spindle with up to 4000 rpm maintains cutting speed on steels and nickel alloys. Positioning capability of X ±0.002 in and Z ±0.001 in, with repeatability of ±0.0001 in, supports tight diameter and length tolerances. Travel covers 7.1 in (180 mm) on X and 18.3 in (465 mm) on Z, and rapid traverse reaches 315 in/min (8000 mm/min). The 1.02 in (26 mm) spindle bore, MT4 taper, 4-position tool changer, and a 6.6 gal (25 L) coolant tank allow stable roughing and light finishing passes, for example 0.005–0.010 in (0.13–0.25 mm) depth at 0.002–0.004 in/rev (0.05–0.10 mm/rev).

For throughput, the triple clamping fixture can process three parts at once. The machine handles specimens up to 16 in × 2 in (406 mm × 51 mm) and fits in a 62.5 in × 27.75 in × 59.65 in (1590 mm × 705 mm × 1515 mm) footprint.

If you would like to review configuration options and detailed specifications, you can explore the

TensileTurn CNC – Classic Upgrade product page.

How Does the TensileTurn Classic Upgrade Speed Up ASTM E8 Round Specimen Preparation?

Operators select an ASTM E8 or ISO 6892-1 template on the 15 in (381 mm) touchscreen, enter target diameter and gauge length, then load blanks in the triple clamping fixture. The machine accepts bars up to 16 in (406 mm) long by 2.0 in (51 mm) diameter, so three specimens can be machined in one cycle with matched geometry across the stack.

Dimensional repeatability comes from the 3-jaw chuck, tailstock support, and a spindle capable of 4000 rpm. Positioning is specified at X ±0.002 in (±0.051 mm) and Z ±0.001 in (±0.025 mm), with repeatability of ±0.0001 in (0.0025 mm). A 6.6 gal (25 L) coolant tank aids surface finish on aluminum, steels, and nickel alloys. For stock up to 55 HRC, the 3 hp (2.2 kW) drive keeps torque available at lower surface speeds.

Choose threaded-end or button-head templates when your grips require them to avoid stress concentrations. After roughing, run a light finishing pass with a sharp insert, then verify gauge diameter and transition radii per ASTM E8 or ISO 6892-1 before releasing the part to the UTM.

You can review capabilities and see full specifications for the

TensileTurn CNC – Classic Upgrade on the product page.

How Does the Upgraded TensileTurn CNC Classic Speed Up ASTM E8 Round Specimen Setup?

The new controller and TensileSoft templates cut setup time. On the 15 in (381 mm) touchscreen, an operator selects an ASTM E8 or ISO 6892 template, enters target diameter, gage length, and shoulder radius, then confirms stock size and tool offsets. The software builds the path and limits automatically, so no G-code writing is needed. Most teams reach productive use within hours, and standard bars follow in minutes.

Hardware changes support that pace. A 3 hp (2.2 kW) drive maintains steady cutting on alloys up to 55 HRC. The triple clamping fixture lets you load three blanks of the same geometry for one setup, which raises hourly throughput. For consistency, indicate the blank in the chuck, set tailstock pressure to prevent bowing, and aim for total indicated runout under 0.001 in (0.025 mm) before the finish pass.

For common ASTM E8 work, many labs machine a 0.5 in (12.5 mm) gage diameter with a 2 in (50 mm) gage length and shoulder radii between 0.25 and 1.0 in (6 to 25 mm). A finishing pass at 0.003 to 0.006 in per rev (0.08 to 0.15 mm/rev) with a 0.016 in (0.4 mm) tool nose often reaches about Ra 32 µin (0.8 µm), which helps limit stress concentrations before testing.

You can review technical specifications and workflow tips for the

TensileTurn CNC – Classic Upgrade on the product page.

How Does the TensileTurn CNC Classic Upgrade Accelerate Round Specimen Prep While Meeting ASTM E8 and ISO 6892?

The Classic Upgrade is a purpose-built CNC lathe for round tensile specimens with standards templates built into the controller. An operator selects ASTM E8 or ISO 6892 geometry, loads blanks, and starts the cycle. Button-head, threaded-end, sub-size, fatigue, and impact geometries are supported. For higher throughput, stacked clamping can machine multiple blanks in one run. Materials up to 55 HRC are handled without special machining centers or outsourcing.

A practical setup starts with a sharp carbide insert with a 0.016 in (0.4 mm) nose radius, tailstock engaged, and steady coolant. For steels up to 55 HRC, rough at 0.010–0.015 in/rev (0.25–0.38 mm/rev) and 300–500 SFM (90–150 m/min). Finish at 0.003–0.006 in/rev (0.08–0.15 mm/rev) with a 0.005–0.010 in (0.13–0.25 mm) depth of cut to maintain a smooth, uniform gauge section.

Before releasing a specimen, break shoulder edges with a 0.02 in (0.5 mm) blend. Check runout below 0.001 in (0.025 mm) and verify gauge parallelism with micrometer checks every 0.5 in (13 mm). ASTM E8 and ISO 6892 call for an axially symmetric gauge free of stress concentrators, so look for tool marks and alignment issues prior to testing.

If you would like to review throughput features and standard templates, you can explore details on the

TensileTurn CNC Classic Upgrade product page.

What Should Labs Evaluate Before Switching To The TensileTurn CNC Classic Upgrade For Round Specimens?

Start with geometry and standards. For ASTM E8 round metals, verify your typical diameters and gage lengths fit the machine envelope. The Classic Upgrade supports up to 16 in (406 mm) length and 2.0 in (51 mm) diameter with positioning of X ±0.002 in (±0.05 mm), Z ±0.001 in (±0.025 mm), and repeatability of ±0.0001 in (±0.0025 mm). If throughput is tight, plan batches with the triple clamping fixture to process three stacked blanks in one cycle.

Check facility readiness. Allocate at least the footprint of 62.5 × 27.75 × 59.65 in (1590 × 705 × 1515 mm) plus space for chip clearance and safe operator access. Provide 220 V single-phase power and shop air. A 6.6 gal (25 L) coolant tank supports tool life and surface finish; schedule coolant maintenance with your daily checks.

Match material mix to the drive train. A 3.0 hp (2.2 kW) spindle up to 4000 rpm handles alloys up to 55 HRC. For steels and superalloys, use sharp inserts and conservative entry cuts to prevent taper in the gage section. When stacking parts, verify clamping torque and tailstock alignment on each layer. If your method specifies a fine gage finish, set a light finishing pass and dial feeds and speeds to hit the target roughness before sending specimens to the UTM.

If you would like to review specifications and plan your workflow, you can explore details on the

TensileTurn CNC – Classic Upgrade product page.

What waylube does the TensileTurn CNC use, and what is the tank capacity?

The TensileTurn CNC Classic Upgrade uses ISO 68 waylube (way oil) for lubrication of the machine’s sliding and motion components. The waylube tank capacity is 4 L (1.06 gal). Keeping the tank topped up with the correct ISO grade helps reduce wear, supports stable motion, and protects long-term accuracy. If you’d like recommended refill practices based on your usage and duty cycle, please contact our technical support team.

What is the machining coolant tank capacity on the TensileTurn CNC Classic Upgrade?

The TensileTurn CNC Classic Upgrade is equipped with a machining coolant tank capacity of 70 L (18.5 gal). Adequate coolant volume supports consistent chip evacuation, surface finish, and tool life—especially when machining tougher alloys and higher-throughput batches. Coolant type, concentration, and service interval depend on your materials and shop practices; our team can recommend a maintenance routine aligned with your workload. For coolant recommendations and refill/cleanup guidance, please contact our technical support team.

What does the industrial chiller require, and how much distilled water does it use?

The TensileTurn CNC Classic Upgrade uses an industrial chiller to support the water-cooled spindle system. The chiller reservoir is filled with distilled water, with a typical capacity of 8 L (2.11 gal). Using distilled water helps reduce mineral buildup and supports stable cooling performance over time. We recommend checking fluid level during routine maintenance and following the service guidance for cleaning and inspection. If you need startup, maintenance, or service recommendations for your facility, please contact our technical support team.