Why Choose the TensileTurn CNC Industrial Upgrade for Round Tensile Specimen Preparation?

This production-ready lathe is built specifically for high-volume, high-precision round tensile specimens, delivering tight geometry and stable surface finish for ASTM E8, ISO 6892, and ASTM B557 workflows while cutting lead times and reducing reliance on outside machining.

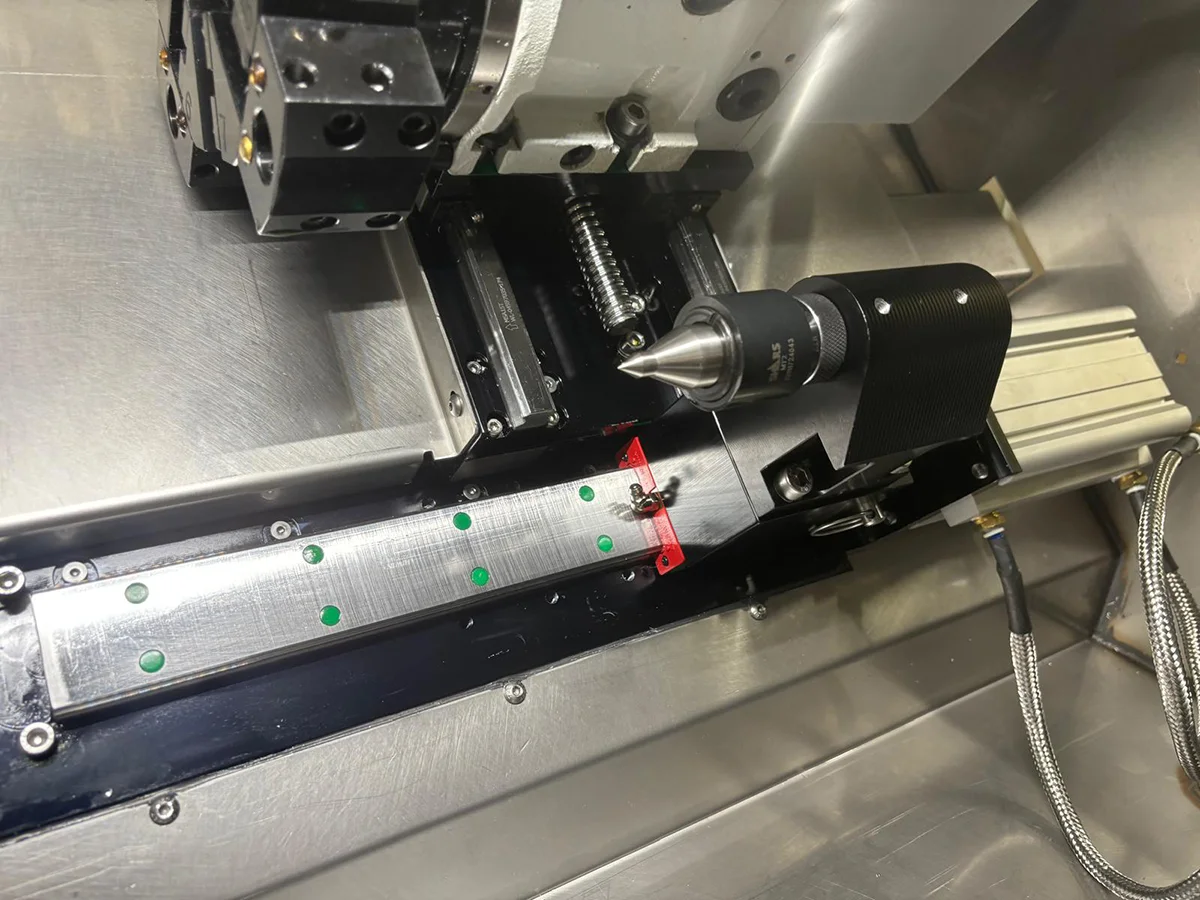

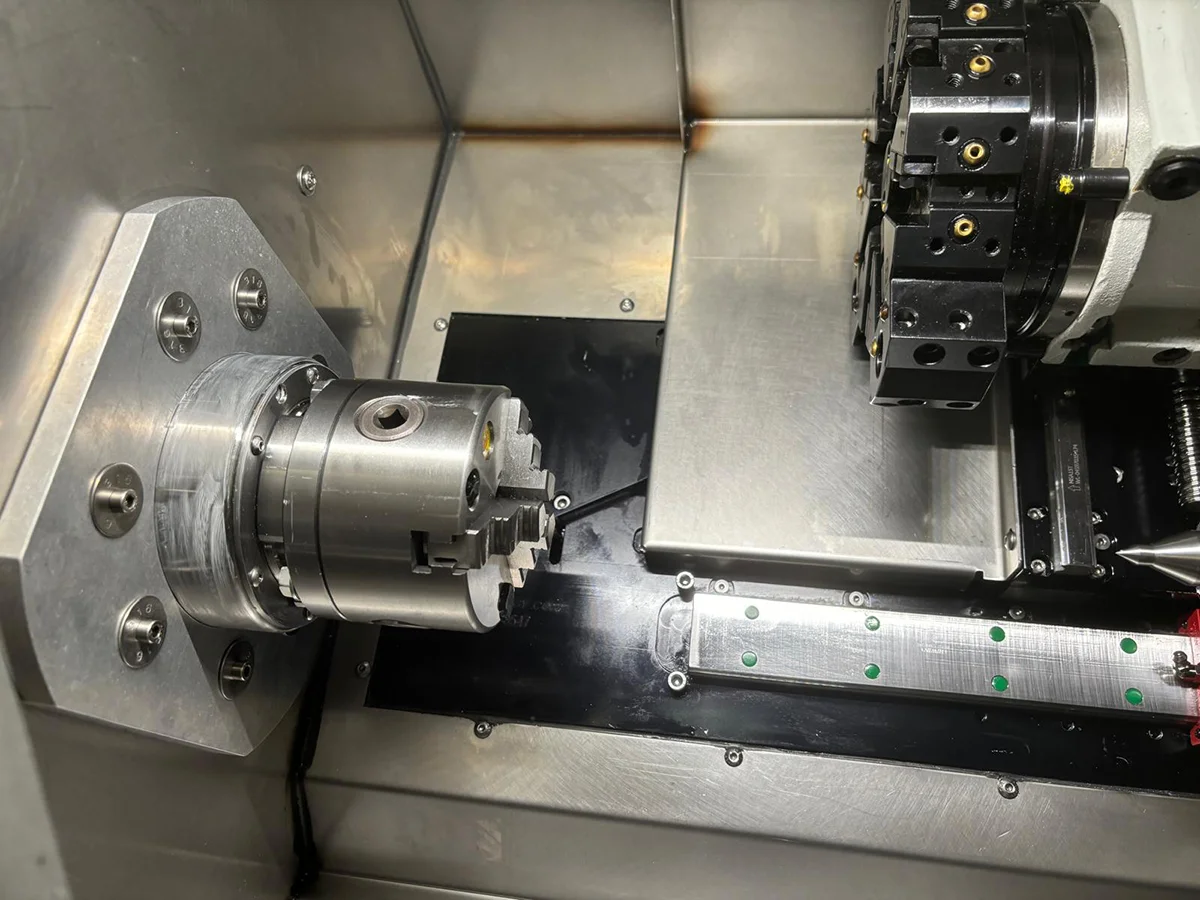

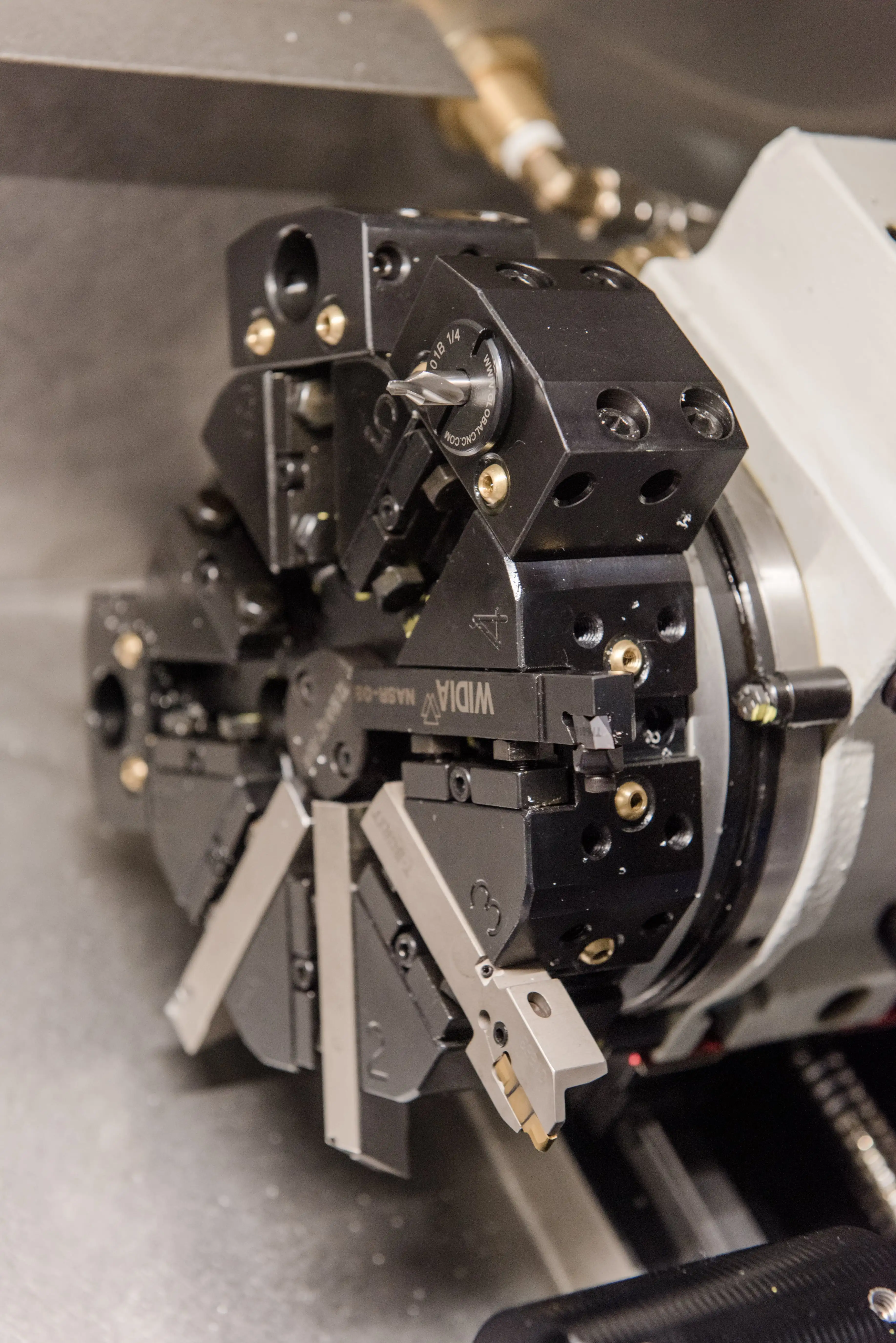

A vibration-damping granite structure and stainless enclosure support industrial duty cutting, while an 8-station turret accepts 0.5 in OD tools and 0.75 in boring bars for fast changeovers. The spindle package delivers about 2 hp (1.5 kW) at up to 3500 rpm, and automated center drilling removes a common bottleneck. The FANUC-based control with TensileSoft v2.0 provides a touchscreen library of standard specimen profiles plus Macro B, canned cycles, Ethernet, and USB, so operators can move from setup to cut in minutes. Typical finishes of about 63 Ra are achievable on a wide range of metals up to 55 HRC, using round, square, or irregular blanks. A compact footprint of 43.8 in × 26.7 in × 39.0 in (1112 mm × 678 mm × 991 mm) and a weight of roughly 810 lb (368 kg) make it easy to place in quality labs. Application guidance, on-site training, and a 12-month warranty support rapid adoption in regulated environments.

If you would like a deeper look at capabilities, videos, and footprint details, you can review the

TensileTurn CNC - Industrial Upgrade on the product page.

What After-Sales Support Comes With the TensileTurn CNC Industrial Upgrade?

You receive lifecycle technical support with the TensileTurn CNC Industrial Upgrade, beginning with installation and commissioning. Our specialists assist with machine setup, alignment and calibration, then deliver operator training tailored to your round specimen workflow and lab procedures.

After startup, you can access ongoing help for programming tensile geometries, CNC control operation, and repeatable sample recipes. Technicians provide phone, email, and ticket-based assistance for remote diagnostics, parameter tuning, and controller updates; they also advise on tooling, workholding, and coolant selection to sustain dimensional accuracy and surface finish. When deeper intervention is needed, field service can be scheduled, and we can coordinate parts, consumables, and preventive maintenance to support uptime across the equipment lifecycle.

For priority assistance, contact 877-672-2622 ext. 3, email support1@tensilemillcnc.com, or submit a request through our online support ticket system.

If you would like to explore specifications and service details, you can review them on the

TensileTurn CNC Industrial Upgrade equipment page.

What Is the Lead Time for the TensileTurn CNC Industrial Upgrade?

Most Industrial Upgrade systems ship in 4 to 6 weeks from purchase order, with timing influenced by selected configuration and destination. We confirm the target ship window during quoting and lock it in after order acceptance.

Lead time may vary if your build includes nonstandard chucking, custom fixturing, voltage adaptations, or added accessories that require procurement and quality checks. After the order is placed, our team completes a configuration review within 2 to 3 business days, schedules production, performs functional testing with trial cuts, and crates the machine for freight. Typical transit within the continental United States adds 3 to 7 business days, while international delivery can add 1 to 2 weeks for customs and inland transport. If you are working toward a specific audit, R&D gate, or production start, we can coordinate delivery and training windows to avoid downtime. For a firm schedule and pricing, call 877-672-2622 or email sales@tensilemillcnc.com.

If you would like to review specifications, build options, or request a quote, you can read more on the

TensileTurn CNC Industrial Upgrade page.

How Easy Is the TensileTurn CNC Industrial Upgrade to Operate, and Do You Provide Training?

Yes. The round-specimen lathe is built for easy operation with a responsive touchscreen HMI, clear menus, and recipe-driven programs that reduce the learning curve for first-time users.

Included training is provided with every system, delivered remotely or on site based on your schedule. Sessions cover interface navigation, safe setup, chucking and tailstock practices, datum setting, tool offsets, selecting programs for common gauge diameters, and finish targets for tensile testing. After onboarding, you can save material-specific recipes, so operators load a job, confirm tooling, and run consistent specimens with minimal steps.

Ongoing support includes application help, refresher training, and remote diagnostics to keep workflows steady over time. This approach lowers error rates, shortens onboarding for new staff, and supports repeatable specimen geometry for standards-based testing such as metals prepared for ASTM E8 or ISO 6892.

If you would like to see interface highlights and training options, you can review details on the

TensileTurn CNC - Industrial Upgrade product page.

Does the TensileTurn CNC Industrial Upgrade Produce Round Specimens That Meet International Standards?

Yes. This round-specimen machining system is built to produce test pieces that meet major international standards, including ASTM E8, ASTM A370, and ISO 6892. It accommodates standard and custom geometries, such as reduced sections, threaded ends, and sub-size blanks, while maintaining consistent diameters, accurate gauge lengths, concentricity, and a smooth surface finish for dependable tensile results and audit-ready documentation.

Operators can run pre-programmed standard profiles or create templates for unique drawings, then apply optimized tooling with material-specific feeds and speeds from the HMI. Rigid workholding and closed-loop servo control support dimensional repeatability across batch runs, and on-screen fields can record heat numbers, operator IDs, and fixture references to strengthen traceability. If formal documentation is required, TensileMill CNC can supply compliance packets and coordinate third-party verification for programs such as NADCAP, as well as support internal or customer-specific quality requirements.

If you would like to explore capabilities and options for round specimen machining, you can review details on the

TensileTurn CNC Industrial Upgrade product page.

What Are the Maintenance Costs for the TensileTurn CNC Industrial Upgrade?

Maintenance spending for the TensileTurn CNC Industrial Upgrade is modest and predictable. The system is engineered for 24/7 reliability, so ongoing costs are typically limited to basic housekeeping and a scheduled preventative maintenance visit each year.

Thanks to industrial-grade mechanical components and a streamlined layout, routine care focuses on chip removal, periodic lubrication checks, and visual inspection of items such as belts, way wipers, and coolant filtration. Most facilities plan one annual preventative maintenance visit that includes an on-site evaluation, precision adjustments, system lubrication, and replacement of normal wear parts to keep accuracy consistent.

Actual cost varies with duty cycle, material hardness, coolant selection, and shop environment. In practice, even with high utilization, most budgets center on consumables plus the annual PM visit. PM Service Packages are available to reduce unplanned downtime and consolidate maintenance into a predictable scope with documented results. For a tailored quotation, you may request a PM proposal from our service team.

If you would like a tailored PM estimate or to review service options, you can read about maintenance support on the

TensileTurn CNC - Industrial Upgrade product page.

How Does the TensileTurn CNC - Industrial Upgrade Reduce Downtime for Round Specimen Preparation?

Unplanned stops are minimized with fast remote triage, same-day diagnostics, and priority parts fulfillment. If an issue occurs, you can reach the service team at 877-672-2622 ext. 3, support1@tensilemillcnc.com, or via the online support ticket system.

Most support cases are diagnosed and closed remotely within 4 hours. When a component or deeper intervention is required, the target for full resolution is 24 to 48 hours. To keep schedules on track, commonly used wear parts and assemblies are stocked for rapid shipment, and on-site visits can be arranged as early as the next business day when warranted.

Technicians guide operators through step-by-step checks, photos or video as needed, and concise functional tests that isolate faults without unnecessary disassembly. This focused workflow helps laboratories sustain specimen throughput, protect dimensional repeatability, and keep production or QA testing on schedule with minimal interruption.

If you would like a closer look at service coverage and machine capabilities, you can review details on the

TensileTurn CNC - Industrial Upgrade product page.

What Is the Typical Cost per Round Tensile Specimen, Including Machining and Testing, With the TensileTurn CNC Industrial Upgrade?

When round specimens are machined on the TensileTurn CNC Industrial Upgrade and then tensile tested on a compatible universal testing machine, labs typically budget about $150 to $300 per specimen. The range reflects material type, geometry, and the required test method.

Actual cost is shaped by several workflow factors: alloy and hardness, initial stock condition, finish turning passes, optional threading or button-heads, and any polishing needed for extensometer grip quality. Tooling consumption and operator touch time contribute to the machining portion. The testing portion varies with setup time, grips and adapters, extensometer style, data capture, and report format aligned with standards such as ASTM E8 or ISO 6892. Batch runs often lower the per-specimen price by spreading setup over multiple parts, while in-house machining with the Industrial Upgrade removes outsourcing freight and minimum lot charges. If you would like a precise estimate for your material and throughput, you can use our calculator inputs or request a tailored quotation from our team.

If you would like to compare specifications or watch application videos, you can review the

TensileTurn CNC Industrial Upgrade on the product page.

What Is the Average Cost Range for Round Tensile Sample Preparation Only With the TensileTurn CNC Industrial Upgrade?

For preparation only, typical machining cost per round tensile specimen on the TensileTurn CNC Industrial Upgrade falls between $150 and $300 per sample. This scope covers turning the blank to final geometry per print or standard, including roughing, finishing, shoulder radii, basic chamfers, parting, and light deburring. Pricing does not include raw material, separate polishing operations, tensile testing, specialized grips or fixtures, shipping, or post-test services.

Actual pricing varies with alloy and hardness, tolerance band and surface finish requirements, geometry complexity such as long gauge lengths or tight shoulder transitions, any added features like threads or grooves, and batch size that affects set ups and tool life. Larger production runs generally lower the per-sample rate due to fewer changeovers and more stable tool wear. The Industrial Upgrade system supports consistent concentricity and repeatable results for metallic specimens prepared to common geometries used with ASTM E8 or ISO 6892 programs when required. For an exact figure based on your print and volume, you can use the TensileMill Round Sample CNC Calculator or connect with a product specialist for a firm quote.

If you would like to compare configuration options or review specs before requesting a quote, you can read more on the

TensileTurn CNC – Industrial Upgrade product page.

Do You Offer Benches for TensileTurn CNC Industrial Upgrade Machines, and What Are the Bench Dimensions?

Yes. A heavy-duty bench is available for the TensileTurn CNC Industrial Upgrade as an optional accessory and will appear on your Round Tensile Sample Preparation System quotation. The bench weighs 248 lb (113 kg) and measures 48 in × 42 in × 38 in, W × D × H (122 cm × 107 cm × 97 cm).

Customers typically select this bench when they want a rigid, factory-matched platform and a clean installation without sourcing third-party shop furniture. The footprint supports comfortable operator access for loading blanks and retrieving finished specimens, while the mass helps damp vibration during turning. When planning your cell, compare the bench dimensions to doorway or elevator clearances, allocate space for chip management and coolant service, and confirm the final placement relative to power and ventilation. If your layout or workflow calls for alternative positioning or additional accessories, your quotation can be tailored accordingly.

If you would like to review specifications and compatible accessories, you may explore details on the

TensileTurn CNC - Industrial Upgrade product page.

What Surface Finish Can The TensileTurn CNC Industrial Upgrade Achieve On Different Materials?

For most metals, the Industrial Upgrade lathe produces turned surfaces of 63 microinch Ra (1.6 micrometers) or finer directly from the tool. On many alloys, such as aluminum and low alloy steels, finishes near 32 microinch Ra (0.8 micrometers) are attainable with a dedicated finishing pass and the appropriate insert grade.

Surface texture varies with material hardness or heat treatment, insert geometry and nose radius, rigid workholding between centers, feed per revolution, cutting speed, depth of cut, coolant delivery, and any interrupted features on the blank. For tensile specimens, a light finishing pass with a sharp finishing insert, a nose radius matched to the gauge section, balanced feeds and speeds, and careful alignment to minimize runout typically deliver the best results. If a specific Ra target is required for your program, our team can recommend tooling and parameters tailored to your material family.

If you would like to validate finish on your alloy and geometry, you may send sample material for complimentary trial cuts, and we will document the achieved Ra along with the machining recipe used.

If you would like to review capabilities and options, you can read more on the

TensileTurn CNC Industrial Upgrade product page.

What Is the Footprint of the TensileTurn CNC Industrial Upgrade?

The Industrial Upgrade model is compact for an industrial CNC lathe. The machine body measures 43.8 in × 26.7 in × 39 in (1112 mm × 678 mm × 991 mm) and weighs about 810 lb (368.2 kg).

This footprint refers to the main lathe enclosure and granite frame, which are designed to deliver high stiffness and vibration damping without requiring excessive floor space. The coolant tank is not part of the footprint. For space-conscious labs, the tank can be positioned beneath a bench or the optional work table to keep the aisle clear and maintain a tidy workflow.

For layout planning, place the system where operators can comfortably load raw stock, access the control, and remove chips. Leave practical clearance around the doors and service points for routine maintenance, coolant refills, and tooling changes. If you select the optional work table, it is supplied with quotations for the round tensile sample preparation system so you can match the bench plan to your available space.

If you would like dimensions, utilities, and accessory options in one place, you can review the details on the

TensileTurn CNC Industrial Upgrade product page.

What Is the Proper Chip Removal Procedure for the TensileTurn CNC Industrial Upgrade?

Stop motion first. Press the E-Stop, wait for the spindle and coolant to stop, then open the enclosure door. Use a chip hook, brush, scoop, magnetic pickup, or a metal-rated vacuum to remove chips from the chuck, toolpost, carriage, ways, and chip pan. Do not handle chips with bare hands. Wear cut-resistant gloves, safety glasses or a face shield, and appropriate sleeves to protect against hot, sharp stringers.

Avoid blowing chips directly at the spindle, bearings, or way covers with compressed air, since debris can be driven into seals. If air use is permitted by your facility, apply low pressure outside critical areas. Empty the chip container into a metal receptacle, and clear any drain screens if equipped to keep coolant flowing. Verify the chuck jaws and toolholders are free of trapped chips, close the door, release the E-Stop, and reset the control before resuming machining. Follow your shop’s lockout or tagout procedures when performing deeper cleaning or service inside the enclosure.

If you would like additional machine details or accessories, you can review specifications on the

TensileTurn CNC – Industrial Upgrade product page.

What Are the Power and Air Requirements for the TensileTurn CNC – Industrial Upgrade Round Specimen Machine?

Standard utilities for this round specimen machine are 220 V single-phase VAC on a 20 A circuit, plus clean, dry compressed air at 90 psi (6.2 bar) for the pneumatic tailstock.

For straightforward installation, place a grounded 220 V outlet within reach of the machine, dedicate a 20 A breaker, and supply a regulated air line with moisture filtration near the tailstock port. The air source actuates the tailstock, while cutting power is electrical, so no additional pneumatic capacity is needed for machining. Confirming both utilities ahead of delivery helps speed commissioning and keeps specimen throughput targets on schedule.

If you would like to review technical specifications and installation details, you can explore the

TensileTurn CNC – Industrial Upgrade on the product page.

What Starting Blank Dimensions Are Recommended for the TensileTurn CNC Industrial Upgrade?

For consistent results, grip a short section of the blank in the chuck and support the opposite end with the tailstock. A chuck clamping length of about 0.50 to 0.75 in (12.7 to 19.1 mm) works well, and keeping a bit of extra length helps when machining threaded-end specimens.

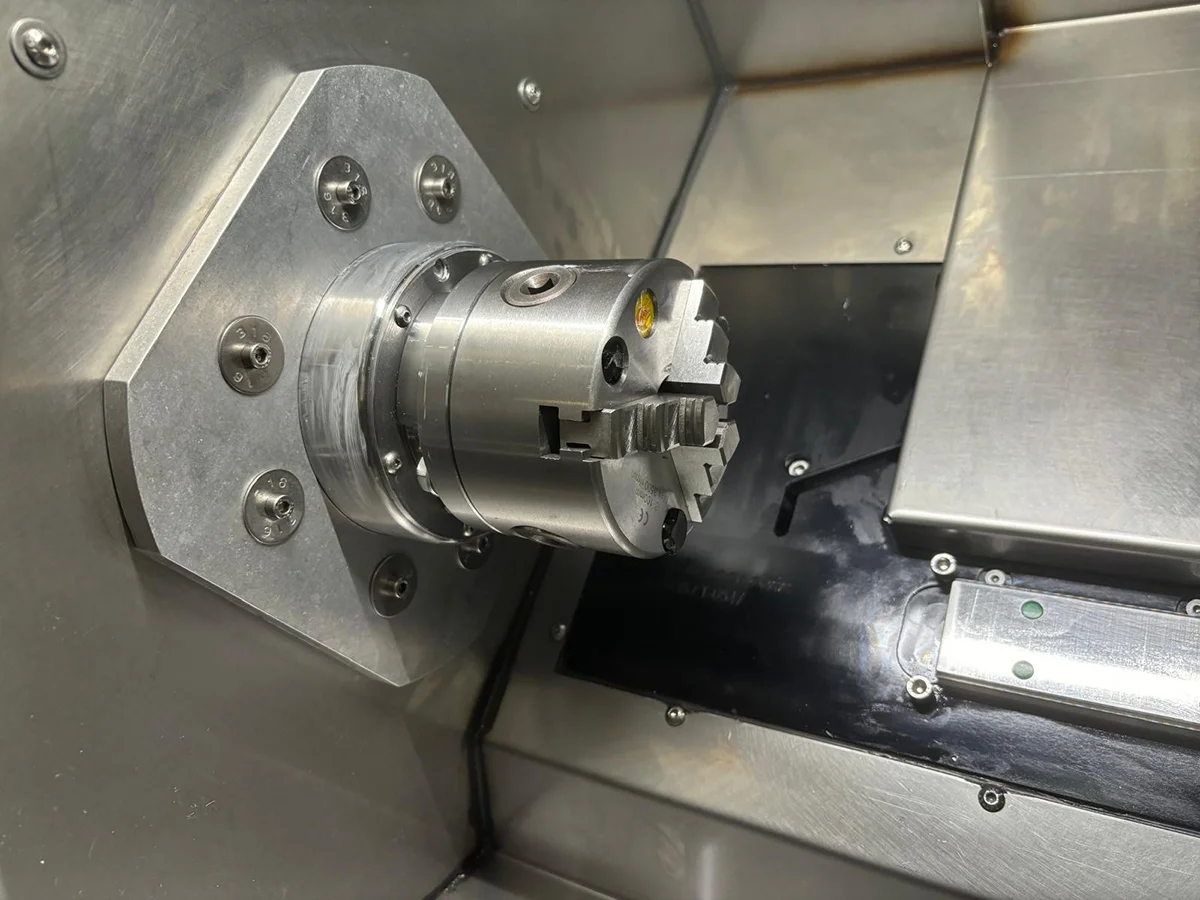

Round starting blanks for tensile specimen preparation can be processed up to 4.00 in diameter (101.6 mm) and approximately 12.0 in length (304.8 mm) when fixtured between the chuck and tailstock. For square stock, typical blanks of 1.00 in × 1.00 in × 12.0 in (25.4 mm × 25.4 mm × 304.8 mm) are suitable. The square chuck can securely hold material that is not perfectly square, which is common with band-saw cuts. If your material has an irregular profile, sharing a photo allows us to recommend a tailored workholding approach. You may also send representative blanks for a complimentary proof cut to confirm fit and cycle strategy before production.

If you would like to compare capacities, workholding, and software options, you can review the details on the

TensileTurn CNC Industrial Upgrade product page.

What Is the Accuracy and Repeatability of the TensileTurn CNC Industrial Upgrade?

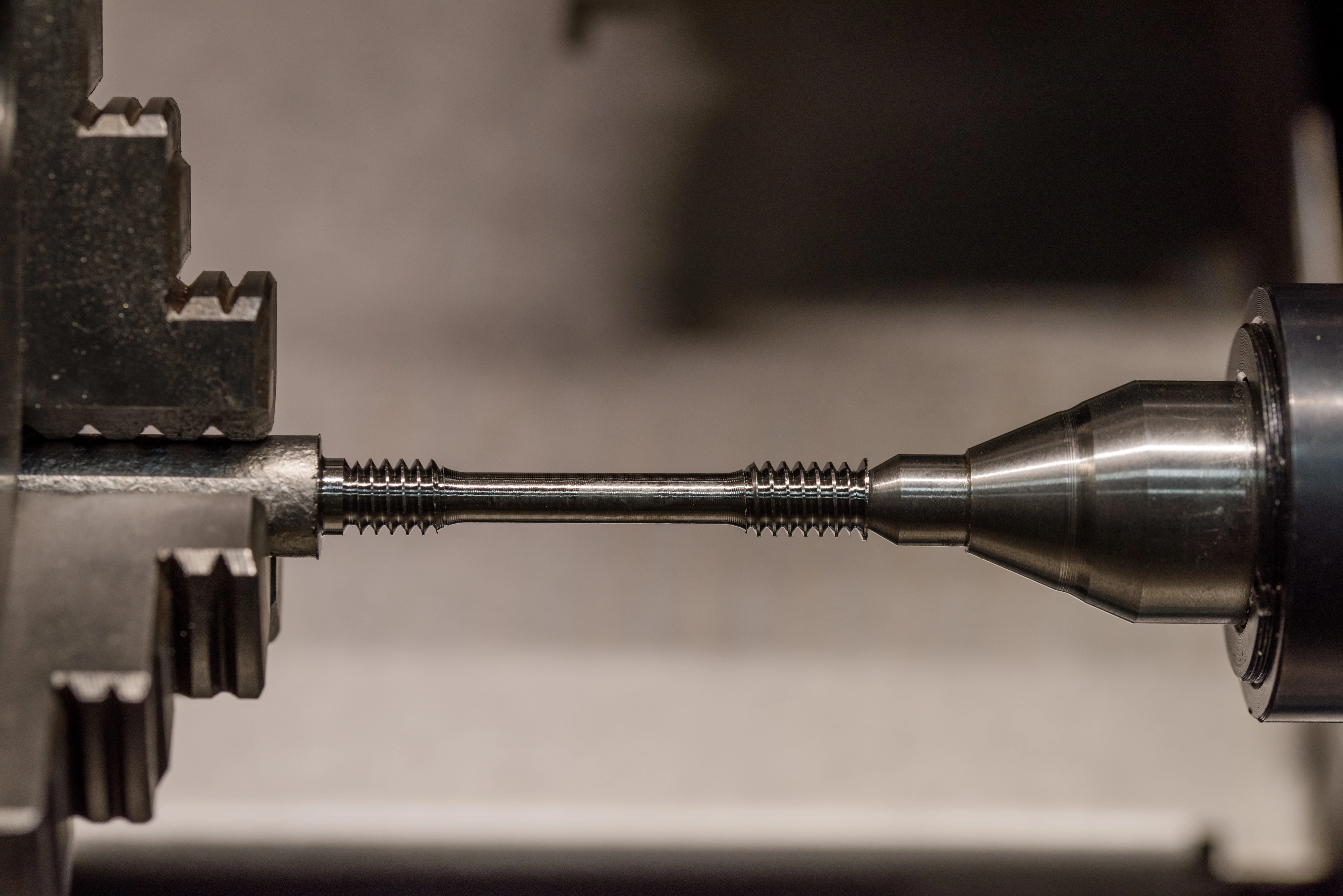

For the TensileTurn CNC Industrial Upgrade, typical dimensional accuracy and repeatability on finished round tensile specimens is 0.0003 in (0.008 mm).

This capability comes from rigid machine construction, closed-loop servos, precision ballscrews, and dedicated tensile programs. With the latest control and motion updates, many labs achieve tighter process capability once tooling, feeds, speeds, and tailstock pre-load are optimized. Using the built-in tensile templates, you can produce gauge diameters, blend radii, and grip transitions that align with common metallic testing geometries in ASTM E8 and ISO 6892-1 when the appropriate program and inserts are selected. For consistent batch-to-batch results, apply a light two-pass finish cut, match insert nose radius to the template, keep cutting edges sharp, and verify final dimensions with a calibrated micrometer or air gage.

If you would like to review performance details and technical specifications, you can read more on the

TensileTurn CNC - Industrial Upgrade product page.

Which Industry Standards Can the TensileTurn CNC Industrial Upgrade Prepare Round Tensile Specimens To?

This round-specimen lathe supports major international testing standards. With the built-in TensileSoft library, you can machine specimens that comply with ASTM E8 and ASTM A370 for metallic materials, ISO 6892-1, DIN 50125, and JIS Z 2241. Programs are selectable by standard and size, producing repeatable geometry and a smooth surface finish ready for tensile testing without secondary machining.

In practice, the operator selects a preset or enters dimensions such as gauge diameter, reduced-section length, fillet radius, and transition details. The software generates toolpaths and organizes the sequence for facing, turning, and optional automatic center drilling to deliver concentric, symmetric specimens. Workflows accommodate standard round tensile bars, sub-size geometries, threaded ends, and button-head styles, so labs can match material and grip requirements while maintaining consistency across batches. This approach supports high throughput, short training curves, and reliable results across a wide range of alloys and starting stock shapes.

If you would like to see the standard libraries and workflow options in detail, you can review the technical information on the

TensileTurn CNC – Industrial Upgrade product page.

How Does the TensileTurn CNC Industrial Upgrade Reduce Downtime in Round Specimen Preparation?

Unplanned stops are limited by rapid remote diagnostics, multi-channel support, and a structured preventive maintenance program. Most technical tickets are assessed and resolved remotely within 4 hours. If a component swap or deeper intervention is required, the typical target for full resolution is 24 to 48 hours.

When an alarm or quality drift appears, your team can reach technical support by phone at 877-672-2622 ext. 3, by email at support1@tensilemillcnc.com, or via the online support ticket system. Through secure remote access to the Fanuc-based control and TensileSoft interface, specialists review logs, verify parameters, and guide corrective steps in real time. Modular assemblies and readily available consumables and spare parts speed shipment and replacement, which keeps specimen throughput and testing schedules on track. Proactive software updates are applied at no additional cost, minimizing future interruptions. Optional training and retraining, paired with periodic preventive maintenance, further reduce repeat issues and extend system life.

If you would like to review features, service options, and technical specifications, you can explore the

TensileTurn CNC - Industrial Upgrade product page.

Which Toolholders, Inserts, and Boring Bars Does the TensileTurn CNC Use?

TensileTurn CNC Industrial Upgrade accepts standard 1/2 in square-shank OD toolholders (12.7 mm) and 3/4 in round-shank boring bars (19.05 mm). Common insert families include DCMT 21.51 and DCGT 21.51. Typical choices are steel-cutting grades such as TT8115 with a 0.016 in corner radius (0.41 mm) and aluminum-cutting grades such as K10 with a 0.016 in corner radius (0.41 mm). Threading options include Top Thread #2-style holders with NT2RK TN6010 inserts for 60 degree threads covering 8 to 36 TPI. Many additional insert sizes and grades are available based on your material and finish targets.

Representative tooling used by customers includes Ingersoll BDJCR08-2C-SH and BDJCL08-2C-SH 1/2 in holders, Ingersoll TTER12.7-24-3SH-TB 1/2 in tooling paired with TDT3.18E-1.59 TT9080 at 0.062 in nose radius (1.57 mm), plus Widia Top Thread #2 right-hand 1/2 in shank solutions. In day-to-day operation, you can load the appropriate holder, set offsets, and switch between roughing, finishing, and threading without changing posts. Using mainstream 1/2 in and 3/4 in interfaces simplifies local sourcing and lets the lab match insert geometry to aluminum, stainless, or harder steels.

If you would like to review compatible tooling and machine details, you can learn more on the

TensileTurn CNC Industrial Upgrade product page.

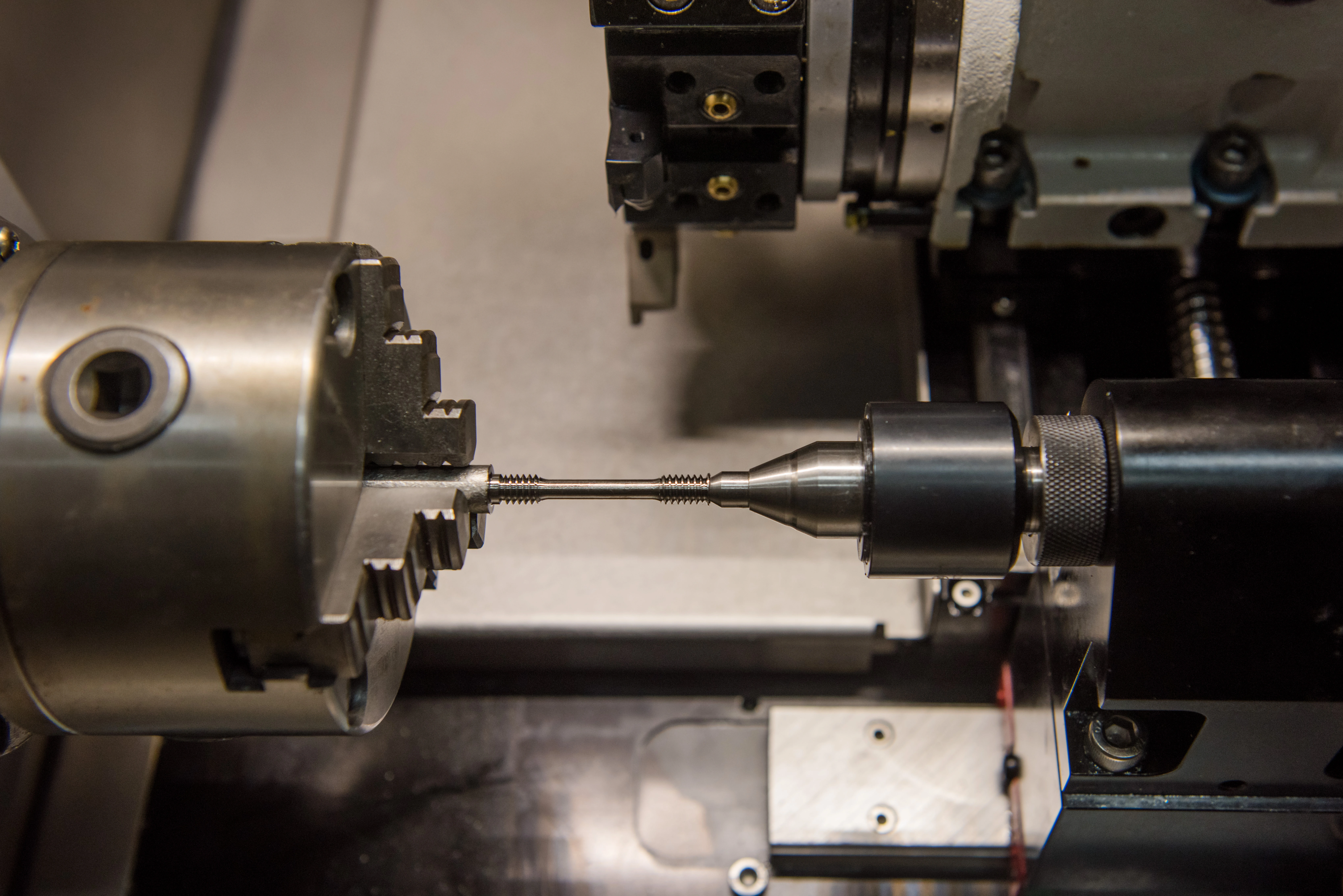

Which Specimen Sizes, Materials, And Standards Does The TensileTurn CNC Industrial Upgrade Support?

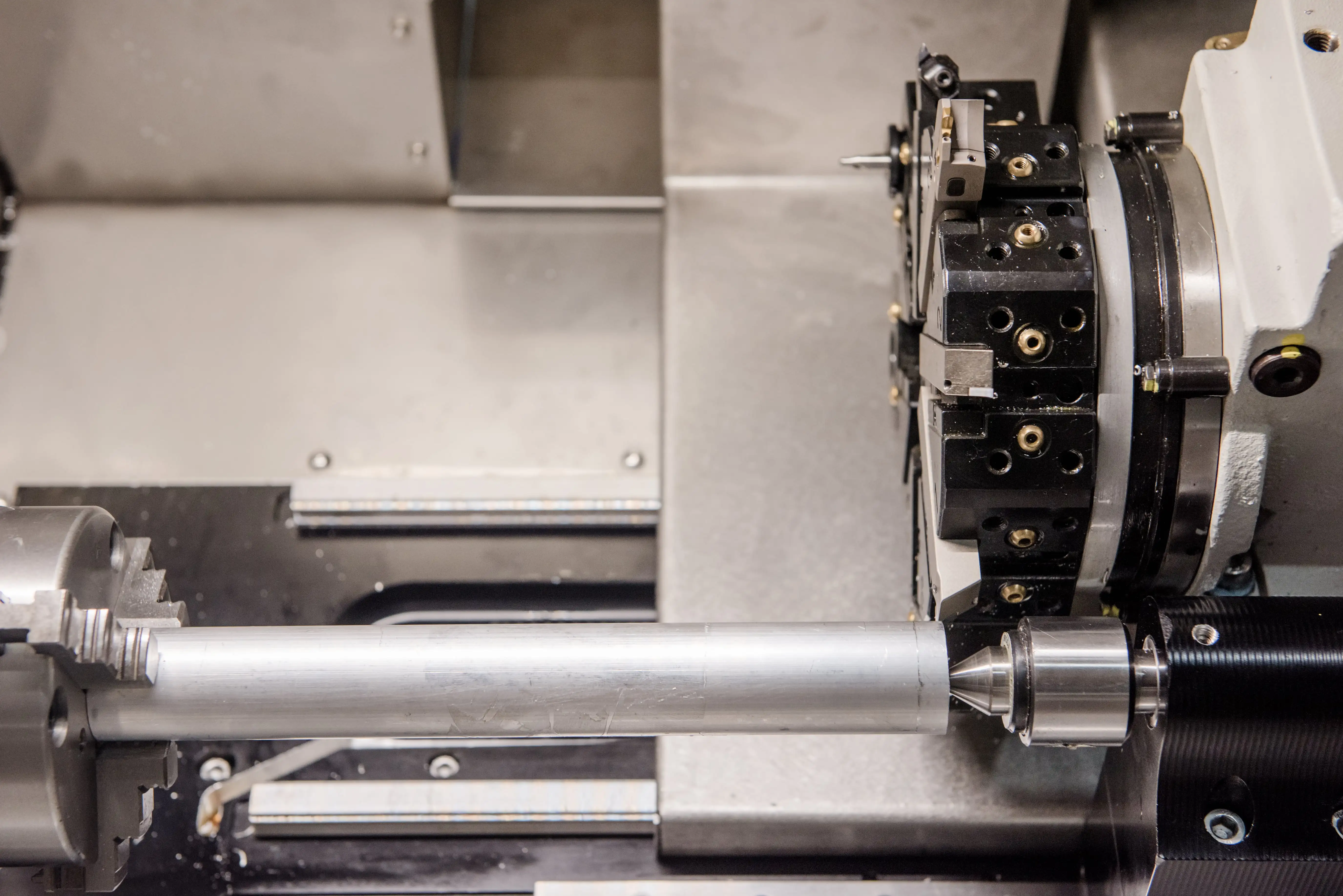

The machine accommodates common round tensile blanks and bar stock, including through-spindle material up to 1.00 in (26 mm) OD. Its work envelope supports typical ASTM E8 geometry such as 0.505 in (12.9 mm) gauge diameter with 2.00 in (50 mm) gauge length, within an approximate 8.0 in (203 mm) swing and 9.0 in (228 mm) between centers, depending on tooling and fixturing. The standard chuck handles short blanks, while centers and tailstock support longer reduced sections.

The equipment routinely machines aluminum, magnesium, copper alloys, carbon and stainless steels, titanium, and nickel alloys. With proper tooling it also handles heat-treated tool steels around 50 HRC. Use sharp carbide or CBN for hard alloys, flood coolant, and conservative finishing passes, for example 0.0015–0.0025 in/rev (0.04–0.06 mm/rev) with light depths of cut near 0.010–0.020 in (0.25–0.50 mm). Spindle speed capability of 50–3500 rpm allows dialing in surface speed for both free-machining and difficult materials.

Standards compliance depends on the dimensions and finish you program. The integrated library covers common sizes for ASTM E8, ASTM A370, and ISO 6892, and you may enter custom dimensions when required. Many labs target Ra 32–63 µin (0.8–1.6 µm) on the reduced section before any optional longitudinal polish, maintain smooth fillet transitions, and avoid tool marks. The system also supports threaded-end and button-head specimens when equipped with appropriate tooling and toolpath selections.

If you are evaluating round-specimen lathes, you can review technical details on the

TensileTurn CNC - Industrial Upgrade product page for a concise overview of capabilities and specifications.

What Power, Space, And Material Capacity Are Needed To Run The TensileTurn CNC Industrial Upgrade?

The machine operates on a standard 220 V AC, 20 A circuit. Plan floor space for a footprint of 43.8 in × 26 in × 42.5 in (1.1 m × 0.66 m × 1.1 m). Place it on a rigid, level surface capable of supporting at least 800 lb (362 kg). The integrated coolant system holds 10 gal (38 L), and Ethernet or USB connections are available for program transfer and data management.

For stock capacity and reach, the spindle bore is 1.0 in (26 mm), the chuck is 4.0 in (101 mm), swing over bed is 8.0 in (203 mm), and center width is 9.0 in (228 mm). Within these limits, the system comfortably produces standard and subsize round tensile specimens to common geometries in ASTM E8, ASTM A370, and ISO 6892. In practice, many labs machine gage diameters around 0.125 to 0.505 in (3.2 to 12.8 mm) with gage lengths near 1 to 2 in (25 to 50 mm), depending on the selected standard and material.

Performance features support tight tolerances and repeatability: spindle speeds from 50 to 3500 rpm, a 2 HP (1.4 kW) motor, and positioning accuracy of ±0.0002 in (±0.005 mm). These capabilities, combined with the tensile specimen library and automated center drilling, help operators achieve consistent results without tying up production lathes.

If you would like full specifications and options, you can review details on the

TensileTurn CNC Industrial Upgrade product page.

How Can I Achieve Concentric, 63 µin Ra Finishes On Round Tensile Specimens With The Industrial Upgrade?

For stable, concentric machining, face and center-drill both ends, chuck one end with 0.5–0.75 in (13–19 mm) of grip length, and support the other with the live center. Verify total indicated runout at the gauge section below 0.001 in (0.025 mm). The machine accepts round blanks up to 4.0 in diameter by 12.0 in length (102 mm × 305 mm), and square or slightly irregular blanks can be fixtured with the correct chuck.

Use a two-step routine. Rough-turn, leaving 0.015–0.020 in per side (0.38–0.50 mm) for finishing, then take a single finish pass. For alloy steels up to about 55 HRC, start near 200–350 sfm (61–107 m/min) with a finishing feed of 0.002–0.006 in/rev (0.05–0.15 mm/rev) using a wiper-style carbide with 0.016–0.031 in (0.4–0.8 mm) nose radius. Maintain consistent coolant, set tailstock pressure near 90 psi (0.62 MPa), and add a spring pass if needed. These practices routinely deliver 63 µin Ra (1.6 µm) or better on the reduced section.

Confirm geometry against ASTM E8, ASTM A370, or ISO 6892 when applicable. Load the matching profile in the tensile library, or enter custom dimensions, then verify diameters and shoulder radii before unclamping. For threaded or button-head ends, leave 0.25–0.50 in (6–13 mm) extra stock to protect grip features during chucking.

If you would like additional setup tips and configuration details, you can review specifications on the

TensileTurn CNC – Industrial Upgrade product page.

How To Machine ASTM E8 Round Tensile Specimens With Consistent Concentricity And Surface Finish

Begin with rigid workholding and center support. Use a precision collet or well-indicated soft jaws, then bring up a live center to support the blank. Verify headstock to tailstock alignment with a test bar and target 0.001 in TIR (0.025 mm) or better at the free end. Face and center-drill both ends to about 0.125 in (3.2 mm) depth, and apply a steady rest when unsupported length exceeds 8 in (200 mm) to prevent chatter.

Rough-turn the gauge region, leaving 0.020 to 0.030 in (0.50 to 0.75 mm) of radial stock for finishing. Make a single, continuous finish pass. For carbon and alloy steels with carbide inserts, use 250 to 400 sfm (75 to 120 m/min) and 0.002 to 0.006 in/rev (0.05 to 0.15 mm/rev). A small nose radius, about 0.015 to 0.031 in (0.4 to 0.8 mm), helps blend shoulders. Aim for 32 to 63 µin Ra (0.8 to 1.6 µm). Add a 0.02 in × 45° (0.5 mm × 45°) entry chamfer to control burrs at the gauge section.

Match geometry to the selected method. Under ASTM E8/E8M, keep the gauge diameter tight, commonly within ±0.001 in (±0.025 mm), use a 2.0 in (50 mm) gauge length or a 4D geometry when specified, and blend shoulders with a smooth radius per the standard for your material. A shallow relief of 0.02 to 0.04 in (0.5 to 1.0 mm) between the shoulder and grip reduces stress risers. Confirm size with micrometers at three locations, recheck TIR in the machine before part-off, and, for sensitive alloys, apply longitudinal finishing with 320 to 600 grit to satisfy finish expectations in ASTM E8/E8M or ISO 6892-1 when required.

If you want to review fixturing, capacity, and automation options for round specimen preparation, you can learn more on the

TensileTurn CNC - Industrial Upgrade equipment page.

What Workholding, Allowances, and Finish Targets Should I Use for Round Tensile Bars on an Industrial CNC Lathe?

For consistent geometry, start with straight bar or sawed blanks that are 0.5 to 1.0 in (13 to 25 mm) longer than the finished specimen. Leave 0.06 to 0.12 in (1.5 to 3.0 mm) over the target gauge diameter for finishing. Center-drill each end at 60 degrees, hold in a collet or soft jaws, and support with a live tailstock center. Indicate runout at the blank OD and at the center hole, and correct to 0.001 in (0.025 mm) or less before cutting. This setup reduces chatter and keeps the gauge section concentric with the grip ends.

Use step roughing followed by a light finish pass. Typical roughing depth of cut is 0.04 to 0.08 in (1.0 to 2.0 mm) with 0.008 to 0.012 in/rev (0.20 to 0.30 mm/rev). Finish with 0.005 to 0.010 in (0.13 to 0.25 mm) depth at 0.002 to 0.006 in/rev (0.05 to 0.15 mm/rev). Select tool nose radius 0.015 to 0.031 in (0.4 to 0.8 mm) to blend the fillets. For steels, 200 to 400 sfm (60 to 120 m/min) is a reliable starting point; for aluminum, 600 to 1000 sfm (180 to 300 m/min). Use flood coolant to manage heat and stabilize size.

After turning, target 32 µin Ra (0.8 µm) or better in the gauge section, and hold diameter within ±0.0005 in (±0.013 mm) when repeatability is critical. Verify geometry against ASTM E8 or ISO 6892 drawings, including gauge length and transition radii. If polishing is required, use longitudinal strokes with 320 to 600 grit, limiting removal to 0.001 in (0.025 mm) so the part stays within tolerance.

If you are planning in-house round specimen machining, you can review technical details on the

TensileTurn CNC - Industrial Upgrade product page.