Many people have at least once noticed the ISO label on products they use daily — from packaged food and bottled water to electrical tools and medical devices. ISO standards are vital in modern life, setting the foundation for quality, safety, and consistency in a number of industries.

The same level of precision and global consistency is equally important in tensile testing. When equipment is ISO-certified, it means the machine has been designed, calibrated, and verified to meet strict international requirements for accuracy and performance. Such certification is not only a mark of technical reliability but also a requirement for producing trustworthy results in both research and industrial settings.

Throughout this article, we will explore why ISO-certified tensile testing equipment is necessary for delivering accurate results, maintaining compliance, and supporting global quality standards. As part of this discussion, we will review relevant ISO standards, examine the key benefits of certified machines, and discuss their use in many high-stakes industries.

The Role of ISO Standards in Tensile Testing

ISO standards are a key component of tensile testing, providing a unified framework that guarantees a high level of accuracy, repeatability, and consistency. Now, let us take a closer look at ISO standards for tensile testing.

Defining Procedures and Calibration

ISO standards specify detailed tensile testing methodologies, test execution, and data analysis. For instance, ISO 6892-1 outlines the method for the tensile testing of metallic materials at room temperature, assuring that tests are conducted under consistent and controlled conditions. Likewise, ISO 527-1 provides comprehensive guidance on evaluating plastic tensile properties, including specifications for specimen geometry and testing speed to maintain uniformity across different laboratories.

Calibration of tensile testing equipment is another critical aspect addressed in ISO standards. ISO 7500-1 sets out the requirements for verifying and calibrating tension and compression testing machines, making sure that force measurement systems remain accurate and traceable to national or international standards. Regular calibration—typically carried out annually—is necessary to compensate for mechanical wear and environmental influences that may gradually impact the equipment's precision.

ISO Standards and Tensile Testing Equipment

Beyond procedures and calibration, ISO standards also contribute directly to the design, performance, and documentation of tensile testing equipment. Machines that comply with relevant ISO standards deliver consistent force application, controlled test speeds, and reliable data acquisition. Such equipment must meet specific criteria for load cell accuracy, grip alignment, extensometer precision, and software validation. This guarantees that the entire testing system, from hardware to software, operates within the defined tolerances necessary for producing valid results.

Key Benefits of ISO-Certified Tensile Testing Equipment

ISO-certified tensile testing tools offer numerous advantages that are critical to the achievement of material performance, product safety, and regulatory compliance. Here is a list of them:

Reliable and Repeatable Results

ISO-certified tensile testing equipment is engineered to deliver high levels of consistency and precision, making it possible to achieve reliable outcomes over repeated tests. This repeatability is particularly important when evaluating critical material properties like tensile strength, ductility, and elongation. When testing the same batch of materials or comparing different batches of materials over time, certified equipment helps make certain that results are not affected by operator technique, machine inconsistency, or environmental factors.

Global Acceptance

Compliance with ISO standards facilitates the international recognition of test results and streamlines global trade and collaboration. Manufacturers and laboratories complying with ISO-certified testing protocols can be certain that their data is accepted across borders, reducing redundant testing and expediting product approvals in different markets.

Improved Product Safety and Quality

Standardized testing procedures help in the early detection of material defects, contributing to greater product safety and quality. By identifying potential issues during the testing phase, manufacturers can prevent failures in the field, protecting end-users and maintaining their brand reputation.

Support for Regulatory and Industry Compliance

ISO-certified testing equipment assists organizations in meeting the technical and legal requirements set by regulatory bodies. Standards such as ISO/IEC 17025 outline the general requirements for testing and calibration laboratories, assuring that equipment and procedures meet stringent quality benchmarks.

Operational Efficiency

The use of ISO-certified equipment helps maximize operational efficiency by reducing testing errors and minimizing retesting. Features like automated calibration routines and standardized testing software streamline the testing process, saving time and resources. For instance, modern tensile testing machines equipped with user-friendly interfaces and automated functions can significantly reduce operator-induced variability.

ISO Certification and Industry Demands

ISO-certified tensile testing equipment is integral across various industries, ensuring materials meet stringent performance and safety standards. Sectors such as aerospace, construction, automotive, and manufacturing must comply with ISO standards such as ISO 6892, ISO 527, and ISO/IEC 17025.

Aerospace Industry

In aerospace, materials are subjected to extreme conditions, necessitating precise tensile testing to ensure component integrity. Standards like ISO 6892-1, which specifies methods for tensile testing of metallic materials at room temperature, are commonly employed to assess properties such as yield strength and tensile strength. Additionally, ISO/IEC 17025 accreditation for laboratories makes sure that testing procedures meet international competence requirements.

Construction Sector

The construction sector relies on tensile testing to verify that materials like steel and concrete meet structural and safety requirements. ISO 6892-1 is frequently used for testing reinforcing bars and structural steel, ensuring they possess the necessary mechanical properties for building applications.

Automotive Manufacturing

Automotive manufacturers perform tensile testing to evaluate vehicle components, aiming to enhance performance and safety. Standards such as ISO 527-1, which outlines methods for determining plastic tensile properties, are applied to assess materials used in interior and exterior parts.

Manufacturing Industry

In general manufacturing, tensile testing is crucial for quality control and product development. Manufacturers test a variety of materials, including metals, plastics, and composites, to ensure they meet specific mechanical property requirements.

Most Relevant ISO Standards for Tensile Testing Equipment

While most ISO standards focus on testing procedures, few are specifically written for tensile testing machines and their components. Below are the 3 core ISO standards directly related to tensile testing equipment, followed by two supporting standards relevant to calibration and specialized testing conditions.

ISO 7500-1 – Metallic Materials – Verification of Static Uniaxial Testing Machines

This is the primary ISO standard for verifying and calibrating tensile and compression testing machines. ISO 7500-1 outlines the accuracy classes (such as Class 0.5 or Class 1) required for different levels of precision, and defines how to perform calibration using certified proofing devices.

The standard applies to the entire force measurement system of a tensile machine, including the load frame, load cell, and controller. Equipment compliant with ISO 7500-1 provides internationally recognized results, making it indispensable for manufacturers, testing labs, and research institutions seeking reliable and traceable force data.

ISO/IEC 17025 – General Requirements for the Competence of Testing and Calibration Laboratories

Although this standard is not exclusively for tensile testing equipment, it is important for regulating the environment where the equipment is used. ISO/IEC 17025 sets out requirements for laboratory competence, including calibration procedures, environmental conditions, documentation, and operator qualifications.

For a laboratory to be accredited under ISO/IEC 17025, its tensile testing machines must be regularly calibrated according to recognized standards (such as ISO 7500-1) and maintained under documented quality systems.

ISO 9513 – Metallic Materials – Calibration of Extensometers Used in Uniaxial Testing

Extensometers are critical accessories in tensile testing systems, used to measure the strain during the test. ISO 9513 defines extensometer calibration requirements and accuracy classes to guarantee precise and consistent strain data.

Although extensometers are not tensile machines themselves, they are integral to the overall equipment setup. Machines using uncalibrated or non-compliant extensometers can produce inaccurate stress-strain curves, making ISO 9513 a key standard for complete system reliability.

While the following ISO standards are not specifically written for general tensile testing equipment, they are commonly used in equipment calibration or specialized forms of tensile testing, and may be relevant depending on the application.

ISO 376 – Calibration of Force-Proving Instruments Used for the Verification of Uniaxial Testing Machines

This standard defines how to calibrate force-proving devices, also known as proving rings or reference transducers, that are used to verify force measurement accuracy of tensile machines (as required by ISO 7500-1). Although ISO 376 does not regulate tensile machines directly, it assists in the certification process by verifying that the calibration tools are precise and traceable.

ISO 204 – Metallic Materials – Uniaxial Creep Testing in Tension – Method of Test

ISO 204 is intended for creep testing machines, which apply tensile loads at elevated temperatures for long durations. While not a standard for conventional tensile machines, it includes equipment-related requirements for creep testing frames, furnaces, and extensometry systems. Manufacturers or laboratories using specialized tensile testing systems designed for high-temperature material evaluation are required to comply with this standard.

ISO-Proof Your Testing Equipment with Certified Calibration and Accreditation Services

At TensileMill CNC, we do more than supply high-performance tensile testing machines—we help you achieve and maintain full ISO compliance through our professional calibration and certification services. Whether you are operating a new system or maintaining legacy equipment from another manufacturer, we provide comprehensive support that ensures your devices meet the most rigorous material testing standards.

Through partnerships with trusted ISO/IEC 17025:2017-accredited laboratories, we facilitate the certification of tensile testing machines, both ours and third-party equipment, extensometers, force measurement systems, and specimen preparation devices. Our services cover key standards, including ISO 7500-1 (force verification), ISO 9513 (extensometer calibration), ASTM E4, ASTM E83, ASTM E1012, and many more, guaranteeing that your testing equipment is accurate and audit-ready for industries such as aerospace, automotive, defense, and industrial manufacturing.

Regular calibration is more than a requirement; it is a proactive step toward long-term performance, measurement reliability, and regulatory approval. Our packages include preventative maintenance, traceable calibration certificates, and even operator training, enabling your team to deliver consistent, ISO-aligned testing outcomes every time.

By choosing TensileMill CNC, you will benefit from:

- Calibration and certification for our machines and third-party equipment

- Support for NADCAP, ISO, ASTM, and ANSI/NCSL Z540-1-1994 standards

- Fast turnaround and expert facilitation from a single trusted source

- Improved test precision, reduced downtime, and extended equipment lifespan

Let us help you ISO-proof your lab or production facility. Whether you need equipment certification, alignment verification, or full NADCAP support, contact us today or request a quote to speak with our compliance specialists.

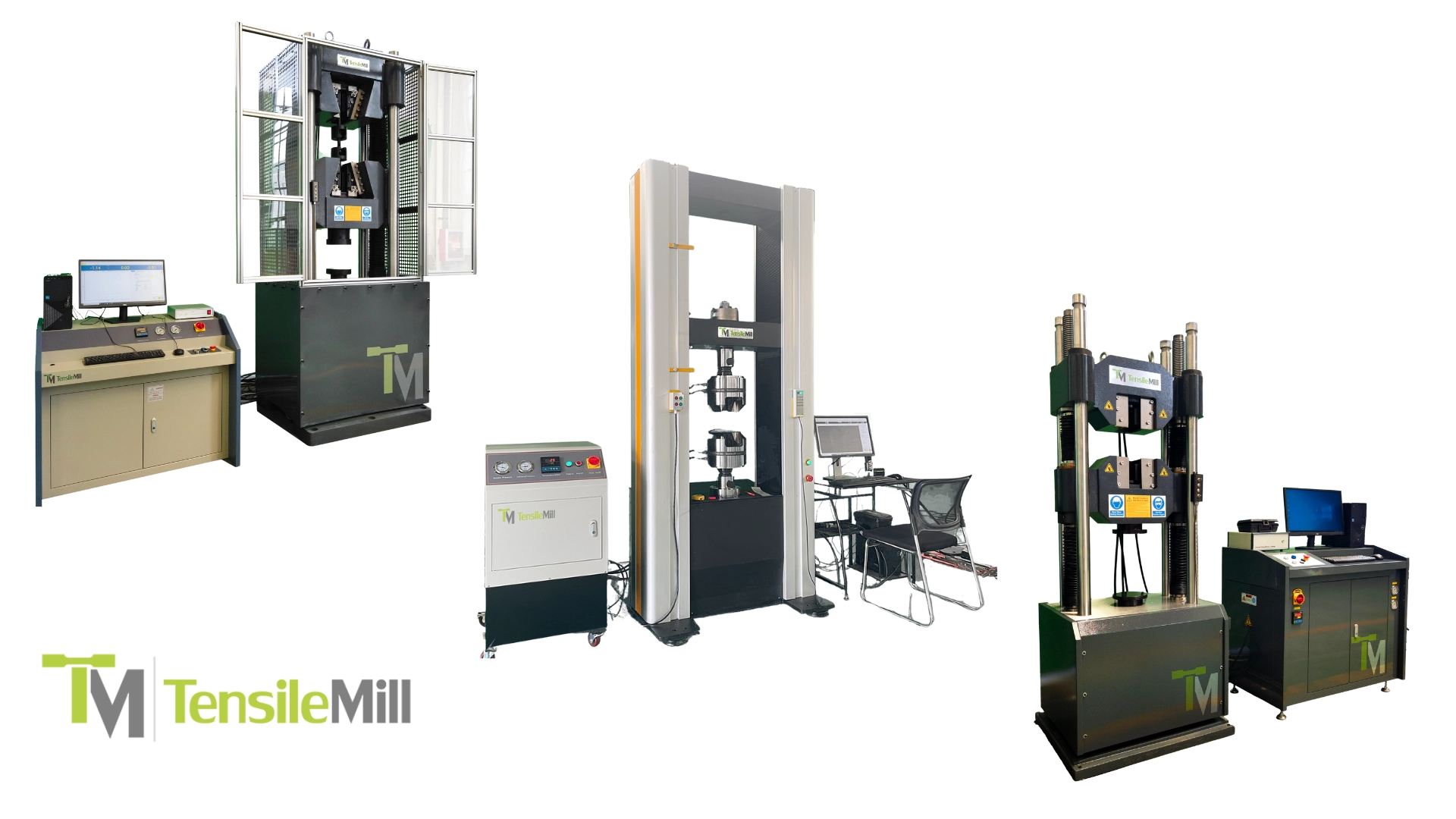

Looking for ISO-Compliant Universal Testing Systems?

If your facility requires high-performance tensile testing solutions that meet ISO, ASTM, NADCAP, and other international standards, TensileMill CNC offers a selection of fully certified Universal Testing Machines (UTMs) designed for the most demanding environments. Whether you are testing metals, composites, or structural components, our UTMs deliver accuracy, consistency, and full traceability.

We do more than supply hardware — our systems are supported by ISO/IEC 17025-accredited calibration services, turnkey installation, operator training, and long-term service plans to assure audit-ready performance. Explore two of our leading solutions:

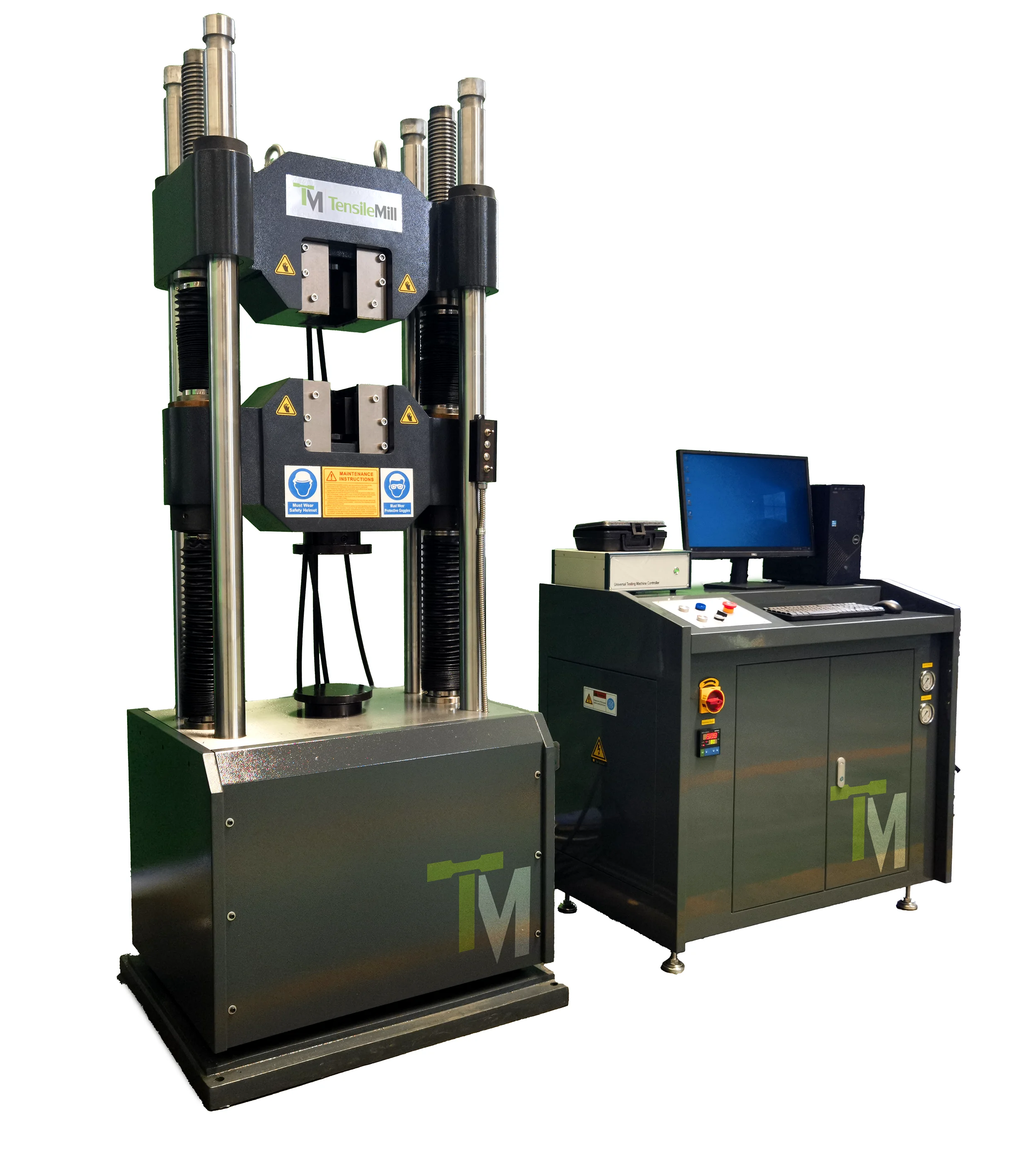

Servo Hydraulic Universal Testing System – 600kN / 1000kN

The Servo Hydraulic Universal Testing System is a high-force, multifunctional testing platform engineered for precise tension, compression, bending, and shearing applications. Available in 600kN and 1000kN capacities, this system is built with a durable four-column, dual-screw frame to deliver long-term stability and structural rigidity. It features direct force measurement through a Class 0.5 high-precision load cell, meeting ISO 7500-1 calibration requirements and guaranteeing test result accuracy within ±0.5% of the reading value. With its advanced EVOTest software interface, operators can conduct standard-compliant tests with ease, while real-time data visualization supports detailed curve tracking and result analysis.

This system is fully compatible with international testing standards such as ISO 6892, ASTM E8, and JIS Z2241. The upper zone is designed for tensile testing, while the lower zone supports compression and bending, allowing versatile dual-function testing without reconfiguration. Its hydraulic-operated wedge grips simplify specimen loading and clamping, while the optional alignment fixture allows laboratories to meet NADCAP and ASTM E1012 coaxiality requirements. An ideal choice for aerospace, steel, and structural material testing facilities seeking fully traceable, standards-compliant results, the Servo Hydraulic system supports continuous testing under heavy loads.

Electro Mechanical Universal Testing System – 50kN to 600kN

The Electro Mechanical Universal Testing System offers a high-accuracy, digitally controlled solution for laboratories and manufacturers testing a broad range of materials. With capacities from 50kN up to 600kN, this dual-column floor-standing system provides ±0.5% force accuracy and is certified to ISO 7500-1 Class 1 or Class 0.5, depending on configuration. It uses low-noise electromechanical drives, precision ball screws, and linear guides to achieve smooth crosshead motion and consistent axial alignment during tensile, compression, or flexural testing.

Equipped with GenTest software, the system features a built-in library of ISO, ASTM, DIN, and EN test standards, with automated reporting, overload protection, and real-time graphical output. For facilities seeking advanced certification readiness, this UTM can be enhanced with a coaxiality alignment fixture compliant with ASTM E1012 and NASM 1312B—enabling fast-track NADCAP preparation. Combined with ISO/IEC 17025-accredited calibration services and optional extensometer integration, the Electro Mechanical system is an all-in-one testing solution for quality control, R&D, and compliance-driven testing labs.

The Value of ISO-Certified Tensile Testing Equipment

ISO certification is more than a formality. It is a mark of trust, precision, and global compatibility. Throughout this article, we have explored the key role ISO standards play in tensile testing and the equipment that supports them. From defining consistent procedures and calibration methods to verifying compliance in industries, ISO-certified equipment is fundamental for delivering accurate, repeatable, and internationally recognized test results.

Choosing tensile testing machines that meet ISO 7500-1, ISO/IEC 17025, and ISO 9513 standards makes sure your lab or production facility is equipped with tools that not only perform reliably but also support audits, certifications, and customer confidence. Beyond technical compliance, such systems improve operational efficiency, reduce training time, and minimize costly errors—benefits that translate directly into product quality and business success.

At TensileMill CNC, we are proud to offer equipment that meets ISO requirements but also exceeds expectations in usability, flexibility, and durability. Whether you require high-precision universal testing machines for tensile, compression, or bending applications, our systems are engineered to help you achieve full compliance with minimal effort.

If you would like to learn more about our ISO-compliant tensile testing equipment or speak to our team about selecting the most suitable solution for your needs, we invite you to contact us directly or request a quote today. We are here to support your testing goals with precision, expertise, and trusted technology.