At TensileMill CNC, we are aware of the importance of reliable equipment and the consequences that can arise from equipment failures. As a result of many years of hard work and many reviews from our customers, we can confidently say that our equipment is designed to be safe, effective, and durable. One of the prime examples of our long-standing dedication to the tensile testing equipment market is the TensileMill CNC MINI - Compact Flat Tensile Specimen Preparation Machine.

The TensileMill CNC MINI is a bestseller in the world of CNC machines for preparing flat tensile specimens. We have ample evidence to prove its superiority through its features and capabilities. As you read this blog, you will learn how one of our finest products can help you in the field of material testing.

Overview of TensileMill CNC MINI

The TensileMill CNC MINI - Compact Flat Tensile Specimen Preparation Machine is designed to meet the diverse needs of the tensile testing industry with exceptional efficiency and precision. Its overall design reflects a commitment to providing a compact, yet highly capable solution for preparing high-quality tensile specimens.

Despite its small footprint, the TensileMill CNC MINI offers full CNC machining capabilities. This unique ability allows it to perform a number of tensile specimen preparation tasks with ease, while also providing a number of advantages for small labs as well as large industrial settings.

Recent upgrades have significantly improved the MINI's performance, making it superior to previous models in almost every aspect. These changes include a larger table size, higher power, improved precision, and better repeatability. The result is a machine that not only occupies less space but also delivers more robust and reliable performance, resulting in consistently defect-free specimens.

Key Features and Benefits

The TensileMill CNC MINI stands out with its impressive array of features designed to meet these critical demands. Below, we discuss some of the key attributes that make this machine a top choice for tensile specimen preparation.

Small Footprint

The compact size of the TensileMill CNC MINI makes it an excellent choice for facilities with limited space. Its small footprint allows for seamless integration into various work environments without compromising performance.

User-Friendly Operation

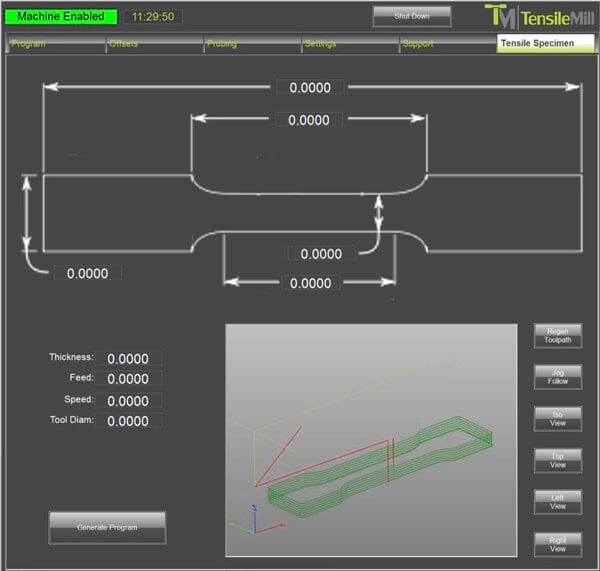

One of the standout features of the TensileMill CNC MINI is its ease of use. Equipped with a 10" LCD touchscreen and our renowned Tensile Software, the machine simplifies specimen preparation. Operators, regardless of their CNC experience, can quickly learn to use the machine, thanks to its intuitive interface and straightforward setup.

Turnkey Solution

The TensileMill CNC MINI is designed as a turnkey solution, meaning it comes ready to use with minimal setup required. This feature allows users to begin preparing tensile specimens almost immediately, saving valuable time and resources.

Accurate and Repeatable Results

Consistency is an important factor in tensile testing, and the TensileMill CNC MINI excels at delivering accurate and repeatable results. The machine guarantees that each specimen is prepared to exact specifications, free from defects such as cracks, tool marks, and deformations.

Improved Performance

Recent upgrades to the TensileMill CNC MINI have significantly improved its performance. With a larger table size, increased power, and better precision and repeatability, the MINI is now more capable than ever. These enhancements make it a superior choice compared to previous models.

Compliance with Industry Standards

The TensileMill CNC MINI is built to meet a variety of industry standards, enabling it to prepare specimens that are suitable for rigorous testing protocols across a variety of industries. Compliance with these standards is crucial for obtaining reliable and comparable test results, and the TensileMill CNC MINI excels in this area.

ASTM Standards

The TensileMill CNC MINI complies with several ASTM (American Society for Testing and Materials) standards, including ASTM E8 and ASTM A370.

- ASTM E8: This standard specifies methods for the tensile testing of metallic materials. It covers the determination of tensile properties, such as yield strength, tensile strength, and elongation. The TensileMill CNC MINI is capable of preparing specimens that meet ASTM E8 requirements.

- ASTM A370: This standard outlines mechanical testing procedures for steel products. It includes guidelines for tensile testing, bending, and hardness tests. By adhering to ASTM A370, the TensileMill CNC MINI guarantees that the specimens are suitable for comprehensive mechanical testing of steel materials.

ISO Standards

The machine also aligns with several ISO (International Organization for Standardization) standards, providing global compatibility and reliability.

- ISO 6892: This standard specifies the method for tensile testing of metallic materials at room temperature. The TensileMill CNC MINI’s precision and repeatability ensure that specimens meet ISO 6892 requirements, facilitating accurate measurement of tensile properties.

JIS Standards

Designed for Japanese users and beyond, the TensileMill CNC MINI meets JIS (Japanese Industrial Standards) requirements.

- JIS Z2241: This standard outlines tensile testing methods for metallic materials. The machine’s compliance with JIS Z2241 guarantees specimen preparation according to Japanese testing protocols.

Advanced Specifications and Features

The TensileMill CNC MINI is equipped with a user-friendly touchscreen controller that can be upgraded to our comprehensive Carbon software. This upgrade improves the machine's capabilities with a 21" touchscreen, 64 GB of storage, 4 GB of RAM, and connectivity options like WiFi, Ethernet, and USB ports. The Carbon software includes advanced features such as macro B programming, 254 tool offsets, 126 work offsets, helical interpolation, drilling canned cycles, scaling and mirroring, advanced trajectory planning, and dual-mode cutter compensation. Additionally, it provides access to MACH4 Industrial CNC Software, which supports professional CNC control functions. You have access to the latest tools with our Carbon software, which is continuously updated with new features.

CNC Mini Technical Specifications

The TensileMill CNC MINI is a compact, high-speed machining center, carefully designed with the testing industry in mind. Despite its small size, it is built on a robust cast iron frame, making it durable and stable. The machine's axes glide smoothly on linear rails, contributing to its precise machining capabilities.

- Dimensions: 44.5 x 42.00 x 70.0 in (1130 x 1066 x 1778 mm)

- Working/Traveling Area: 400 mm x 400 mm x 200 mm (15.75 x 15.75 x 7.87 inches)

- Weight: 1500 lbs (680 kg)

- T-Slot Size: 12 mm (0.472 inches)

- Unit Dimensions (Closed Door): 72 x 43 x 44 inches (1829 x 1092 x 1321 mm)

- Unit Dimensions (Open Door): 72 x 73 x 52 inches (1829 x 1855 x 1321 mm)

- Suggested Floor Dimensions: 82.7 x 78.5 inches (2100 x 2000 mm)

The machine's spindle, capable of rotating at 24,000 rpm, is powered by a 2.2 kW (3 hp) water-cooling spindle motor. The spindle's ER 20 collet taper is also available in ISO20 as an option.

- Servo Power: 0.54 hp (400 W)

- Servo Torque: 566.0 oz-in (4.0 Nm)

- Max Feedrate: 500 ipm (12.7 m/min)

- Input Voltage: 220 V 1 ph

- Total Power: 3.3 kW (15 Amps)

- Controlling Code: Tensile Soft - TensileMill interface on a 10" touchscreen control

- Full Carbon CNC Package: Upgrade available

The machine operates at a volume level of 70 - 90 dB at the point of entry and features position repeatability accuracy of 0.01 mm (0.0003 inches) and a max engraving speed of 10,000 mm/min (394 inches/min). The servo motor drive mechanism uses a precision ball screw, and the machine can accommodate tool shanks up to 12.00 mm (0.47 inches).

Additional Features and Options

The TensileMill CNC MINI offers a range of additional features and options to further improve its versatility and user-friendliness. It comes standard with a turnkey package that includes a .250" ER collet, a .250" shank endmill, and a custom tensile clamp fixture. The machine is also undergoing door design upgrades to improve safety standards and the user experience.

Why the TensileMill CNC MINI is a Smart Choice

The TensileMill CNC MINI - Compact Flat Tensile Specimen Preparation Machine provides a flexible and compact solution for tensile testing. Its small footprint, combined with full CNC machining capabilities, makes it an ideal choice for many different work environments. The machine's user-friendly Tensile Software, along with the optional Carbon software upgrade, guarantees that even operators with minimal CNC experience can achieve precise and repeatable results. The machine's robust construction and advanced features make it a superior option than previous models.

The TensileMill CNC MINI is compliant with multiple industry standards, including ASTM, ISO, DIN, and JIS, making it suitable for an array of applications. Its impressive technical specifications, such as the 24,000 RPM spindle, high-powered servos, and precision ball-screw drive mechanism, provide exceptional machining capabilities. Despite its compact size, the TensileMill CNC MINI delivers powerful and efficient performance, guaranteeing high-quality tensile specimen preparation.

If you are interested in the TensileMill CNC MINI, have questions about our other products, or want to learn more details, you can contact us directly or request a quote. TensileMill CNC is here to assist you with all your tensile testing needs.