The tensile testing machine industry is expected to reach a market value of $9.421 billion by 2027, growing at a CAGR of 3.9%. The growth of this industry is consistent with the development of materials science. With the increase in demand from dynamic sectors such as automotive and textiles, tensile testing's market value has increased significantly, indicating that testing for tensile strength is crucial for product quality, integrity, and durability.

An important part of testing tensile strength is determining whether a material is capable of withstanding uniaxial tension until failure, revealing important data such as strength, ductility, and toughness. This type of testing is essential for a number of applications, including robust frameworks in construction and precision components in aerospace. Hence, the materials are ensured to be able to withstand the stresses of daily operations as well as extreme environmental conditions. Tensile testing is widely used in materials science due to its versatility, which involves a wide range of methods, including handheld force gauges and technologically advanced equipment.

Due to technological advancements and changing market demands, the future of materials tensile testing is set to reveal innovative methodologies and applications as the industry continues to evolve. In addition to enhancing your knowledge of material properties, this article will discuss industries that use tensile tests to develop high-quality products and ensure quality.

The Current State of Tensile Testing

As tensile testing continues to evolve, its methodologies have become more diverse and technologically advanced. A practice that was initially characterized by simple tools such as handheld force gauges is now incorporated with highly advanced systems. Designed for detailed analysis, these modern systems are equipped with advanced software that allows for precise control and extensive data collection. It reflects the move towards greater precision and customization, customizing equipment and methods to meet the unique requirements of each material. In order to achieve reliable characterization of a wide variety of materials, it is necessary that highly accurate, consistent, and repeatable results are achieved.

A number of standards, such as ASTM and ISO, are critical in testing tensile properties, providing guidelines for methodologies and ensuring consistency among different industries. By defining specific tensile testing procedures, like sample preparation, testing conditions, and data interpretation, these standards maintain uniformity and reliability. A material test requires samples to be prepared in a prescribed shape and size, such as round, flat, rectangular, or square, and with a known gauge length. The following standards are essential for obtaining consistent and accurate material characterization in a range of fields, including construction and aerospace.

Multiple industries use tensile testing for material selection and product development, each relying on its precise results. In construction, it is used to ensure the structural integrity of materials such as steel and concrete. If we are talking about the automotive industry, the tensile test is used to verify the durability of components such as axles and frames. The aerospace industry uses tensile tests for critical parts such as turbine blades and fuselage structures, where material failure is not an option. Testing for tensile strength is also widely used in the medical device industry, including the development of prosthetics and surgical tools. The examples provided above illustrate how tensile testing plays a significant role in maintaining high standards of safety, reliability, and performance in an array of fields.

Technological Advances and Innovations in Tensile Testing

We already mentioned at the outset that tensile testing is undergoing significant changes, driven by technological advances and the need for precise and reliable material characterization. There are numerous reasons for this.

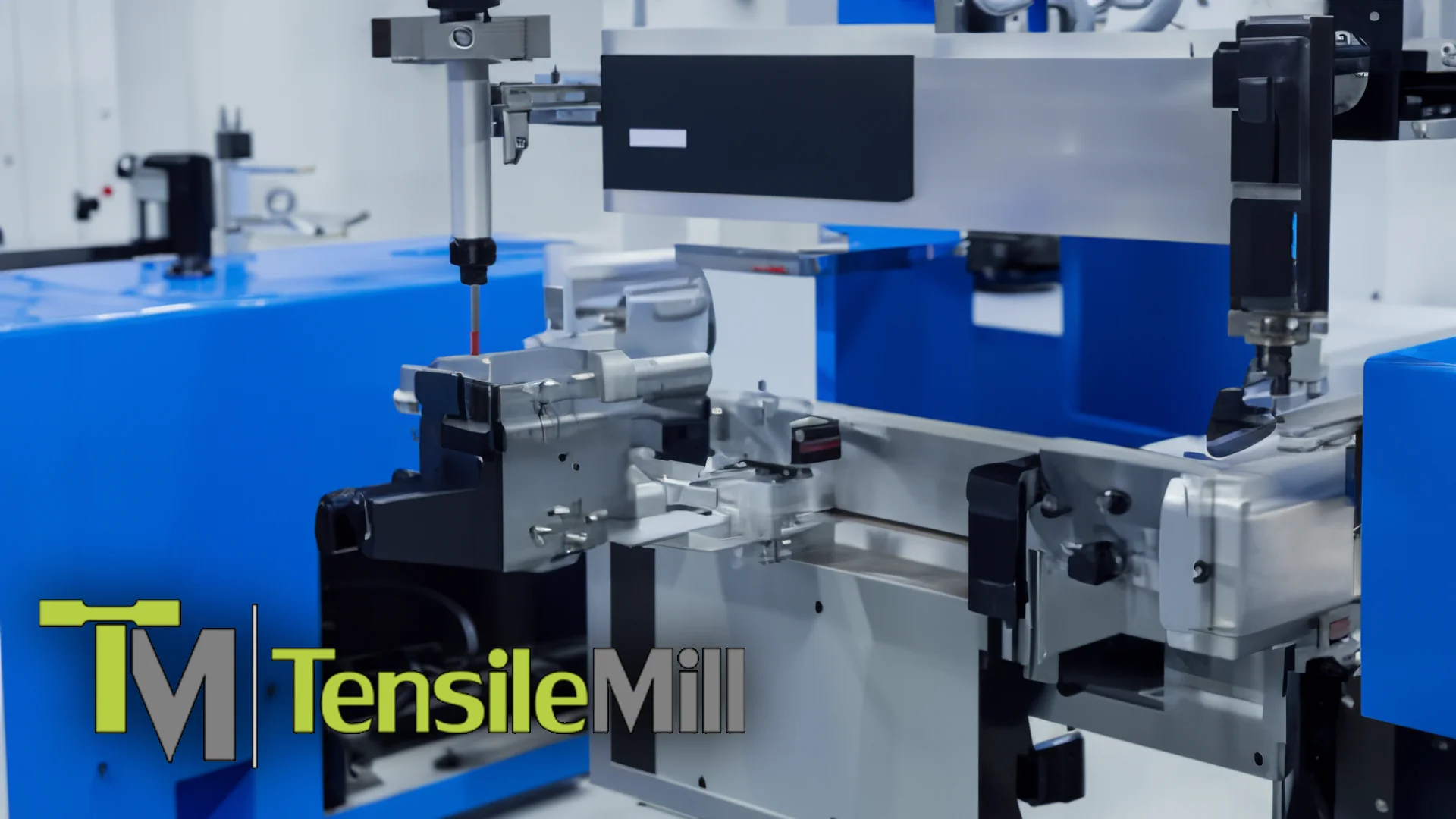

With advancements in technologies, there is a pressing need to upgrade equipment to meet modern material analysis demands. As an example, if we are talking about tensile tests, sample preparation is an essential step in this process. TensileMill CNC MINI, the Compact Flat Tensile Specimen Preparation Machine, exemplifies this advancement, specifically designed to simplify the preparation process. By ensuring samples are correctly prepared, the TensileMill CNC MINI sets the stage for more accurate and reliable tests. This improvement in sample preparation is a key step in the development of technological advancements in tensile testing, which now include more sophisticated testing methods, automation integration, and the use of advanced materials in test equipment.

Increasing demands in testing laboratories have led to the adoption of automation as a solution to enhance testing capabilities with existing resources. Automated testing relieves operators and engineers of the need to constantly monitor testing processes, allowing them to focus on more productive endeavors. XY stages, carousels, and collaborative robots (cobots) for batch testing as well as fully automated robotic systems capable of handling continuous, unattended testing demonstrate the diversity of applications for automation in this field.

As well, the shift towards electrification in the automotive industry highlights how market trends impact tensile testing. Testing equipment for tensile strength must also adapt as electric vehicle demand grows, as well as battery technology that is evolving. An example of this type of adaptation is the development of custom fixturing, the development of safe environmental chambers for live battery testing, as well as the establishment of testing setups that can accommodate high throughput demands.

Adapting Tensile Testing to Pandemic Challenges

There has been a significant transformation in the tension testing industry as a result of the COVID-19 pandemic. A rapid adoption of automation in tensile testing was facilitated by the urgency of the situation. In this industry, the shift to automation has established new standards, with long-term implications likely to be felt for many years to come.

- Reduced Human Error: The reduction of human error is one of the most compelling arguments for automating the testing of tensile strength. Although manual testing processes are effective, they are susceptible to inconsistencies due to human intervention. On the other hand, automated test systems provide a consistent approach that minimizes errors and enhances the reliability of results. It was particularly essential during the pandemic that material testing was performed with the utmost precision, owing to the urgency and volume of PPE production that was required.

- High-Volume Testing Capability: Manufacturers faced the challenge of rapidly scaling up production while maintaining quality in the wake of the pandemic. This was achieved through the use of automated tensile testing systems. With their ability to handle high-volume testing without compromising accuracy, they ensured that personal protective equipment met the necessary safety standards.

- Flexibility and Adaptability: The pandemic also highlighted the need for flexible testing systems that could be quickly adapted to new products and materials. Due to the versatility of automated test machines, manufacturers were able to quickly transition to PPE testing. System configurations can be changed with minimal downtime.

- Integrating Advanced Technologies: The integration of advanced technologies such as artificial intelligence and machine learning has enhanced the efficiency and accuracy of tensile testing systems. Artificial intelligence algorithms are capable of predicting material behavior under stress, enabling more precise adjustments to be made during testing. The importance of this integration became apparent during the pandemic, as it allowed for rapid analysis and adaptation to new materials used in personal protective equipment.

- Remote Monitoring and Control: Another advantage that emerged during COVID-19 was the ability to monitor and control automated systems remotely. Labs and factories benefited greatly from this feature in order to maintain social distance protocols. A remote operation enabled testing to be conducted without interruption, in compliance with safety regulations.

As well as presenting numerous challenges, the pandemic also stimulated innovation in tensile testing. As automation is adopted more rapidly and PPE testing requirements are successfully handled, the industry has been able to set new standards. In the coming years, this trend is likely to continue, as automated test systems become more prevalent, reducing the possibility of human error and increasing overall testing efficiency and accuracy.

Material Innovations for Advanced Tensile Testing

As we have already mentioned, new tensile testing tools can handle a wide range of materials. This capability is crucial when dealing with advanced materials with highly specific properties that are superior to traditional materials.

Take cellulose nanofibers, for instance. Originally created from wood, these fibers have a tensile stiffness of 86 gigapascals and a tensile strength of 1.57 gigapascals, making them stronger than steel on a weight basis and stronger than spider silk, the strongest known biomaterial. In many applications, such lightweight, environmentally friendly materials could replace plastics as a material of choice. In order to harness these materials effectively, tensile testing methods must evolve, ensuring that these new materials are suitable for the intended applications, whether in construction, automotive, or consumer products.

Additionally, advanced materials such as self-healing gels, platinum-gold alloys, and composite metal foams are transforming manufacturing. Due to their unique properties, each of these materials presents unique challenges and opportunities in tensile tests. In particular, platinum-gold alloys are more resistant to abrasion than high-strength steels and produce a diamond-like carbon when stressed, which could serve as a lubricant. In order to assess their unique properties, these materials require sophisticated tensile testing methods.

Impact on Industries and Global Markets

As we explore the field of tensile testing and its far-reaching impacts, it is important to highlight industry sectors that have been greatly impacted by these advances. Three major industries - aerospace, automotive, and construction - demonstrate a number of stress determination applications. Why is that so? Let's find out.

- Aerospace Industry:

- Innovative Materials: Aircraft manufacturers are leading the way in the adoption of advanced materials such as carbon fiber composites and titanium alloys. Materials must undergo tensile testing in order to ensure that they can withstand the extreme conditions found in aerospace environments.

- Safety and Performance: As safety is a priority, the tensile test helps in determining the performance and reliability of materials used in aircraft construction, from fuselage panels to turbine blades. Using lighter, stronger materials directly impacts fuel efficiency and aircraft service life, which has a significant impact on operational costs.

- Economic Impact: It is estimated that the global aerospace materials market will reach $25.80 billion by 2027, reflecting the significance of tensile testing for developing materials that meet stringent aerospace standards.

- Automotive Industry:

- Electrification and Lightweight: Due to the shift towards electrification in the automotive industry, there has been a surge in the demand for lightweight, high-strength materials. A tensile test ensures that these materials contribute to the overall efficiency and safety of electric vehicles (EVs).

- Material Innovation: Testing of advanced high-strength steels (AHSS), aluminum alloys, and composites is essential for vehicles that are both lighter and safer, affecting everything from fuel economy to crashworthiness.

- Market Dynamics: At 149.3 billion dollars in 2021, the automotive materials market is driven by the demand for materials that can undergo rigorous tensile tests, indicating a close connection between advances in tensile testing and advancements in automotive materials.

- Construction Industry:

- Structural Integrity: Tensile testing is used to assess the reliability of materials such as steel, concrete, and emerging composites. Buildings, bridges, and infrastructure must undergo this testing to verify their structural integrity.

- Sustainable Materials: Sustainable materials are becoming increasingly popular in construction, such as green concrete and recycled steel. A tensile test can be used to assess the viability and longevity of eco-friendly alternatives.

- Economic Growth: Construction contributes significantly to global GDP. The global construction market is expected to grow to over $11.9 trillion by 2024.

In light of this list of how advanced tensile testing is transforming industries such as aerospace, automotive, and construction, it is yet another example of how these advances transcend industry boundaries. There are wide-ranging implications associated with advanced testing of tensile strength, which can have a profound impact on global markets and trade. Taking this broader perspective into account, the testing of tensile strength is of vital importance in the progress of not only industries but also global trade, economics, and regulations.

- Enhanced Standardization and Trade Facilitation:

- The standardization of tensile testing, particularly with protocols such as ASTM and ISO, has simplified international trade processes. Manufacturers who use materials that comply with these global standards have easier access to global markets, allowing them to expand their reach across borders. As a result of the uniformity of testing standards, a common language has been created for the quality of material, thereby facilitating the smooth negotiation and implementation of trade agreements.

- Driving Innovation and Competitive Edge:

- Innovation is a key component of a global market that is becoming more and more competitive. The use of advanced tensile testing enables manufacturers to push the boundaries of material science, resulting in the development of superior and more efficient products. A company's ability to differentiate itself on the basis of innovation is not just a technical asset, but a strategic one in market competition.

- Economic Ripple Effects:

- Several new materials and technologies have been introduced to the market as a result of advances in tensile testing. Consequently, this dynamic fosters economic growth, facilitates the creation of jobs, and stimulates the development of new technologies. The development of new materials and products opens up new markets and opportunities for global economic growth.

On the one hand, the tensile test drives industry-specific innovations that enhance safety, performance, and sustainability. We also observe its influence on global trade, standardization, regulatory compliance, and economic growth. Combined, these factors highlight the critical role that advanced tensile testing will have on not only the future of material science but also the future of global markets and trade.

The Future of Eco-Friendly Tensile Testing

Global industries are turning towards more environmentally friendly methods, and tensile testing is adapting to these changes but actively promoting them. This advancement reflects not only technological progress but also a commitment to a sustainable and environmentally responsible future.

Achieving Environmental Sustainability in Tensile Testing

As sustainable materials are increasingly used, tensile testing has taken on new responsibilities. Currently, biodegradable polymers, recycled metals, and bio-composites are being rigorously tested for their mechanical properties and environmental benefits. For industries attempting to replace traditional materials with more sustainable ones, this process is critical. A tensile test ensures that these environmentally friendly materials are not only robust and reliable, but are also eco-friendly.

Furthermore, the importance of tensile testing in promoting the reuse and recycling of materials cannot be overstated. Testing the integrity of materials, such as recycled steel or plastic, is essential to determining their reusability, which is an essential component of circular economy concepts. In this way, waste is effectively reduced and resources are made use of efficiently.

Innovations in Eco-Friendly Tensile Testing

The future of tensile testing equipment is oriented towards sustainability. The newer machines are designed to be more energy-efficient and to use materials that have a lower environmental impact. This includes optimizing the machines to reduce energy consumption and incorporating features that reduce their overall carbon footprint.

There are changes being made to the testing process itself in order to minimize waste. There is a focus on reducing the use of single-use materials and exploring the possibility of reusing test specimens. Further, digital and non-destructive testing techniques are becoming more prevalent, providing the necessary data while conserving resources.

A further step towards sustainability can be achieved by integrating advanced software and efficient data management systems into testing tensile strength. With the development of these technologies, simulations can be performed with greater accuracy and, as a result, physical testing can be reduced and, consequently, material consumption will be reduced as well. As a result of this digital transformation, not only is tensile testing more efficient, but also more environmentally friendly.

Looking Towards a Sustainable Future in Tensile Testing

As we look forward, we expect that eco-friendly practices and sustainability will continue to gain traction in tests of tensile strength. Material science must align with global environmental goals as a result of this trend. Testing for tensile strength will be at the forefront of innovation as industries evolve to adopt greener materials and practices, ensuring these innovations meet the highest standards of quality and sustainability. Thus, the future of tensile testing does not just involve technological advancements, but rather the development of a more sustainable world by conducting careful material testing and innovation.

Tensile Testing Innovations at TensileMill CNC

The TensileMill CNC team is honored to be at the forefront of this transformational change in materials tensile testing. Throughout our history, our mission has been to empower operators of all skill levels to achieve the highest levels of manufacturing testing. Our advanced tensile sample preparation systems, equipped with user-friendly software interfaces, demonstrate our commitment to innovation and quality. Industry demands such as those in aerospace, automotive, and construction are constantly evolving, and we are committed to providing solutions that not only meet but also exceed these requirements.

Regarding the future, we are aware of the growing emphasis on sustainability and eco-friendly practices. With this future in mind, we have designed our equipment and methodologies to ensure that we contribute to a more sustainable and responsible industry. Our company believes in providing continuous support and development to our clients. By doing so, we ensure that our equipment remains at the forefront of technology. To meet the challenges of the future, we adapt and grow as the industry evolves. As part of an evolving industry, TensileMill CNC continues to lead the way, ensuring our clients have access to the very most advanced tensile testing equipment.

If you are looking for the most advanced, reliable, and user-friendly tensile sample preparation machines, we are here to help. Whatever your needs are, whether it is preparing samples for testing or finding the right equipment for your specific requirements, our team is available to assist you. Please contact us to discuss how we can help you enhance your tensile testing processes and contribute to the highest standards in your manufacturing and testing activities.