What happens when a test report doesn't arrive on time? For a quality control manager, that one delay can mean a full production line held back. Materials that don't have verified properties can't move forward. Shipping schedules freeze. Orders pile up.

In material testing, timing is rarely flexible. Test results often dictate whether a batch gets approved or held. A tensile test, for example, may need to confirm strength before finished parts can be released. In other cases, regulatory standards demand that testing happens within hours or days after production, leaving no room for extensions.

This isn't about paperwork moving slowly. It's about real-time decisions in manufacturing, where late data can block processes, affect safety, and cost thousands. Understanding how testing deadlines work, and what happens when they're missed, is essential for keeping operations on track.

How Turnaround Times Are Set in Real Labs

Turnaround time, often abbreviated as TAT, refers to the total duration from the moment a sample is received in the laboratory to the delivery of final, reviewed test data. In most material testing facilities, TAT is segmented into two parts: preparation time and analysis time. The preparation stage includes identification, cutting, surface machining, and conditioning. The second stage involves the actual test procedure and documentation.

Standard lead times vary depending on the test method. Tensile and compression tests are often scheduled within 24 to 72 hours after sample intake. For static tension tests in accordance with ASTM E8/E8M, the specimen must reflect proper geometry and surface finish before testing begins. If the material has undergone heat treatment, the tensile test is frequently required within a 6–48 hour window post-process to capture representative mechanical properties. Exceeding this window may alter the results due to microstructural relaxation or oxidation.

Concrete compressive strength tests follow predefined intervals: typically at 7 days (early strength) and 28 days (design strength), in line with ASTM C39/C39M. These timelines are embedded in construction schedules, with cylinders stored under strict humidity and temperature controls prior to testing.

Polymers and elastomers require stabilization periods after molding or curing. For instance, tensile tests under ASTM D638 or ISO 527 generally require 40 to 48 hours of post-curing at controlled ambient conditions before specimens are considered valid. Variability in temperature, time, or storage medium can shift mechanical results by up to 10 percent in some thermoplastics.

Turnaround is not determined solely by lab availability. It is often dictated by the material's physical behavior after processing. In manufacturing workflows, tensile test certificates are usually required before goods can be released or shipped. As a result, production managers schedule tests to occur in tight synchronization with batch completion.

Test timing depends on standards and material behavior. Tensile tests often follow a 6–48 hour window after heat treatment. Concrete is tested at 7 and 28 days. Polymers need post-curing time. Labs schedule tests based on these rules, not just machine availability.

Delays Create Risks for Quality and Compliance

In regulated industries, test results are not optional; they are legal and operational requirements. Material cannot be approved for use until its mechanical, chemical, or structural characteristics have been verified in writing. The absence of timely documentation halts release. In many production contracts, the material test certificate (MTC) or certificate of analysis (CoA) is a non-negotiable component of the shipment. If that document is delayed, the product cannot be transferred, invoiced, or accepted.

Most clients demand test results before receiving goods, especially in high-risk sectors such as aerospace, automotive, construction, and energy. For example, steel plates destined for structural components must comply with ASTM A370 mechanical testing, with results available prior to welding or machining. The same applies in aviation, where material conformance must be documented under tight tolerances and timing, often specified by internal specifications layered on top of ISO 17025 requirements.

Delays in laboratory processing can trigger cascading compliance failures. Regulatory frameworks such as ASME, NADCAP, or API stipulate that tests be completed within fixed intervals. For heat-treated alloys, missing the test window may render the batch noncompliant, even if the mechanical results later fall within range. In these cases, retesting may not be permitted, and the batch is downgraded or scrapped.

Legal risk follows as well. Auditors and procurement officers often review the timestamp on test reports against the recorded process date. A report issued outside the allowed timeframe can invalidate the material traceability record. For defense or nuclear work, this leads to automatic rejection, regardless of the result values. Financial consequences may include loss of supplier approval, penalties written into supply agreements, or added costs from emergency retesting.

Even when internal, a late test report can compromise safety margins. Production teams may act on preliminary assumptions to avoid holding up assembly, assuming the material will pass. If it fails once the result is finally issued, all downstream work must be re-inspected or dismantled. In sectors that use critical parts, pressure vessels, load-bearing structures, or aircraft panels, this creates unacceptable exposure.

Deadlines exist to maintain a chain of control. Without timely testing, that chain breaks, and both traceability and reliability are lost.

When One Missed Deadline Stops a Full Line

Late test results create immediate pressure across the production chain. A single missed deadline can stall an entire line, particularly when batch release depends on lab confirmation. Without documented test data, materials cannot move forward. Finished components remain in storage. Equipment stands idle. Downstream operations—coating, assembly, shipping—pause while waiting for clearance.

These delays generate measurable losses. In medium-volume manufacturing, a one-day hold on a 12-station line can result in tens of thousands of dollars in lost output. In high-throughput environments, such as metal service centers or extrusion plants, that figure climbs rapidly. When customers operate under just-in-time agreements, even a short disruption can trigger contractual penalties or rejected shipments.

In tensile testing, delays often stem from sample readiness issues. Improperly prepared specimens (poor surface finish, incorrect geometry, or contamination) require re-machining. If the lab lacks internal machining capacity, retesting may be postponed until a subcontractor is available. Each additional step adds hours or days, extending downtime and increasing labor costs.

Repeat testing also consumes physical resources. Certain materials, such as heat-treated alloys or thermoplastics, cannot be sampled repeatedly without altering their structure. This limits the number of valid retests, especially when the production batch is small. In such cases, a failed or expired sample window leaves no fallback option.

Human factors compound the problem. Technicians under deadline stress are more likely to rush specimen polishing or enter setup parameters incorrectly. Inconsistent grinding pressure, for example, can leave micro-scratches on the gauge section, introducing stress risers that distort tensile strength readings. A single preparation error often means scrapping the sample and starting over.

For the end customer, these issues are rarely visible, but delays affect delivery dates and reduce confidence. After two or three late shipments, suppliers may be flagged as unreliable, regardless of test quality. In markets where certification and punctuality are linked, that perception is difficult to reverse.

Production stalls, shipments are delayed, and costs rise quickly. Without test data, batches can't be released. Rework adds time and expense, especially when specimens are limited. Poor preparation or stress-driven mistakes make things worse. Even if the results are valid later, supplier trust often doesn't recover.

Sample Preparation Is Often the Bottleneck

In many laboratories, the slowest part of the testing process is not the test itself, but the preparation of the specimen. When turnaround time targets are missed, it is often because the sample was not ready in time, not because the equipment failed or the method was too complex.

Manual preparation introduces several delays. Grinding and polishing are labor-intensive and prone to inconsistency. A technician may spend 20 to 40 minutes preparing a single tensile specimen, adjusting feed rates or switching abrasive belts between different material types. When multiple geometries are required (round, flat, sub-size) the setup must be recalibrated. Each change adds friction to the workflow.

Unscheduled interruptions, such as tool wear or vibration issues, further slow progress. If the surface finish falls outside the tolerance range defined by standards like ASTM E8/E8M or ISO 6892, the specimen must be redone. Poor parallelism or rough edges can cause stress concentrations that distort strain data or trigger premature failure.

In high-volume or short-lead testing environments, even minor slowdowns accumulate. Preparing ten to fifteen specimens per shift using manual methods is typical. By contrast, automated systems, such as CNC-based preparation mills, can complete one specimen in 8 to 12 minutes, with minimal technician intervention. More importantly, the geometry and surface quality remain consistent, reducing the need for rework.

The variability introduced by manual work also affects scheduling. If one out of five specimens needs to be remade, timelines stretch unexpectedly. When technicians can't predict prep time accurately, lab planners are forced to insert buffer windows, limiting total capacity.

Deadlines Vary Across Test Types

Not all material tests follow the same timeline. Each method has its own setup, duration, and conditioning requirements, which directly impact how deadlines are managed.

Hardness testing is typically the fastest. Most methods, including Rockwell (ASTM E18) or Brinell (ASTM E10), can be completed within minutes per sample. These tests are often used for preliminary screening or batch verification and are usually scheduled early to identify clear nonconformities.

Tensile testing takes longer. Specimens require controlled geometry, clean surfaces, and precise alignment with the test machine. Once prepared, each tensile test run takes 5 to 20 minutes depending on the material and the standard applied. Post-processing may include stress-strain data analysis and certificate generation, which adds to the overall time. Because the results often define whether a batch can be released, tensile testing is placed early in the workflow but scheduled close to production deadlines.

Fatigue and creep testing operate on entirely different time scales. A single fatigue cycle test, conducted under ASTM E466 or ISO 1099, may take several days to complete depending on the load and frequency. Creep testing under ASTM E139, particularly for high-temperature applications, can extend into weeks or months. These tests require dedicated machines, environmental chambers, and long blocks of uninterrupted runtime. Scheduling them demands advance notice and alignment with long-term production planning.

Thermal analysis, such as Differential Scanning Calorimetry (DSC, ASTM D3418) or Thermogravimetric Analysis (TGA, ASTM E1131), usually takes one to three hours per sample. The instruments require stabilization periods, calibration routines, and cooldown phases between runs. While shorter than mechanical tests in duration, thermal instruments are often shared across departments, creating bottlenecks if scheduling is not precise.

Metallographic examination adds another layer. Before imaging or microhardness testing, samples must be mounted, ground, polished, and etched. Depending on the material, this process may take several hours. Drying and etching time can introduce idle gaps, especially when multiple steps are spread across different technicians or shifts.

A well-managed lab workflow places quick tests early, aligns long-duration methods with external deadlines, and reserves capacity for preparation-heavy procedures. Tensile testing, in particular, often serves as a release gate: its results are typically required before goods can be certified and moved forward. For that reason, even when not the longest test, it becomes the critical path in most test schedules.

How Labs Keep Tests on Schedule

To meet internal turnaround targets and external delivery dates, laboratories rely on structured planning systems. These are not abstract principles—they are applied methods with measurable outcomes.

Schedule buffers are a first layer of control. For tests with a 48-hour turnaround, most labs schedule them with a 60–72 hour buffer to absorb rework, machine maintenance, or delays in specimen preparation. These buffers are built into planning templates and adjusted based on historical data.

Redundant machines are deployed for critical tests. When tensile results are required for batch release, labs often maintain two identical frames. If one fails calibration or enters a service window, the second unit prevents schedule disruption. Redundancy is especially common in creep and fatigue testing, where test duration can span weeks and interruptions are costly.

LIMS systems (Laboratory Information Management Systems) allow detailed test tracking. Once a sample is logged, the system assigns it a due date, test sequence, and status. Many labs configure automatic alerts when a task approaches its deadline or when a sample stays too long at one processing stage. In multi-user environments, LIMS dashboards highlight bottlenecks in real time—where too many jobs queue behind one technician or one machine.

Staff training supports consistency. Preparation errors are a common cause of delays. When personnel understand not just the procedure, but the reason for each step—surface finish, geometry control, conditioning periods—repeat testing drops sharply. Well-trained staff also transition faster between test types and materials, reducing downtime from machine setup or cross-contamination.

Statistical tracking keeps labs accountable. Most facilities monitor the percentage of tests completed on or before the promised date. This is usually calculated weekly and reviewed by team leads. If a particular method or shift regularly misses targets, the data points to specific issues: undertrained staff, underpowered equipment, or unrealistic customer commitments.

With built-in buffers, tracking tools, and trained personnel, labs can manage risk before it escalates. Test schedules stay on course, not because problems disappear, but because they're caught and corrected in time.

Start by building in time buffers. If a test usually takes 48 hours, plan for 60 to cover rework or prep delays. Use a tracking system to monitor sample progress and set alerts before deadlines slip. Keep backup machines for critical tests. Most delays come from preparation, so train staff to avoid common mistakes and understand why timing matters. Review completion stats weekly to catch patterns before they turn into bottlenecks.

Respecting Timeframes Is Part of Quality Work

In material testing, deadlines are not administrative details. They define whether a product can move forward with confidence. When test data arrives on time, manufacturers know the material meets its required properties. Not in theory, but in documented fact.

Timeframes also reflect the lab's reliability. A predictable process signals control. It shows that preparation, testing, and reporting follow a known rhythm, even under pressure. This consistency builds trust across the chain: from lab staff to production teams, and from suppliers to clients.

Meeting deadlines isn't about working faster. It's about working with discipline. Each result supports a wider system of safety, compliance, and technical precision.

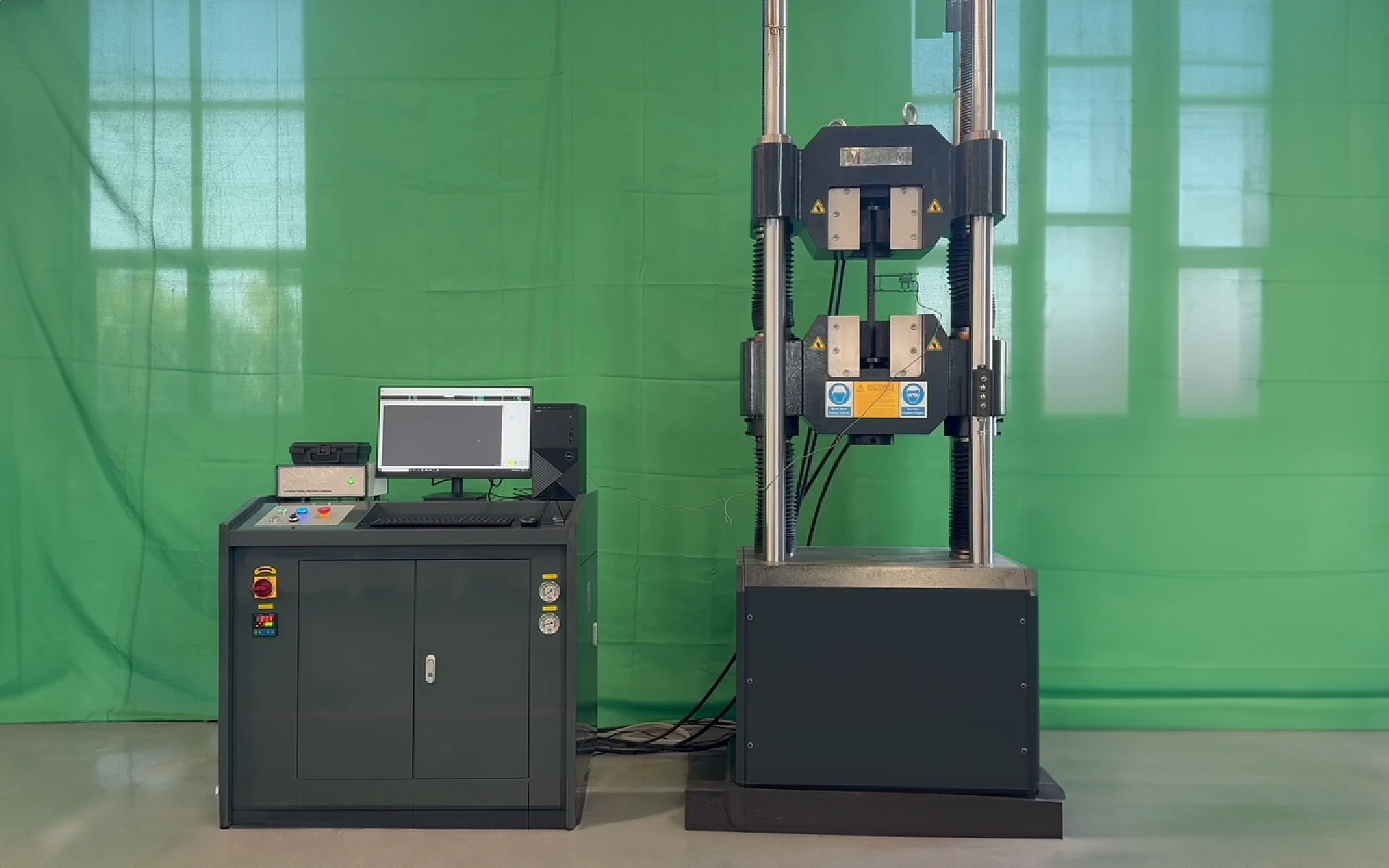

We at TensileMill CNC understand what testing deadlines mean in the material testing field. And we know what it takes to stay within those timeframes. One of the key factors we've covered is the role of testing equipment. That includes both tensile testing systems and machines for sample preparation. When your equipment is stable and predictable, your deadlines are too.

If you're planning to upgrade your lab, build one from scratch, or need guidance on how to manage preparation times effectively, our team is here to help. Feel free to contact us. We'll get you where you need to be on time.