The circular economy is redefining how we approach materials and resources, aiming to eliminate waste and maximize the value of every product throughout its lifecycle. At the core of this concept are recycling and upcycling. These are the two processes that transform discarded materials into new resources or higher-value products. However, for these practices to thrive, guaranteeing the quality, durability, and safety of the resulting materials is fundamental.

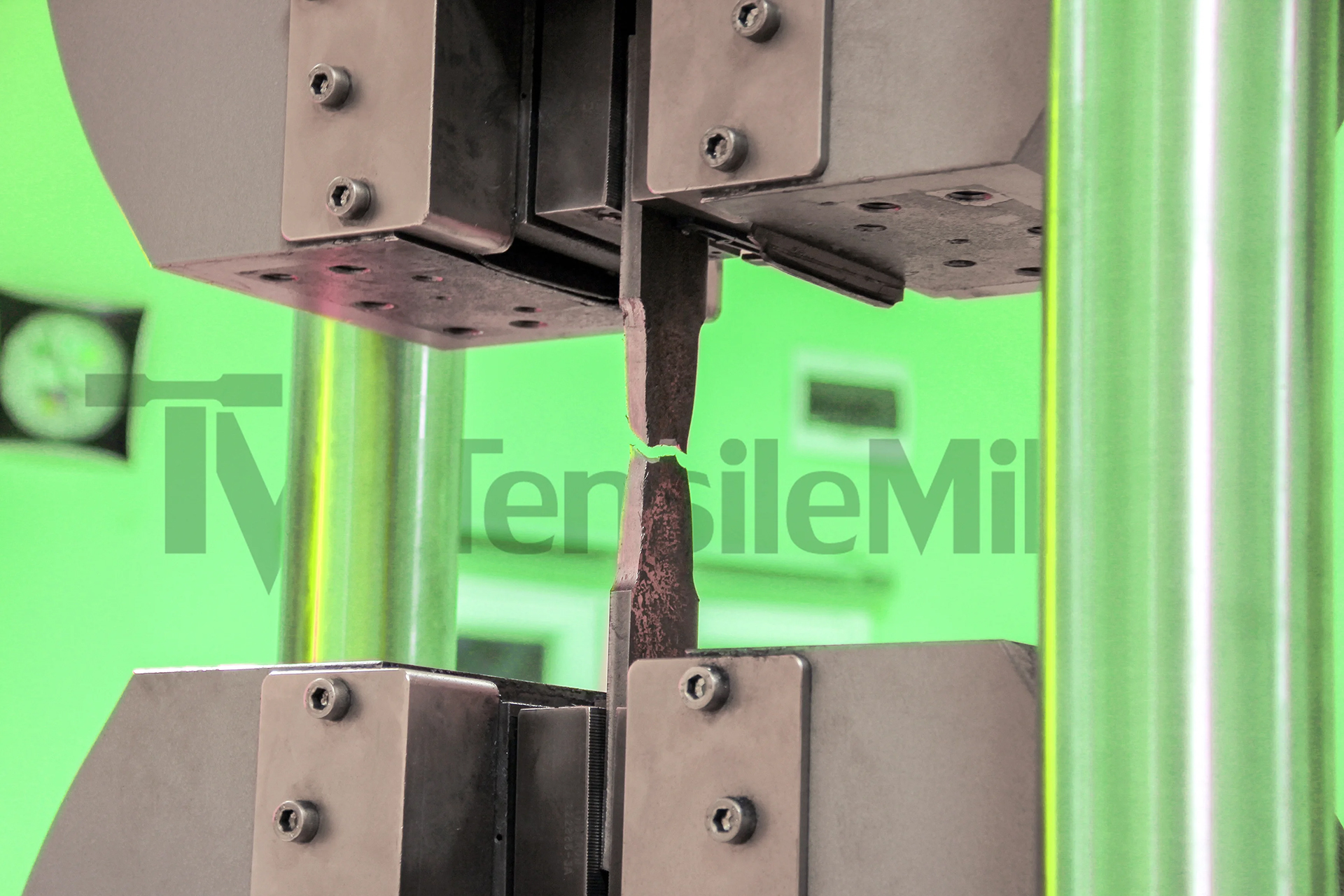

Tensile testing confirms that recycled and upcycled materials meet reuse standards by assessing the mechanical properties of materials such as strength, flexibility, and elongation. The purpose of this article is to examine the significance of tensile testing in supporting recycling and upcycling efforts, and discuss how these processes contribute to the circular economy.

What is Recycling and Upcycling?

Let us cover the first step in understanding the role of tensile testing in recycling and upcycling. While both are integral to a circular economy, they serve distinct purposes and require different approaches. Here is a closer look at them:

Material Recycling

Material recycling is the process of converting waste into reusable materials through mechanical, chemical, or thermal treatments. The goal is to reduce raw materials consumption and minimize waste, conserving energy and resources.

-

How it Works:

Recycling involves several steps:- Collection of waste materials like plastics, metals, and glass.

- Sorting to separate recyclable items by type and quality.

- Processing through shredding, melting, or re-polymerization to create raw materials.

- Re-manufacturing into new products, such as bottles, cans, or building materials.

- Commonly Recycled Materials:

Plastics (e.g., polyethylene terephthalate, or PET), metals (e.g., aluminum and steel), glass, paper, and electronics are commonly recycled today.

Material Upcycling

Material upcycling involves transforming waste materials into new products of higher value or utility. Unlike recycling, which often returns materials to their raw state, upcycling repurposes materials creatively, increasing their value and extending their lifecycle.

- How it Works:

Upcycling involves innovative design and craftsmanship. For instance, discarded textiles can be transformed into fashionable clothing, and industrial scraps like wood and metal can be repurposed into furniture or art pieces. - Benefits of Upcycling:

- Environmental Impact: Upcycling reduces landfill waste and requires less energy than traditional recycling processes.

- Economic Value: It creates new revenue streams by adding value to discarded materials.

- Innovation Driver: Upcycling encourages sustainable product design and material use, fostering creativity in repurposing materials.

Despite their distinct characteristics, recycling and upcycling complement each other in advancing the circular economy. During both manufacturing processes, quality control is crucial, and tensile testing confirms that the materials are durable and reliable enough to last for many years to come.

Why Tensile Testing Matters in Recycling and Upcycling

The importance of tensile testing in recycling and upcycling efforts should not be underestimated. It guarantees materials' mechanical performance, allowing them to be safely and effectively reused or repurposed into higher-value products. An in-depth look into why tensile testing is so important in these processes is provided below.

Assuring Material Quality in Recycling

Recycled materials often go through multiple processing stages, which alter their mechanical properties. Tensile testing provides a detailed analysis of these properties, thereby verifying that recycled materials meet reuse standards. For example, recycled plastics like polyethylene terephthalate are tested to confirm they retain the durability required for applications such as beverage bottles or textile fibers.

Mechanical integrity is a major concern when working with recycled materials. Over time and through multiple recycling cycles, materials can degrade, losing their original strength, elasticity, and other mechanical properties. Tensile testing helps identify these changes so that only materials that meet stringent standards are reintegrated into production. Contamination and material inconsistency can also affect recycled output reliability. Testing provides an effective way to measure and verify quality.

A study conducted by Penn State Behrend examined polypropylene's mechanical properties over three generations of mechanical recycling. The research found that mechanical properties such as impact strength and elongation at break decreased with each recycling generation, highlighting the importance of tensile testing in monitoring material degradation.

Supporting Upcycling Innovation

Upcycling involves transforming waste materials into products with higher value, often requiring superior material performance. Tensile testing is a crucial step in making sure that upcycled materials meet or exceed performance expectations. For example, ocean plastics, when upcycled into fibers for athletic apparel, must demonstrate durability and stress resistance to be suitable for high-performance applications.

Safety and durability are particularly important for upcycled materials to compete with or replace virgin materials. Upcycled steel might be used in construction, but only after tensile testing to confirm it can handle load-bearing applications. This testing confirms that upcycled products are not just environmentally friendly but also safe and reliable for consumers.

A real-world example involves Adidas’s collaboration with Parley for the Oceans, which resulted in sneakers made from upcycled ocean plastic. Tensile testing proved that these fibers were robust enough to meet athletic wear demands.

Advancing Circular Economy Goals

Tensile testing is not only about verifying material reliability; it also directly supports the broader goals of the circular economy. Replacing virgin resources with recycled or upcycled alternatives leads to significant energy savings and waste reductions. For example, using recycled aluminum, which requires up to 95% less energy than producing aluminum from raw materials, is feasible only because tensile testing guarantees that its structural integrity is unaffected.

In addition to energy efficiency, tensile testing contributes to waste reduction by enabling manufacturers to confidently incorporate recycled or upcycled materials into production processes. This prevents large quantities of waste from ending up in landfills. Moreover, tensile testing data assists engineers in designing products that optimize material reuse and extend product lifecycles, reinforcing circular economy principles.

Overcoming Challenges in Tensile Testing for Recycling and Upcycling

Several challenges complicate the process of tensile testing in recycled and upcycled materials. Contamination, material heterogeneity, and variability in mechanical properties often lead to inconsistent results and hinder the broader adoption of recycled materials.

Contamination is a prevalent issue, especially in recycled plastics, where additives, dyes, and residues from previous use can alter their mechanical properties. Among other things, flame retardants in plastic waste can weaken the tensile strength, complicating reuse.

Material heterogeneity adds another layer of complexity. Recycled materials frequently consist of mixed polymers, resulting in uneven phase separation during processing. This inconsistency affects cohesion and mechanical reliability, making it difficult to achieve standardized test results.

In mixed-material composites, such as those derived from electronic waste, the combination of plastics, metals, and glass introduces unique challenges. The material behaves differently under stress, leading to unpredictable performance. Developing testing protocols that account for these interactions is key to improving reliability.

Furthermore, not all tensile testing equipment is able to handle recycled and upcycled materials. Some machines lack the precision or adaptability required to test inconsistent materials. Adaptive tensile testing tools, such as CNC sample preparation machines or universal testing machines (UTMs), are important instruments for addressing these challenges. Despite the complexity or heterogeneity of materials, these advanced systems provide accurate results even when sample preparation is precise.

Reliable Equipment for Tensile Testing in Recycling and Upcycling

At TensileMill CNC, we are dedicated to providing industry-leading solutions for tensile testing. Among our flagship products is the TM-EML Dual Column Floor Standing Universal Testing System, a powerful and high-precision machine designed to cater to an extensive range of testing needs. Whether you’re working with metals, composites, or other materials, this system delivers the reliability and accuracy required for even the most demanding applications.

The TM-EML Universal Testing Machine is engineered for performance, with a force capacity ranging from 50kN to 600kN (11,240 lbf to 135,000 lbf), making it ideal for testing metals, building components, large fasteners, and wood products. Its dual-column load frame configuration offers durability and stability, while the electromechanical drives minimize vibration, providing a smooth testing experience.

One of the standout features of this system is its precision load cell, which features an accuracy of ±0.5% of the reading value. This allows for exact measurements across tensile, compression, bending, and shearing tests. In order to provide greater flexibility, the system supports dual testing zones, allowing users to test a variety of specimens easily. Pre-loaded ball screws and linear motion guides guarantee exact alignment and precision during every test.

The TM-EML system also incorporates flexible and user-friendly software with pre-programmed libraries of industry standards, including ASTM, ISO, DIN, EN, and BS. This software provides automatic limit checks and high-resolution digital closed-loop controls for comprehensive testing and data management. USB 2.0 communication allows real-time monitoring and real-time data exchange between hardware and software.

Achieving the Circular Economy Through Reliable Tensile Testing

The circular economy has redefined industry resource management, highlighting the need for sustainable practices like recycling and upcycling. At the heart of these processes lies tensile testing—a vital component in verifying material quality, durability, and performance. From verifying the reliability of recycled polymers to advancing the innovation of upcycled materials, tensile testing enables industries to confidently incorporate sustainable materials into production.

By addressing challenges such as contamination, material heterogeneity, and variability in mechanical properties, tensile testing assists in overcoming barriers to the widespread adoption of recycled and upcycled materials. Advanced tools like CNC sample preparation machines and universal testing machines are paving the way for more precise, efficient, and adaptable testing processes, making certain that even complex materials meet industry standards.

At TensileMill CNC, we are proud to support the transition to a circular economy by providing industry-leading tensile testing equipment. Our solutions are built to meet the highest standards of accuracy and reliability, enabling businesses to achieve their sustainability goals with confidence.

If you’re interested in purchasing reliable tensile testing equipment, you’ve come to the right place. Explore our website to find the right solution for your material testing needs. If you have questions, feel free to contact us directly or request an online quote—we’re here to help you succeed.