In our time, we are accustomed to feeling completely safe while being on the 20th or even the 50th floor of a building. We do not think anything could go wrong because we trust the architects and engineers who design these structures. This confidence extends to the selection of materials through material testing methods, specifically tensile testing, a key part of the construction industry.

Thanks to the precise and accurate testing of necessary materials by engineers, from which buildings are later constructed, we can be assured of our safety within these structures. It is for this reason that tensile testing is considered crucial for people's safety.

Here, we will discuss how the tensile test helps engineers select the appropriate materials. Moreover, we will discuss the importance of obtaining accurate and high-quality test results in order to avoid fatal errors.

The Basics of Tensile Testing in Construction

What is Tensile Testing?

Tensile testing, also known as tension testing, is a materials science test that measures a material's response to a controlled tensile force until it fails. This test helps determine several critical properties of materials, including:

- Ultimate Tensile Strength: The maximum stress a material can withstand while stretching before breaking.

- Yield Strength: The stress at which a material deforms plastically. Beyond this point, the material will not return to its original shape when the force is removed.

- Elongation: The extent to which a material can be stretched before breaking, expressed as a percentage of its original length.

- Reduction in Area: The decrease in the cross-sectional area of a specimen at fracture, indicating ductility.

Importance of Tensile Testing in Construction

Tensile testing is particularly important in the construction industry for a number of reasons:

Assuring Material Suitability

Construction materials must be able to withstand significant stresses caused by loads, environmental conditions, and usage over time in construction. Tensile testing verifies that materials can handle these stresses without failing. For instance, steel used in a building's framework must have high tensile strength to support the structure's weight and resist deformation.

Preventing Structural Failures

By determining the yield strength and ultimate tensile strength of materials, tension testing prevents structural failures. Materials that do not meet the necessary strength criteria could fail under load, leading to catastrophic consequences such as building collapses or infrastructure failures. For example, testing the tensile strength of steel rebar confirms that it can support concrete in a building's foundation and prevent cracks and failures.

Ensuring Safety and Durability

The elongation and reduction in area properties measured by tensile testing indicate how much deformation a material can undergo before breaking. Materials with higher ductility can absorb more energy and deform more before failing, allowing them to withstand dynamic loads such as earthquakes or heavy machinery operations.

Examples of Tensile Testing in Construction

Reinforced Concrete: Testing the tensile strength of both concrete and steel reinforcement (rebar) guarantees that the composite material can handle both compressive and tensile forces.

Bridge Cables: Testing of steel cables used in suspension bridges determines whether they can support bridge weight and traffic dynamic loads.

Steel Beams and Columns: Tensile testing verifies that steel beams and columns have the necessary tensile strength to support buildings and resist bending under load.

Compliance with Tensile Testing Standards in Construction

Building structures must meet established standards for tensile strength to be safe, reliable, and durable. Organizations like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) provide comprehensive guidelines for conducting tensile tests and preparing tensile samples. Compliance with these standards guarantees that materials used in construction projects can withstand the required loads and stresses.

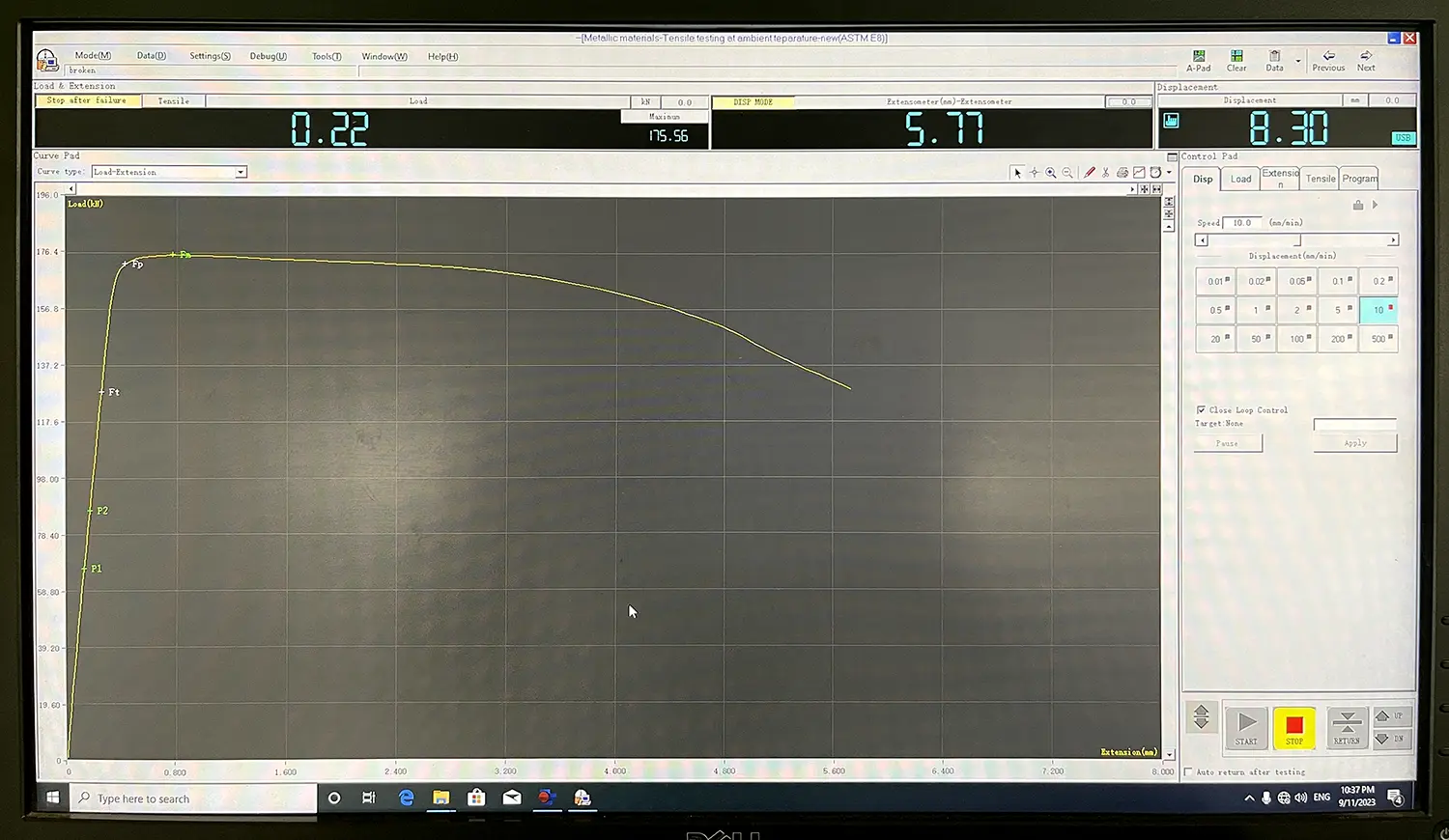

Standards provide consistency and reliability in tensile tests, allowing to obtain uniform and comparable results across different laboratories and projects. Uniformity is crucial for accurately comparing materials and verifying their eligibility. For example, ASTM E8/E8M outlines standard test methods for the tensile testing of metallic materials. ASTM D638, on the other hand, is the standard for evaluating plastic tensile properties.

Complying with these standards is a requirement for regulatory compliance. Many construction projects are subject to regulations that mandate materials tested according to specific standards. Meeting these standards is important not only for legal reasons but also for safety in the first place. As an example, steel that meets ASTM A370 standards for mechanical testing guarantees structural safety and durability.

The preparation of tensile samples is just as important as the actual testing. Thus, for instance, ASTM E8/E8M specifies dimensions and preparation methods for tensile test specimens. This provides assurance that samples are uniform and representative of the material being tested. Proper preparation avoids errors that could lead to inaccurate results and unsafe material performance.

Most Common Construction Materials Tested for Tensile Strength

It is a fact that many materials in the construction industry need to undergo tensile testing in order to be used. Here is a brief overview of some of the most common materials, without which modern construction would not be possible.

Steel

Steel is one of the most commonly tested materials in construction due to its critical role in structural integrity. It is widely used in the construction of beams, columns, reinforcement bars (rebar), and frameworks for buildings and bridges. Steel's high tensile strength and ductility make it ideal for supporting heavy loads and withstanding various stresses and environmental conditions.

Steel tensile testing involves subjecting samples to controlled tension until they fail. This process measures properties such as ultimate tensile strength, yield strength, elongation, and area reduction. Specific types of steel, such as carbon steel, stainless steel, and alloy steel, are tested according to standards like ASTM A370, which covers steel products' mechanical testing. ASTM E8/E8M provides standard test methods for determining metallic materials' tensile properties.

Plastics

Plastics are increasingly used in construction due to their versatility, lightweight nature, and resistance to corrosion. They are used in applications such as piping, insulation, flooring, windows, and doors. Plastics need to be tested for tensile strength to determine their mechanical properties and ensure they can withstand construction forces.

Tensile testing of plastics involves stretching a sample until it breaks. This is done by measuring properties such as tensile strength, yield strength, elongation at break, and modulus of elasticity. ASTM D638 is the standard test method for plastic tensile properties, providing guidelines for specimen preparation, testing conditions, and data analysis. By complying with this standard, plastic materials used in construction are guaranteed to have the mechanical properties needed to perform reliably under stress and in a variety of environmental conditions.

Composites and Advanced Materials

Composites, such as fiber-reinforced polymers (FRPs), are used in construction for their unique properties, including high strength-to-weight ratios, corrosion resistance, and design flexibility. These materials are employed in applications such as bridge decks, structural panels, and reinforcement for concrete structures.

Composites are tested for strength and stiffness, both of which are crucial to verifying that they can perform under load. Standards like ASTM D3039 specify guidelines for tensile testing of polymer matrix composites, including procedures for specimen preparation, testing, and data interpretation. This standard provides assurance that composites used in construction meet mechanical performance criteria.

The Importance of Correct Test Results

In today's construction industry, there is trust that structures are safe and durable. This confidence stems from the rigorous testing and precise work carried out by construction professionals, including engineers who verify the accuracy of tensile test results.

Role of Qualified Personnel in Testing

The reliability of tensile test results is also dependent on the qualifications and expertise of the personnel conducting the test. Professionals who have been trained and certified are essential to maintaining high standards of accuracy and consistency in tensile testing. Engineers and scientists undergo extensive training and certification programs in order to gain a thorough understanding of the complexities of material testing procedures, equipment operation, and data analysis.

Moreover, experienced professionals are adept at troubleshooting and resolving issues that may arise during testing, such as equipment malfunctions or sample misalignment. Their expertise guarantees optimal test conditions.

Need for Reliable Equipment

It must be noted that whether it is specimen preparation machines or tensile testers, the equipment must be reliable. High-quality tensile testing machines apply controlled tension to materials, resulting in precise property measurements. Equipment such as universal testing machines, load cells, and extensometers must be calibrated and maintained to perform consistently under different testing conditions.

Advanced tensile testing systems, like those compliant with ASTM E8/E8M for metallic materials or ASTM D638 for plastics, incorporate features such as automated data collection, real-time analysis, and robust construction to withstand high forces. These systems assist in assuring that material properties are accurately measured.

The Perfect Tensile Testing Machine for You

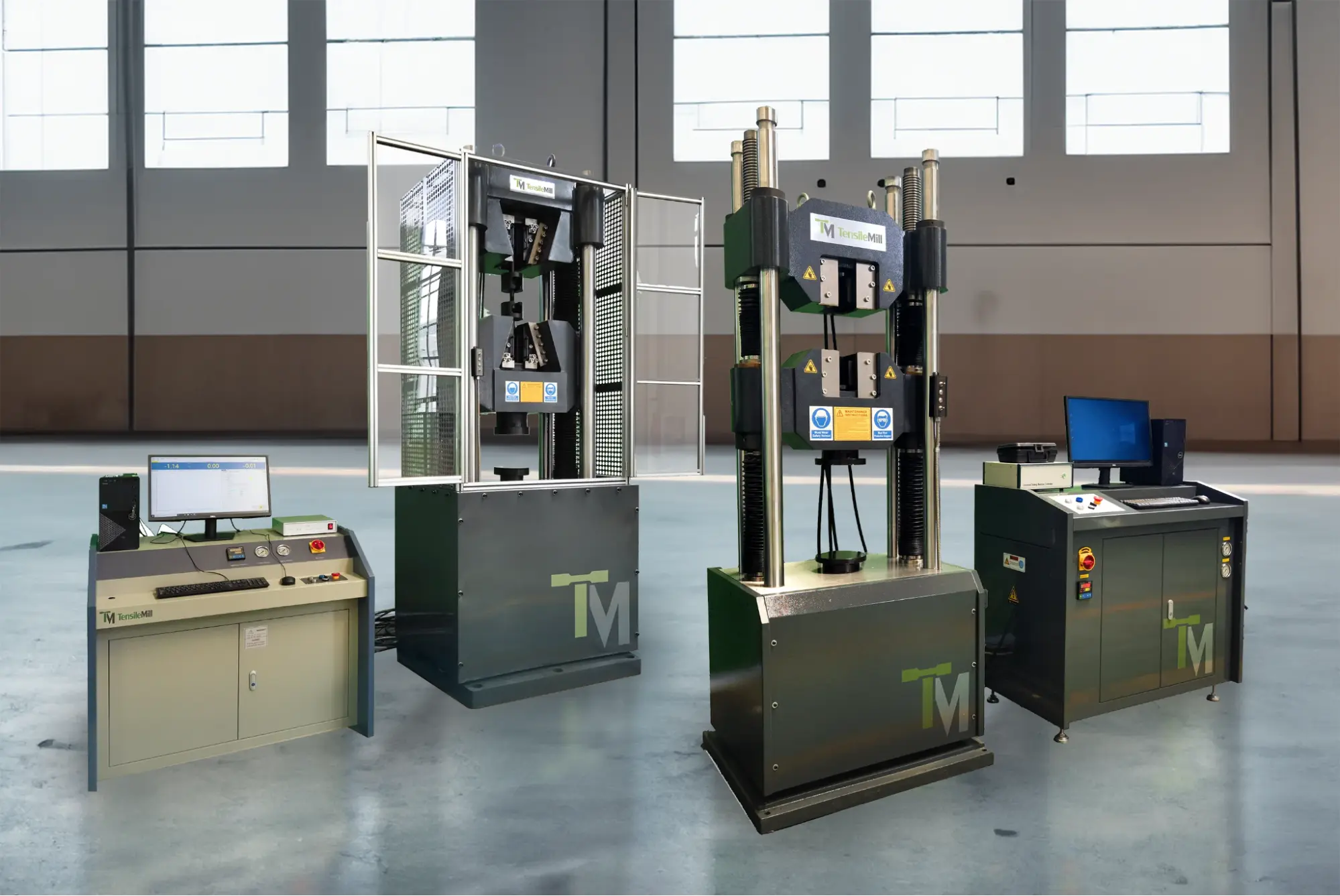

If you are on the market for reliable tensile testing equipment, let us introduce you to our top-of-the-line product.

The TM-EML Dual Column Floor Standing Universal Testing System provides exceptional accuracy, with a tolerance of ±0.5% of the reading value. Covering a wide testing spectrum from 50kN to 600kN (11,200lbf to 135,000lbf), it meets virtually all metal testing requirements. For greater precision in lower capacity testing, these units can also be equipped with a sub-cell.

The system is a versatile instrument, offering tensile, compression, bending, and shearing tests. It also offers compatible extensometer solutions for comprehensive material analysis. The force capacity ranges from 50kN to 600kN, making it suitable for many types of specimens, including metals, building components, large fasteners, composites, and wood products.

Features include:

- Robust, space-efficient dual-column load frames.

- High-speed, low-vibration electromechanical drives.

- Precision, pre-loaded ball screws, and linear motion guides for superior alignment and accuracy.

- User-friendly software with a pre-programmed library of industry standards (ASTM, ISO, DIN, EN, BS).

- High-resolution digital closed-loop controls.

- Automatic limit checking for critical parameters.

- A diverse selection of grips, fixtures, environmental systems, and extensometers.

Achieving Construction Safety through Tensile Testing

Tensile testing is one of the most important aspects of any construction project safety and durability. Testing tensile strength helps verify that construction materials can withstand the significant stresses and environmental conditions they will encounter by measuring accurate tensile strength, yield strength, elongation, and reduction in area. It is through rigorous testing that structures are protected from structural failures and ensure that buildings, bridges, and other infrastructures will be safe and reliable for many years to come.

Furthermore, compliance with established standards, such as those from ASTM and ISO, ensures consistency and reliability in tensile tests. Thus, comprehensive guidelines for conducting tests and preparing specimens are followed to assure that materials meet the required performance criteria. The use of reliable equipment and qualified personnel further improves the accuracy of these tests. It helps to provide engineers with dependable information that can be used to make informed decisions regarding the choice of materials and structural design.

At TensileMill CNC, we are dedicated to providing top-notch equipment for tensile testing, whether it involves specimen preparation or the tensile testing procedure itself. Our advanced systems, such as the TM-EML Dual Column Floor Standing Universal Testing System, offer exceptional accuracy and functionality, catering to a broad spectrum of testing needs. Contact us directly or request an online quote if you are searching for advanced equipment for your lab. With our reliable solutions, you can be certain of the highest standards of safety and durability in your construction projects.